Recycling method for rare earth leaching and leaching water of sulfuric acid roasted rare earth ore concentrate

A rare earth concentrate, sulfuric acid roasting technology, applied in the direction of improving process efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

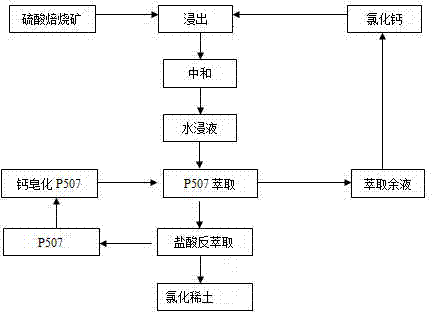

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: get 390 gCaCl 2 Dissolved in 3500 mL water to prepare 1mol / L CaCl 2 solution. Add 1700 g of concentrated sulfuric acid to roast ore under normal temperature stirring conditions, continue stirring for 2 hours after adding, add calcium oxide to neutralize to pH 2~3, and filter to obtain water immersion solution; the concentration of rare earth in the water immersion solution is about 100g / L. The extractant P507 is saponified with an aqueous solution of calcium oxide, and the saponified wastewater is reused for calcium oxide pulping. Saponification of P507 is used to extract the water immersion solution, and the loaded organic phase is back-extracted with hydrochloric acid to obtain rare earth chloride with a concentration of about 280g / L for subsequent extraction and separation. Obtain 3500 mL of raffinate containing about 1 mol / L of calcium chloride and return to leaching rare earth.

[0022] Add 1700 g of concentrated sulfuric acid roasted ore to the ab...

Embodiment 2

[0023] Embodiment 2: get 780 gCaCl 2 Dissolved in 3500 mL water to prepare 2mol / L CaCl 2 solution. Add 900 g of concentrated sulfuric acid to roast the ore under normal temperature stirring conditions, continue to stir for 2 hours after adding, add calcium hydroxide to neutralize to pH 2~3, and filter to obtain the water immersion solution; the concentration of rare earth in the water immersion solution is about 60g / L. The extractant P507 is saponified with an aqueous solution of calcium hydroxide, and the saponified wastewater is reused for calcium oxide pulping. Saponification of P507 is used to extract the water immersion solution, and the loaded organic phase is back-extracted with hydrochloric acid to obtain rare earth chloride with a concentration of about 280g / L for subsequent extraction and separation. Obtain 3500 mL of raffinate containing about 2 mol / L of calcium chloride and return to leaching rare earth.

[0024] Add 900 g of concentrated sulfuric acid roasted o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com