A method of producing a high-protein organic fertilizer by converting edible fungus dregs utilizing housefly larvae

An organic fertilizer and edible fungus technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and biological organic parts treatment, etc., can solve the problems of waste and environmental pollution of agricultural organic resources, etc., to extend the industrial chain, improve economic benefits, and promote agriculture. The effect of circular economy development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Select 60 kg of dried Pleurotus ostreatus after passing through a 20-mesh sieve, 30 kg of fresh chicken manure, 10 kg of wheat bran, and 1 kg of fish meal. , covered with plastic cloth and sealed, and fermented for 5 days to make a fly maggot culture substrate. Take 10 kg of substrate, insert about 70,000 eggs of housefly, and after 4 days, dry and pulverize the whole to make high-protein organic fertilizer.

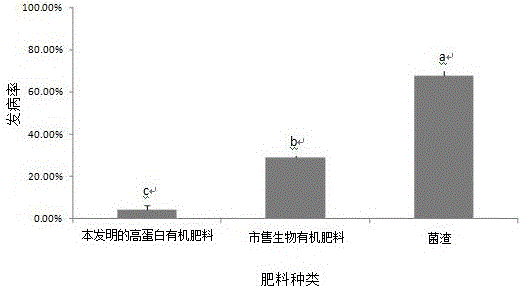

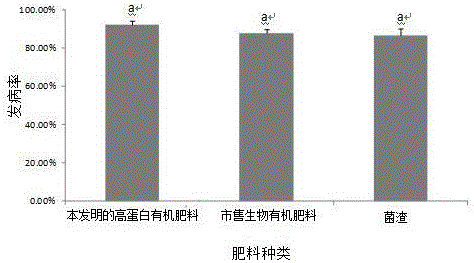

[0017] Get cucumber seeds and use high-protein organic fertilizer of the present invention, commercially available organic fertilizer and bacterium residue as culture substrate respectively, insert Fusarium oxysporum cucumber specialization type respectively in the substrate Fusarium oxysporum f.sp. , fill the matrix of the inoculated bacteria in plastic culture pots with a diameter of 10 cm and a depth of 10 cm, observe the number of germinated cucumber seeds and the number of diseased plants, and count the germination rate and incidence rate. Each fertilizer is...

Embodiment 2

[0021] Select 30 kg of dried Flammulina velutipes slag after passing through a 20-mesh sieve, 60 kg of fresh chicken manure, 10 kg of wheat bran, and 1 kg of fish meal. Cover with plastic cloth and seal, ferment for 5 days to make fly maggot culture substrate. Take 10 kg of substrate, insert about 50,000 eggs of housefly, and after 4 days, dry and pulverize the whole to make high-protein organic fertilizer.

Embodiment 3

[0023] Select 70 kg of dry Auricularia slag after passing through a 20-mesh sieve, 20 kg of fresh chicken manure, 10 kg of wheat bran, and 1 kg of fish meal. , covered with plastic cloth and sealed, and fermented for 5 days to make a fly maggot culture substrate. Take 10 kg of substrate, insert about 100,000 eggs of housefly, and after 4 days, dry and pulverize the whole to make high-protein organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com