Method for controlling system under steam protection mode after MFT of secondary reheat unit boiler

A technology of secondary reheating and control method, applied in the control of superheated temperature, boiler drum/box header, control system, etc., can solve the problems of risk, unutilization, reliable supply of shaft seal of the unit, etc., to reduce the wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

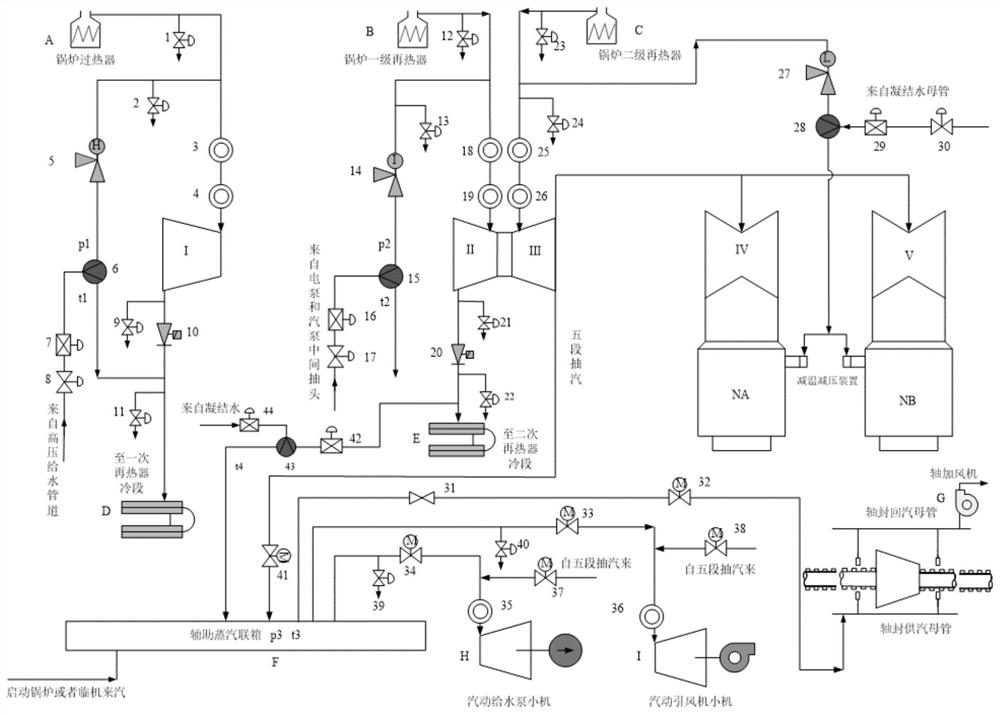

[0078] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0079] Such as figure 1 As shown, a typical double reheat unit is equipped with 4 cylinders, which are ultra-high pressure cylinder (I), high-medium pressure combined cylinder (II and III) and two low-pressure cylinders (IV and V). The steam at the outlet of the superheater A of the boiler passes through the ultra-high pressure main steam valve 3 and the ultra-high pressure regulating valve 4 and then enters the ultra-high pressure cylinder I to do work, and the steam after doing work enters the cold section D of the primary reheater of the boiler through the ultra-high discharge check valve 10 for reheating . The heated steam enters the high-pressure cylinder II from the outlet of the first-stage reheater B through the main steam valve 18 of the high-pressure cylinder and the regulating valve 19 of the high-pressure cylinder, and the exhaust steam enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com