Method for producing low-carbon low-silicon high magnetic induction non-oriented electrical steel plate by CSP process

An oriented electrical steel sheet, low-carbon and low-silicon technology, applied in the direction of metal rolling, etc., can solve the problems affecting the continuous production of CSP, unable to provide cost, secondary oxidation of molten steel, etc., to ensure the fluidity of molten steel and flexible control of rolling temperature , reducing the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

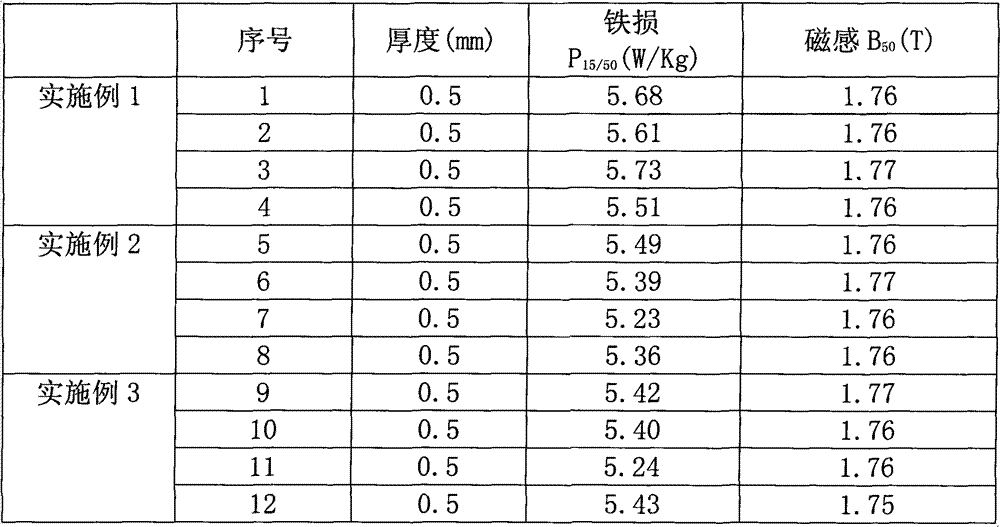

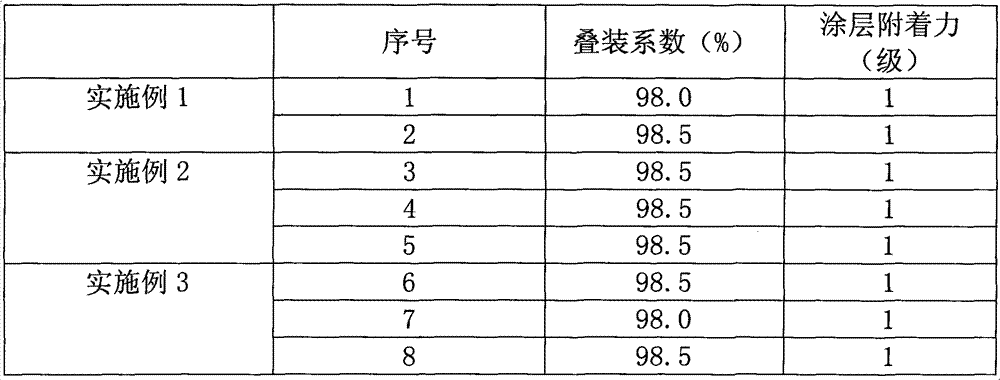

Embodiment 1

[0009] The chemical composition of the low-carbon, low-silicon, aluminum-free, high-magnetism non-oriented electrical steel sheet of the invention is C 0.005%, Si 0.04%, Mn 0.20%, P 0.12%, S 0.008% and Als 0.005%. The production method is produced by CSP process: pretreatment of molten iron, the superheat of molten steel is controlled at the liquidus line + 15°C, and the active oxygen content in the steel is lower than 40ppm to reduce oxidation and ensure the fluidity of molten steel; then smelted by a 120-ton converter , after argon blowing in the ladle and RH vacuum treatment, it enters thin slab continuous casting. The crystallization process adopts non-sinusoidal mold vibration curve and secondary cooling curve hydraulic vibration. The vibration frequency of the non-sinusoidal mold vibration curve is 210 times / S, and the amplitude is 2mm. The casting speed of continuous casting is controlled at 3.0m / min, and the raw material molten steel is cleaned and modified by ladle sla...

Embodiment 2

[0011] The chemical composition of the low-carbon, low-silicon, aluminum-free, high-magnetism non-oriented electrical steel sheet of the invention is C 0.002%, Si 0.20%, Mn 0.38%, P 0.08%, S 0.006% and Als 0.008%. The production method is produced by CSP process: pretreatment of molten iron, the superheat of molten steel is controlled at liquidus line + 20°C, the active oxygen content in the steel is lower than 40ppm to reduce oxidation and ensure the fluidity of molten steel, and then smelted by a 120-ton converter , after argon blowing in the ladle and RH vacuum treatment, it enters thin slab continuous casting. The crystallization process adopts non-sinusoidal mold vibration curve and secondary cooling curve hydraulic vibration. The non-sinusoidal mold vibration curve has a vibration frequency of 250 times / S and an amplitude of 2mm. The casting speed of continuous casting is controlled at 4.0m / min, the raw material molten steel is modified by ladle slag to control the iron o...

Embodiment 3

[0013] The chemical composition of the low-carbon, low-silicon, aluminum-free, high-magnetism non-oriented electrical steel sheet of the invention is C 0.010%, Si 0.68%, Mn 0.55%, P 0.11%, S 0.009% and Als 0.003%. The production method is produced by CSP process: pretreatment of molten iron is carried out first, the superheat of molten steel is controlled at the liquidus line + 30°C, and the active oxygen content in the steel is lower than 40ppm to reduce oxidation and ensure the fluidity of molten steel, and then smelted by a 120-ton converter , after argon blowing in the ladle and RH vacuum treatment, it enters thin slab continuous casting. The crystallization process adopts non-sinusoidal mold vibration curve and secondary cooling curve hydraulic vibration. The non-sinusoidal mold vibration curve has a vibration frequency of 230 times / S and an amplitude of 2.5mm , the continuous casting casting speed is controlled at 4.5m / min, the raw material molten steel is modified by lad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com