Patents

Literature

71results about How to "Solve unhandled problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

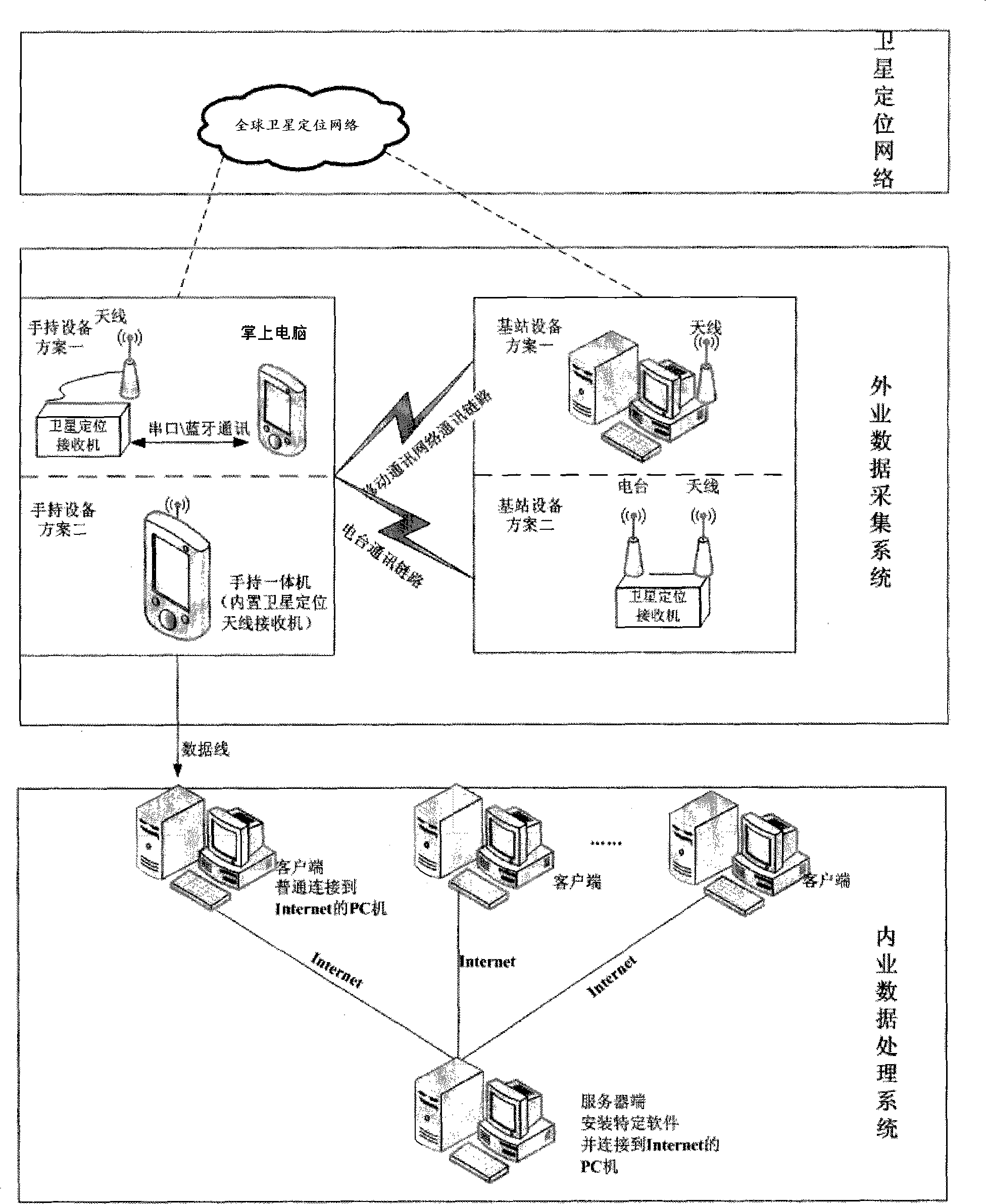

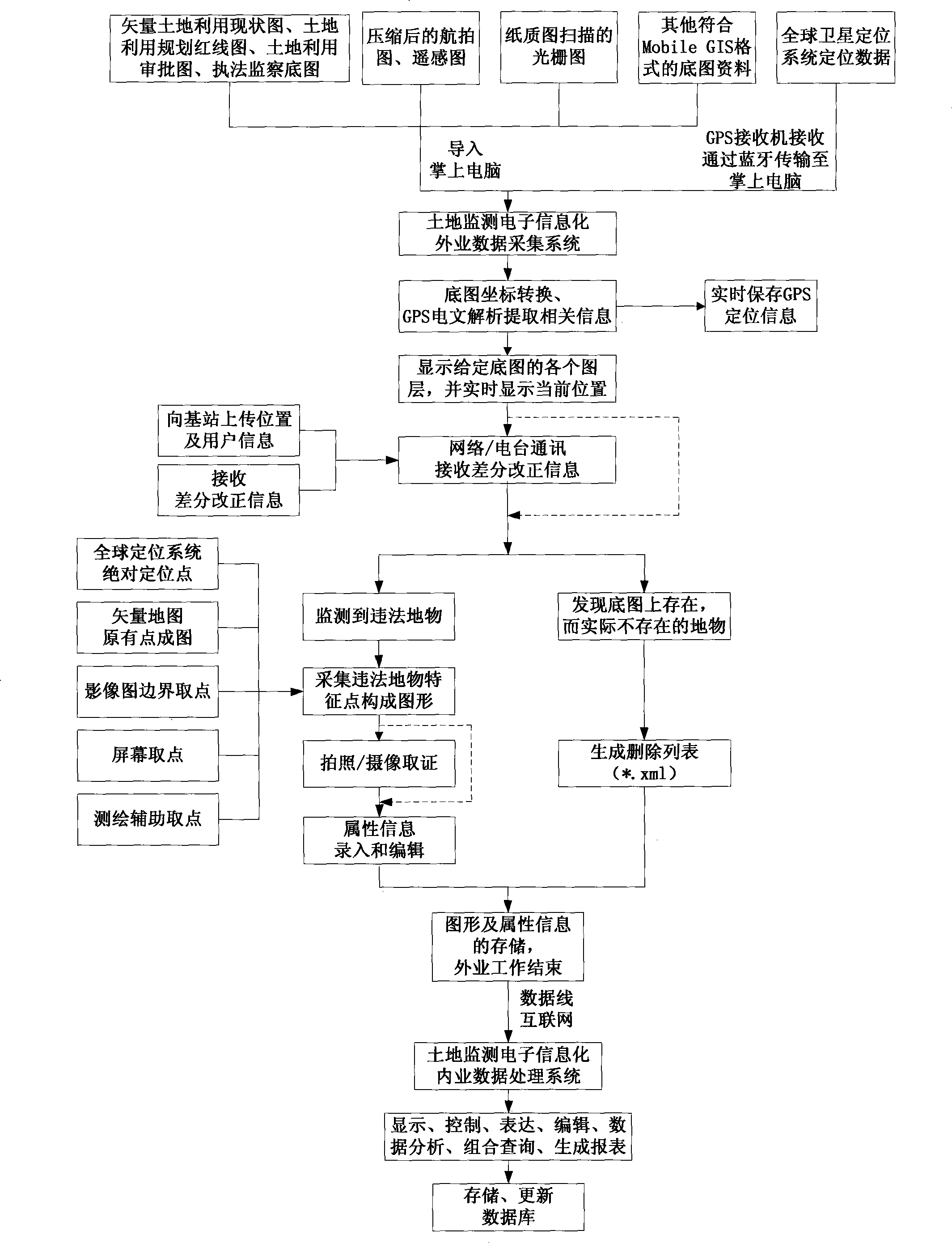

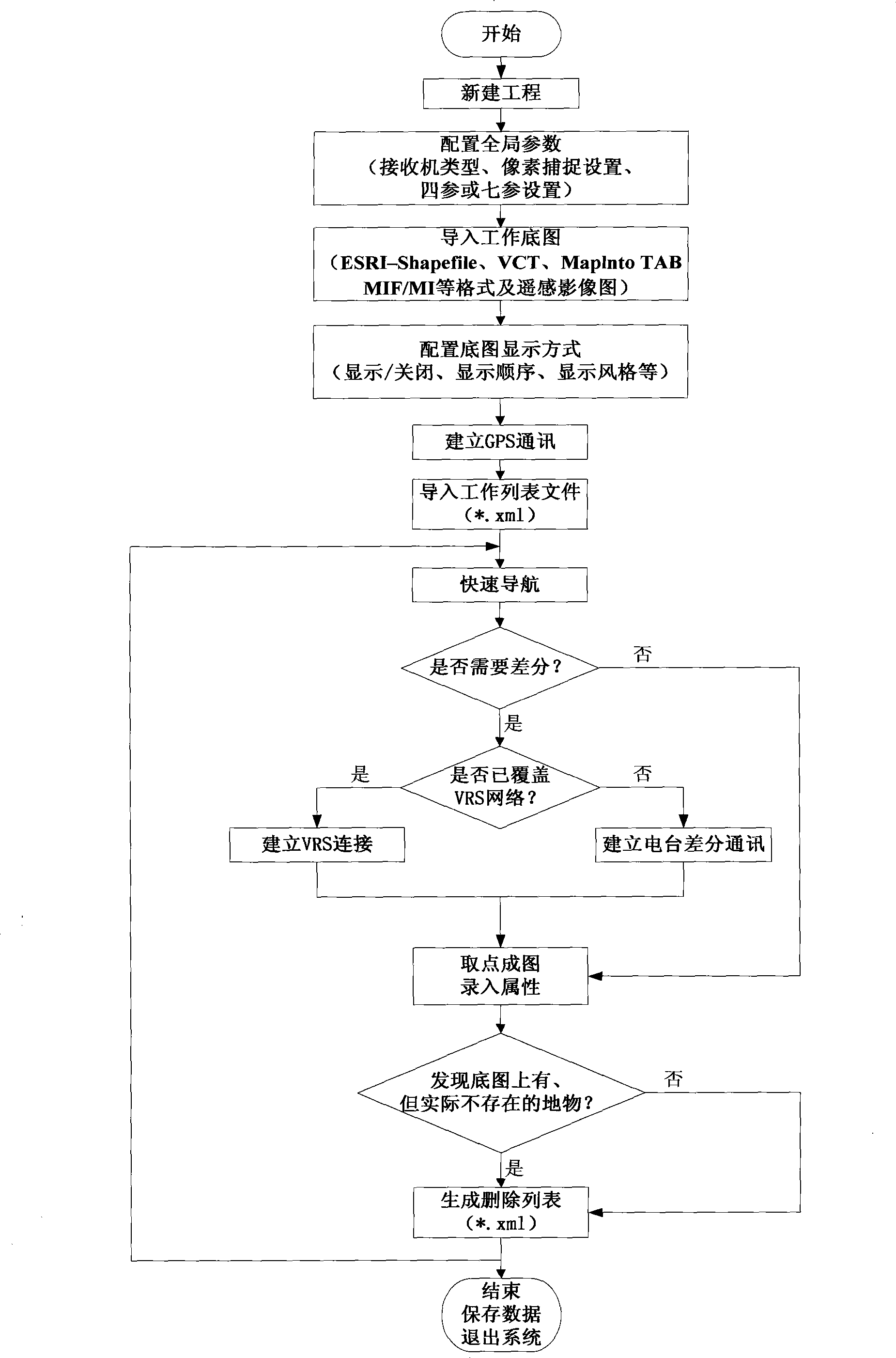

Electronic information system for earth monitor and method thereof

InactiveCN101452072AMeet real needsGuaranteed real-time updatesPosition fixationSatellite radio beaconingTerrainData acquisition

The present invention provides an electronic information system and a method thereof, and constructs two sets of subsystems of field data collecting and indoor data processing. The field data collecting system is based on a Mobile GIS platform and is combined with GPS positioning, GPRS network, bluetooth communication, etc. The field data collecting system realizes high-precision positioning of earth monitoring, uses different methods for executing difference positioning, digital information collecting, eraser list constructing, photograph taking / camera shooting evidence obtaining and terrain hyperlinking for realizing electronic information of field land surveying at the state with / without VRS network. The indoor data processing system is based on SuperMap GIS developing platform and Browser / Server structure, and is combined with XML data interchange, spatial geographical coordinate projection switching, overlapping analyzing, etc. The indoor data processing system realizes multiple functions of indoor multi-source map data expression and operation, combined inquiry, report generation, land monitoring database updating, property formwork customizing, etc., and realizes electronic information of indoor land monitoring operation.

Owner:SOUTHEAST UNIV

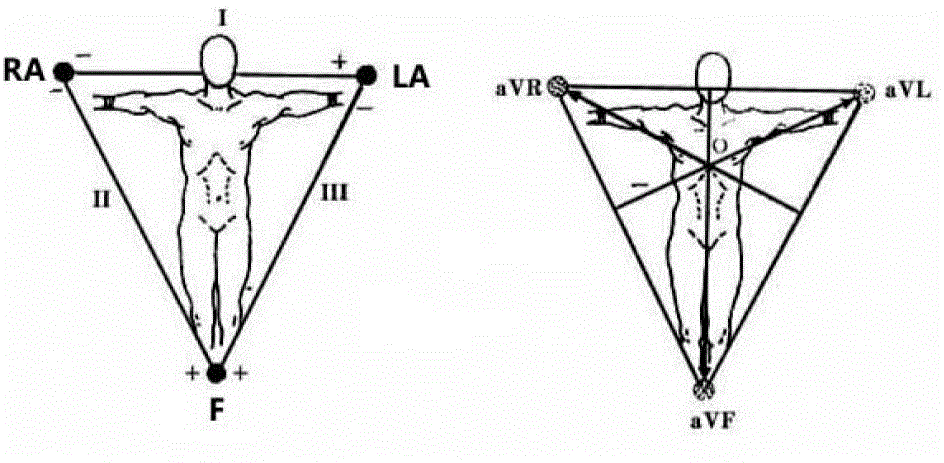

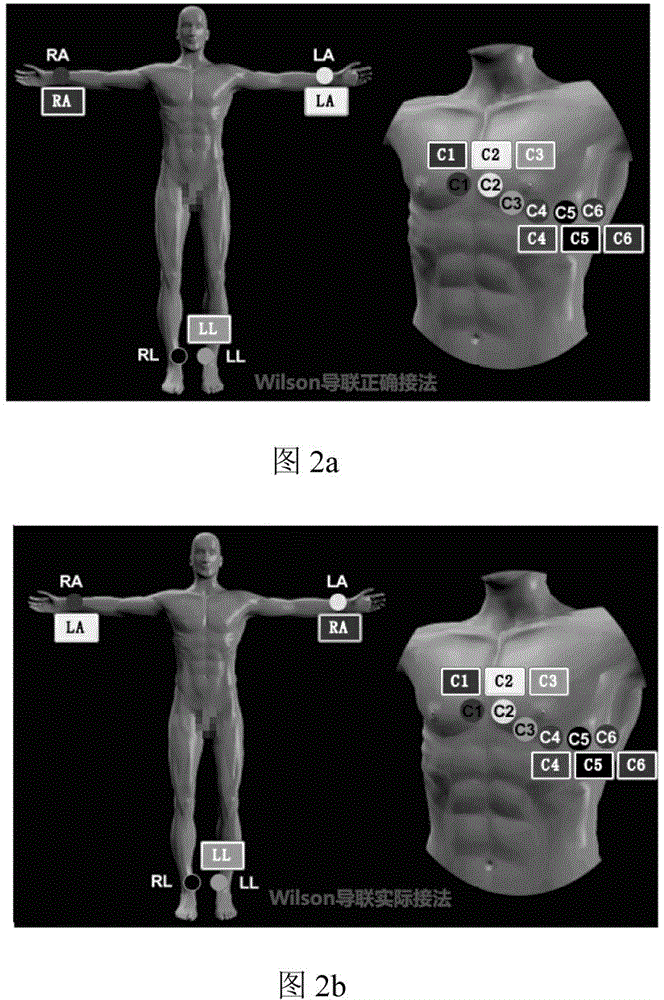

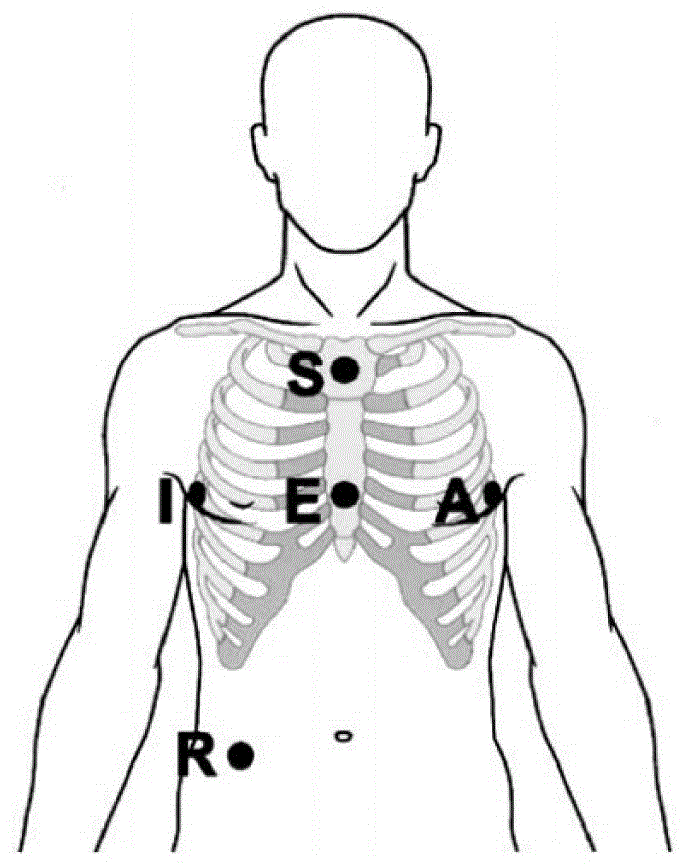

Method for correcting electrocardiographic lead misconnection

ActiveCN104856669ASolve unhandled problemsImprove work efficiencyDiagnostic recording/measuringSensorsElectrocardiograph leadLead system

The invention relates to the medical field and specifically relates to a method for correcting electrocardiographic lead misconnection. The method introduces a concept of an electrode displacement matrix and combines lead data calculation manners in different lead systems to map data generated from the misconnection into correct lead connection data. The method for correcting the electrocardiographic lead misconnection provided by the invention can be applicable to different complicated misconnection manners in multiple lead systems (such as Wilson, EASI, 15 leads and 18 leads), solves problems such as the misconnection between a chest lead and limb leads which cannot be dealt with by current methods, and plays an important role in increasing doctors' working efficiency and relieving doctor-patient relations in actual clinical applications.

Owner:厦门纳龙健康科技股份有限公司

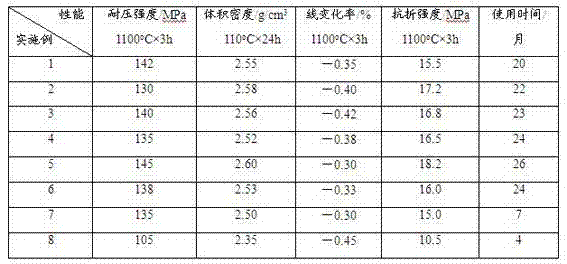

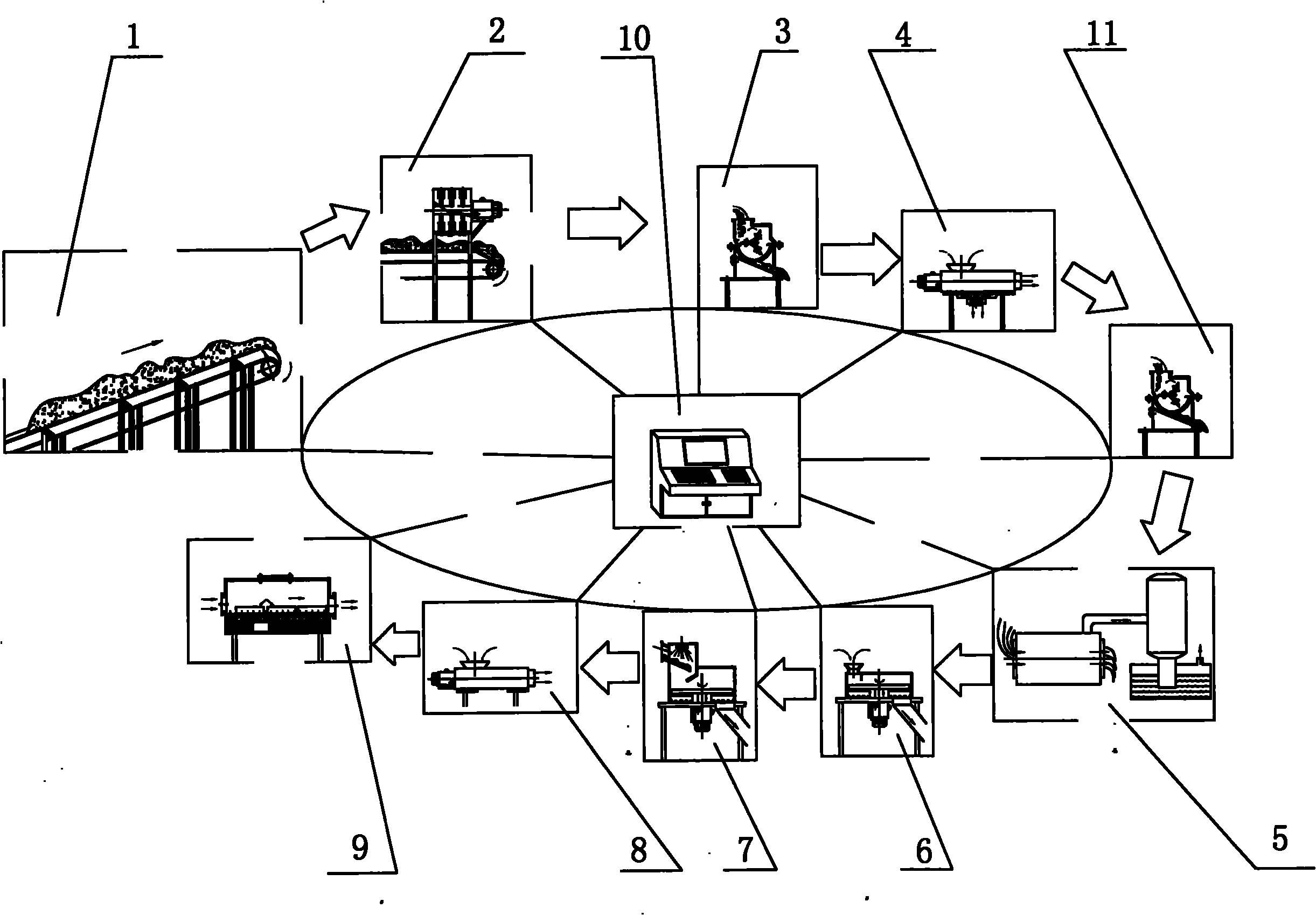

High-strength, wear-resistant and quick-change preform

ActiveCN102515792AImprove high temperature resistanceWith heat insulation effectSolid waste disposalBrickWear resistant

The invention discloses a high-strength, wear-resistant and quick-change preform, belonging to the field of refractory material. The high-strength, wear-resistant and quick-change preform disclosed by the invention contains components in the following parts by weight: 10-30 parts of mullite, 10-25 parts of silicon carbide, 10-20 parts of waste silicon-mullite bricks, 10-20 parts of a homogenizing material, 10-25 parts of a waste iron hook material, 5-15 parts of mullite hollow spheres, 3-8 parts of alumina powder, 3-6 parts of silica micropowder and sodium tripolyphosphate occupying 0.08-0.2% of the total. The high-strength, wear-resistant and quick-change preform disclosed by the invention is good in wear resistance and thermal shock stability, simple in construction, convenient in detachment, long in life, low in cost and especially suitable for being used in cement kiln.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

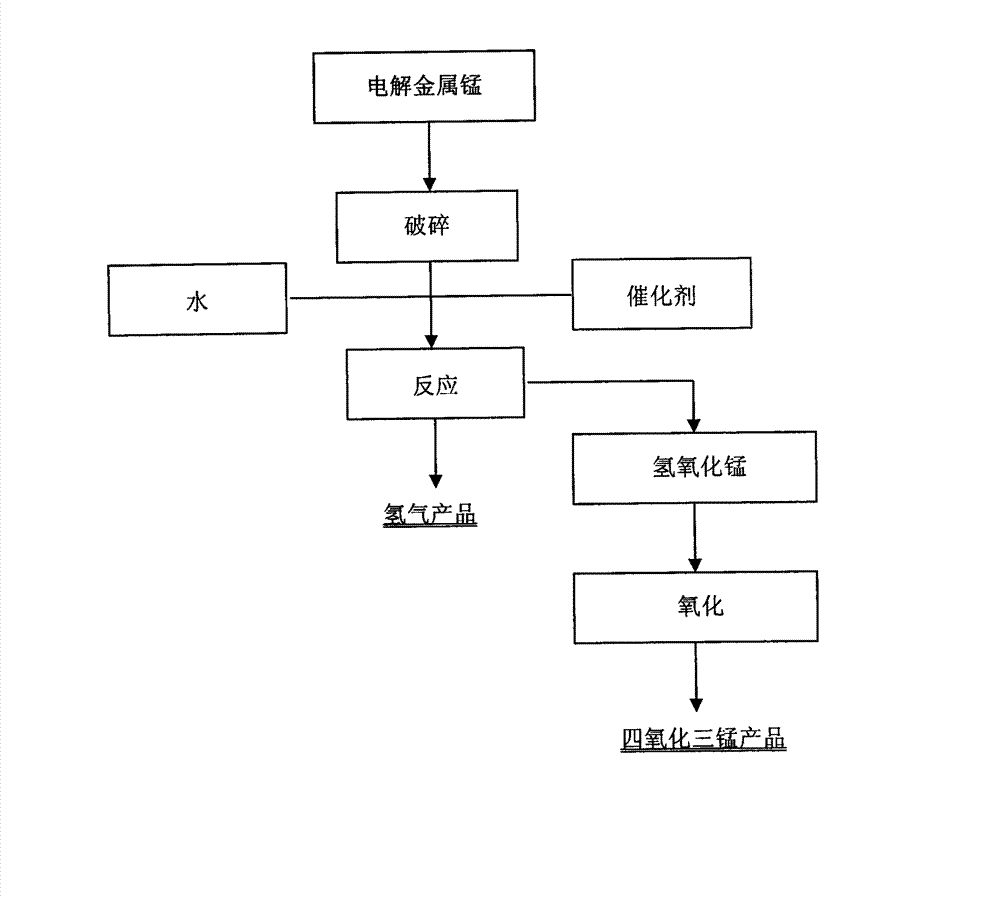

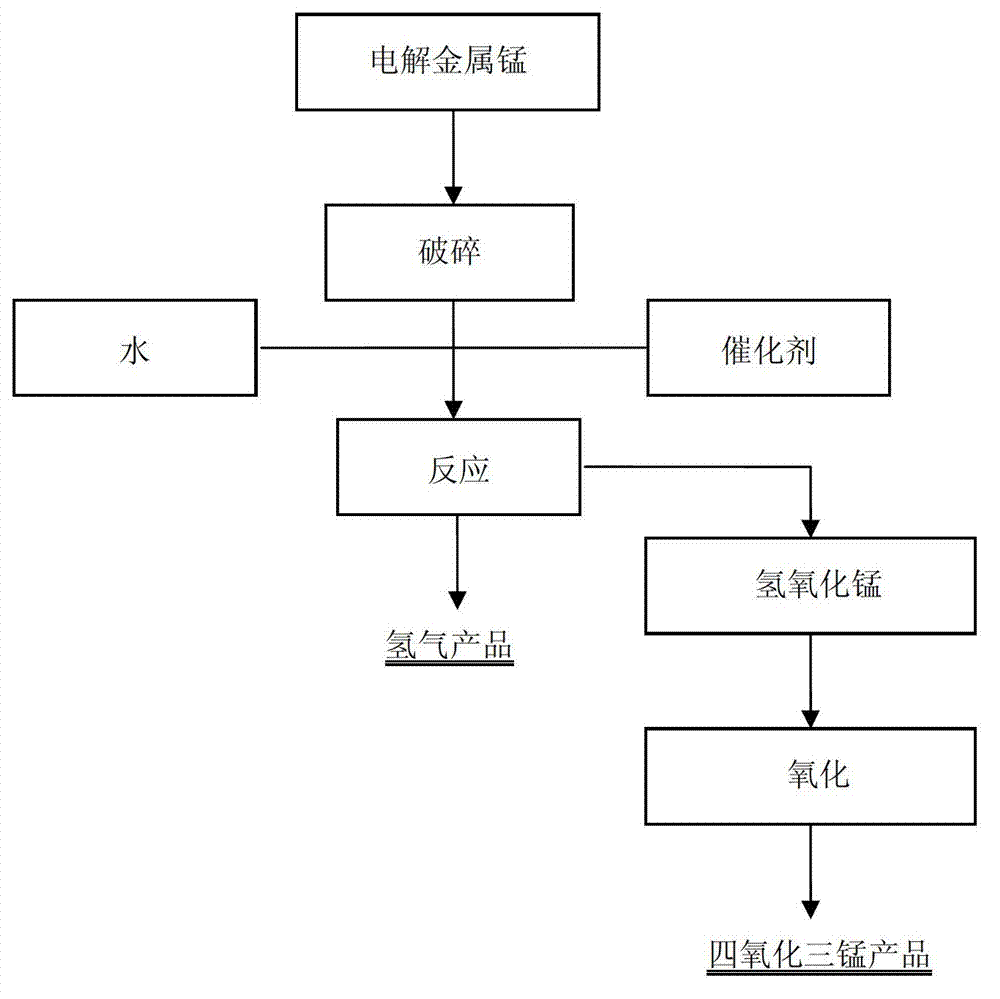

Method for preparing hydrogen in process of producing manganous-manganic oxide through electrolytic manganese metal

InactiveCN103030110AEnergy savingSolve flammable and explosiveHydrogen productionManganese oxides/hydroxidesAmmonium sulfateHydrogen concentration

The invention relates to a method for preparing hydrogen in process of producing manganous-manganic oxide through electrolytic manganese metal and belongs to the field of chemical metallurgy. The preparation method comprises the following steps: crushing the electrolytic manganese metal in the process of producing the manganous-manganic oxide by taking the electrolytic manganese metal as a raw material, reacting the electrolytic manganese metal with water to generate manganese hydroxide under specific conditions under the catalytic action of a catalyst, and releasing the hydrogen, wherein the specific reaction conditions in the process of preparing the hydrogen are that the crushing particle size of the electrolytic manganese metal is less than 150 microns, the addition amount of the catalyst is 5-15g of catalyst added into each 1000g of electrolytic manganese metal, the reaction temperature is controlled to be 40-90 DEG C, and the PH value of the reaction process is controlled to be 6-12. The manganese hydroxide generated through the reaction is prepared into a manganous-manganic oxide product through other oxidation processes, and the hydrogen concentration of the hydrogen released from the reaction can reach 80-90 percent, and the hydrogen becomes a final gas product. The added catalysts are ammonium chloride, ammonium sulfate, hydrochloric acid, manganese chloride and oxalic acid and also comprise two or more catalysts.

Owner:湖南特种金属材料有限责任公司宁乡分公司

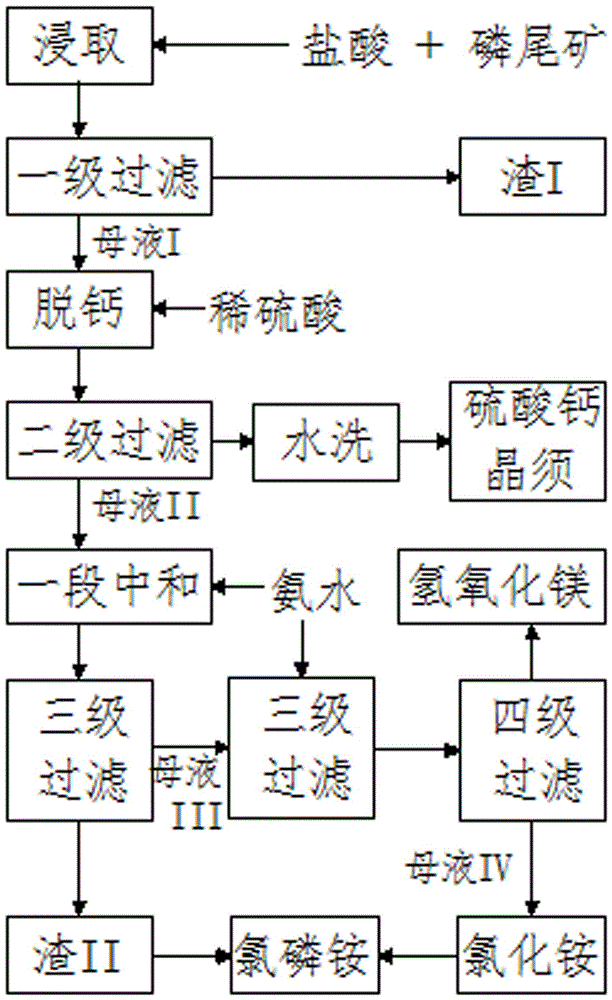

Method of decomposing phosphate tailings by hydrochloric acid to produce Mg(OH)2 and CaSO4

ActiveCN106495191ASolve unhandled problemsReduce pressure on environmental protectionCalcium/strontium/barium sulfatesAmmonium salt fertilisersPhosphateRaw material

The invention belongs to the field of chemical engineering and particularly relates to a method of decomposing phosphate tailings by hydrochloric acid to produce Mg(OH)2 and CaSO4. The method includes the steps of: soaking the phosphate tailings in hydrochloric acid and water to perform a complete mixing reaction, and performing primary filtration to obtain a mother liquid (I); adding diluted sulfuric acid to the mother liquid (I) and performing secondary filtration to obtain a mother liquid (II) and filter cake, water-washing and crystallizing the filter cake to generate CaSO4 crystal whiskers; adding ammonia water to the mother liquid (II) to perform primary and secondary neutralization to obtain a Mg(OH)2 product and a mother liquid (IV); and mixing the mother liquid (IV) with residue (II), which is generated in primary neutralization, to produce ammonium chloride-phosphate. With the phosphate tailings and hydrochloric acid as raw materials, the method can produce the Mg(OH)2 and CaSO4 and can by-produce the ammonium chloride-phosphate. The whole process is simple and is in a total-closed circulating manner. The method can turn waste into resources and achieves clean production.

Owner:HUBEI SANNING CHEM

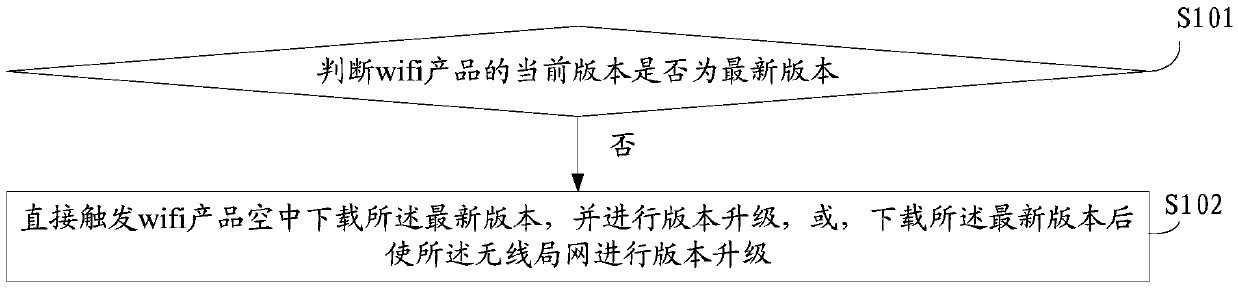

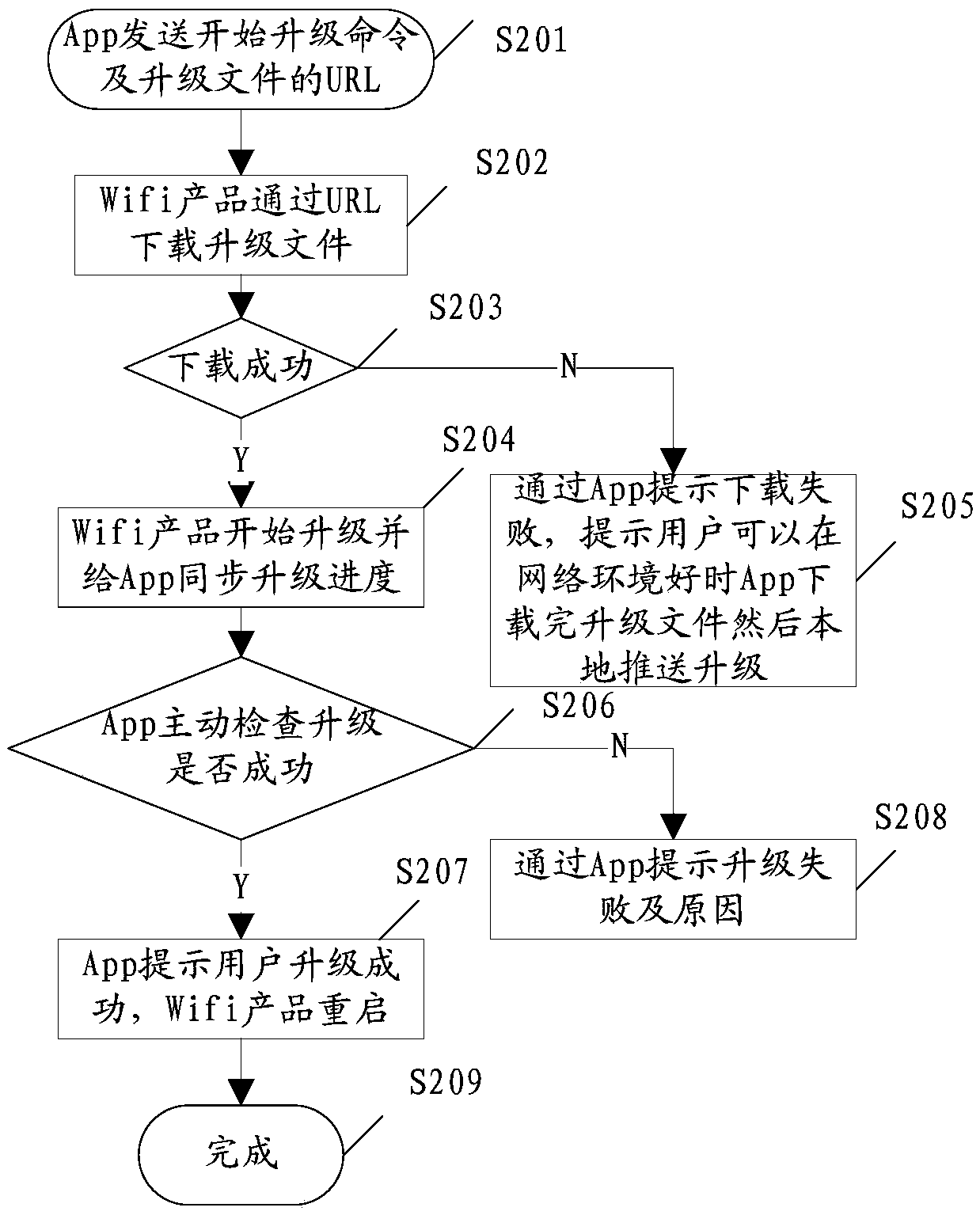

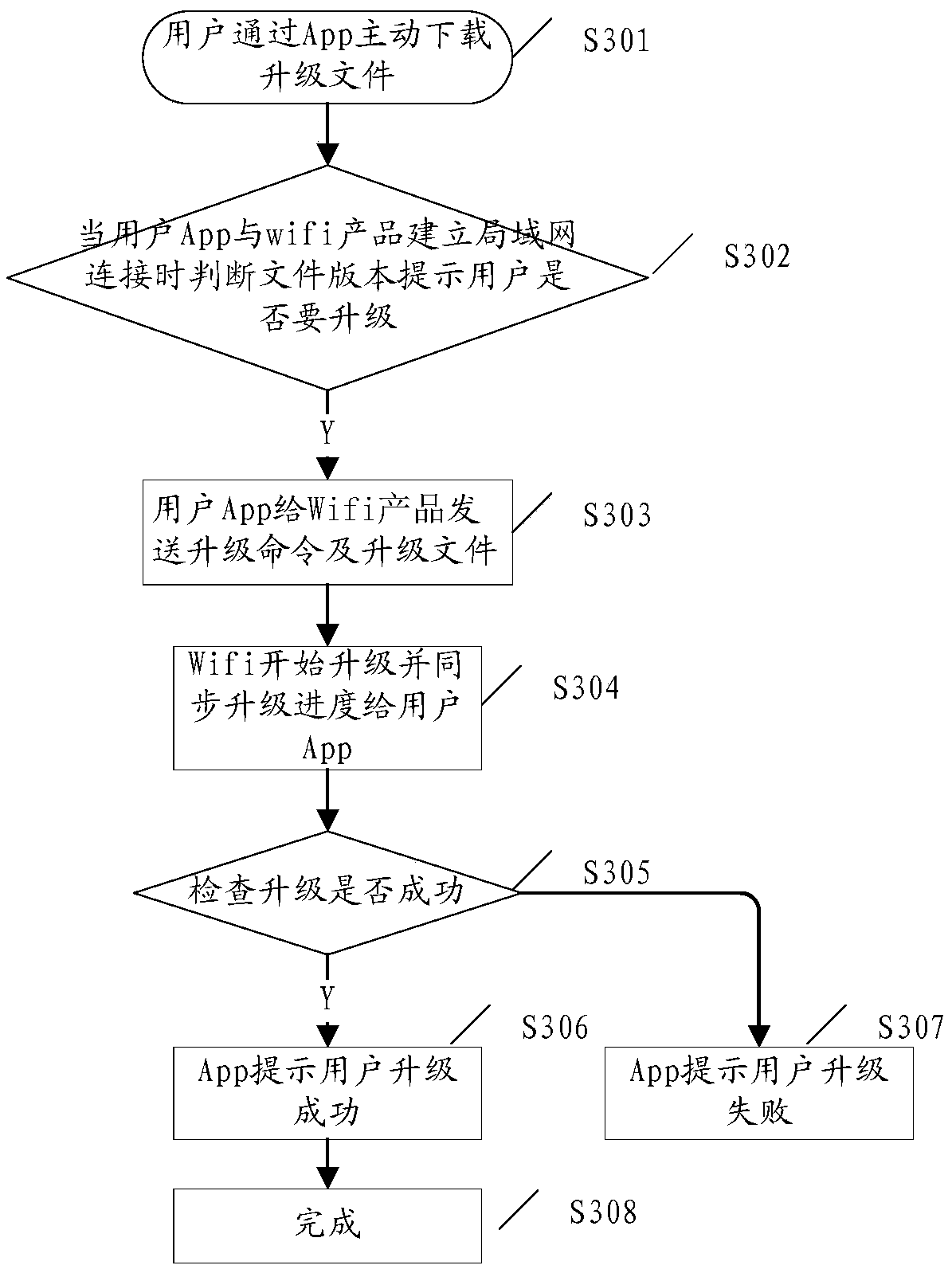

Upgrading method, device of wifi product by over the air OTA and terminal

InactiveCN105517015ASolve unhandled problemsData switching networksWireless communicationWorld Wide WebUser control

The invention discloses an upgrading method, device of a wifi product by over the air OTA and a terminal. According to the invention, a user control terminal judges whether the current version of the wifi product is the newest version; under the condition that there is an updated version, the terminal controls the wifi product to upgrade. The problem that a user cannot know the upgrading result of the wifi product leaded by the server, the user cannot process when the wifi product upgrades unsuccessfully, and the normal use of the wifi product by the user is influenced is effectively solved.

Owner:QINGDAO HAIER TECH

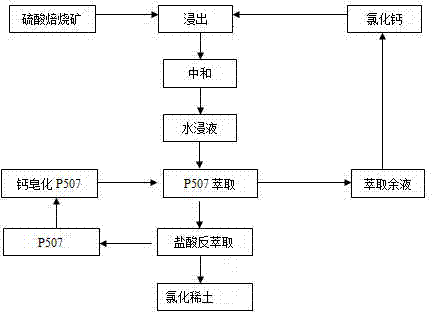

Recycling method for rare earth leaching and leaching water of sulfuric acid roasted rare earth ore concentrate

ActiveCN104232949AReduce water consumptionReduce the amount of waterProcess efficiency improvementPregnant leach solutionChloride

Owner:BAOTOU RES INST OF RARE EARTHS

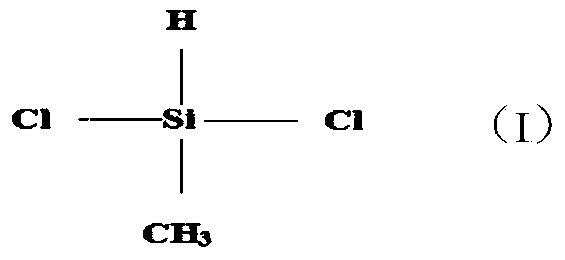

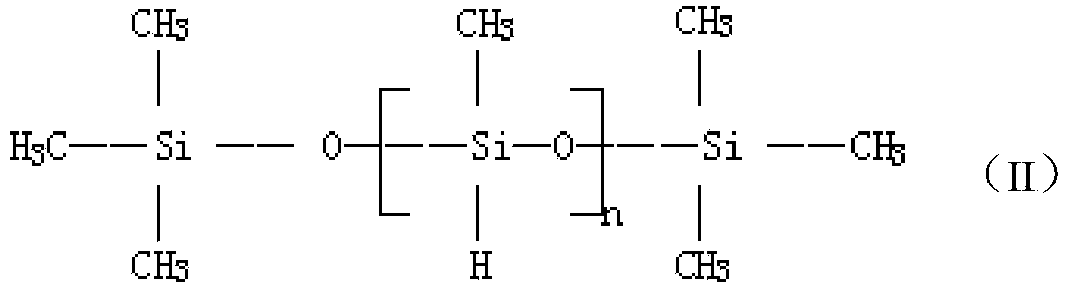

Solvent-free hydrogen-containing silicone oil and preparation method thereof

The invention belongs to the field of chemical engineering, and in particular relates to solvent-free hydrogen-containing silicone oil and a preparation method thereof. The solvent-free hydrogen-containing silicone oil disclosed by the invention is composed of the following components in weight ratio: 100 parts of methyldichlorosilane, 1-10 parts of blocking agent, 10-70 parts of hydrochloric acid, 1-10 parts of acid catalyst, and alkaline neutral substance. The hydrogen-containing silicone oil disclosed by the invention is prepared by comprising the following steps of: reacting by dropping hydrochloric acid into methyldichlorosilane, separating, reacting again by adding the blocking agent and the acid catalyst into oil phase, adding the alkaline neutral substance, filtering, removing boiling substances from filtrate, etc. The hydrogen-containing silicone oil prepared by the invention is better in waterproof effect and can be used for waterproof treatment.

Owner:LUZHOU NORTH CHEM IND

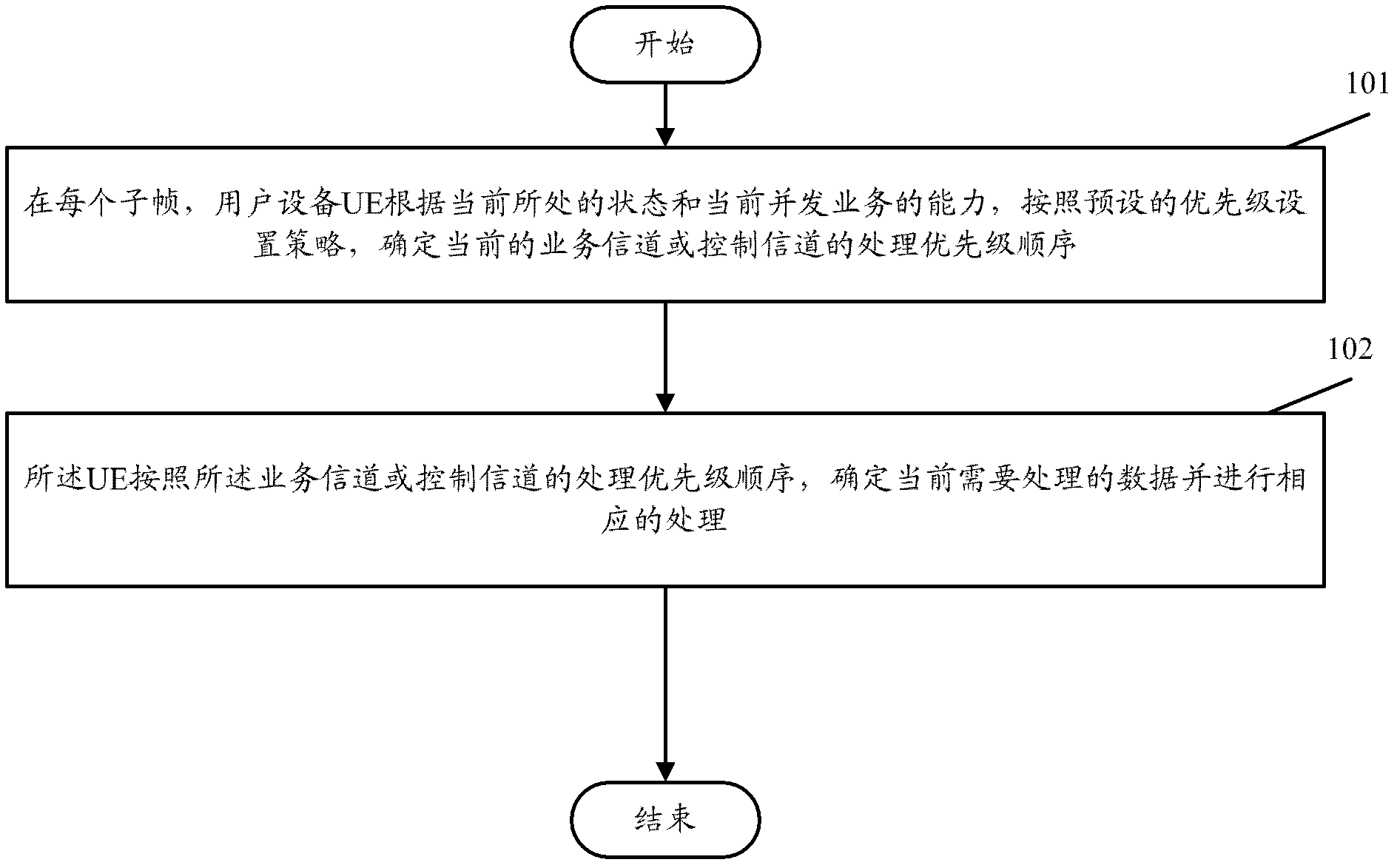

Data processing method of user equipment in private network

InactiveCN103052033ASolve unhandled problemsError prevention/detection by using return channelBroadcast service distributionRadio networksPrivate network

The invention provides a data processing method of user equipment in a private network. The data processing method comprises the following steps of: determining a processing priority order of a current service channel or control channel on basis of a pre-set priority setting protocol by user equipment (UE) according to a current state and current concurrent service capacity; and determining data in need of being processed at present and carrying out corresponding processing by the UE according to the processing priority order of the service channel or the control channel. With the adoption of the data processing method provided by the invention, the problem which cannot be processed by the UE when the data corresponding to a plurality of RNTIs (Radio Network Temporary Identities) in the current system simultaneously reach the same processor can be solved.

Owner:TD TECH COMM TECH LTD

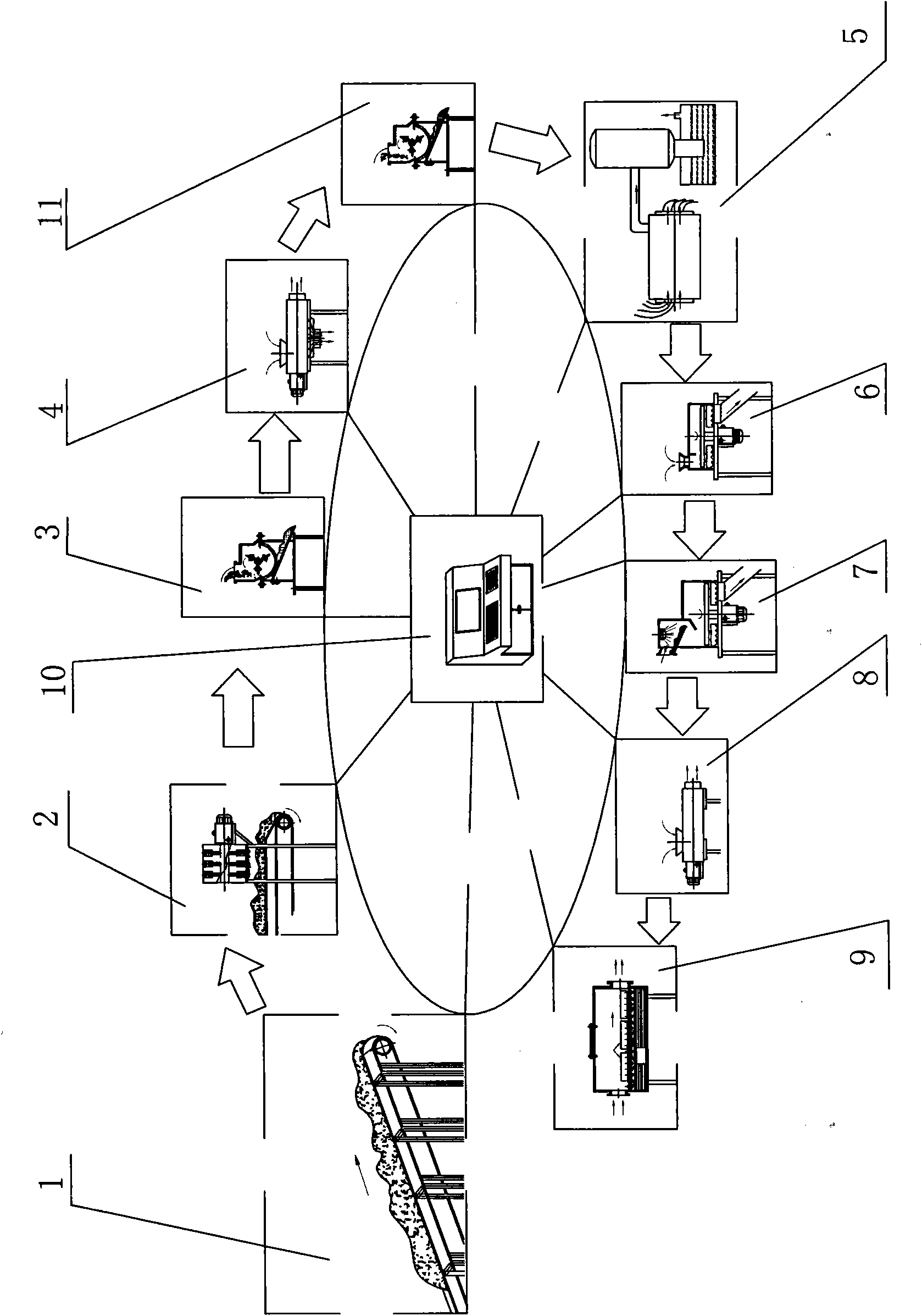

Production flow process and production line for manufacturing fire coal products from garbage

InactiveCN101831338AEasy to storeEasy to transportBiofuelsSolid fuelsProduction lineEcological environment

The invention discloses a production flow process for manufacturing fire coal products from garbage, which comprises the following steps: bulk loading treatment of garbage, magnetic screening of bulk loading garbage, primary crushing of the screened garbage, drying of garbage after primary crushing, secondary or multiple crushing of the garbage after be dried, pyrolytic reaction of the garbage after the secondary or multiple crushing, addition of catalyst and reactant to the garbage after the pyrolytic reaction and full mixing, humidification treatment of the mixed garbage, forming processingof the garbage after the humidification into the fire coal products, drying of the fire coal products into finished products, and the like; and special equipment is adopted according to the process flow to form an automatic production line. In the invention, the garbage is treated, nonmetal substances are all manufactured into the fire coal material, and the combustion value of the coal product to which the catalyst and reactant are added is 20%-30% higher than that of common coal. The invention changes garbage into valuables, utilizes the garbage cyclically, solves the problem that a large amount of garbage residue can not be treated, improves the ecological environment, and saves the land resources.

Owner:GUILIN UNIV OF ELECTRONIC TECH

High-strength thermal-shock-resistant refractory brick

The invention discloses a high-strength thermal-shock-resistant refractory brick. The high-strength thermal-shock-resistant refractory brick is characterized by being prepared from the following raw materials in parts by weight: 16-20 parts of fused corundum powder, 12-16 parts of tabular corundum, 48-52 parts of aluminum oxide micro powder, 2-6 parts of magnesia fine powder, 2-6 parts of zirconium dioxide powder, 1-4 parts of silicon carbide, 1-4 parts of silica powder, 2-6 parts of sodium silicate, 2-6 parts of andalusite powder, 1-2 parts of a titanium boride additive, 5-15 parts of sillimanite fine powder, 5-8 parts of Guangxi clay, 10-15 parts of waste iron trough materials and 10-15 parts of waste silicon mullite bricks. The material proportion of the refractory brick is optimized, and the refractory brick is good in high temperature resistance, corrosion resistance and thermal shock resistance, improves refractoriness under load, is not liable to have cracks and damages in use, and prolongs the service life.

Owner:XUZHOU SUPAI HIGH TEMPERATURE NEW MATERIAL CO LTD

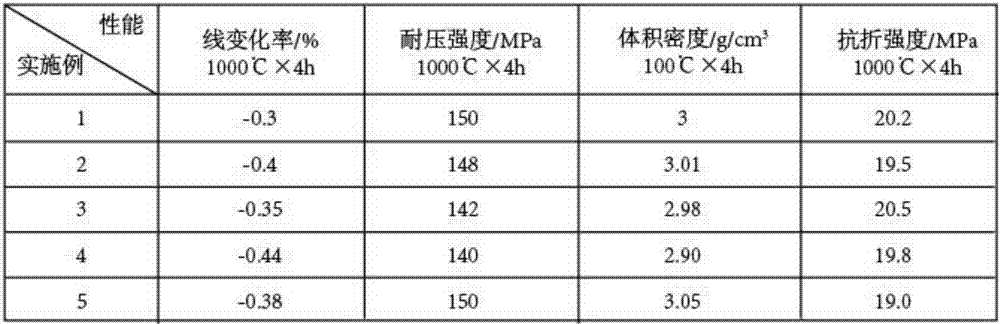

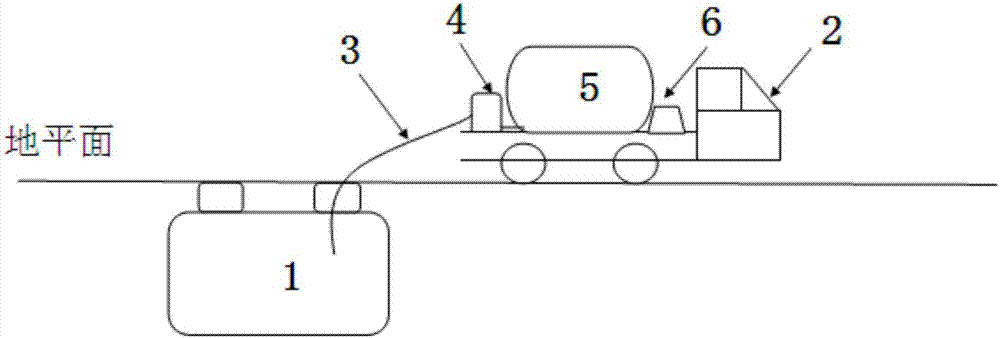

Sweeping system and method for dispersed type purifying tanks of villages and small towns

PendingCN107268771ALow costAvoid secondary pollutionSludge treatment by de-watering/drying/thickeningClimate change adaptationSewage treatmentSludge dewatering

The invention belongs to the technical field of dispersed type domestic sewage treatment of villages and small towns. Aiming at the sweeping problems in the operation and maintenance processes of dispersed purifying tanks in villages and small towns, the invention provides a sweeping system and a sweeping method for dispersed type purifying tanks of villages and small towns, namely, based on the mainstream idea of 'equipment integration' in the market at present, according to the current situations of the rural infrastructure, the invention provides the idea of 'equipment dispersed cooperation'. The treatment device comprises a pollutant suction device, a sweeping device and a sludge dewatering device. The method comprises the steps that two or more small vehicles are adopted to form a maintenance queue, pollutant suction, dehydration and sweeping are carried out on the purifying tanks, and the generated sludge is transported to a treatment point to be subjected to centralized treatment. The system and mode provided by the invention belong to the professional sweeping equipment, method and mode aiming at the problems in operation and maintenance processes of the dispersed purifying tanks in villages and small towns, and adapt to the current situation that the rural infrastructure is poor; the cost is saved by 80% compared with a manual mode or a sweeping maintenance means adopting a simple tool, meanwhile, secondary pollution caused by sludge in the purifying tanks is avoided, and thus the environment is protected.

Owner:JIANGSU CRRC ENVIRONMENT CO LTD

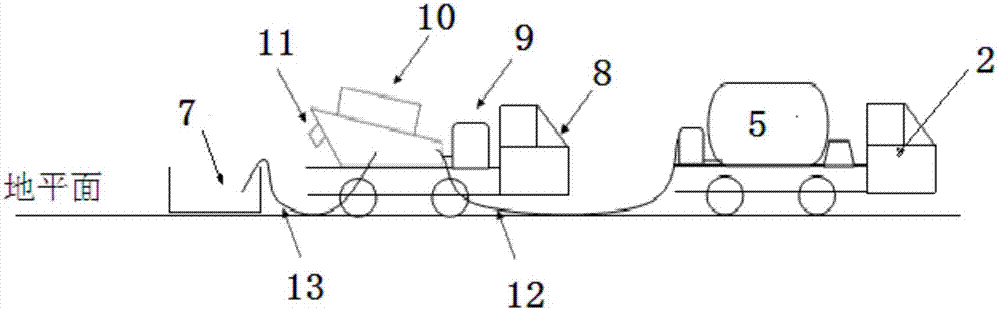

Method for preparing calcium sulfate whisker and magnesium hydroxide by hydrochloric acid and phosphate tailing

InactiveCN107043956ASolve unhandled problemsReduce pressure on environmental protectionPolycrystalline material growthFrom normal temperature solutionsPhosphateSlurry

The invention relates to a method for preparing calcium sulfate whisker and magnesium hydroxide by hydrochloric acid and phosphate tailing. The method comprises the following steps: phosphate tailing and hydrochloric acid are fully mixed in a leaching groove, an obtained reacted first slurry is subjected to solid-liquid separation I, the acid insoluble substance and mother liquor I are separated, the mother liquor I is added in sulfuric acid in proportion to generate a second slurry containing calcium sulfate whisker, through solid-liquid separation II, the calcium sulfate whisker and mother liquor II are separated, a part of the mother liquor II is subjected to flash evaporation, a part of free hydrochloric acid is recovered, the mother liquor after recovery of hydrochloric acid is added in calcium hydrate (or calcium oxide), a third slurry containing magnesium hydroxide precipitate is obtained through a reaction, the third slurry is subjected to solid-liquid separation III, the magnesium hydroxide and mother liquor III are separated, and the mother liquor III is returned to the leaching groove. According to the invention, waste phosphate tailing and industrial by-product hydrochloric acid are taken as the production raw materials, sulfuric acid and calcium hydrate (calcium oxide), and whisker of magnesium hydroxide and calcium sulfate are added, the whole production has the advantages of simple process and totally-enclosed circulation, the waste can be changed to valuables, and cleaning production is realized.

Owner:HUBEI SANNING CHEM

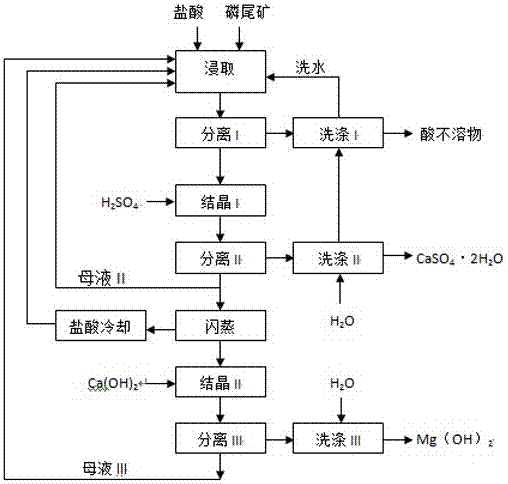

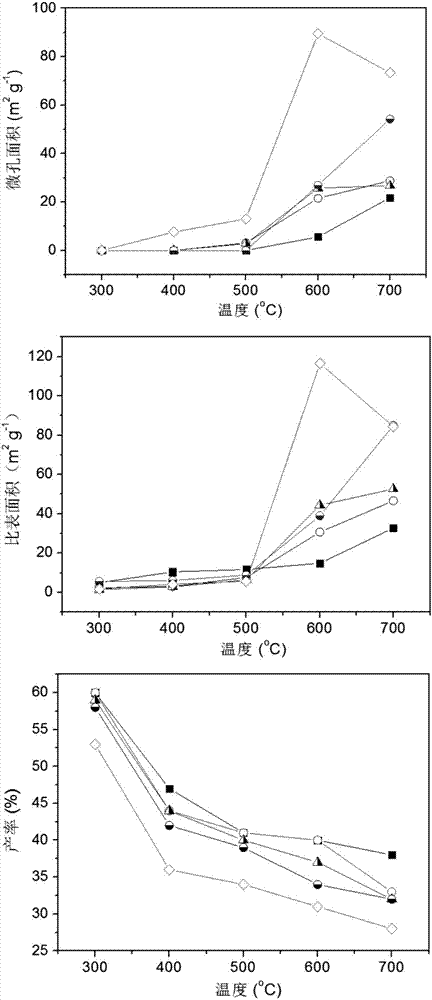

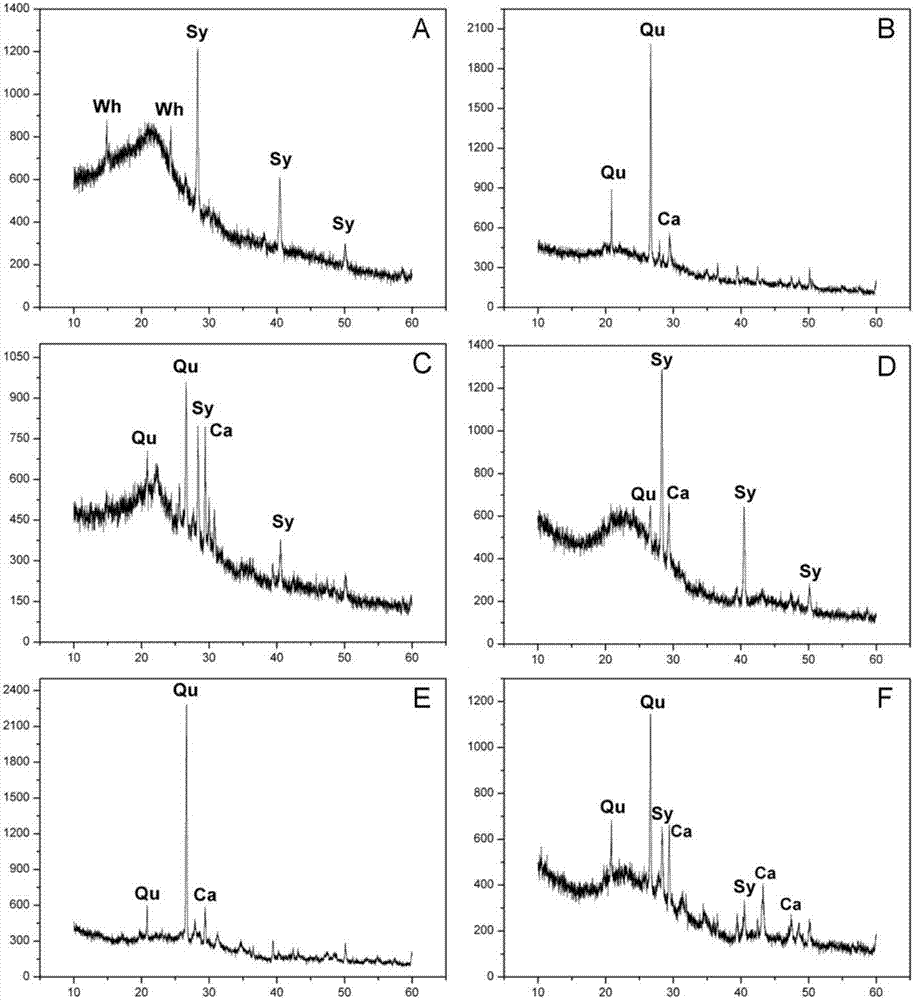

Mixture biological carbon used for improving acidic soil and preparation method thereof

InactiveCN107254312ASolve processingSolve a series of problems that ariseOther chemical processesCarbon preparation/purificationMass ratioOxygen

The invention discloses a mixture biochar for improving acidic soil. The preparation method comprises the following steps: 1) Manure and straw are subjected to the following treatment respectively: first drying to a moisture content of ≤5%, and then pulverizing to a particle size of ≤ 5mm, so as to obtain manure granules and straw granules respectively; 2) Mix manure granules and straw granules according to the weight ratio of 3~1:1~3, and then put the mixture into an anaerobic airtight container and heat it to 300~700℃ Heat treatment for 2±0.25 hours; get a mixture of biochar for improving acidic soil. The invention uses manure and straw mixtures of different mass ratios as raw materials, and prepares novel high-efficiency biochar at different pyrolysis temperatures, which is used to improve the fertility of acidified soil, reduce soil acidity, and reduce the toxicity of heavy metals in soil.

Owner:ZHEJIANG UNIV

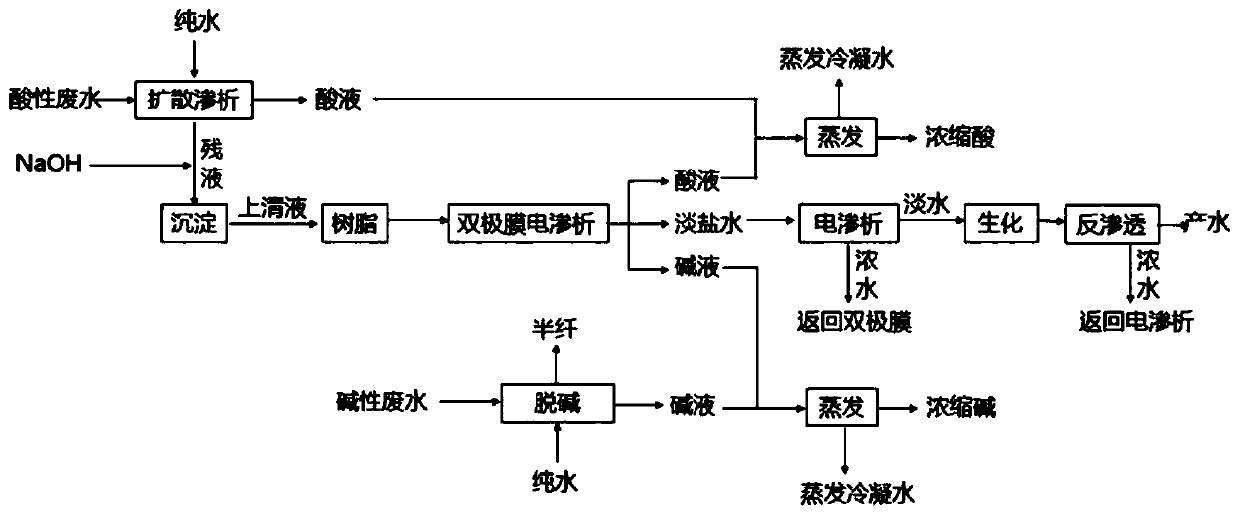

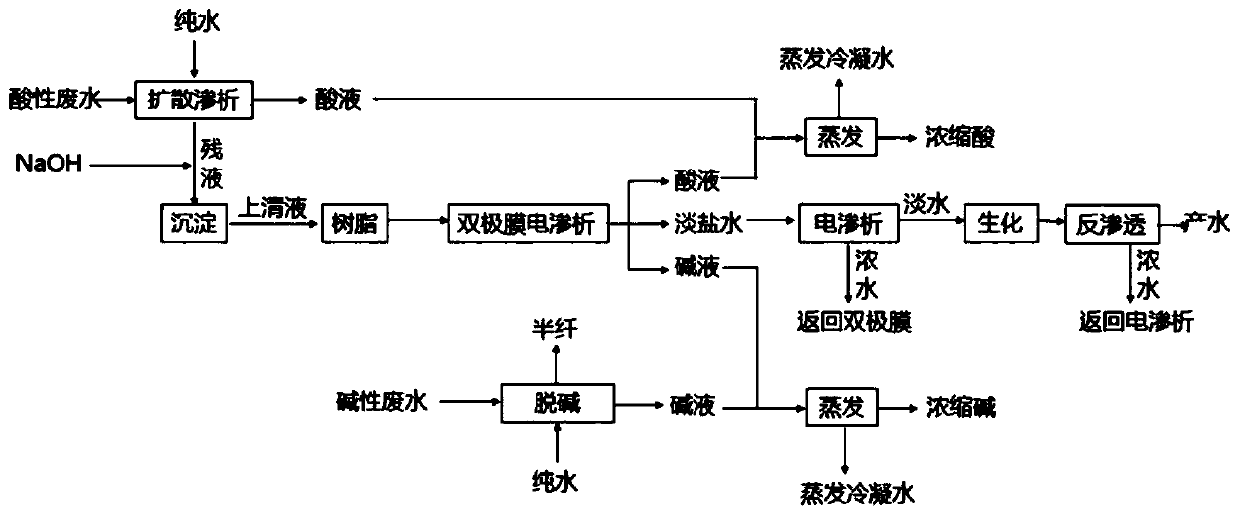

Method for processing acidic wastewater and alkaline wastewater of viscose fiber industry

ActiveCN109970274AReduce manufacturing costSolve unhandled problemsTreatment using aerobic processesGeneral water supply conservationProduction lineViscose

The invention discloses a method for processing acidic wastewater and alkaline wastewater of the viscose fiber industry, and belongs to the field of wastewater processing method. The method comprisesan acid wastewater processing method and an alkaline wastewater processing method. Acids, alkalis, and semi-fibers can be maximally recovered from wastewater. After concentration, acids and alkalis can be returned to the production line. Semi-fibers can be used as a byproduct for sale. The production cost is reduced, and the benefits are increased for enterprises. Salts in wastewater are convertedinto acids, alkalis, and water, resources are recovered and utilized, the problem that waste sodium sulfate cannot be recovered is solved, the amount of discharged solid wastes is reduced, the provided method is applied to viscose fiber production, no wastewater or waste is discharged during the whole technical process, wastewater is recovered and reutilized in the forms of water, acids, alkalis,and semi-fibers, the organic substances are removed through a biochemical method, and the method is simple, green, and environmentally friendly and has a good industrial application prospect.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

Method for preparing hydrogen in process of producing trimanganese tetroxide from electrolytic manganese metal

InactiveCN103241711ADoes not affect the production processSolve the safety hazards of flammable and explosiveHydrogen productionManganese oxides/hydroxidesElectrolysisReaction temperature

The invention relates to a method for preparing hydrogen in process of producing manganous-manganic oxide through electrolytic manganese metal and belongs to the field of chemical metallurgy. The preparation method comprises the following steps: crushing the electrolytic manganese metal in the process of producing the manganous-manganic oxide by taking the electrolytic manganese metal as a raw material, reacting the electrolytic manganese metal with water to generate manganese hydroxide under specific conditions under the catalytic action of a catalyst, and releasing the hydrogen, wherein the specific reaction conditions in the process of preparing the hydrogen are that the crushing particle size of the electrolytic manganese metal is less than 150 microns, the addition amount of the catalyst is 5-15g of catalyst added into each 1000g of electrolytic manganese metal, the reaction temperature is controlled to be 40-90 DEG C, and the PH value of the reaction process is controlled to be 6-12. The manganese hydroxide generated through the reaction is prepared into a manganous-manganic oxide product through other oxidation processes, and the hydrogen concentration of the hydrogen released from the reaction can reach 80-90 percent, and the hydrogen becomes a final gas product. The added catalysts are ammonium chloride, ammonium sulfate, hydrochloric acid, manganese chloride and oxalic acid and also comprise two or more catalysts.

Owner:湖南特种金属材料有限责任公司宁乡分公司

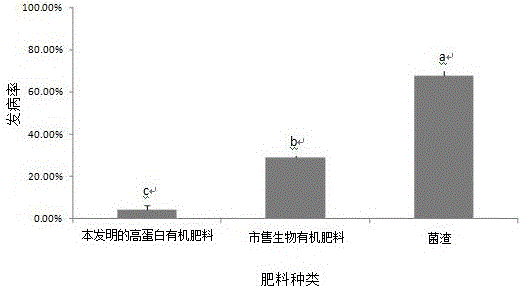

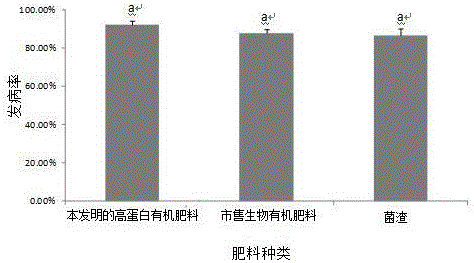

A method of producing a high-protein organic fertilizer by converting edible fungus dregs utilizing housefly larvae

InactiveCN106167423ASolve unhandled problemsSolve the problem of ecological treatmentBio-organic fraction processingFood processingBiotechnologyHousefly

A method of producing a high-protein organic fertilizer by converting edible fungus dregs utilizing housefly larvae is disclosed. The method includes (1) collecting the edible fungus dregs, drying in the sun, crushing and sieving with a sieve having a size of 20 meshes, (2) fully mixing the sieved edible fungus dregs with chicken manure and wheat bran in a ratio of 3-7:2-6:1, adding an EM bacterial stock liquid according to a ratio of 1% by weight and fish meal according to a ratio of 1%, adding water until the water content is 40-50%, and sealing and fermenting to prepare a housefly larva culture medium, and (3) adding the housefly larva culture medium into a converting pool, inoculating with fly blow, culturing at 25-30 DEG C with humidity being 60-75% for 4-5 days, drying the culture medium and the housefly larvae in the culture medium as a whole part, and crushing to prepare powder of the high-protein organic fertilizer or processing into particles. The method overcomes a problem that a large amount of waste in an edible fungus industry development process cannot be treated, produces the organic fertilizer having high quality, and generates ecological benefit and obvious economic benefit.

Owner:TAISHAN MEDICAL UNIV

Method for producing metal compound by waste zinc-manganese dioxide dry cell

InactiveCN1530180ASolve unhandled problemsSolid waste disposalZinc compoundsCadmium sulfateElectrolysis

Owner:于之涛

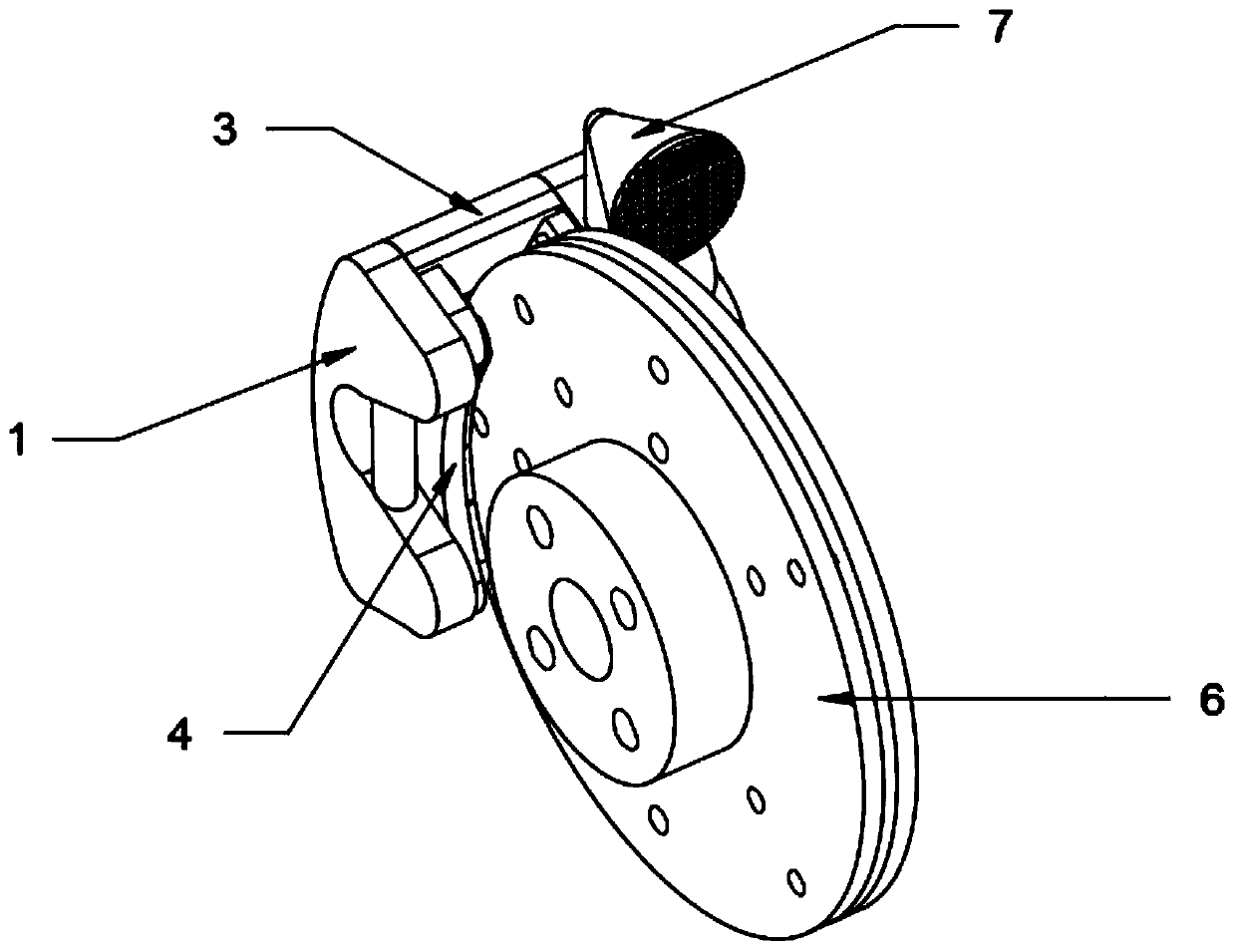

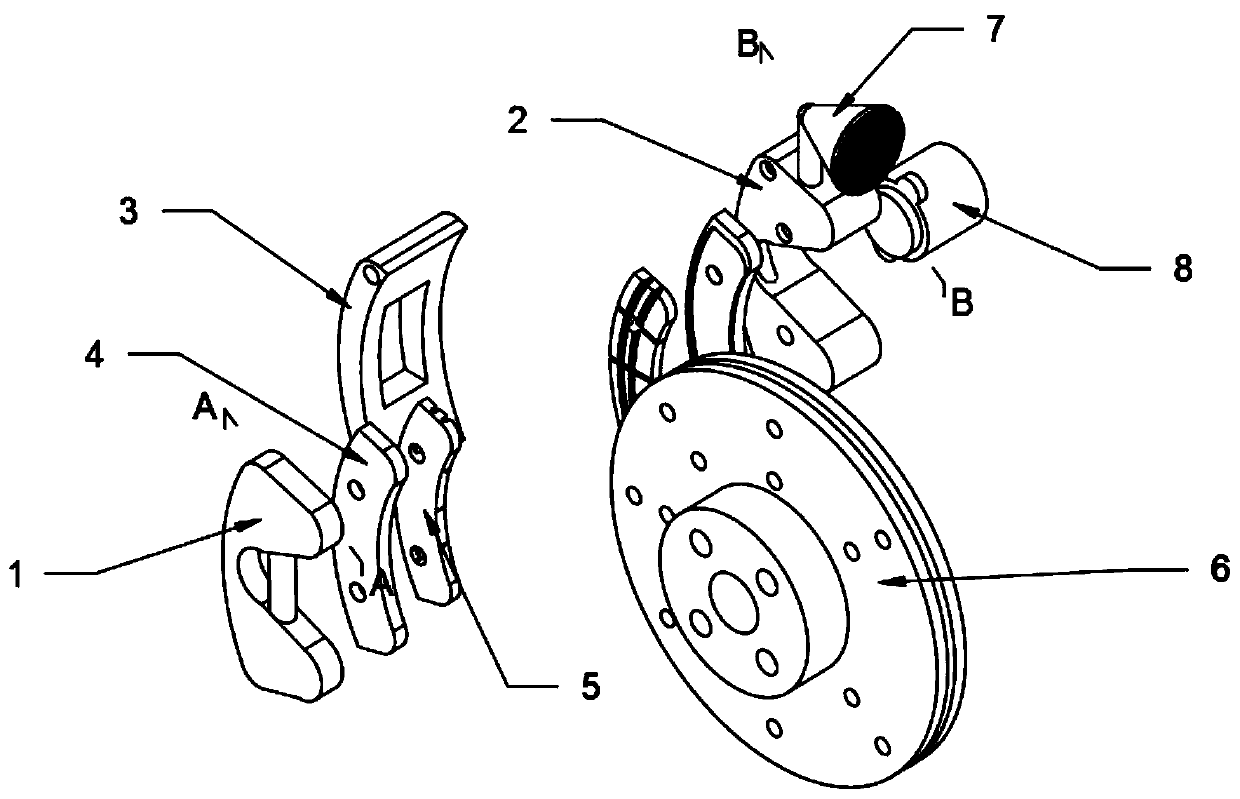

Disk brake pad for commercial vehicle

InactiveCN110043588AReduce heating rateImprove securityBraking elementsCleaning using gasesCommercial vehicleBrake pad

The invention provides a disk brake pad for a commercial vehicle. The disk brake pad comprises a left mounting rack, a right mounting rack and a front mounting rack. One side of the front mounting rack is fixedly connected to the inner edge of the left mounting rack. The other end of the front mounting rack is fixedly connected to the inner edge of the right mounting rack. The mounting racks, liner blocks and brake pad bodies are provided with corresponding air holes. The air swarming into an air inlet can be delivered to the surfaces of the brake pad bodies through an internal pipe, and the air can also be uniformly delivered to the surfaces of the brake pad bodies through grooves in the surfaces of the brake pad bodies so as to conduct blowing cooling on the brake pad bodies in the wholeprocess when an automobile runs, and the heating rate of the brake pad bodies is reduced. Moreover, the air can blow away the dust on the surfaces of the brake pad bodies. Through the design, the problems that brake pad bodies are too hot after long-time use and dust on the surface of the brake pad bodies cannot be dealt with are solved. Meanwhile, the safety of the automobile in the running process is improved.

Owner:HUBEI ZANBO INFORMATION TECH CO LTD

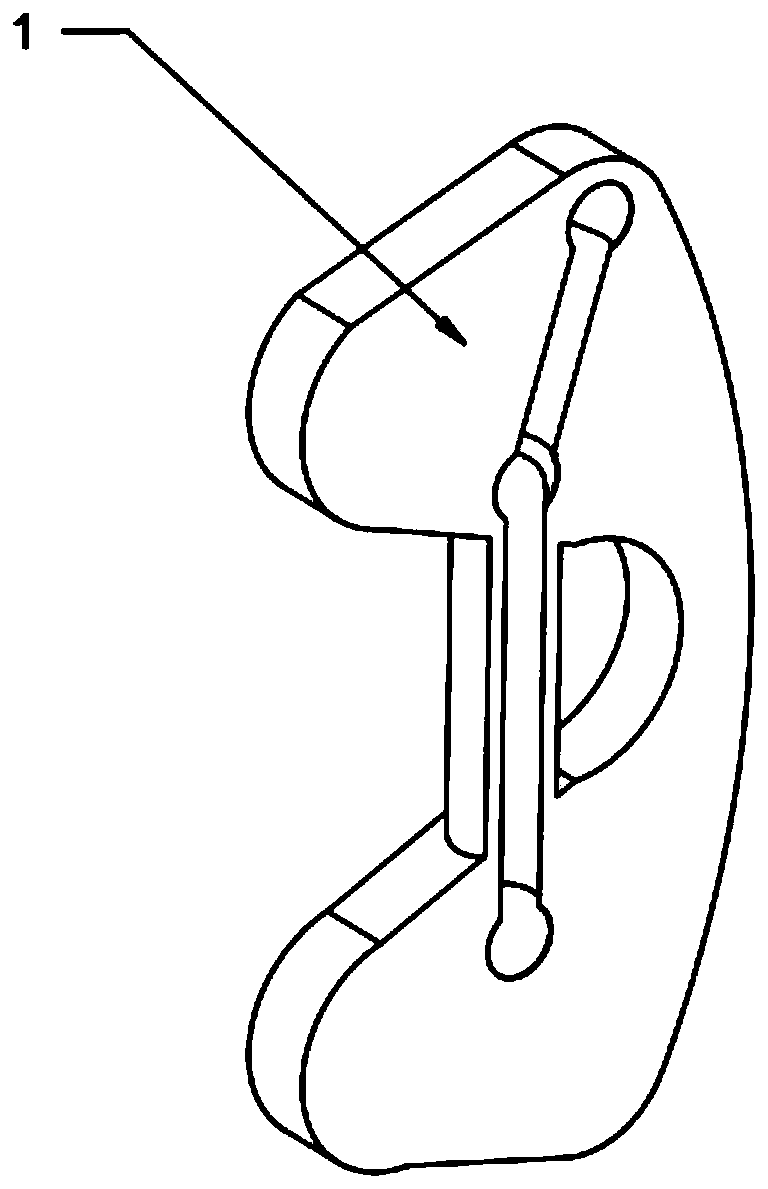

Clean and environment-friendly straw briquette coal and preparation method thereof

InactiveCN103952202ASolve unhandled problemsEfficient use ofSolid fuelsWaste based fuelCombustionEngineering

The invention discloses clean and environment-friendly straw briquette coal and a preparation method thereof. The environment-friendly straw briquette is processed by adding finish-washed coal, coal slime, gangue, additive and a binder into straw materials and mixing through scientific preparation under action of a certain pressure. The clean and environment-friendly straw briquette coal provides a clean and environment-friendly biological energy source. Compared with raw coal, the clean and environment-friendly straw briquette coal is good in gas permeability, higher in heating efficiency and more sufficient in combustion, so that pollution on environment is reduced.

Owner:宁巨忠

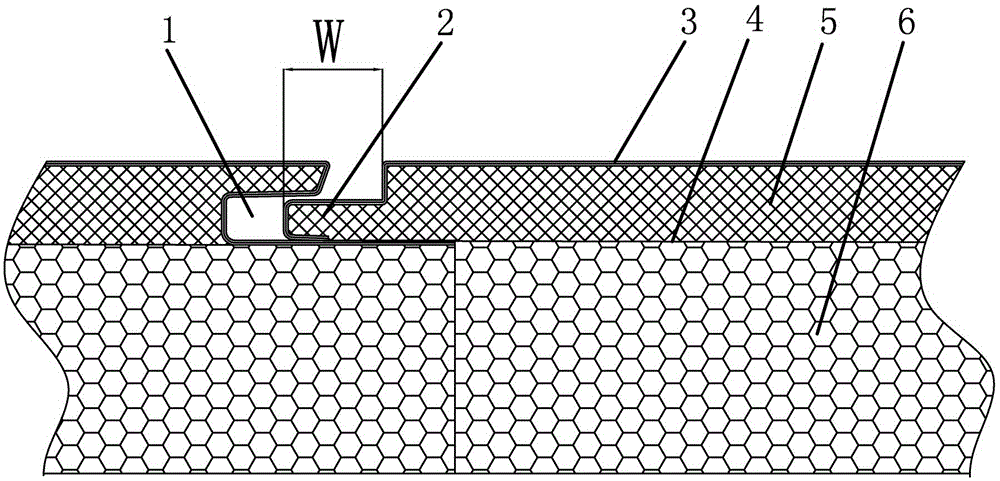

Method for producing metal decorating surface heat-insulating plate with anti-thermal deformation structure

InactiveCN106149908AAvoid stress deformationGuaranteed flatnessCovering/liningsLaminationAluminium foilElectric heating

The invention discloses a method for producing a metal decorating surface heat-insulating plate with an anti-thermal deformation structure. The method comprises the following steps: (1) feeding an aluminium alloy plate or a zinc plated or aluminium and zinc plated steel plate which forms a metal decorating surface layer into a pressing moulding machine through a screen open-type unwinding machine for performing pressing moulding treatment; (2) uniformly mixing isocyanate and premixed polyether polyol according to the ratio of 1:1 in a polyurethane pouring machine, coating the metal decorating surface layer with a mixture to form a polyurethane heat-insulating layer, then, covering the polyurethane heat-insulating layer with an aluminium foil, a glass fibre fabric, a cement base fabric, an embossed steel plate or an embossed aluminium foil which forms an interlayer, and sizing through a laminating machine; (3) feeding a cured and moulded plate into an electric heating treatment box through a conveying belt for performing heat treatment, wherein the heating temperature in the heat treatment box is at least 50 DEC G, and the heat treatment time is at least one minute; (4) uniformly pouring phenolic foam resin on the bottom surface of the plate which is produced in the step (3) through a pouring metering pump to form a base layer, feeding the base layer in a laminating conveying machine, and cutting the moulded plate into required sizes through a cutting machine.

Owner:URUMQI QIXIN NUOLANGDA ENERGY SAVING TECH CO LTD

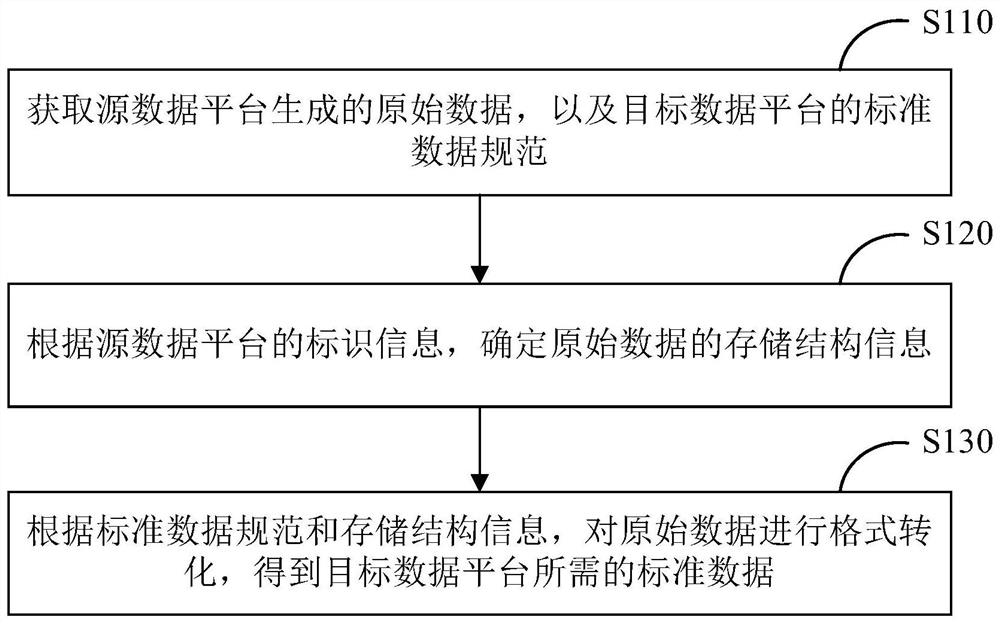

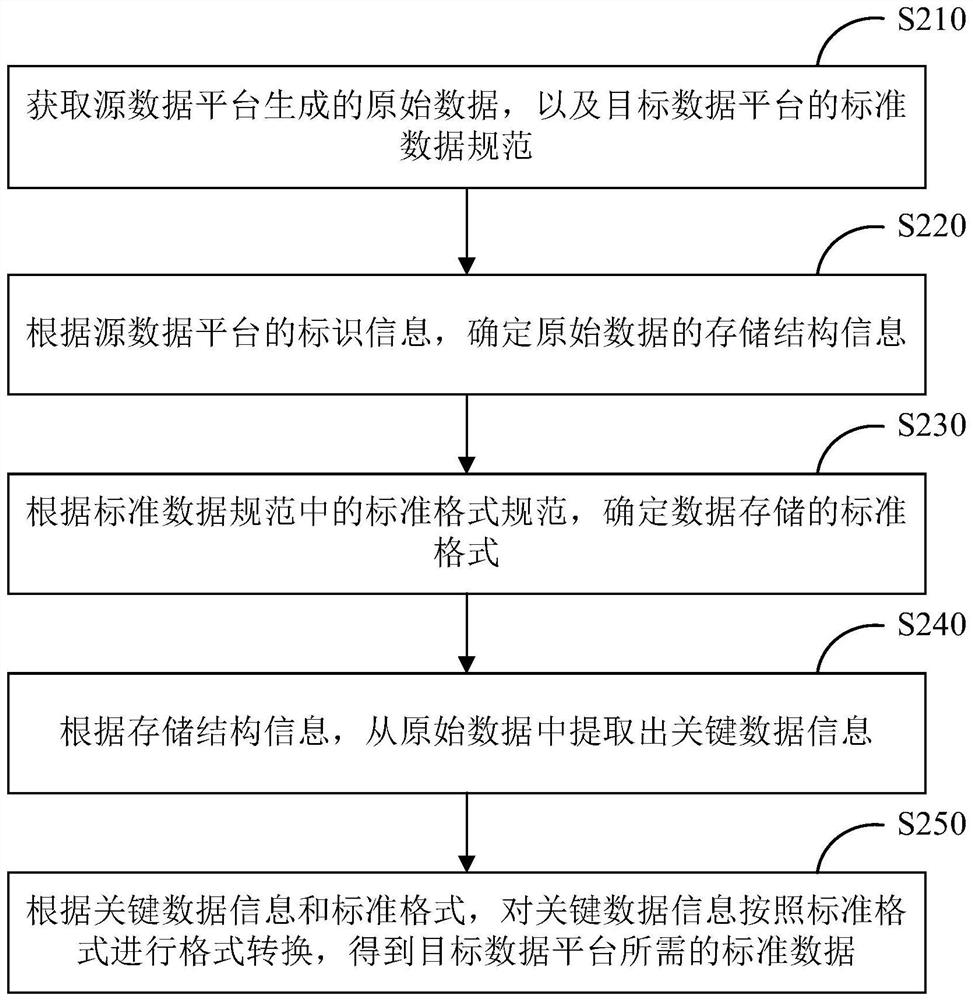

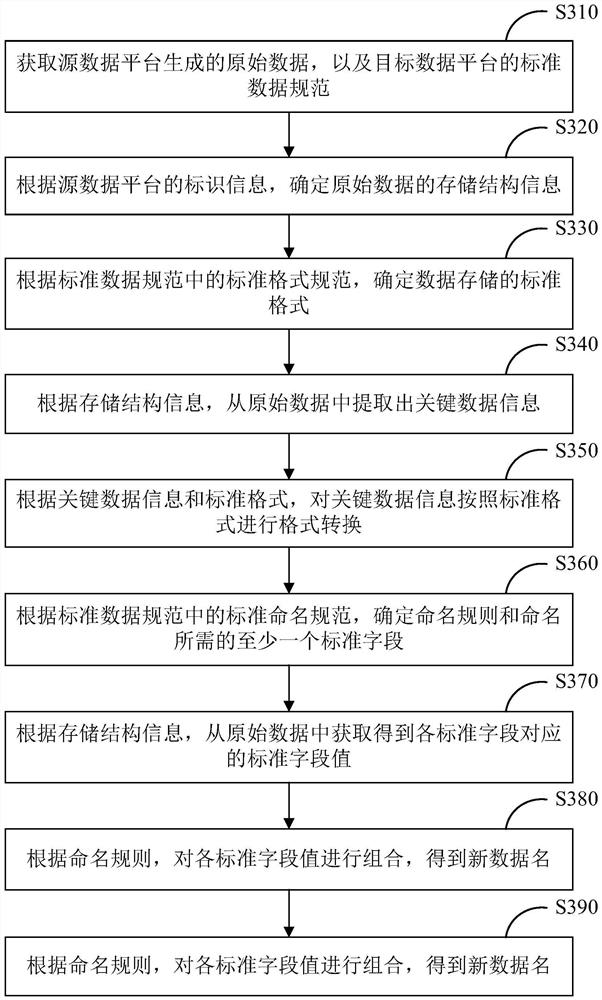

Data processing method and device, equipment and storage medium

PendingCN114281876AReduce workloadSolve unhandled problemsDatabase management systemsProgram loading/initiatingData platformOriginal data

The embodiment of the invention discloses a data processing method and device, equipment and a storage medium. The method comprises the steps of obtaining original data generated by a source data platform and a standard data specification of a target data platform; determining storage structure information of the original data according to the identification information of the source data platform; performing format conversion on the original data according to the standard data specification and the storage structure information to obtain standard data required by the target data platform; through the technical scheme, the problem that the multi-source heterogeneous data access platform cannot process is solved, and the workload during data access is reduced.

Owner:RUN TECH CO LTD BEIJING

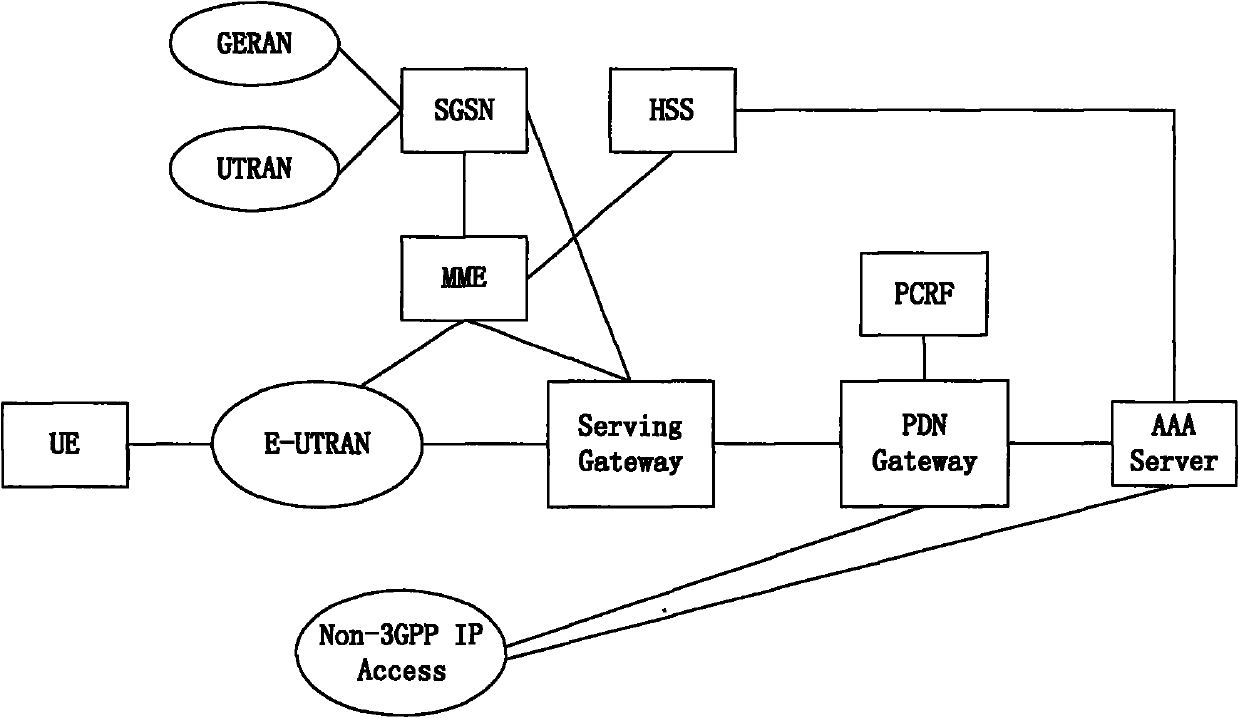

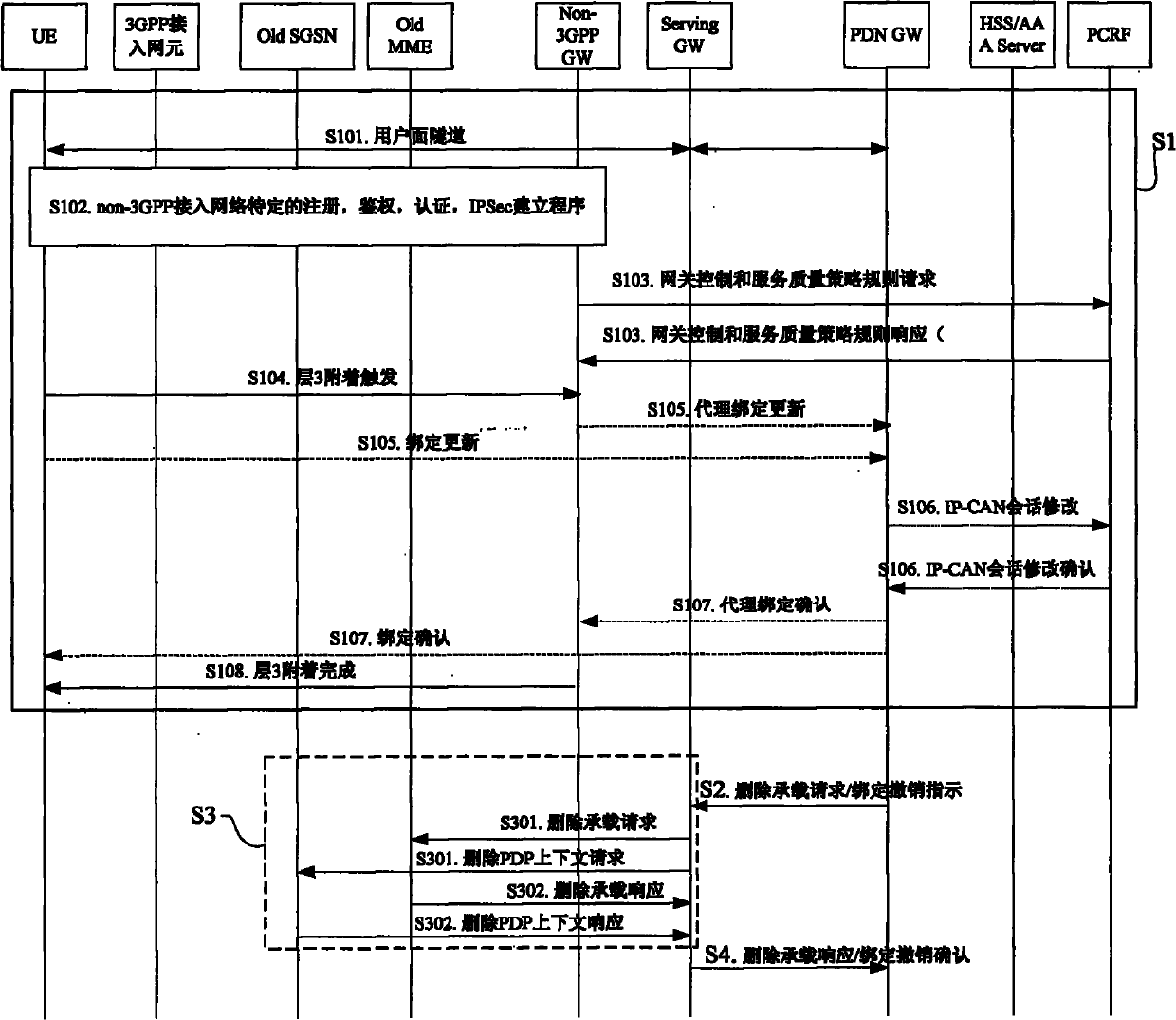

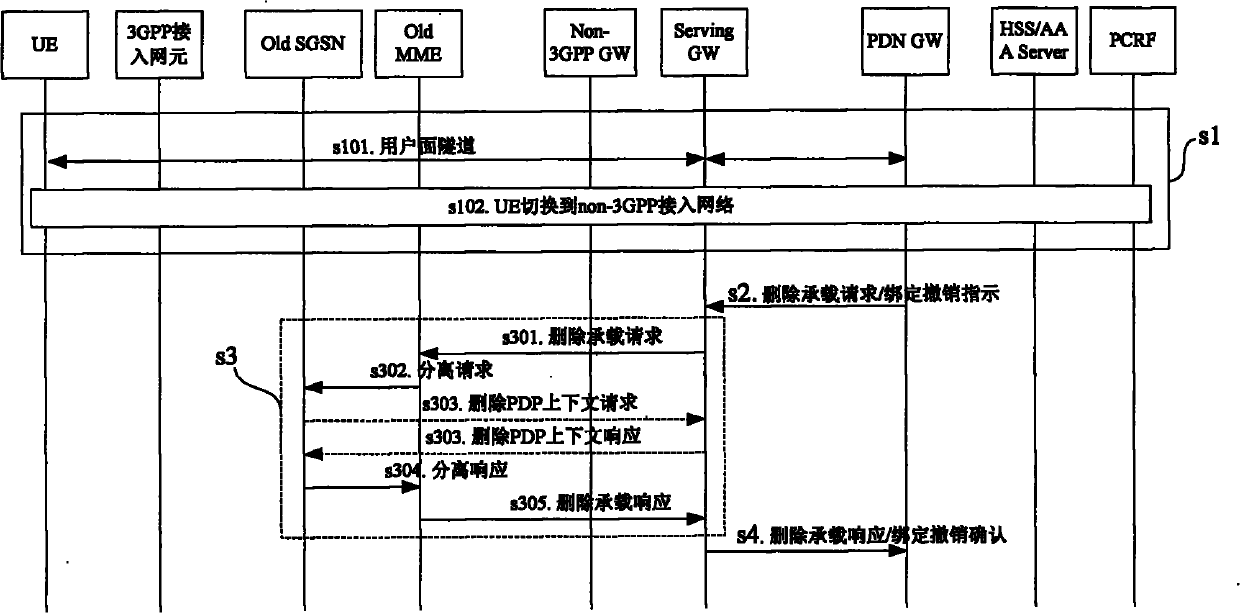

Method for releasing and processing network resources and equipment thereof

ActiveCN101448294BGuaranteed service qualityAchieve releaseConnection managementTransmissionService gatewayMobility management

The invention discloses a method for releasing and processing network resources, comprising the following steps: after user equipment using an ISP mechanism registers two 3GPP communication networks and when the user equipment changes the 3GPP network into a non 3GPP communication network, the service gateway receives a message sent by an opposite end network element and deletes the network resources which is established by the two 3GPP communication networks for the user equipment according to the massage. The invention also discloses a mobility management network element and the service gateway. The embodiment of the method and equipment for releasing and processing the network resources realizes the releasing of resources when the user using the ISP mechanism equipment changes the 3GPP network into the non 3GPP communication network.

Owner:NOKIA TECH OY

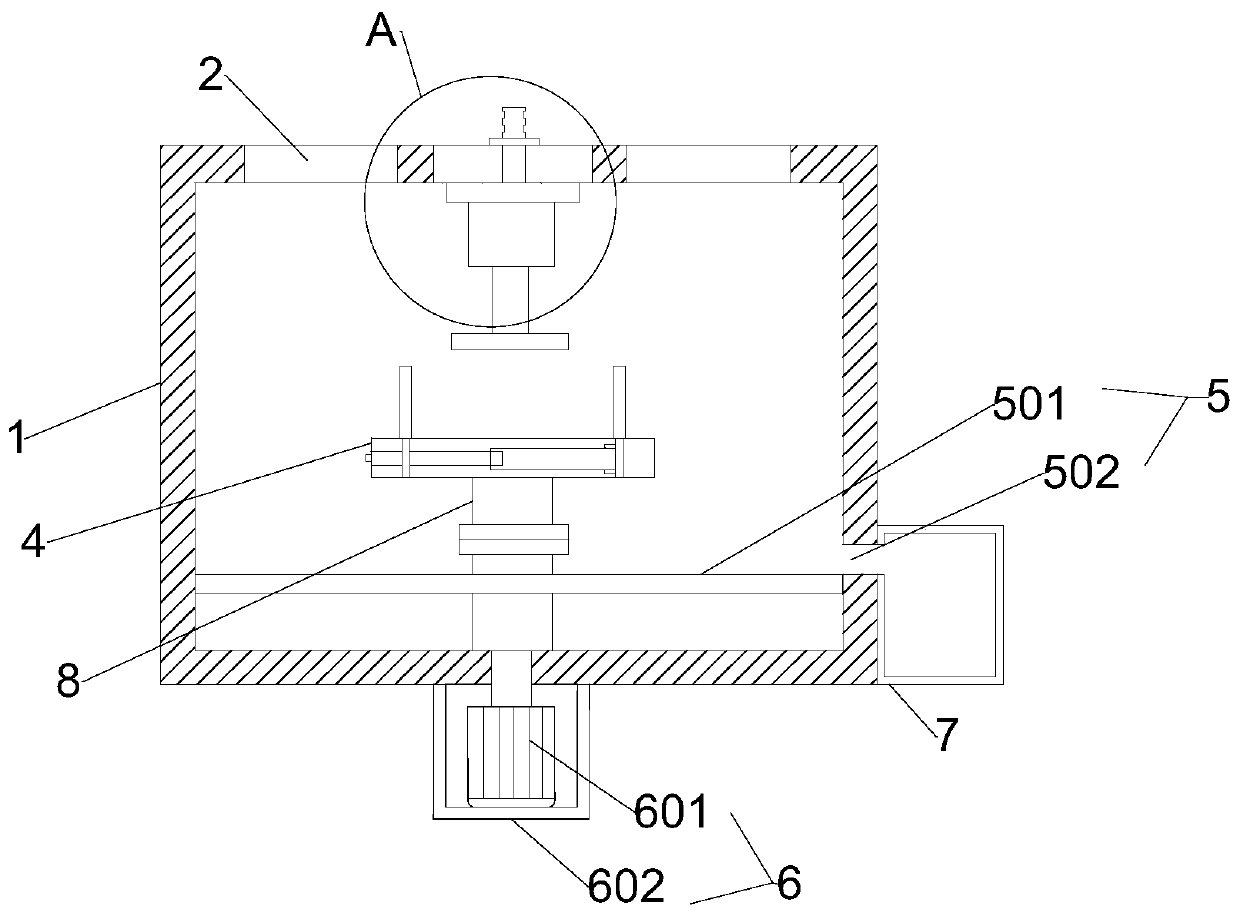

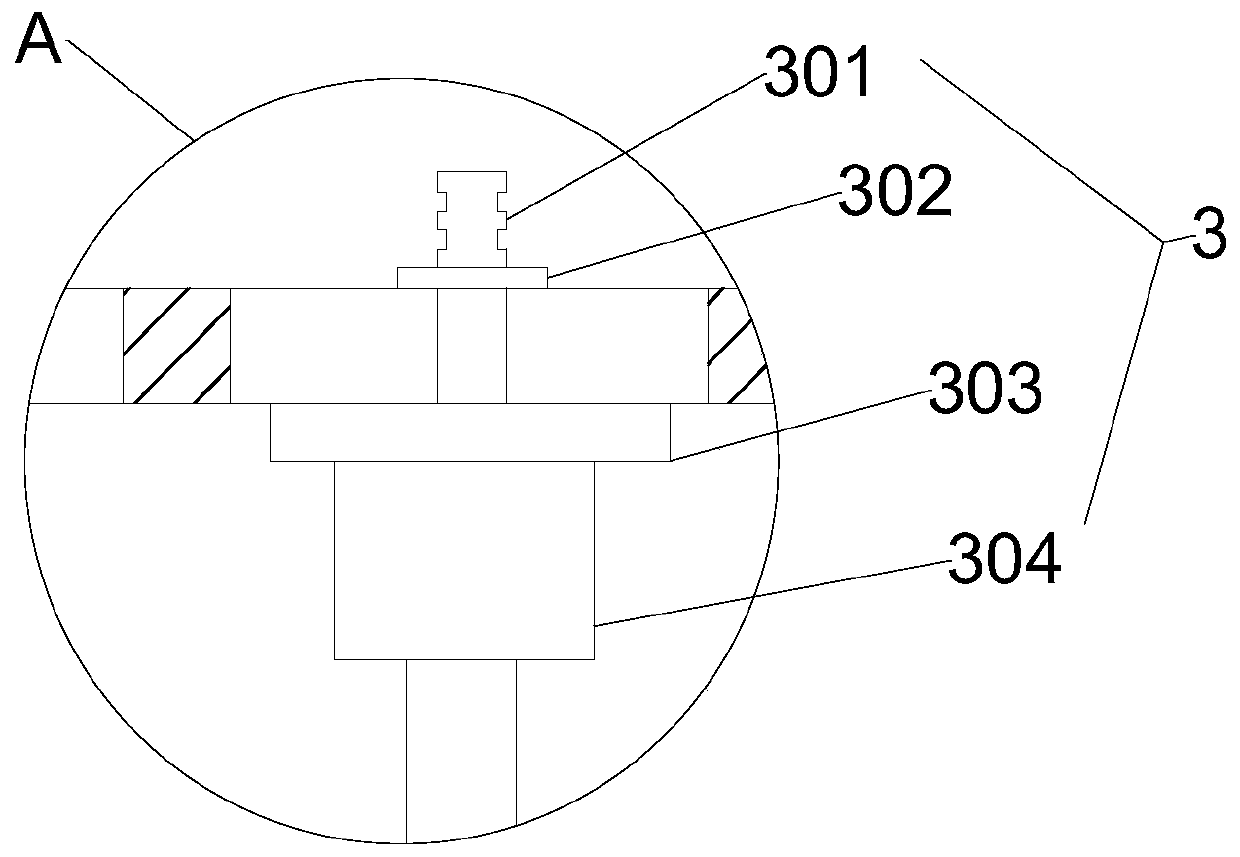

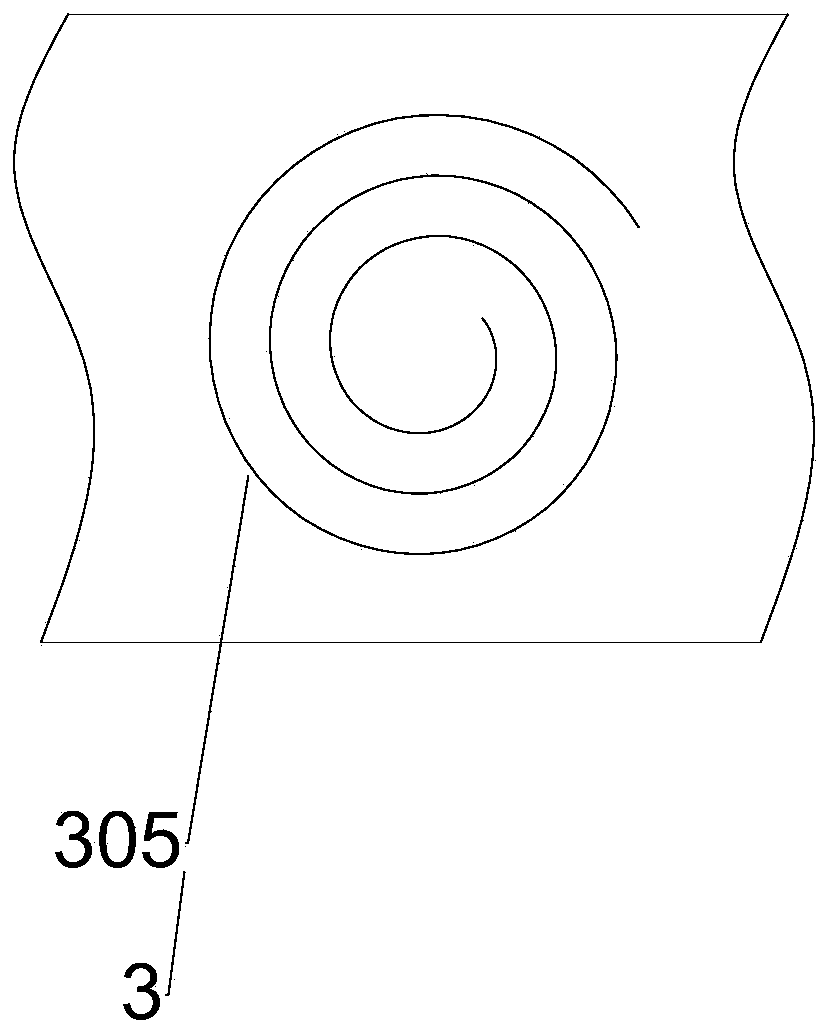

Glass polishing equipment

InactiveCN111215981APolished evenlySolve unhandled problemsGrinding drivesGrinding work supportsPhysicsEngineering

The invention relates to glass polishing equipment. The glass polishing equipment comprises a shell, a polishing mechanism, a fixing mechanism, a rotating mechanism, a driving mechanism, a dust collecting box and a rotating rod, wherein the polishing mechanism is arranged in the middle of the top of the shell, and the fixing mechanism is arranged at the position, right under the interior of the shell, of the polishing mechanism; the lower portion of the fixing mechanism is fixedly connected with the rotating mechanism through the rotating rod, the lower end of the rotating rod penetrates through the rotating mechanism and is fixedly connected with an output shaft of the driving mechanism, and the fixedly-connected dust collecting box is further arranged on the side wall of the shell; and aspiral rail is formed in the middle of the top of the shell, and the polishing mechanism penetrates through the spiral rail to extend into the interior of the shell and slides along the track of thespiral rail. According to the glass polishing equipment, the polishing mechanism can move along the spiral rail, and the spiral rail can cover all parts of a glass finished product after the polishingmechanism moves along the spiral rail so that uniform polishing can be realized.

Owner:安徽超文玻璃科技有限公司

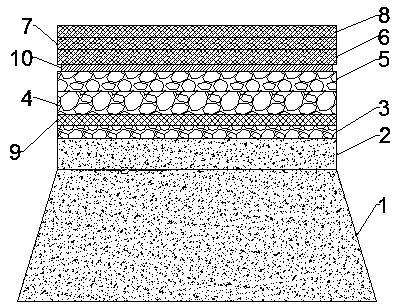

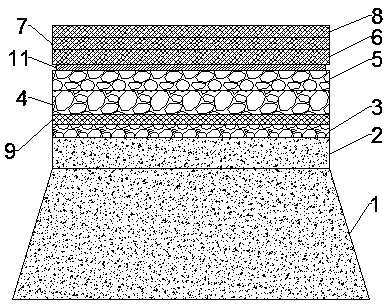

Green low-carbon environment-friendly road structure adopting regenerative material

ActiveCN110205895AProtect environmentSave natural resourcesIn situ pavingsClimate change adaptationFoundation engineeringCushion

The invention discloses a green low-carbon environment-friendly road structure adopting regenerative material. The structure comprises a subgrade and a pavement which are sequentially arranged from bottom to top; the subgrade comprises an embankment and a road bed which are sequentially arranged from bottom to top, wherein the embankment is prepared from urban building waste regenerative mixture,and the road bed is prepared from urban building waste regenerative grading mixture; and the pavement comprises a cushion layer, a bottom base layer, a base layer, a lower layer, a middle layer and anupper layer which are sequentially arranged from bottom to top, and the cushion layer is prepared from building waste regenerative grading aggregate. According to the structure, the requirements of the existing traffic development can be guaranteed, the environmental problems left due to the urban development are resolved, and the problem of destructive mining on natural resources due to the foundation engineering construction is solved.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

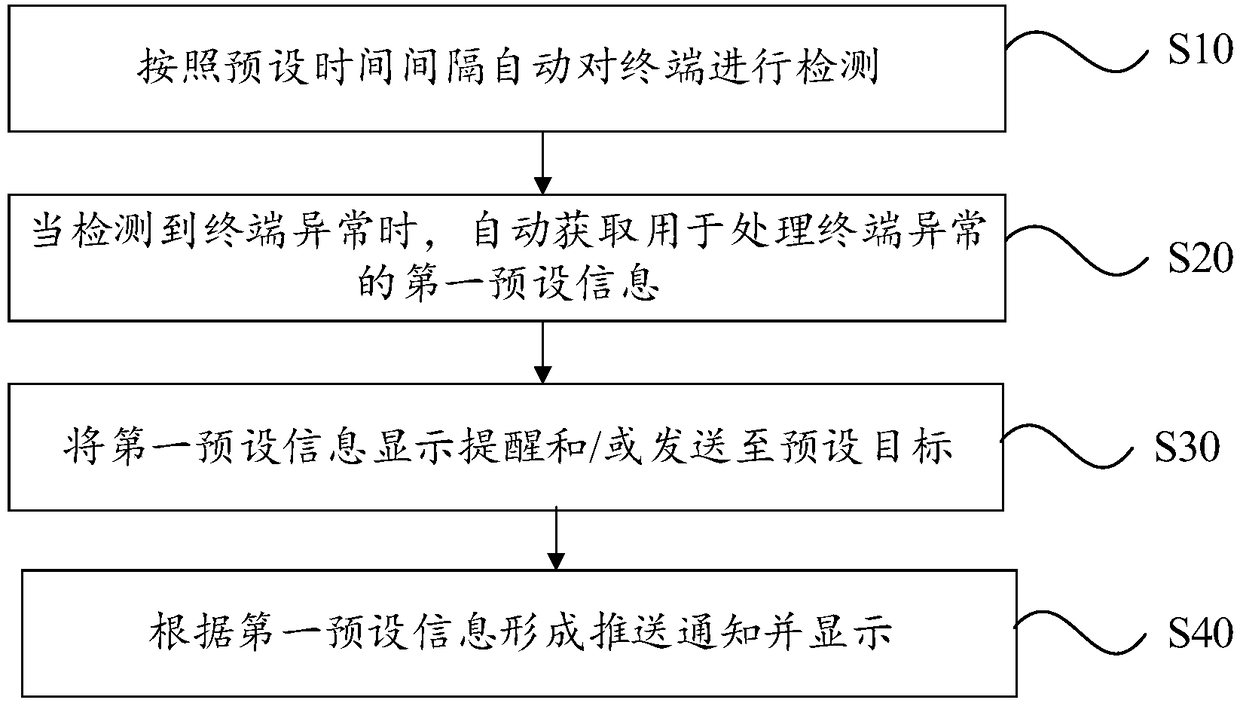

Method for automatic detection and request for repair of terminal, mobile terminal and device with storage function

The invention discloses a method for automatic detection and request for repair of a terminal. The method comprises the following steps of automatically detecting the terminal according to a preset time interval; when detecting an abnormity of the terminal, automatically acquiring first preset information for processing the abnormity of the terminal; displaying the first preset information, prompting and / or sending the first preset information to a preset target; or forming a push notification according to the first preset information and displaying the push notification. The invention also provides a mobile terminal. The mobile terminal comprises a processor and a memory which are electrically connected; the processor executes the above-mentioned method when working; and the memory storesan executed result when the processor works and program data of the above-mentioned method. The invention also provides a device with a storage function. The program data are stored in a storage device; and the above-mentioned method is implemented when the program data are executed.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

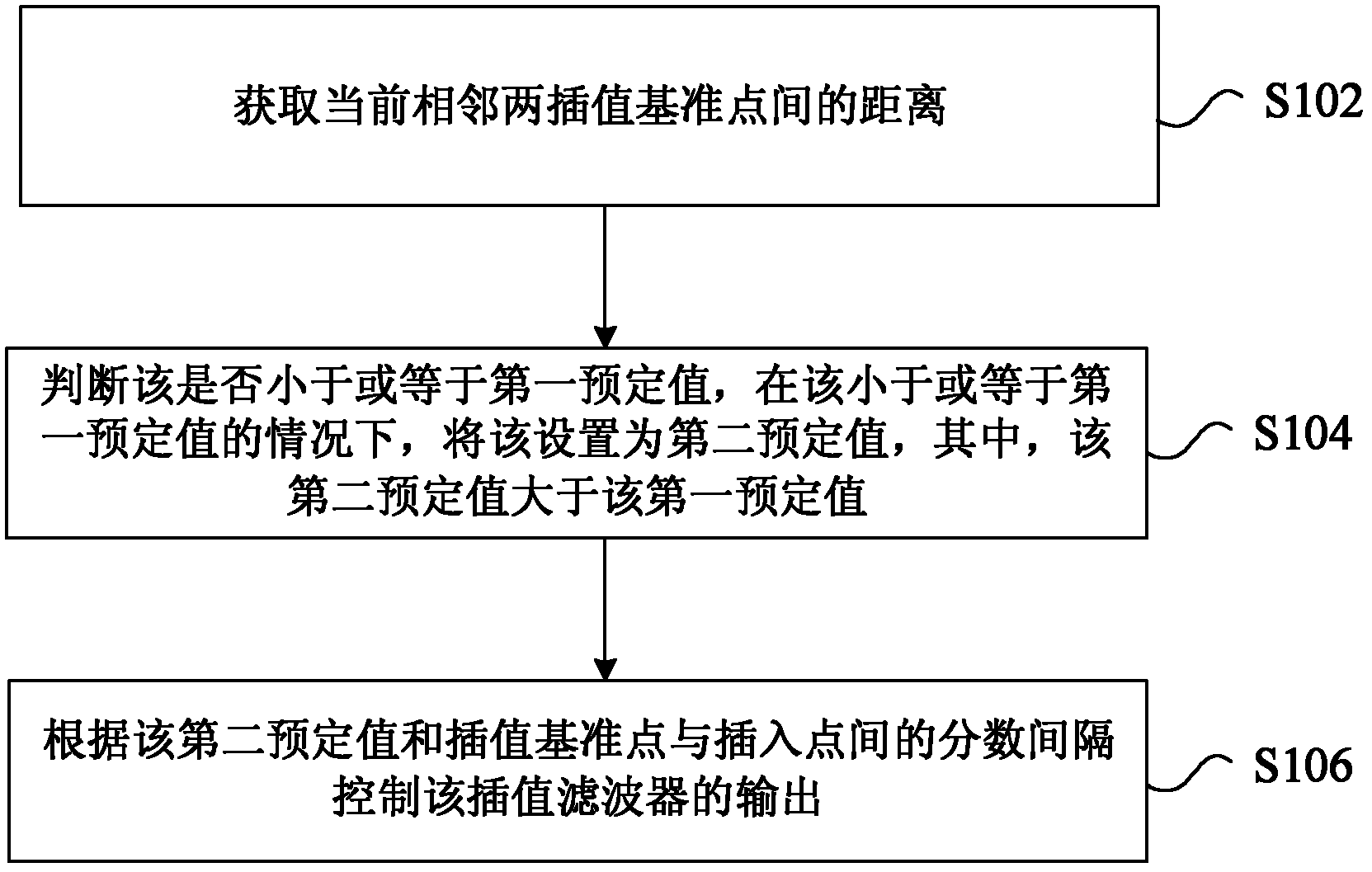

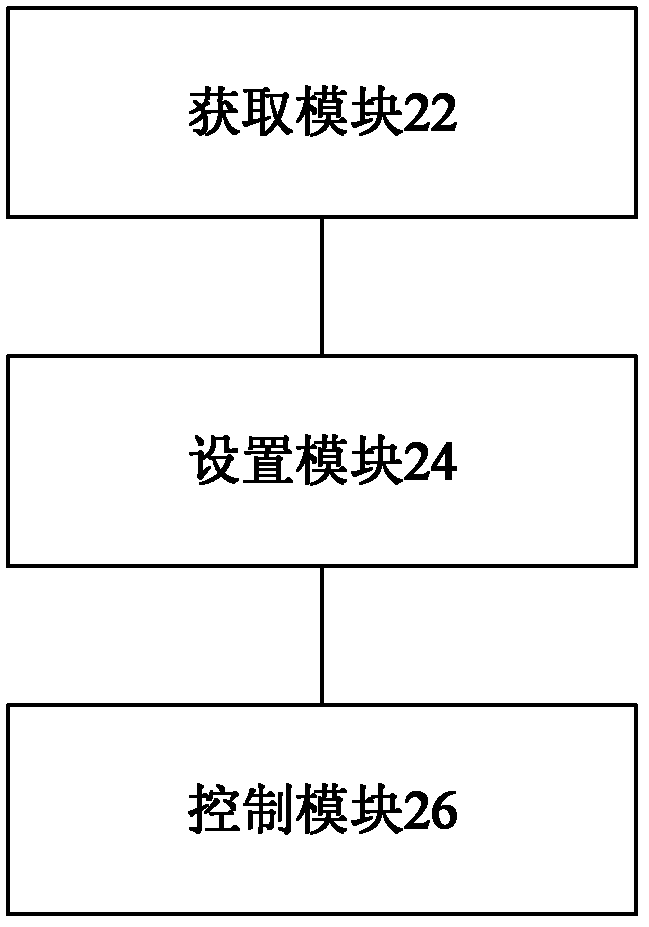

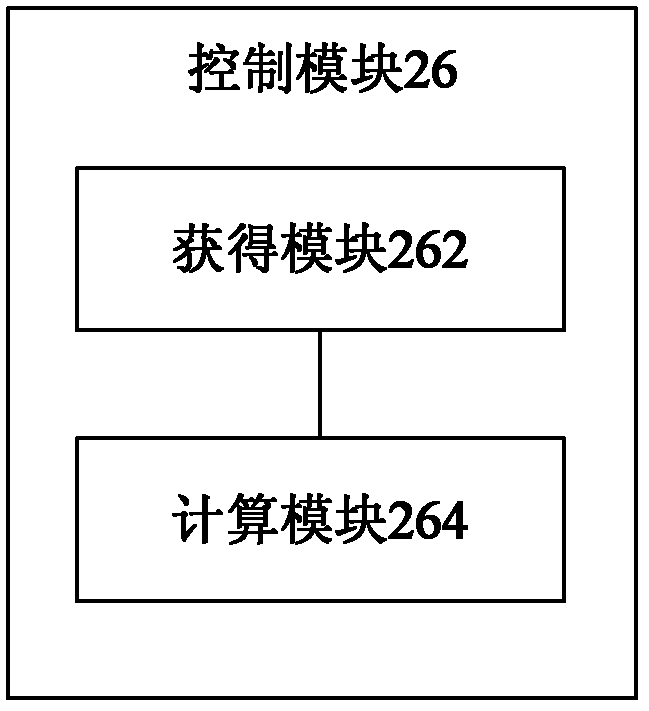

Method, device and system for controlling interpolation filter output

ActiveCN103178805ASolve unhandled problemsSmooth handlingDigital technique networkInsertion pointComputer science

The invention discloses a method, device and system for controlling an interpolation filter output. The method comprises the steps of acquiring a distance mk between existing adjacent two interpolation datum points; judging whether the mk is smaller or equal to a first preset value, wherein the mk is set to be a second preset value when the mk is smaller or equal to the first preset value, and the second preset value is larger than the first preset value; and controlling the interpolation filter output according to a fractional interval muk between the second preset value and the interpolation datum points and insertion points. The problem that an output interval of an interpolation filter in the prior art cannot be controlled (for example, the output interval is too short), and accordingly interpolation filtering results cannot be processed through hardware is solved, effective control of the output interval of the interpolation filter can be further achieved, and the hardware performing follow-up processing can smoothly process the interpolation filter output.

Owner:亚太卫星宽带通信(深圳)有限公司

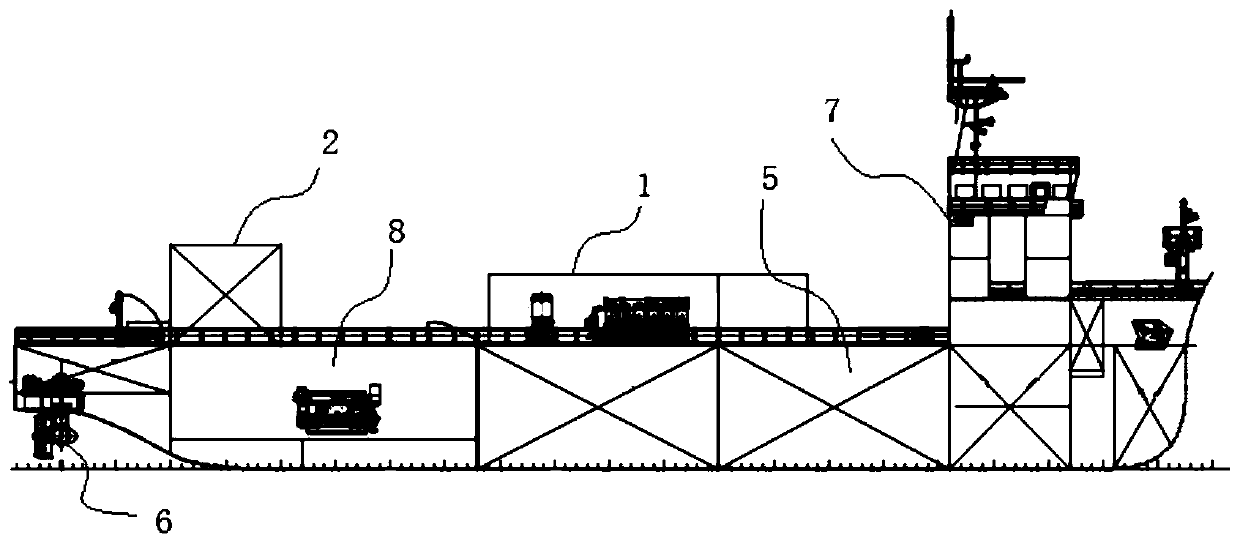

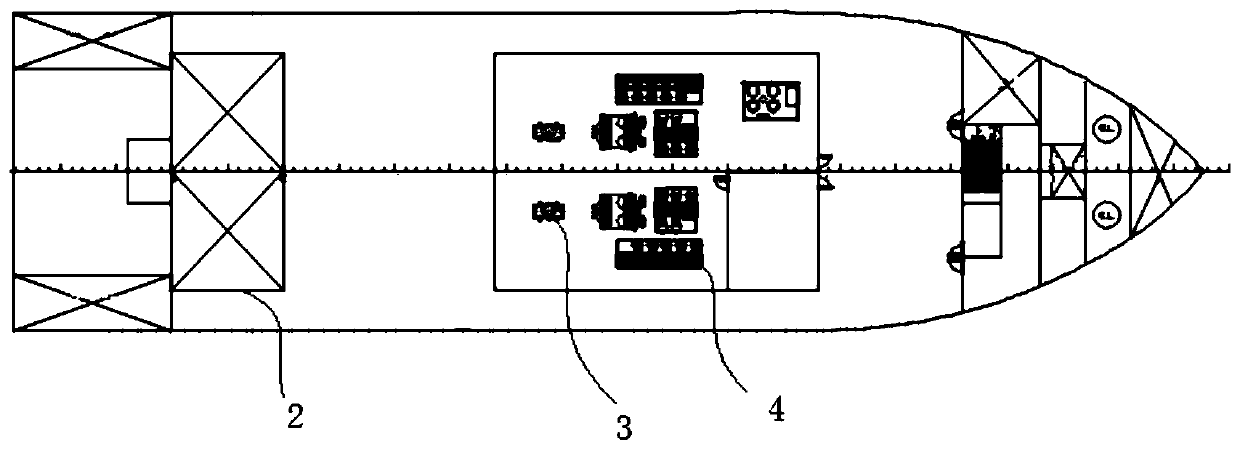

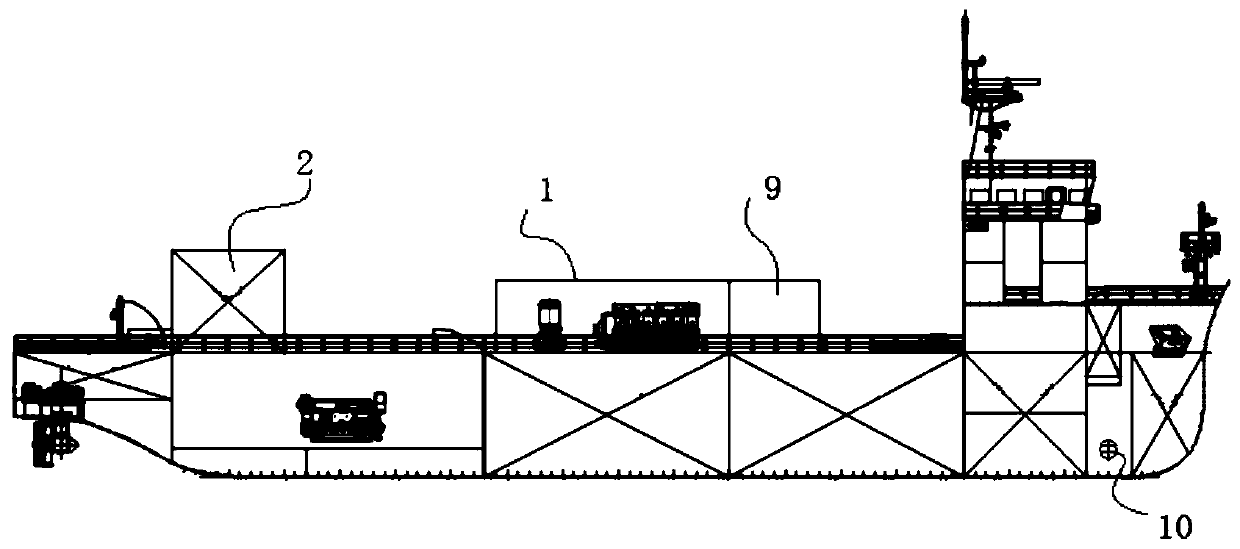

Ballast water receiving and processing barge

InactiveCN109895962AAvoid strandedInto a stableAuxillariesWater treatment installationsWater dischargeBuffer tank

The invention discloses a ballast water receiving and processing barge. The ballast water receiving and processing barge comprises a ballast water processing chamber in the middle of a barge main decksurface, two ballast water buffer tanks arranged at the rear of the barge main deck surface and for receiving ballast water, two ballast water lightering pumps arranged inside the ballast water processing chamber and communicated in one-to-one correspondence with the two ballast water buffer tanks, two ballast water processing devices arranged inside the ballast water processing chamber and communicated in one-to-one correspondence with he two ballast water lightering pumps, and at least one ballast water tank arranged under the barge main deck surface and communicated with the ballast waterprocessing devices. The ballast water receiving and processing barge can on an anchorage site receive and process unprocessed ballast water discharged by ocean vessels.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

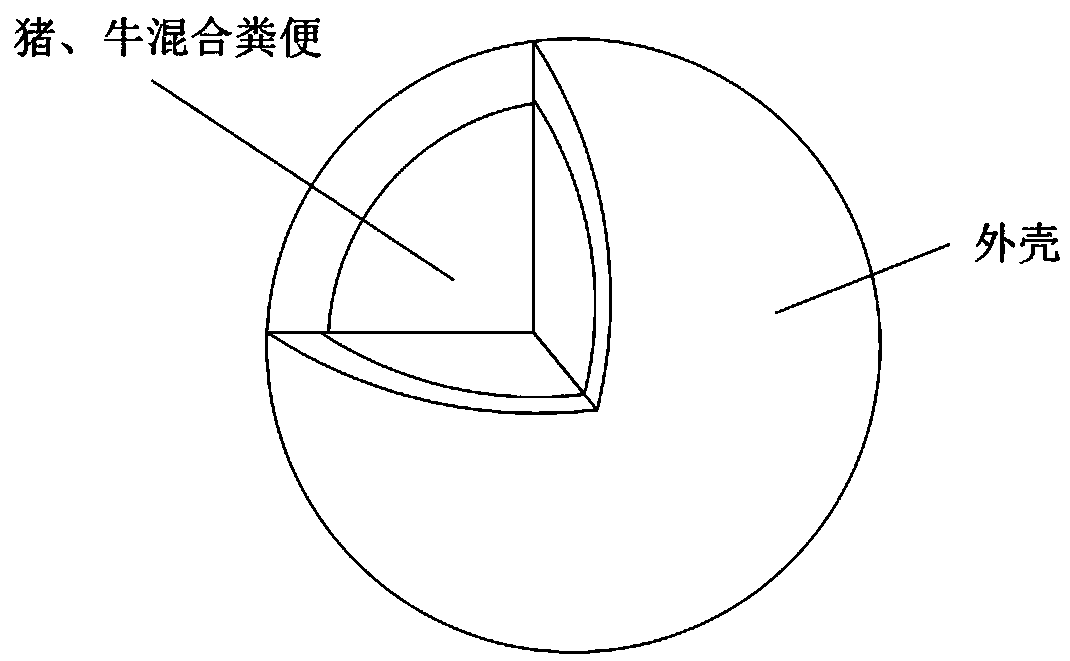

Organic fertilizer produced by means of animal waste and production method thereof

InactiveCN107652098AFull of nutritionNutritiousBio-organic fraction processingOrganic fertiliser preparationFiberFeces

The invention provides organic fertilizer produced by means of animal waste. The organic fertilizer comprises core bodies composed of pig feces, cow feces and straw ash, the proportion of the components of the core bodies is 10 to 3 to 1, the core bodies are covered with shells, and the shells are straw powder shells. A production method of the organic fertilizer is further provided. Nitrogen fertilizer and potassium fertilizer are provided at the same time by means of the mixed feces. The mixed feces is easy to shape through addition of the straw ash. By means of the shells, the core bodies are insulated from the air after production is completed, so that the core bodies are fermented and decomposed in the shells after production is completed, and the production efficiency is improved. The shells can be produced by mixing straw powder with corn meal, the shells are slowly decomposed after fertilization, so that the organic fertilizer is slowly released into the soil, and long-acting fertilizer is provided for farmland. Fermentative bacteria go into the mixed feces after production is completed, decomposition is conducted, the pig feces is thoroughly decomposed effectively, and lots of fibers in the cow feces are effectively decomposed. The organic fertilizer produced by means of animal waste has the advantages that the production means is simple, the fertility is sufficient, the organic fertilizer can be effectively stored for a long term and is applicable to crop rotation.

Owner:福清市冠丰现代农业农民专业合作社

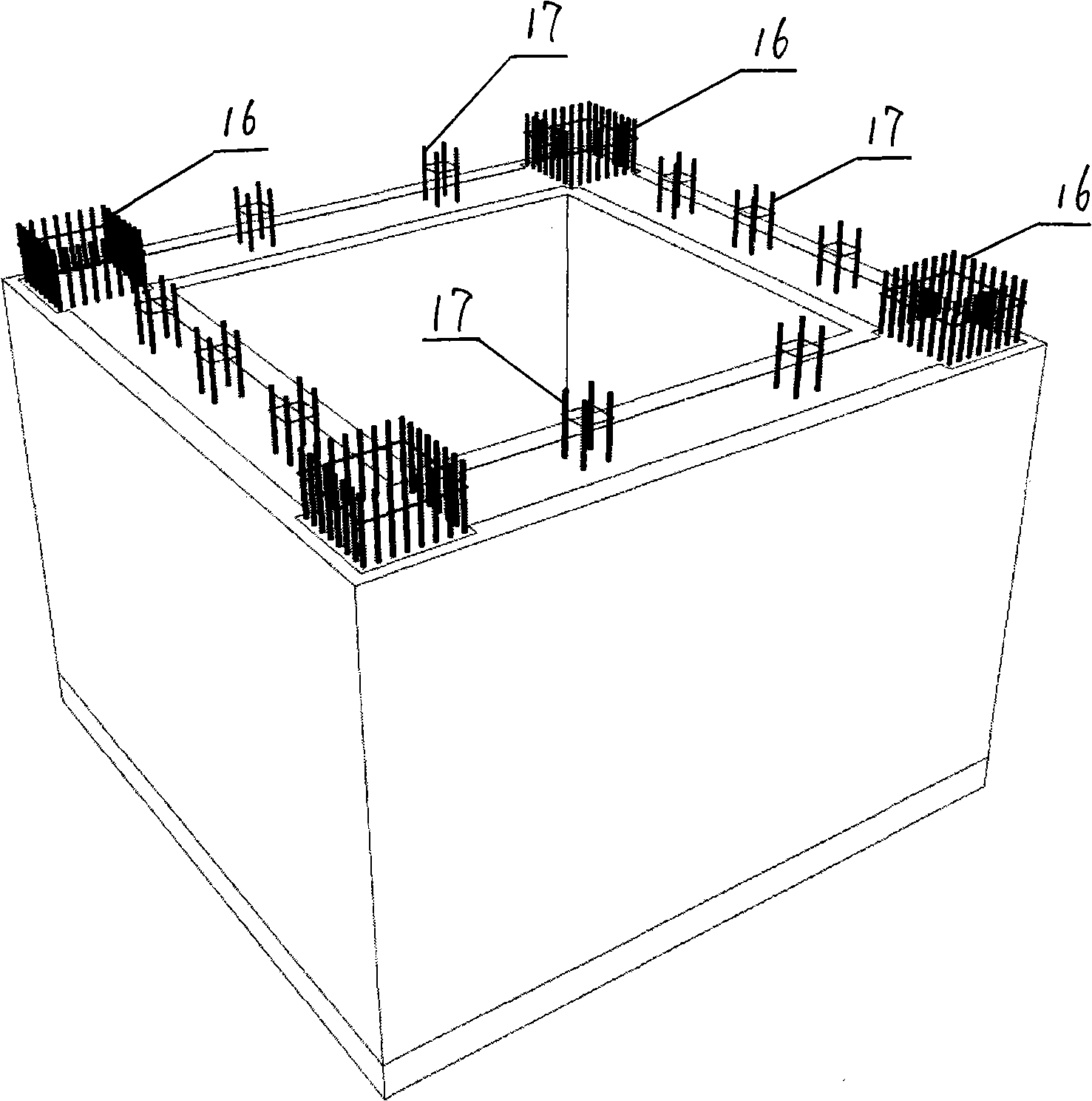

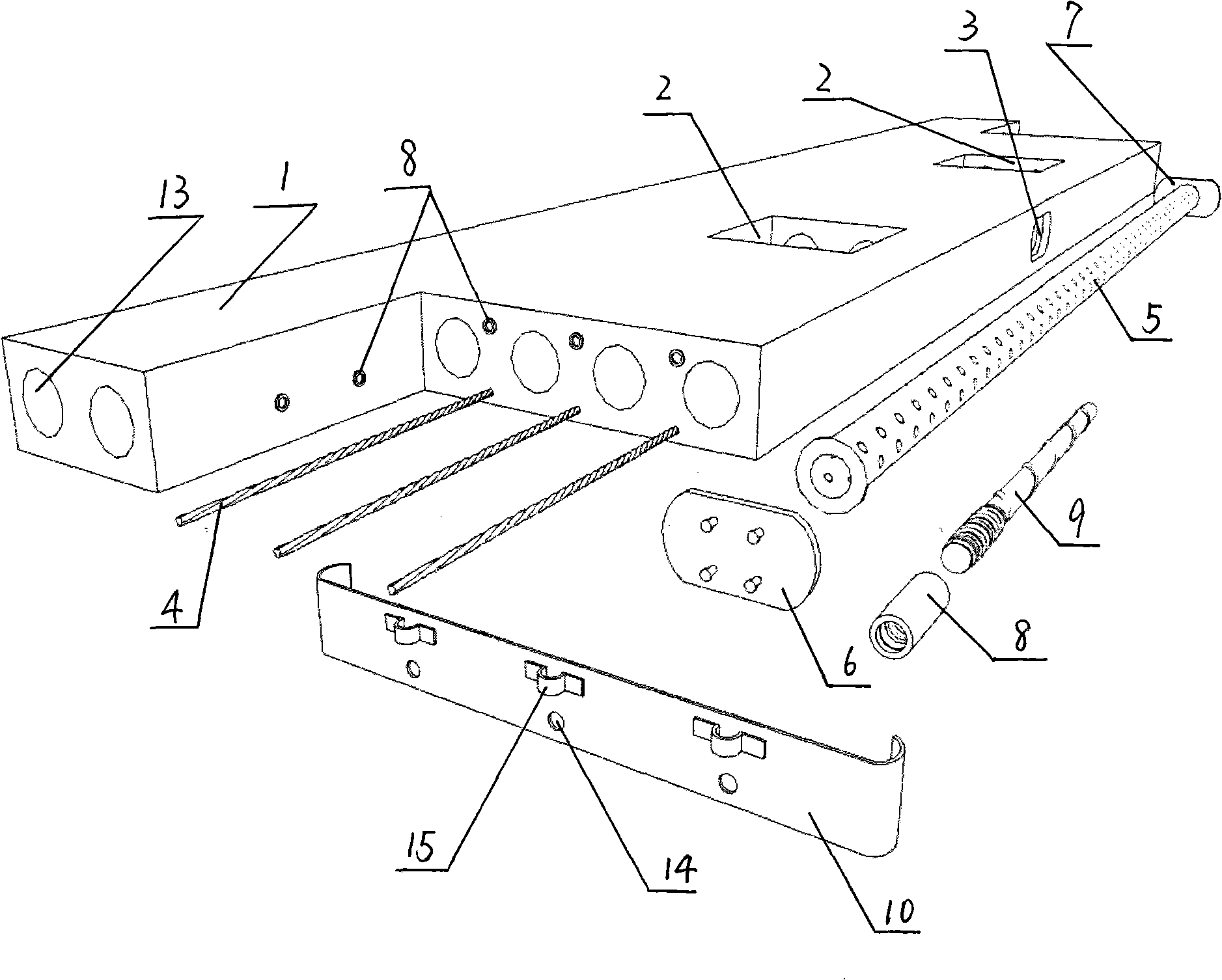

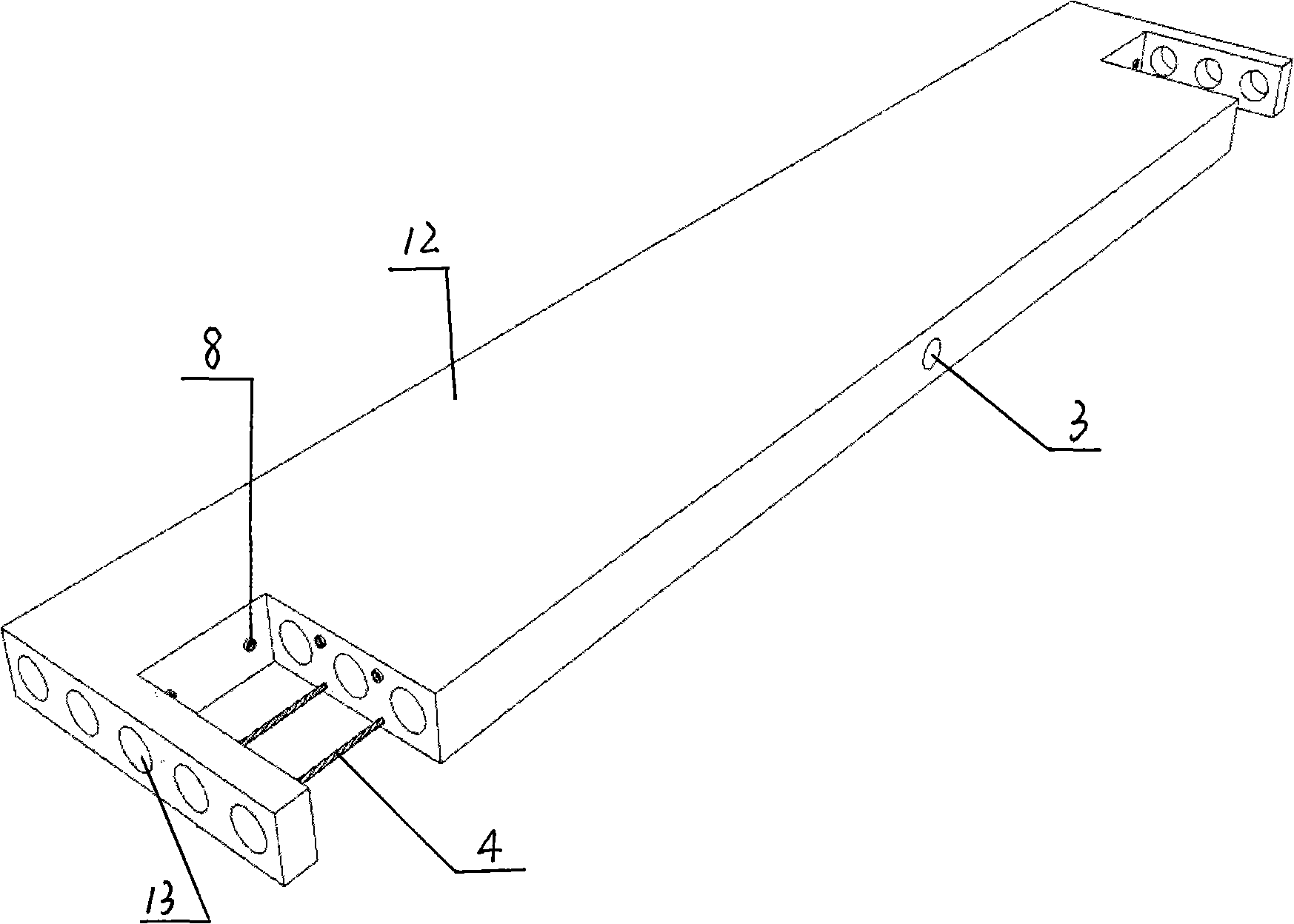

Prestressed concrete hollow slab and construction method thereof

The invention relates to a building floor slab, in particular to a prestressed concrete hollow slab and a construction method thereof. The hollow slab comprises two SP plates, wherein two ends of each SP plate are provided with nicks for holding column reinforcements respectively; the sections of each SP plate are provided with a plurality of reinforcement casings; one end of each reinforcement is connected with the one reinforcement casing, and the other end of each reinforcement is free; a plurality of steel hinge ropes are pre-embedded inside the two SP plates along the direction of long edges; and two ends of the steel hinge ropes are threaded out from the nicks, wherein the out-treaded ends of the steel hinge ropes pre-embedded inside a first hollow SP plate are connected with a steel-hinge-rope fixing frame. The method comprises the steps of placing the reinforcements in the SP plates through the nicks at two ends of the two SP plates, installing and fixing the steel-hinge-rope fixing frame and the reinforcements on the column reinforcements, bundling and fixing intersections of the steel hinge ropes, the reinforcements and the column reinforcements by use of bundling reinforcements, inserting porous steel pipes into second holes of the SP plates, injecting concrete into the pipes and casting the concrete into the SP plates after concrete strength is up. The prestressed concrete hollow slab has the characteristics of saving energy consumption and the like, along with simple rapid installation.

Owner:谭齐阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com