High-strength, wear-resistant and quick-change preform

A prefabricated and high-strength technology, applied in the field of refractory materials, can solve the problems of insufficient wear resistance and thermal shock stability, affect the service life of prefabricated parts, and affect the service life of rotary kilns, etc., to shorten maintenance time and enhance thermal shock stability , enhance the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

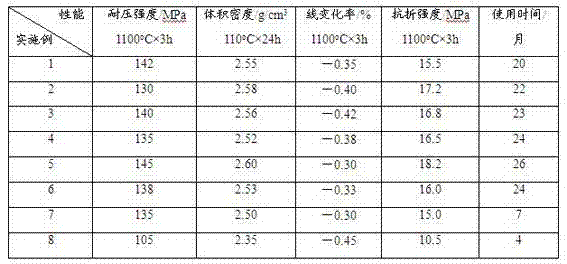

Examples

Embodiment 1

[0050] A high-strength wear-resistant quick-change prefabricated part, the weight of each component is as follows: mullite: 10 parts, silicon carbide: 25 parts, waste silicon molybdenum brick: 16 parts, the aluminum content is 85%, and the particle size is 5mm. Bauxite homogenizing material: 10 parts, scrap iron hook material: 10 parts, mullite hollow ball: 15 parts, alumina powder: 8 parts, silicon micropowder: 6 parts, plus sodium tripolyphosphate accounting for the above total amount 0.08% and water 5%.

Embodiment 2

[0052] A high-strength wear-resistant quick-change prefabricated part, the parts by weight of each component are as follows: mullite: 30 parts, silicon carbide: 10 parts, waste silicon molybdenum bricks with a particle size of 2mm after crushing and screening: 10 parts , bauxite homogenized material with an aluminum content of 90% and a particle size of 7mm: 14 parts, after crushing and screening, scrap iron hook materials with a particle size of 10mm: 25 parts, mullite hollow balls: 5 parts, oxidized Aluminum powder: 3 parts, silicon micropowder: 3 parts, plus 0.20% of sodium hexametaphosphate and 7% of water accounting for the above total amount.

Embodiment 3

[0054] A high-strength wear-resistant quick-change prefabricated part, the parts by weight of each component are as follows: mullite: 15 parts, silicon carbide: 17 parts, waste silicon molybdenum bricks with a particle size of 12mm after crushing and screening: 20 parts , bauxite homogenized material with an aluminum content of 88% and a particle size of 6mm: 20 parts, after crushing and screening, scrap iron hook materials with a particle size of 1mm: 12 parts, mullite hollow balls: 8 parts, oxidized Aluminum powder: 5 parts, silicon micropowder: 3 parts, plus 0.15% of sodium tripolyphosphate and sodium hexametaphosphate and 6% of water accounting for the above total amount.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com