Solvent-free hydrogen-containing silicone oil and preparation method thereof

A hydrogen-containing silicon and solvent-free technology, applied in the chemical industry, can solve the problems of inconvenient control, difficult handling, high hydrogen content in hydrogen-containing silicone oil, etc., and achieve the effects of easy reaction control, stable product quality, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

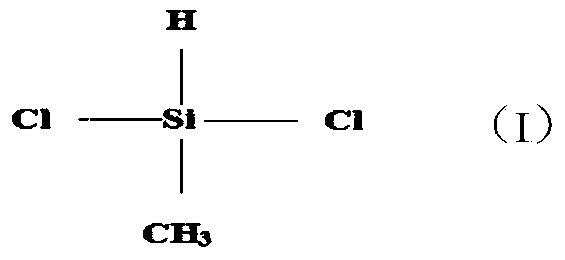

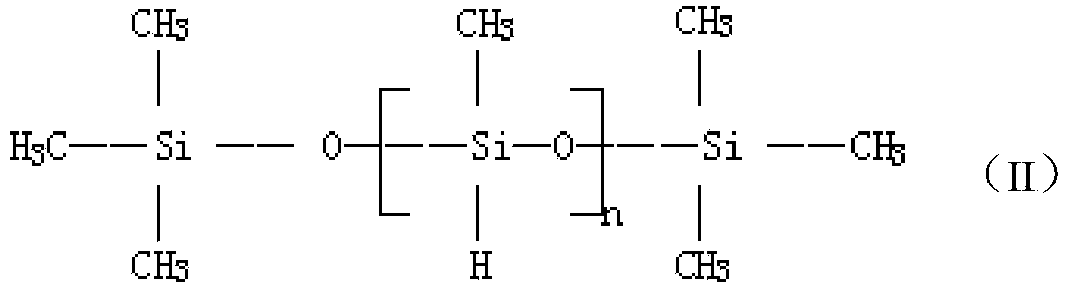

[0019] The invention relates to a solvent-free hydrogen-containing silicone oil and a preparation method thereof. The hydrogen-containing silicone oil is added dropwise into methyldichlorosilane with hydrochloric acid, telomerized with an acidic catalyst, capped with a capping agent, and alkaline substance The product obtained after neutralization has good storability, and at the same time, the method of the invention has good controllability and environmental protection.

[0020] A solvent-free hydrogen-containing silicone oil, the raw material of which is composed of the following components by weight: 100 parts of methyldichlorosilane, 1-10 parts of capping agent, 10-70 parts of hydrochloric acid, 1-10 parts of Acidic catalyst, alkaline neutralization; wherein, the capping agent is hexamethyldisiloxane or octamethyltrisiloxane; the mass fraction of hydrochloric acid is 5-36%; the acidic The catalyst is one of concentrated sulfuric acid, concentrated hydrochloric acid, acid ...

Embodiment 1

[0038] Add 10 parts by weight of dilute hydrochloric acid (5wt%) dropwise to 100 parts by weight of methyldichlorosilane at a constant speed, control the temperature at 10°C, and stir vigorously. The hydrogen chloride gas generated enters the absorption device. After the reaction is completed, separate the oil phase. The acidic silicone oil is obtained, and the aqueous hydrochloric acid is recovered and stored for future use. Add 2 parts by weight of hexamethyldisiloxane and 1 part by weight of concentrated sulfuric acid to the acidic silicone oil, raise the temperature and control the temperature at 50±2°C, and react for 2 hours. After completion, add solid sodium carbonate to neutralize to neutrality, filter, and The filtrate was removed for 3 hours at 130±2°C and a vacuum of -0.08MPa to obtain the product. The physical and chemical indicators of the obtained hydrogen-containing silicone oil were hydrogen content of 1.58%, refractive index of 1.3987, and viscosity of 24mm 2 ...

Embodiment 2

[0040] Add 10 parts by weight of dilute hydrochloric acid (20wt%) to 100 parts by weight of methyldichlorosilane dropwise at a constant speed, control the temperature at 10°C, and stir vigorously. The hydrogen chloride gas generated enters the absorption device. After the reaction is completed, the oil phase is separated. The acidic silicone oil is obtained, and the aqueous hydrochloric acid is recovered and stored for future use. Add 2 parts by weight of hexamethyldisiloxane and 1 part by weight of concentrated sulfuric acid to the acidic silicone oil, raise the temperature and control the temperature at 70±2°C, and react for 2 hours. After completion, add solid sodium carbonate to neutralize to neutrality, filter, and The filtrate was removed for 3 hours at 130±2°C and a vacuum of -0.08MPa to obtain the product. The physical and chemical indicators of the obtained hydrogen-containing silicone oil were hydrogen content of 1.61%, refractive index of 1.3962, and viscosity of 27m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com