A kind of multiple modified nickel-rich ternary material and its preparation method and application

A ternary material, nickel-rich technology, applied in electrical components, structural parts, battery electrodes, etc., can solve the problems of bulk doping, easy structure collapse, poor coating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

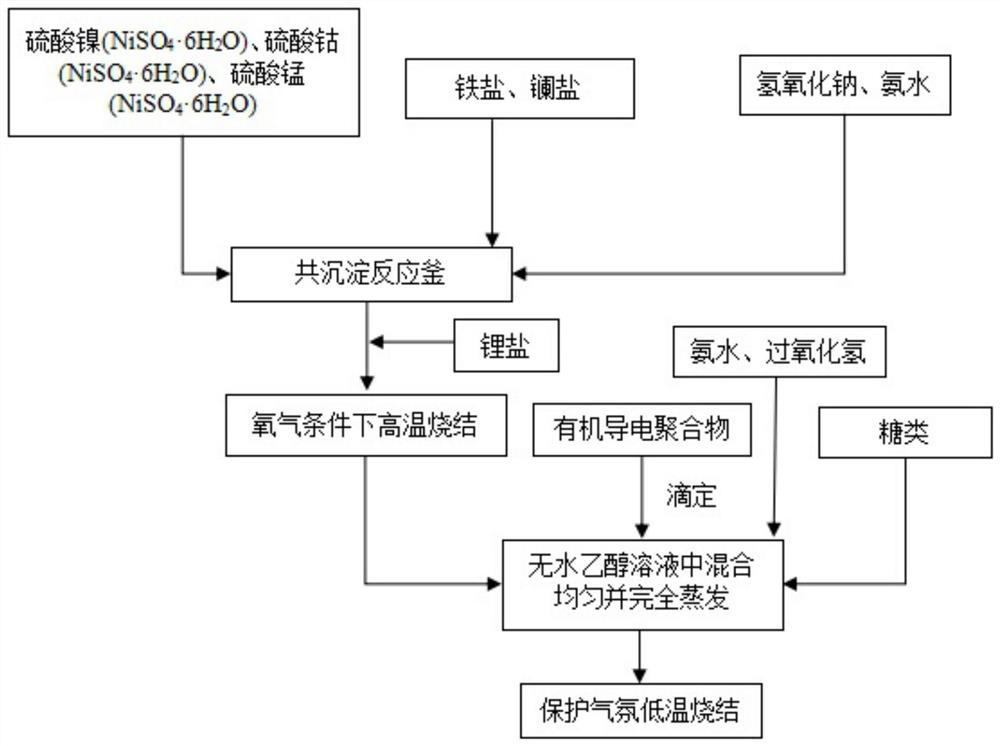

Method used

Image

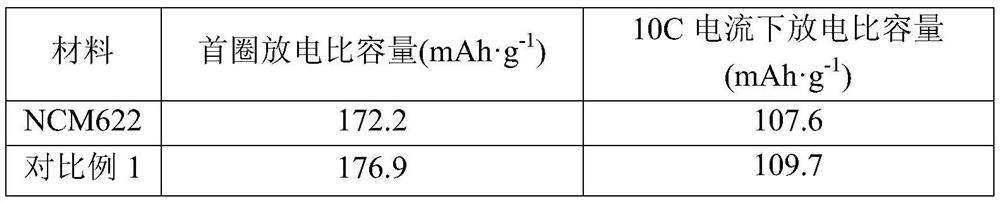

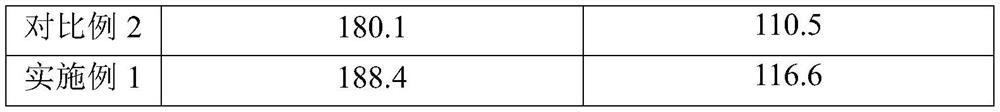

Examples

Embodiment 1

[0039] This embodiment provides a multiple modified nickel-rich ternary material, the preparation method of which is as follows:

[0040] Step a, add 0.5L of ammonia water with a concentration of 0.5mol / L in the reaction kettle as the reaction bottom liquid, and use ultrapure water to dilute nickel sulfate, cobalt sulfate, and manganese sulfate according to the molar ratio Ni:Co:Mn=6:2:2 Dissolve in a beaker to make 0.75L sulfate mixed solution, the sulfate concentration in the mixed solution is 1.5mol / L;

[0041] Step b, adding ferric sulfate and 1% lanthanum acetate equivalent to 1% of the total mass of nickel sulfate, cobalt sulfate, and manganese sulfate respectively to the sulfate mixed solution obtained in step a, to prepare a quinary mixed salt solution;

[0042] Step c, pump ammoniacal liquor, sodium hydroxide solution and the mixed solution of pentabasic sulfate obtained in step b into the co-precipitation reactor to obtain the mixed solution at a rate of 48ml / h, 104m...

Embodiment 2

[0046] This embodiment provides a multiple modified nickel-rich ternary material, the preparation method of which is as follows:

[0047] Step a, add 2L of ammonia water with a concentration of 0.4mol / L in the reaction kettle as the reaction bottom liquid, and use ultrapure water to dissolve nickel sulfate, cobalt sulfate, and manganese sulfate according to the molar ratio Ni:Co:Mn=5.5:1.8:1.8 In a beaker, make 2L sulfate mixed solution, the sulfate radical concentration in this mixed solution is 2mol / L;

[0048] Step b, adding ferric nitrate and 3% lanthanum nitrate equivalent to 3% of the total mass of nickel sulfate, cobalt sulfate, and manganese sulfate respectively to the sulfate mixed solution obtained in step a, to prepare a quinary mixed salt solution;

[0049] Step c, with the rate of 122.5ml / h, 333.3ml / h and 34.3ml / h respectively pump ammoniacal liquor, sodium hydroxide solution and step b gained pentabasic sulfate mixed solution into coprecipitation reactor and obta...

Embodiment 3

[0053] This embodiment provides a multiple modified nickel-rich ternary material, the preparation method of which is as follows:

[0054] Step a, add 1.3L of ammonia water with a concentration of 0.6mol / L in the reaction kettle as the reaction bottom liquid, and use ultrapure water to dilute nickel sulfate, cobalt sulfate, and manganese sulfate according to the molar ratio Ni:Co:Mn=6:2:2 Dissolve in a beaker to make 0.9L sulfate mixed solution, the sulfate concentration in the mixed solution is 2.5mol / L;

[0055] Step b, in step a gained sulfate mixed solution, add respectively iron sulfate, 3% ferric oxide, 2% lanthanum acetate and 3% lanthanum oxide equivalent to nickel sulfate, cobalt sulfate, manganese sulfate gross mass 2%, Prepare a quinary mixed salt solution;

[0056] Step c, with the rate of 48.9ml / h, 183.3ml / h and 12.2ml / h respectively pump ammoniacal liquor, sodium hydroxide solution and step b gained pentabasic sulfate mixed solution into coprecipitation reactor a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com