Sweeping system and method for dispersed type purifying tanks of villages and small towns

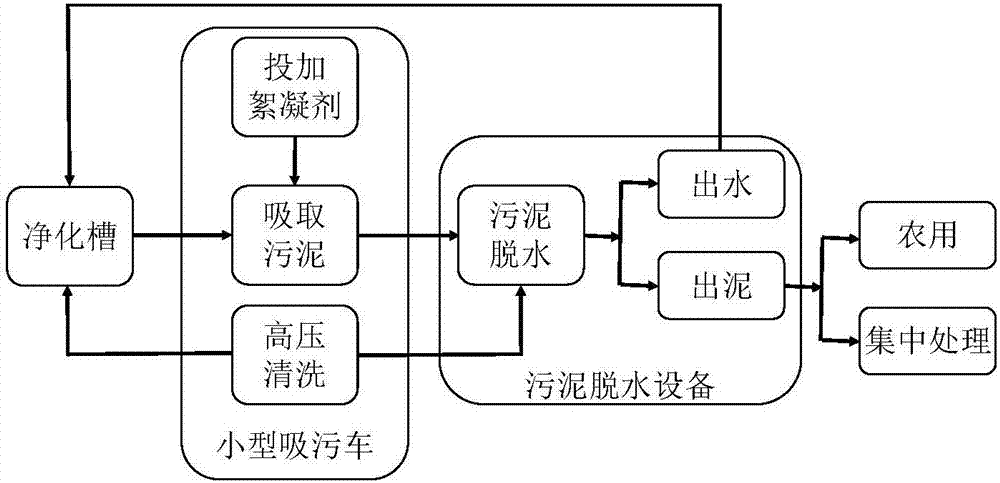

A cleaning system and purification tank technology, applied in waterway systems, climate change adaptation, construction, etc., can solve the problems of non-professional sewage suction, large vehicles, and non-professional cleaning equipment, so as to save costs, avoid secondary pollution, protect The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

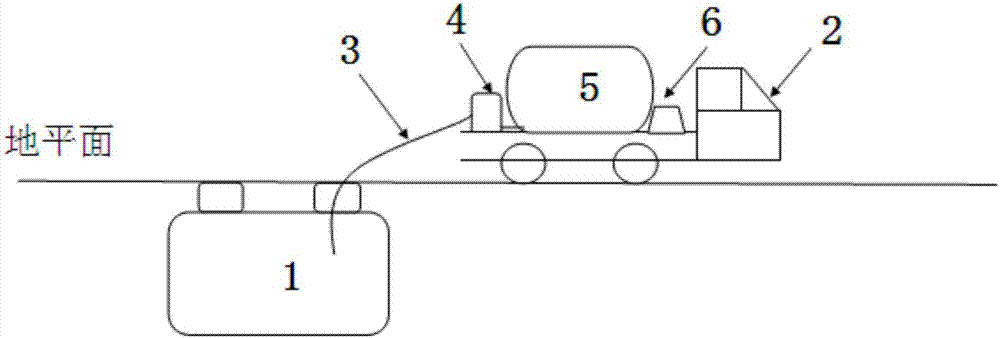

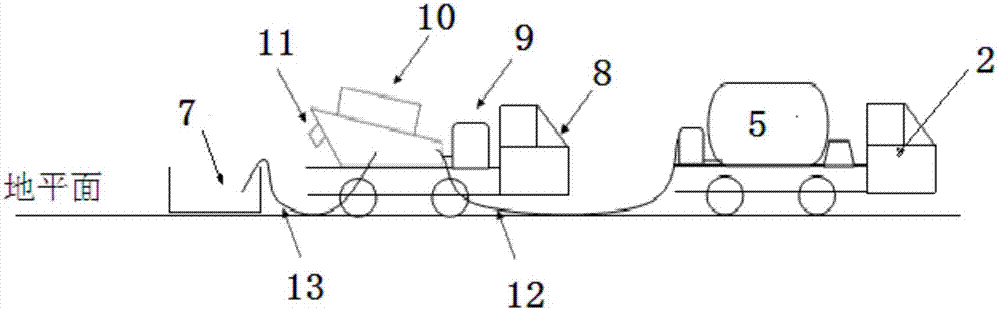

[0054] The agricultural small-scale vacuum suction truck loads the cleaning equipment to the site of the purification tank, and goes to the dirt tank (volume 2m) 3 ) into 50L of PAM flocculant with a concentration of 30%; then the sewage suction pipe is deep into the septic tank, and according to the cleaning requirements of the septic tank, the sewage suction operation is performed on each tank type of the septic tank in turn (the amount of dirt is 1.5m 3 ). After the suction is completed, the cleaning equipment uses the power supply (voltage 220V, pressure 1MPa) in the distribution box of the purification tank to take water from the sedimentation tank of the purification tank to clean the purification tank and its surroundings. After cleaning, the small agricultural vacuum suction truck moves to the vehicle-mounted screw dehydration equipment near the rural garbage station.

[0055] The sludge that has been flocculated in the dirt tank of a small agricultural vacuum suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com