Long-span steel vertical cylindrical oil tank of above 100 thousand cubic meters

A large-span, cylindrical technology, applied in the directions of large-scale containers, packaging, transportation and packaging, can solve the problems of increased structural self-weight, not meeting the requirements of specifications, etc., to improve stability, strengthen anti-uniform load ability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

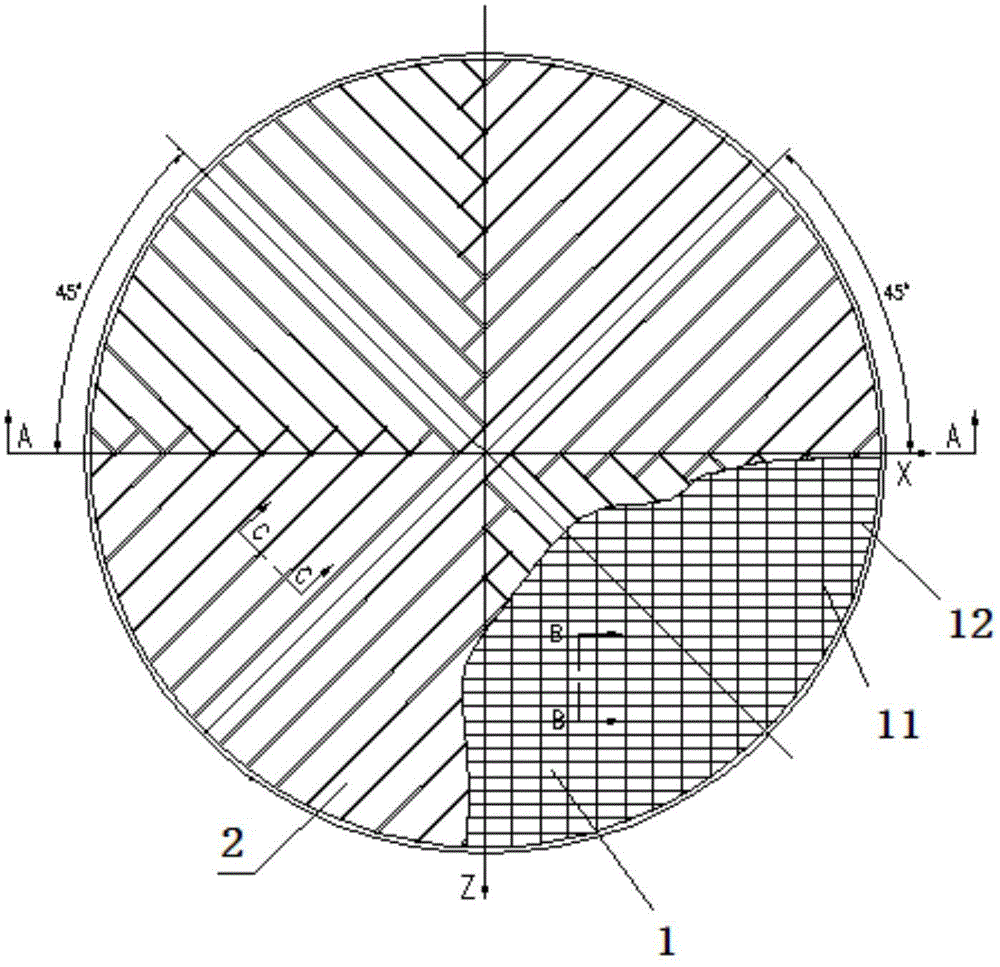

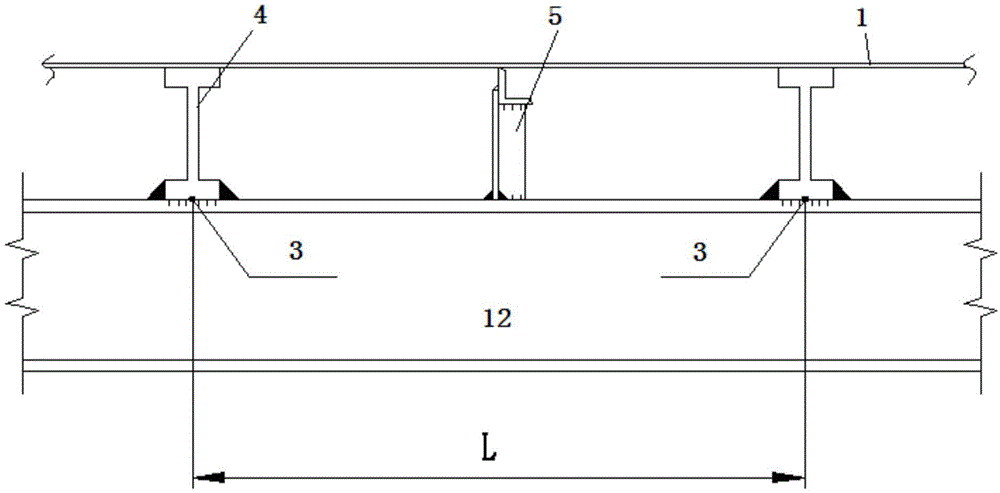

[0025] A large-span vertical cylindrical oil tank of 100,000 cubic meters or more, including a cylindrical tank body composed of a tank foundation, a tank bottom plate and a tank wall. The top of the tank body is provided with a diameter of 70 meters to 95 meters The top cover of meters is composed of a combined grid structure 1 with a large span and two-way meridian and a skin 2 set on the grid structure. Such as figure 1 As shown, the combined grid structure 1 of the large-span two-way meridian is composed of two-way meridian arc-shaped net poles welded by through-type rigid joints, and the curvature radius of each meridian arc-shaped net pole is the same spherical radius. Each net pole is welded into an arc-shaped continuous net pole by I-shaped steel group, and is arranged along two radial lines, and both ends are welded together with the ring beam at the top of the tank body.

[0026] The combined grid structure is a grid structure in which the north-south and east-west ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com