A process for preparing low-oxygen copper rods by using scrap copper

A low-oxygen copper and waste copper technology is applied in the field of preparing low-oxygen copper rods, which can solve the problems of poor conductivity, easy breakage, low tensile strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

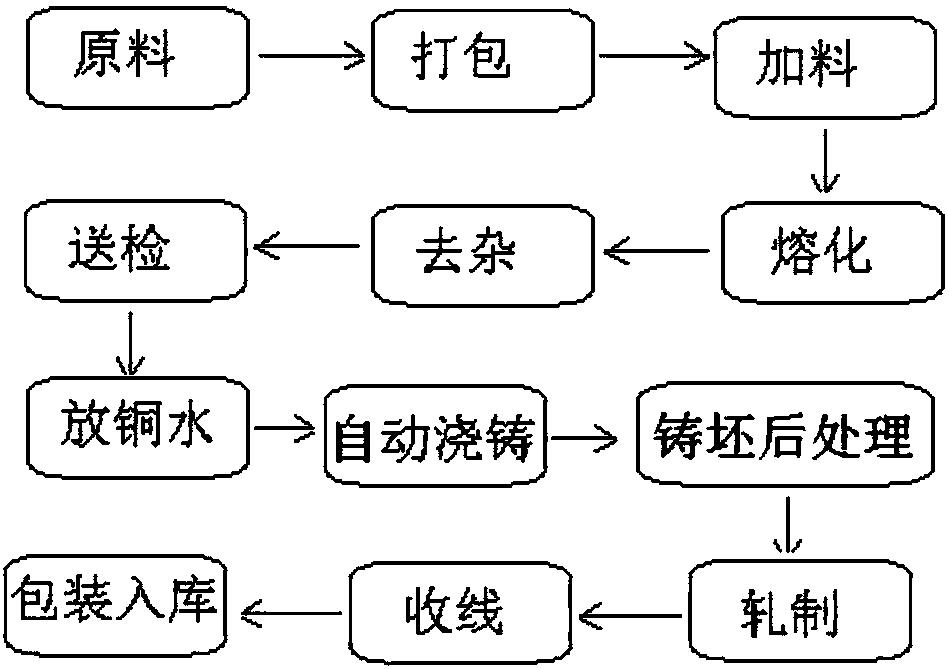

[0052] Such as figure 1 As shown, a kind of process of utilizing waste miscellaneous copper to prepare low-oxygen copper rod of the present embodiment comprises the following steps:

[0053] Step 1, the melting of raw materials comprises the following operations:

[0054] 1. Feeding: Use 90% waste motor wires and 10% bright copper to mix and pack into 60-100kg square raw materials. Use an automatic feeding machine to add the raw materials into the copper melting furnace, and cover the surface of the raw materials with a layer of broken glass. The mass ratio of glass to raw material is 1:65.

[0055] The waste motor wires in this embodiment come from various types of waste motors, and before the waste motor wires are put into the furnace, they are firstly treated to remove the paint film to remove surface impurities. Mixing waste motor wires with bright copper as raw materials, on the one hand, the waste motor wires are used for secondary use of waste copper resources, which ...

Embodiment 2

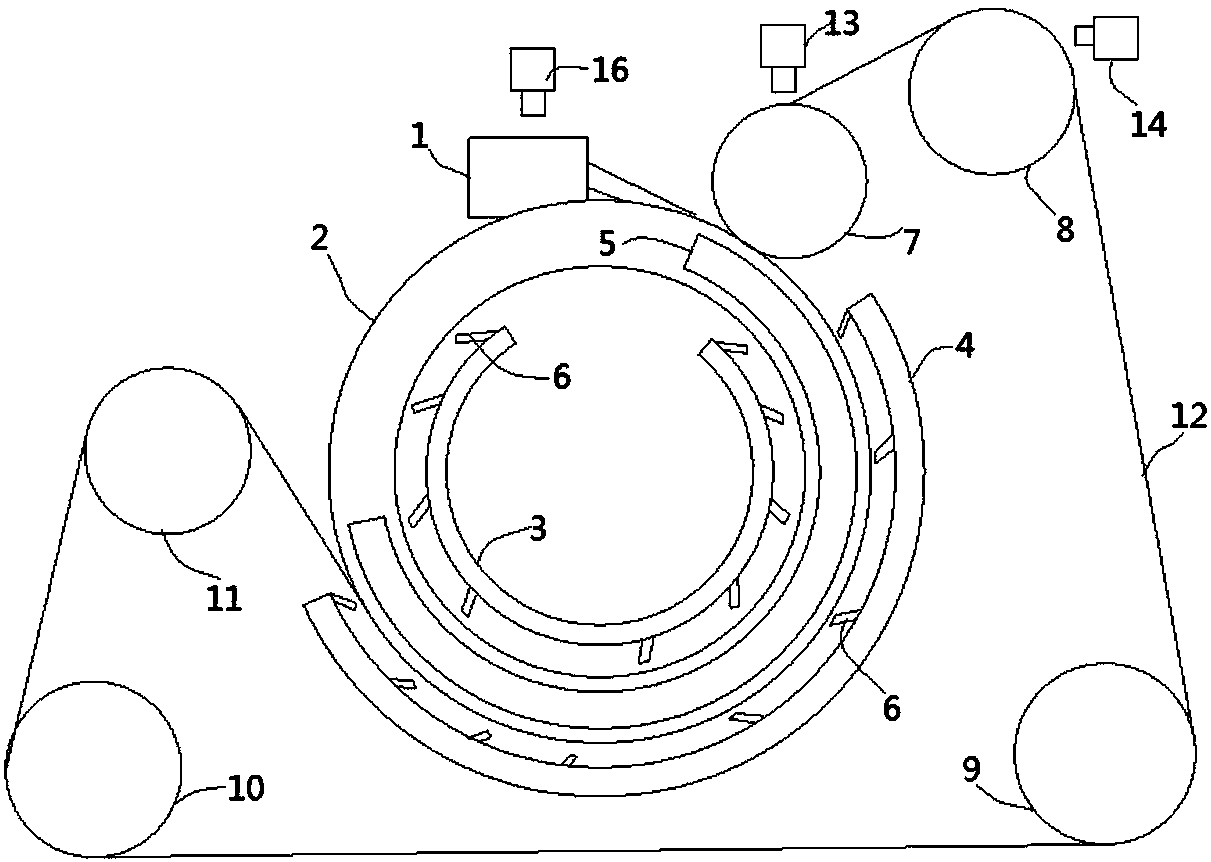

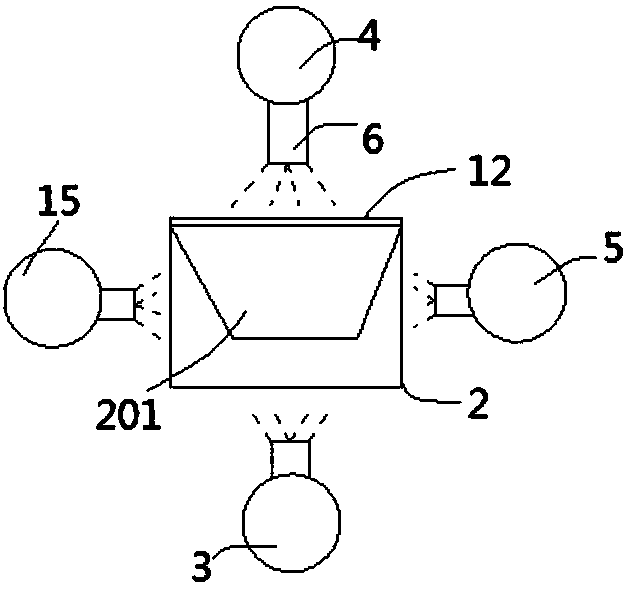

[0088] A process for preparing low-oxygen copper rods using scrap copper, which is basically the same as in Example 1, except that in step 1 of this example, 95% of waste motor wires and 5% of bright copper are used as raw materials for mixing and packaging, and glass The mass ratio to the raw material is 1:75, and the natural gas flow rate is 780m 3 / h, the temperature of molten copper in the copper melting furnace reaches 1200°C; the casting temperature of the copper liquid in step 2 is controlled at 1110°C, and the temperature of the crystallization wheel 2 is controlled at 120°C.

[0089] In the present embodiment, the inner cooling pipe 3 includes a front cooling section, a middle cooling section and a rear cooling section, and the inlet water pressure of the front cooling section, the middle cooling section and the rear cooling section is 8kg / cm 2 ; The outer cooling pipe 4 includes a front cooling section and a rear cooling section, and the inlet water pressure of the f...

Embodiment 3

[0093] A process for preparing low-oxygen copper rods using scrap copper is basically the same as in Example 1, except that 93% of waste motor wires and 7% of bright copper are used as raw materials for mixing and packaging in step 1 of this example, and glass The mass ratio to the raw material is 1:70, and the natural gas flow rate is 800m 3 / h, the temperature of molten copper in the copper melting furnace reaches 1300°C; the casting temperature of the copper liquid in step 2 is controlled at 1120°C, and the temperature of the crystallization wheel 2 is controlled at 110°C.

[0094] In this embodiment, the inner cooling pipe 3 includes a front cooling section, a middle cooling section and a rear cooling section, and the inlet water pressure of the front cooling section, the middle cooling section and the rear cooling section is 7.5kg / cm 2 ; The outer cooling pipe 4 includes a front cooling section and a rear cooling section, and the inlet water pressure of the front cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com