Prestressed concrete hollow slab and construction method thereof

A construction method and concrete technology, which is applied in the field of building floor slabs, can solve problems such as SP slab joints cannot be handled, and achieve the effects of reducing construction loss and construction waste, reducing pollution, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

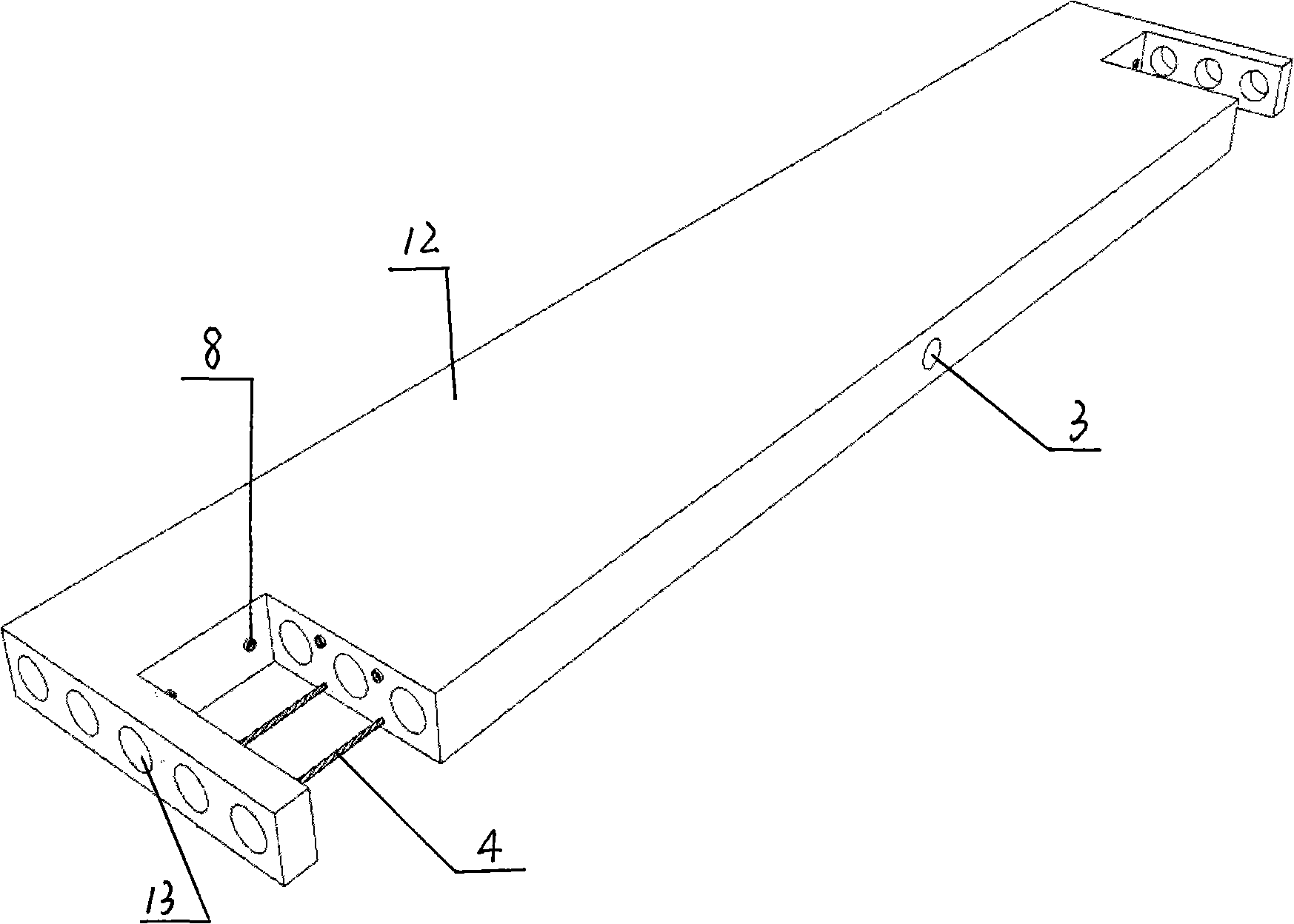

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] The present invention can be applied to the composite thermal insulation wall with the application number 200710159331.X and the title of the invention "a composite thermal insulation wall and its installation method" previously applied by the applicant, and the building floor using the composite thermal insulation wall.

[0028] The present invention can also be applied to the composite thermal insulation wall composed of the window that the applicant applied for before, the application number is 200810010118.7, and the title of the invention is "a composite thermal insulation wall composed of a window and its installation method", and the composite thermal insulation wall is adopted of building floors.

[0029] The present invention can also be used as floor slabs in the construction of ordinary composite thermal insulation walls and composite therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com