Disk brake pad for commercial vehicle

A technology of disc brake pads and commercial vehicles, which is applied in the field of disc brake pads, can solve the problems of brake pad dust that cannot be handled, brake pad heating, etc., and achieve the effects of reducing heating rate, increasing pressure, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

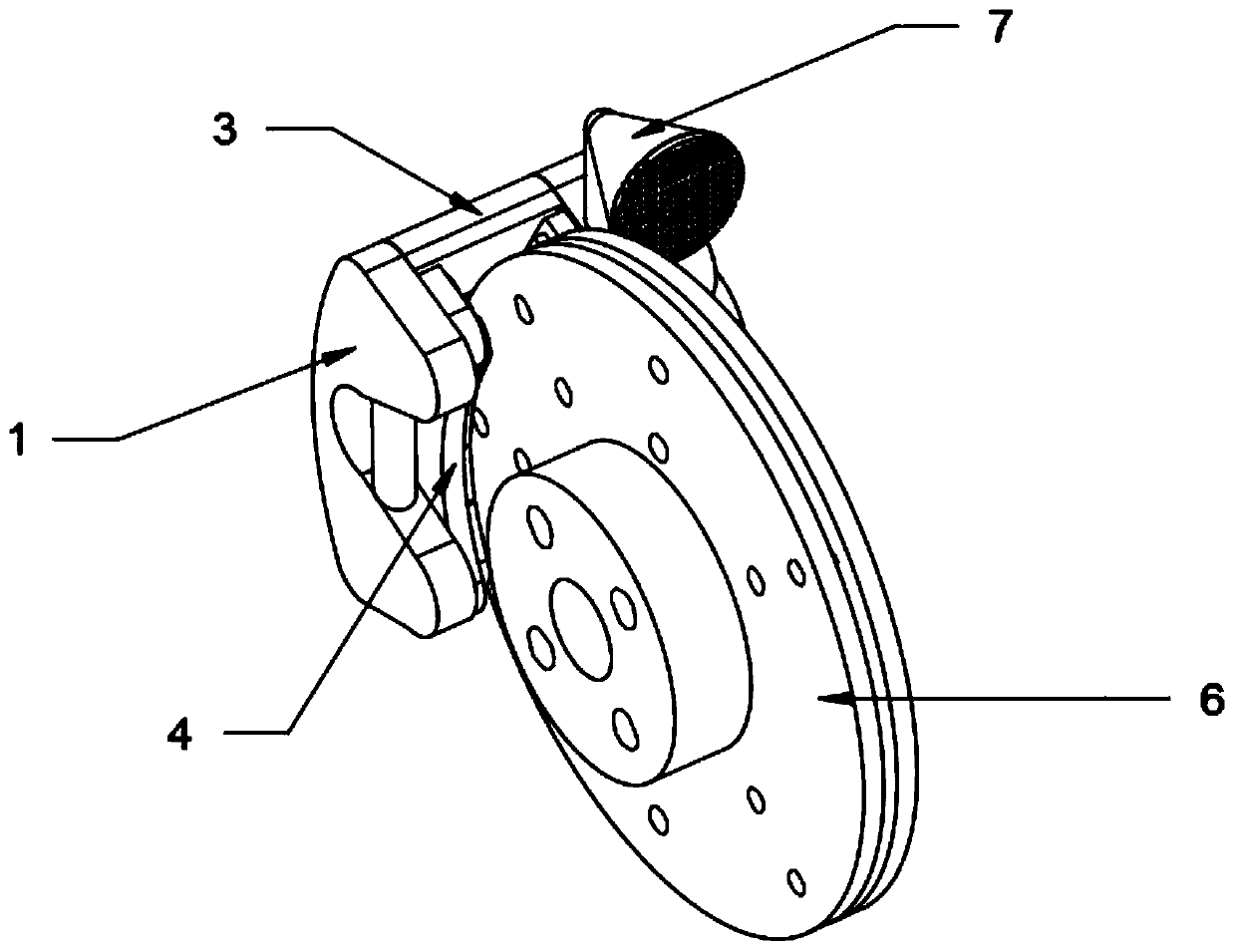

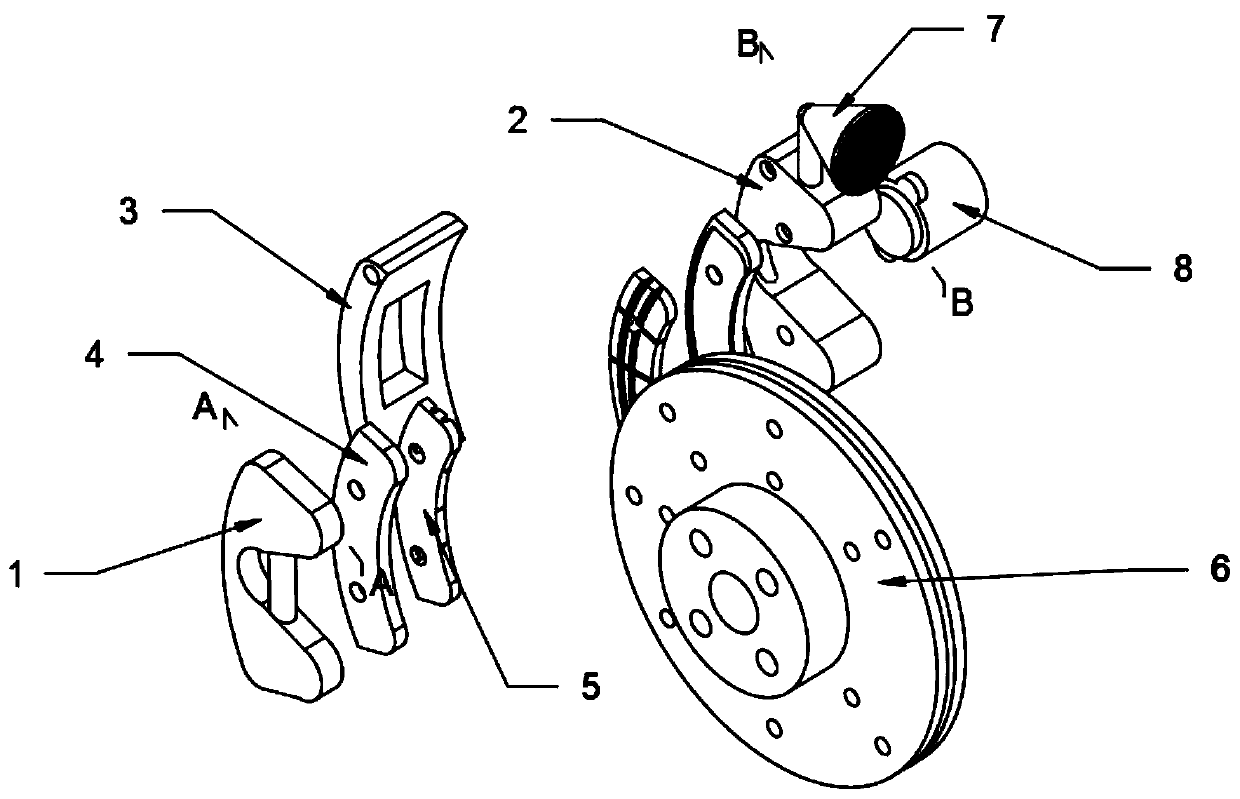

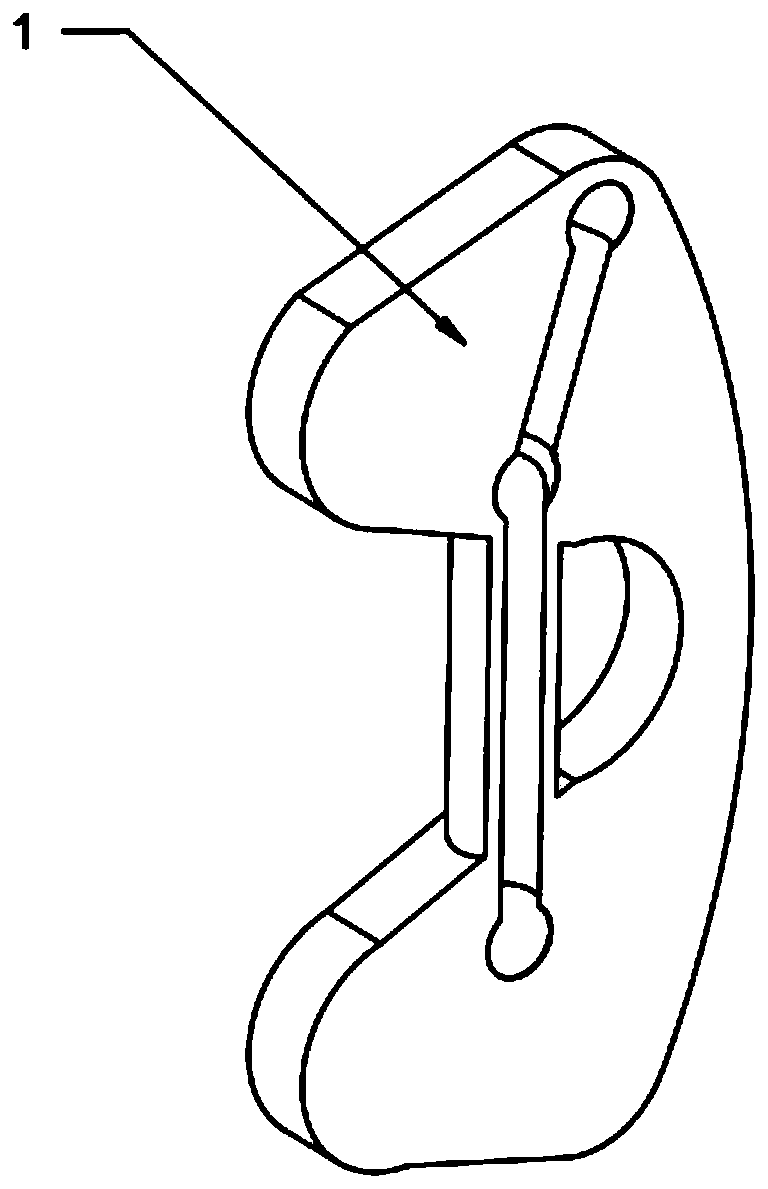

[0030] as attached figure 1 to attach Figure 7 Shown:

[0031] The invention provides a disc brake pad for a commercial vehicle, comprising a left mounting frame 1, a right mounting frame 2, a front mounting frame 3, a pad 4, a brake pad 5, a brake disc 6, an air inlet 7 and a brake piston 8 One side of the front mounting frame 3 is fixedly connected to the inner edge of the left mounting frame 1, and the other end of the front mounting frame 3 is fixedly connected to the inner edge of the right mounting frame 2; Groove, and the lining block 4 is screwed on the inner surface of the left mounting frame 1 and the right mounting frame 2; the brake pad 5 is fixedly connected in the groove inside the lining block 4; the brake disc 6 is located in the left and right two brake The middle position of the plate 5, and the brake disc 6 is screwed with the wheel hub of the automobile; the brake piston 8 is fixedly connected to the middle part of the right mounting frame 2.

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com