Method of separating lactotransferrin from whey liquid

A technology of lactoferrin and whey, applied in the field of obtaining lactoferrin, can solve the problem of high liquid cost and achieve the effects of reduced investment, easy management, fast and complete production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

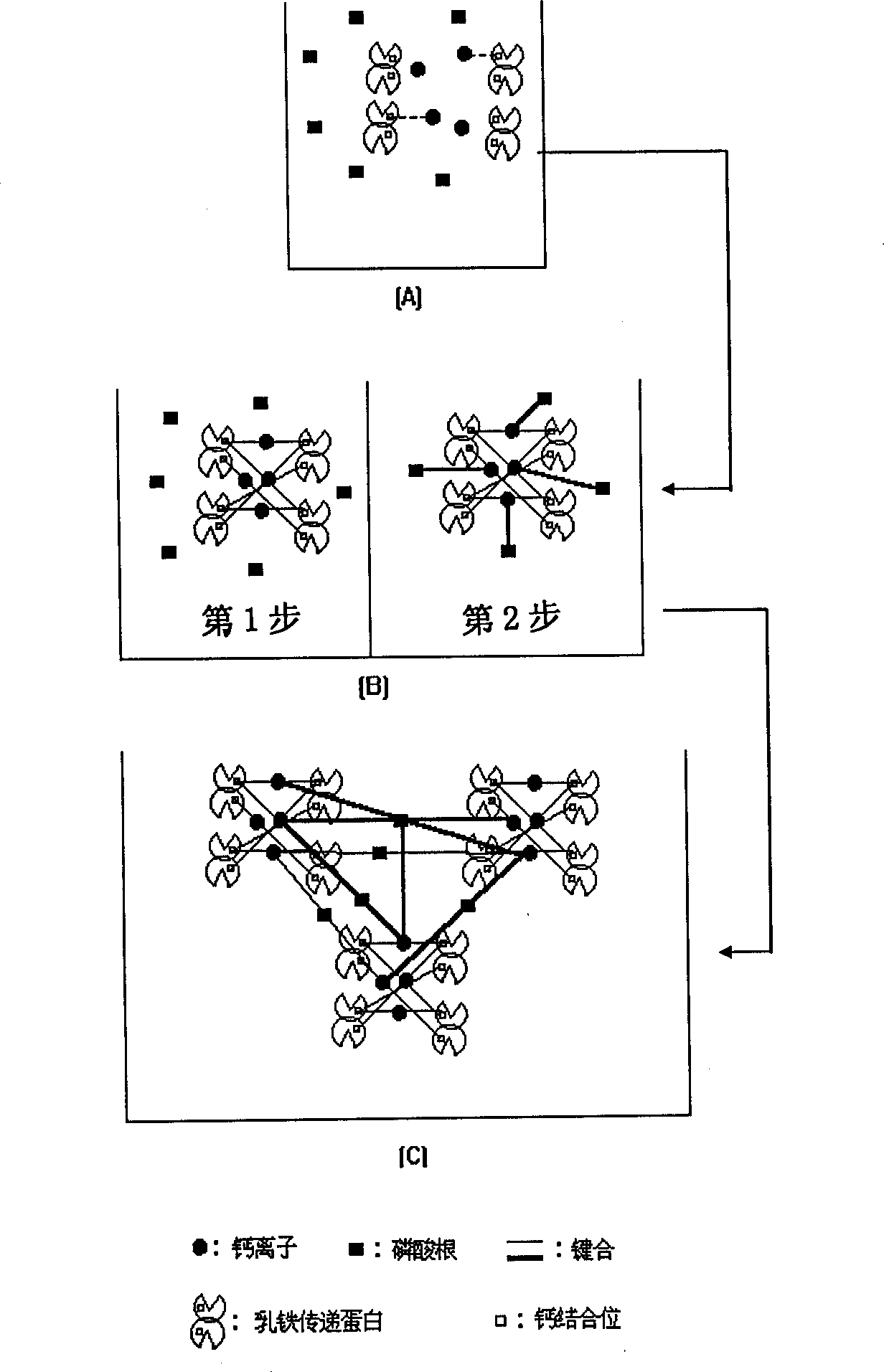

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Isolation and preparation of lactoferrin from whey

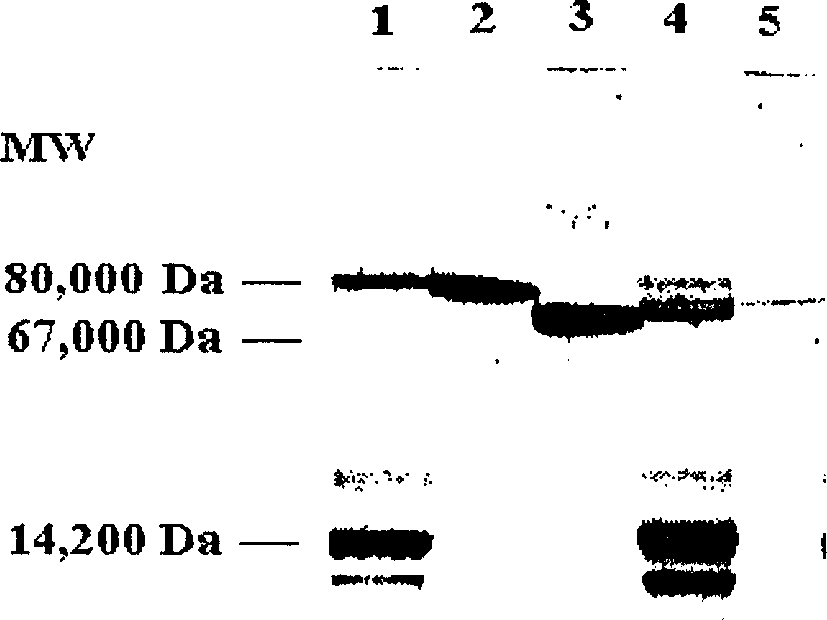

[0044] Cheddar cheese whey from cheese factories is first skimmed in a centrifuge. The content of lactoferrin in skim cheddar cheese whey is 93 mg / L. Add food grade CaCl to 420 liters of skim cheddar whey 2 3.4 kg and NaH 2 PO 4 2H 2 O 0.62 kilograms, then adjust the pH value to 7.5 with 6 equivalents of sodium hydroxide while stirring. After stirring for 5 minutes, let stand for 10 minutes. The suspension is separated with a liquid-solid centrifuge (or a plate and frame filter press, or a drum vacuum filter or other filtering machinery) to obtain 38.2 kg of calcium phosphate sediment. The clarified liquid is sent to the whey protein and lactose production workshop. The precipitated mud is freeze-dried (or low-temperature vacuum-dried, or spray-dried after adding 80 kg of water) to obtain 8.4 kg of calcium phosphate precipitated powder (identifications such as its electrophoresis analysis are shown i...

Embodiment 2

[0045] Example 2 Isolation and preparation of lactoferrin from whey

[0046] The content of lactoferrin in raw cheese whey was 124.9 mg / L. Adding CaCl to 540 liters of raw cheese whey 2 4.5 kg and NaH 2 PO 4 2H 2 O 0.8 kg, then adjust the pH value to 6.5 with 6 equivalents of sodium hydroxide while stirring. After stirring for 5 minutes, let stand for 10 minutes. The suspension is separated with a liquid-solid centrifuge (or a plate and frame filter press, or a drum vacuum filter or other filtering machinery) to obtain 15 kg of calcium phosphate sediment. The clarified liquid is sent to the whey protein and lactose production workshop. The precipitated mud is freeze-dried (or vacuum-dried at low temperature, or spray-dried after adding 40 kg of water) to obtain 3.4 kg of calcium phosphate precipitated powder, which is stored at low temperature (-10°C) for future use. Each kilogram of precipitation powder contains 14.5 grams of lactoferrin, and 73% of the lactoferrin in...

Embodiment 3

[0047] Example 3 Preparation of High Purity Lactoferrin

[0048] Equilibrate a carboxymethyl Sephadex resin cation exchange column (or a commercial carboxymethyl cation exchange column, Carboxymethyl-Productive TM ). 30 milliliters of concentrated solutions (made by Example 1) are pumped in from the top of the column, and then gradient eluted with 0.7 mol / liter of sodium chloride acetate buffer (pH3.8), and the flow rate of the eluent is 2 milliliters / liter minute. Collect liquid from 120 to 170 milliliters, total 50 milliliters, the separation yield of lactoferrin column is over 90%. The collected liquid was deionized with a dialysis membrane and then freeze-dried. The lactoferrin purity of the product is 95%, and the total yield is 61.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com