Production flow process and production line for manufacturing fire coal products from garbage

A production process and production line technology, which is applied in the production process and production line field of coal-fired products made from garbage, can solve the problems of air quality pollution damage, impractical application, and inability to organize large-scale production, etc., to achieve easy storage and transportation, and easy Simple operation and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

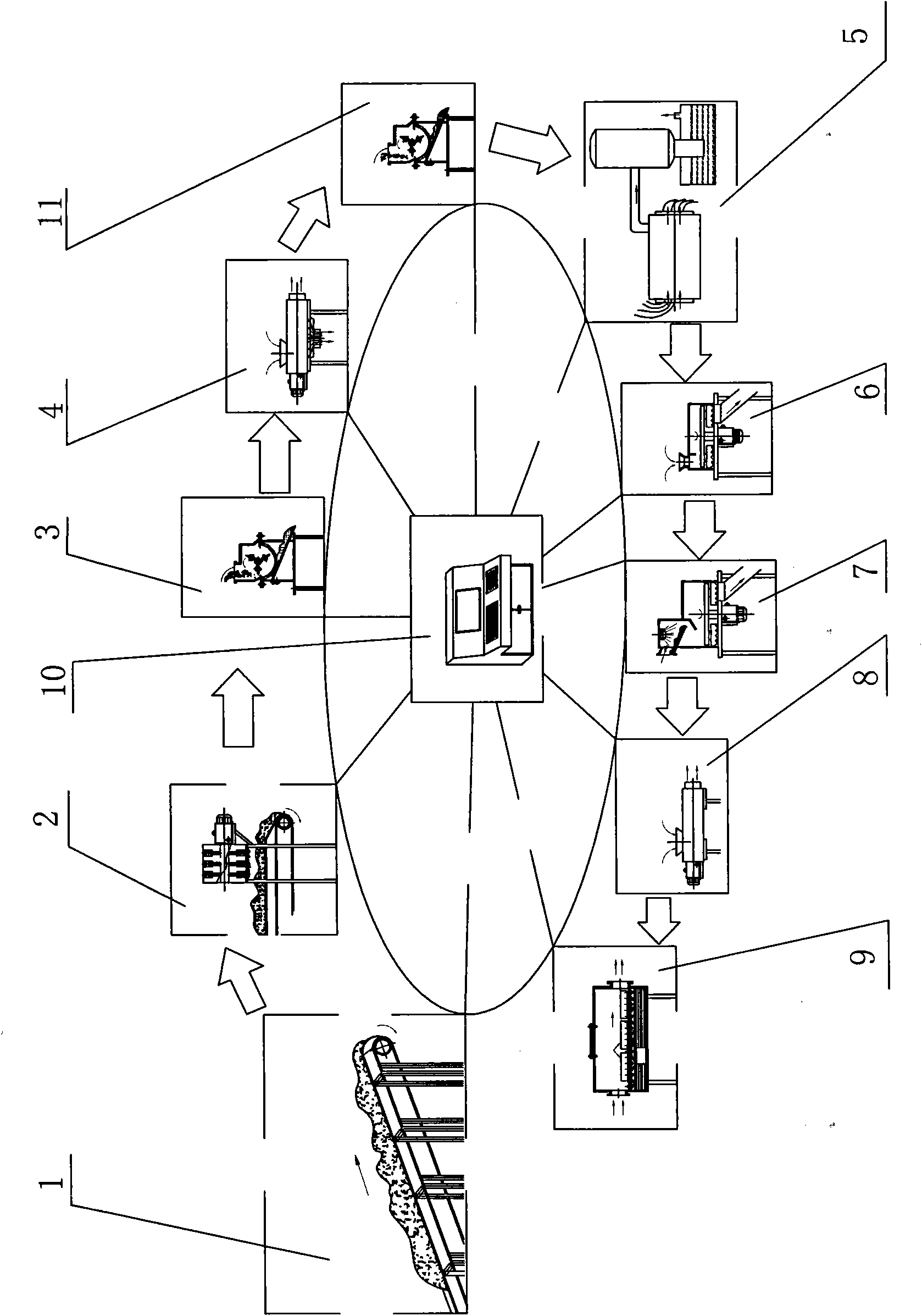

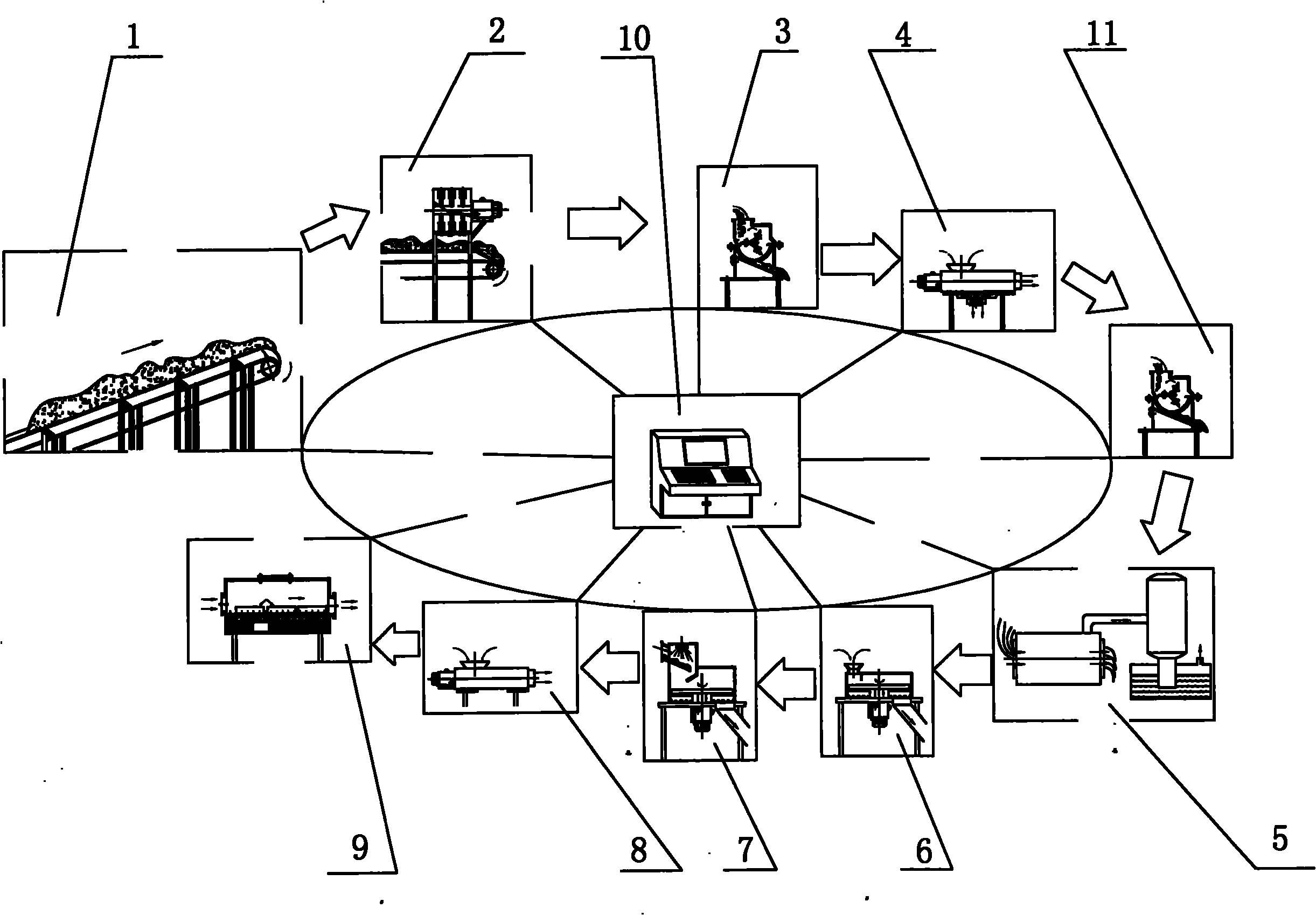

[0035] Can make the production process technology of coal-fired product by rubbish of the present invention, select relevant special equipment to organize a production line of making coal-fired product from rubbish, as figure 1 shown.

[0036] The production flow process and corresponding equipment for making coal products from garbage in the present invention:

[0037] Bulk disposal of garbage. The garbage conveying equipment 1 is selected for use, and the conveyor belt of the garbage conveying equipment 1 is driven by a motor, and the garbage broken up by a machine or manually is conveyed by the belt.

[0038] Magnetic screening of bulk garbage to remove metal materials. The magnetic separator 2 is selected, and the magnetic separator 2 is arranged on the tape conveying path of the garbage conveying equipment 1, and the electromagnetic head absorbs the metal substances in the bulk garbage.

[0039] Primary shredding of garbage after magnetic screening. The garbage primar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com