Self-cooling iron liquid pretreating spray gun

A molten iron pretreatment, self-cooling technology, applied in the direction of manufacturing converters, etc., can solve the problems of unavoidable uneven expansion of the metal gun core, short service life of the desulfurization lance, limited service life of the lance, etc., to ensure the performance of injection desulfurization. , The effect of improving the performance of injection and avoiding local cracks and spalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

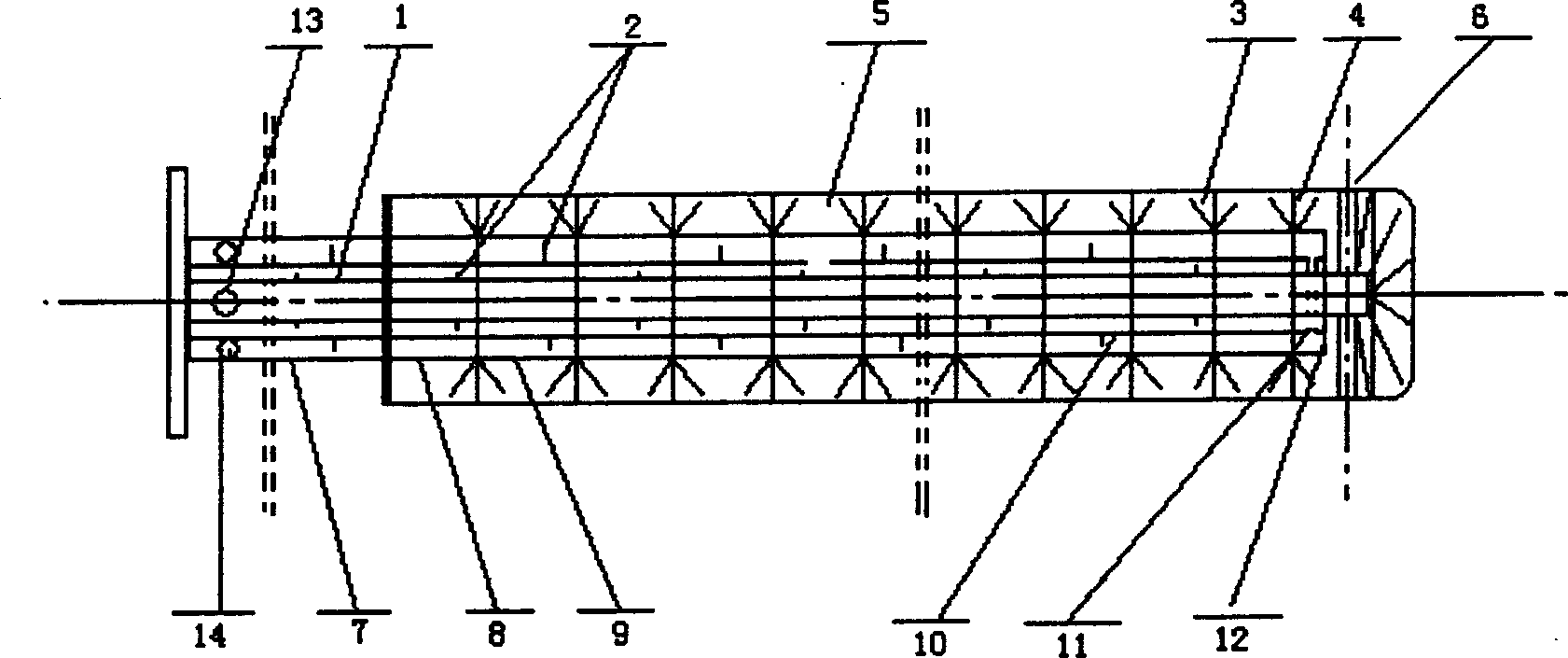

[0027] Using materials such as No. 45 carbon steel seamless pipe, ordinary carbon steel wire rod, iron-chromium-aluminum heat-resistant wire and other materials, an inverted T-shaped blowing port self-cooling molten iron pretreatment spray gun is made. The structure is as follows: figure 1 shown. No. 45 carbon steel seamless pipes are used to make the main pipe (1), air-cooled pipe (15) and reinforced pipe (8). The end of the pipe (15) is processed with an air-cooled spout (11). Connect the reinforcing tube baffle (12) with threads or welding on the reinforcing tube (8) at the end of the blowing port (6); adopt the iron-chromium-aluminum heat-resistant metal wire to make the ring riveting piece (4), the wire diameter is 4mm, The diameter of the ring rivets (4) is 5mm smaller than the gun body diameter, and the distance between each ring rivets (4) is 80mm. The V-shaped anchor (3) is made of ordinary carbon steel wire rod, the wire diameter is 6 mm, and the V-shaped included ...

Embodiment 2

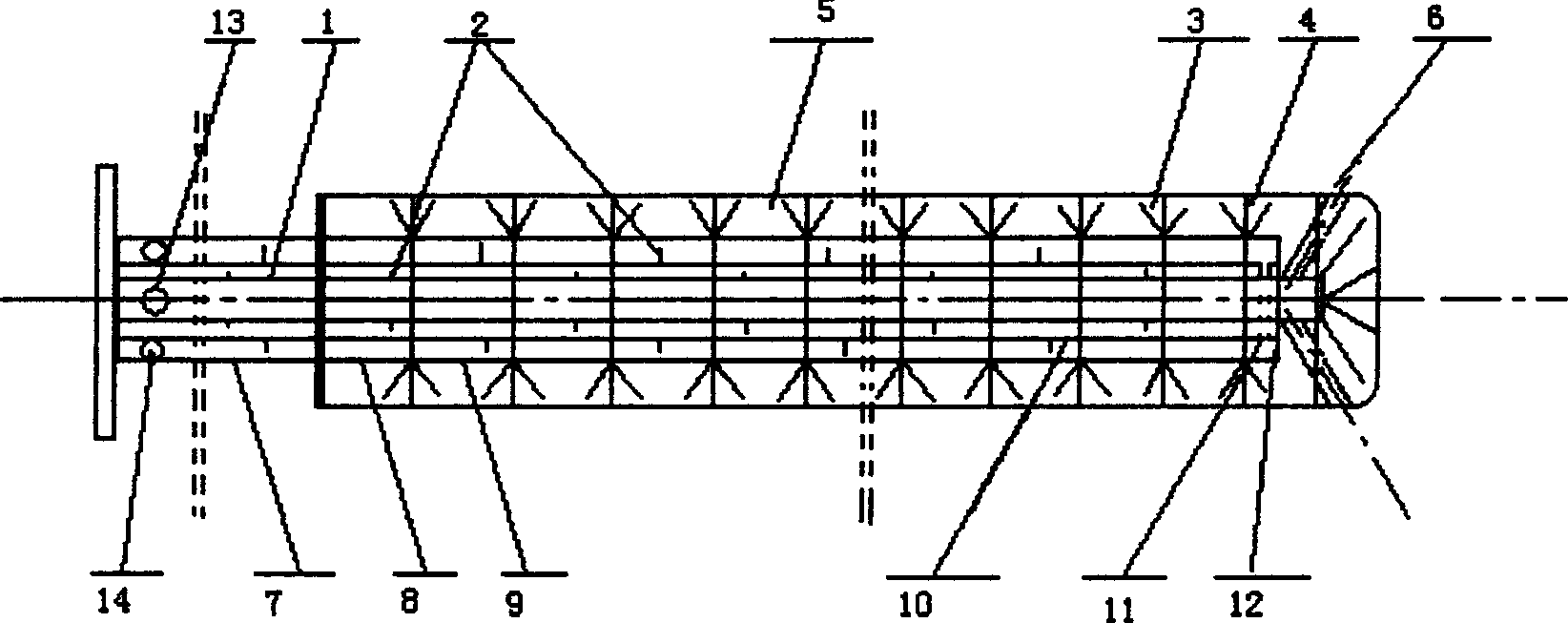

[0029] Using materials such as No. 15 carbon steel seamless pipes, ordinary carbon steel wire rods, and iron-chromium-aluminum heat-resistant wires, a self-cooling molten iron pretreatment spray gun with direct blowing at the bottom of the injection port is made. The structure is as follows: image 3 shown. The main pipe (1), air-cooled pipe (15) and reinforced pipe (8) are made of No. 15 carbon steel seamless pipe, and the air-cooled pipe (15) is inserted between the main pipe (1) and the reinforced pipe (8). The end of the pipe (15) is processed with an air-cooled spout (11). Connect the reinforcing tube baffle plate (12) on the reinforcing tube (8) at the end of the blowing port (6); adopt the iron-chromium-aluminum heat-resistant metal wire to make the ring riveting piece (4), wire diameter 4mm, the ring riveting piece ( 4) The diameter is 5mm smaller than the diameter of the gun body, and the distance between the ring rivets (4) is 80mm. Common carbon steel wire rods ar...

Embodiment 3

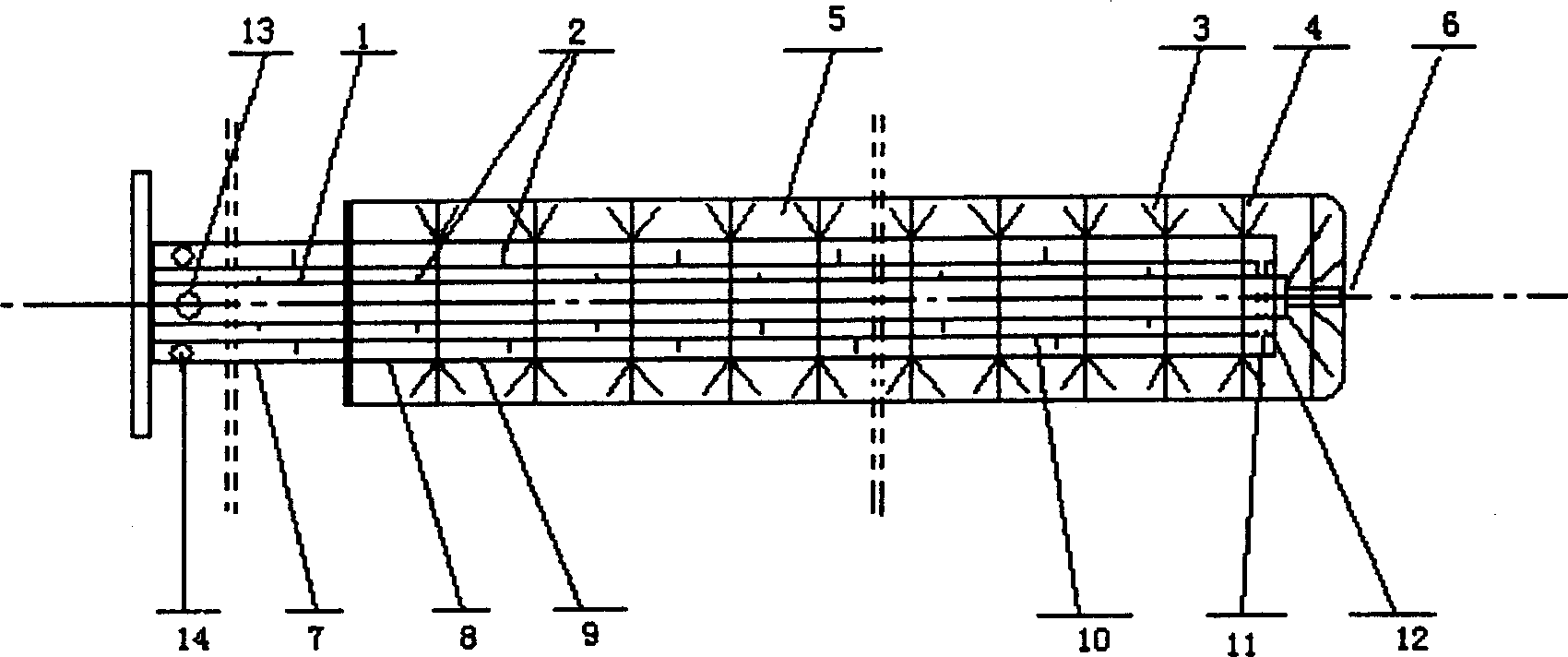

[0031] Using No. 45 carbon steel seamless pipe, ordinary carbon steel wire rod, iron-chromium-aluminum heat-resistant wire and other materials, a self-cooling molten iron pretreatment spray gun with the injection port of the vaporization chamber is made, and the structure is as follows: Figure 4 shown. Use No. 45 carbon steel seamless pipe to make the main pipe (1), air-cooled pipe (15) and reinforced pipe (8), the air-cooled pipe (15) is set outside the main pipe (1), and the end of the air-cooled pipe (15) Process the air-cooled spout (11). Connect the reinforcing tube baffle plate (12) on the reinforcing tube (8) at the end of the blowing port (6); adopt the iron-chromium-aluminum heat-resistant metal wire to make the ring riveting piece (4), wire diameter 5mm, the ring riveting piece ( 4) The diameter is 5mm smaller than the diameter of the gun body, and the distance between the ring rivets (4) is 100mm. The V-shaped anchor (3) is made of ordinary carbon steel wire rod,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com