Method of decomposing phosphate tailings by hydrochloric acid to produce Mg(OH)2 and CaSO4

A technology of magnesium hydroxide and phosphorus tailings, applied in the direction of magnesium hydroxide, calcium/strontium/barium sulfate, ammonium salt fertilizers, etc., can solve problems such as low quality, restriction of compound fertilizer production capacity, and overcapacity, and achieve the production process Simple, low production cost, and the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

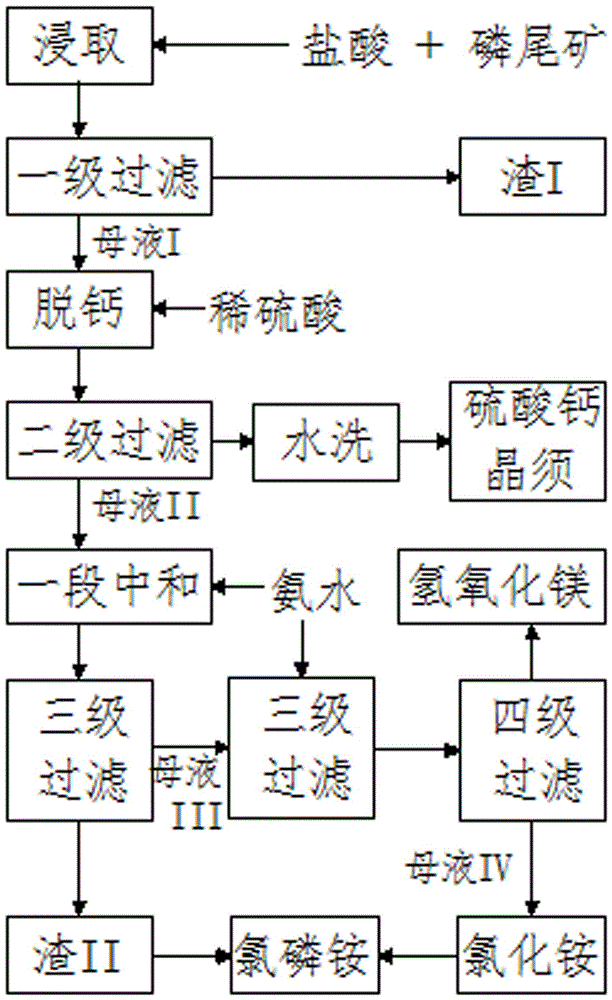

Image

Examples

Embodiment 1

[0032] Phosphorus tailings and water are made into a slurry at a mass ratio of 1:0.5, and hydrochloric acid is added to the leaching tank to fully mix and react. The ratio of the molar amount of hydrochloric acid to the sum of the molar amounts of CaO and MgO in the phosphorous tailings is 1.6:1 , control the reaction temperature at 30°C, react for 0.5h under the condition of sufficient stirring, filter and separate to obtain slag I and mother liquor I, add sulfuric acid with a molar ratio of CaO of 1:1 to the mother liquor I to react and crystallize, and then enter the filtration and separation. Wash the filter cake with water to obtain the product calcium sulfate whiskers and mother liquor II, add ammonia water to the mother liquor II for two-stage neutralization, one-stage neutralization to control the pH to 2.5, filter and separate slag II and mother liquor III, and perform two-stage neutralization for mother liquor III , control the pH to 6.5, filter and separate to obtain...

Embodiment 2

[0035] Phosphorus tailings and water are made into a slurry at a mass ratio of 1:0.7, and hydrochloric acid is added to the leaching tank to fully mix and react. The ratio of the molar amount of hydrochloric acid to the sum of the molar amounts of CaO and MgO in the phosphorous tailings is 1.8:1 , control the reaction temperature at 30°C, react for 0.5h under the condition of sufficient stirring, filter and separate to obtain slag I and mother liquor I, add sulfuric acid with a molar ratio of CaO of 1:1 to the mother liquor I to react and crystallize, and then enter the filtration and separation. Wash the filter cake with water to obtain the product calcium sulfate whiskers and mother liquor II, add ammonia water to the mother liquor II for two-stage neutralization, one-stage neutralization to control the pH to 3.0, filter and separate slag II and mother liquor III, and carry out two-stage neutralization for mother liquor III , control the pH to 7.0, filter and separate to obta...

Embodiment 3

[0038] Phosphorus tailings and water are made into a slurry at a mass ratio of 1:0.8, and hydrochloric acid is added to the leaching tank to fully mix and react. The ratio of the molar amount of hydrochloric acid to the sum of the molar amounts of CaO and MgO in the phosphorous tailings is 1.7:1 , control the reaction temperature at 30°C, react for 0.5h under the condition of sufficient stirring, filter and separate to obtain slag I and mother liquor I, add sulfuric acid with a molar ratio of CaO of 1:1 to the mother liquor I to react and crystallize, and then enter the filtration and separation. Wash the filter cake with water to obtain the product calcium sulfate whiskers and mother liquor II, add ammonia water to the mother liquor II for two-stage neutralization, one-stage neutralization to control the pH to 3.0, filter and separate slag II and mother liquor III, and carry out two-stage neutralization for mother liquor III , control the pH to be 7.5, filter and separate to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com