Building energy-saving heat preservation system and construction method of building heat preservation reverse method

A technology of thermal insulation system and building energy saving, applied in thermal insulation, construction, building components, etc., can solve problems such as easy cracking, and achieve the effect of improving earthquake resistance, saving costs, and improving earthquake resistance (shear resistance)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

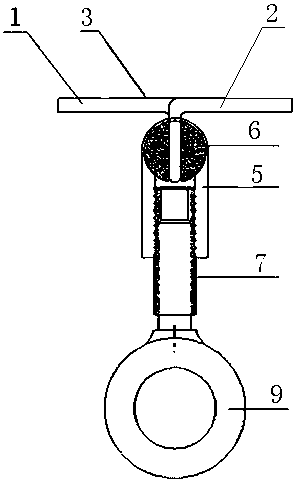

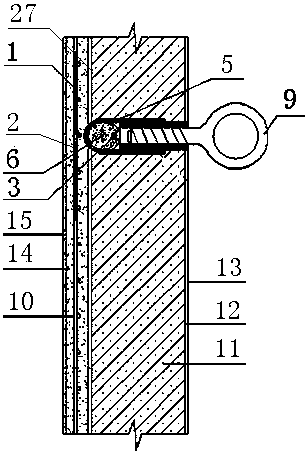

[0056] The heat preservation prefabricated panel fixing device of the present embodiment comprises a U-shaped upper hanging buckle 3 and a lower hanging buckle 5. The two ends of the U-shaped opening of the upper hanging buckle 3 are respectively provided with a first horizontal arm 1 and a second horizontal arm extending horizontally outward. 2. The upper hanging buckle 3 and the lower hanging buckle 5 are cross-hooked and connected through the heat insulating ball 6, and the nut column 7 is welded to the U-shaped inner vertical arm of the lower hanging buckle, and the screw hole of the nut column 7 is screwed with a lifting ring 9; heat insulation The ball 6 is provided with alternate positioning grooves for accommodating the upper hanging buckle 3 and the lower hanging buckle 5 respectively; the heat insulating ball 6 is made of engineering plastics.

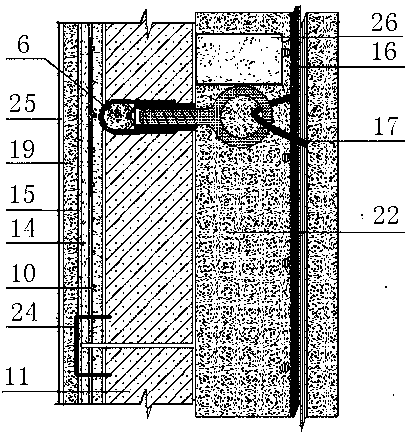

[0057] An energy-saving and thermal insulation system for a building, comprising a plurality of thermal insulation panels 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com