Power-frequency online anti-icing de-icing method for electrified railway contact network

A technology of electrified railway and ice-melting method, which is applied to the installation of electrical components, power lines, cables, etc., can solve the problems of soil environmental pollution, no application cases, etc., achieve low operating costs, improve reliability, and save investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

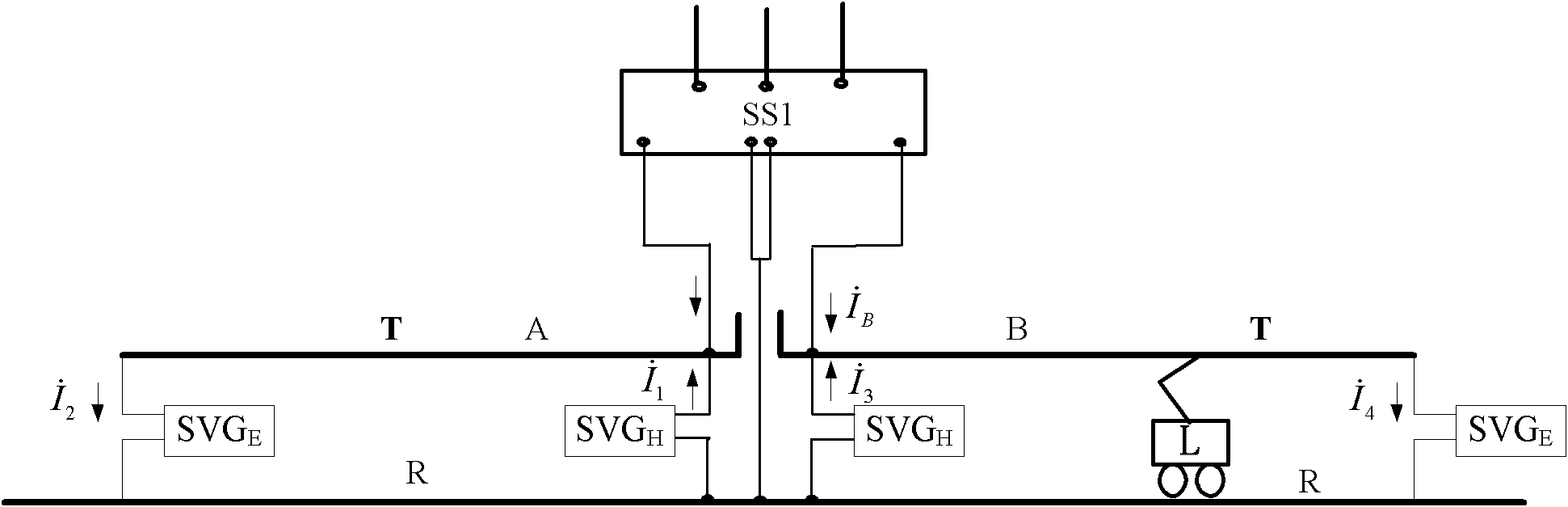

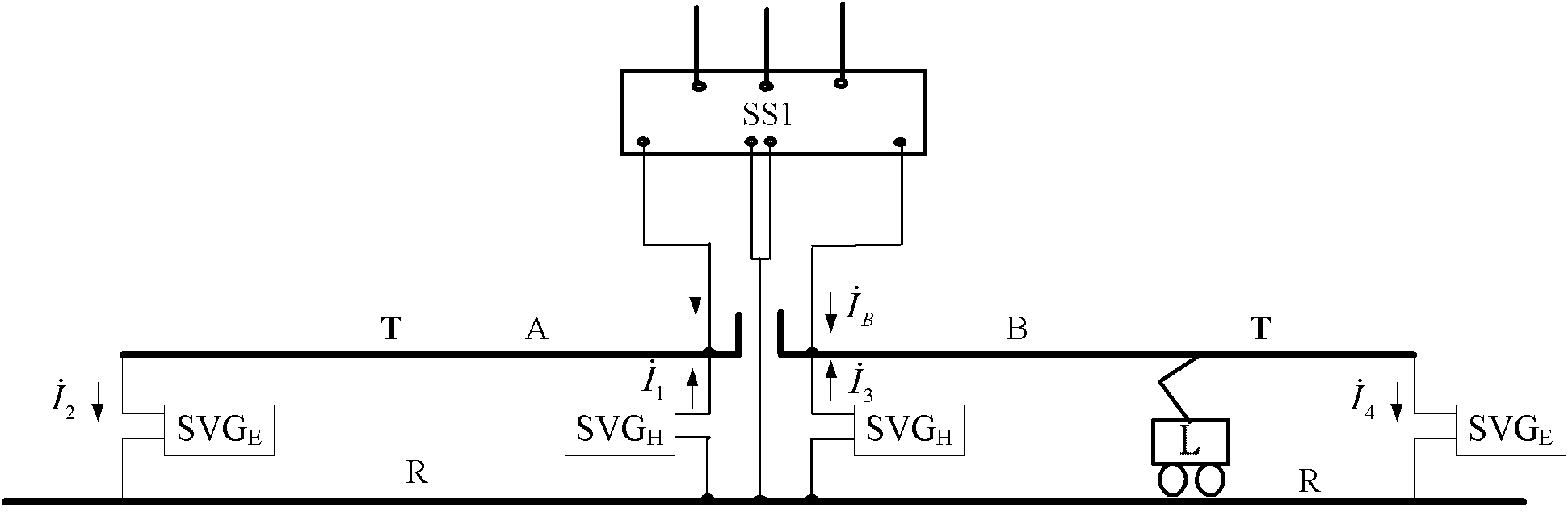

[0027] figure 1 Shown, a kind of embodiment of the present invention is:, a kind of electrified railway catenary power frequency on-line anti-icing and thawing method, and its concrete practice is:

[0028] A. The head and end of any power supply arm A and B of the two-phase power supply arm of the electrified railway traction substation SS1 are respectively connected to the head-end dynamic reactive power compensation device SVG H And terminal dynamic reactive power compensation device SVG E ; Set a temperature sensor on the catenary T, the temperature sensor and the head-end dynamic reactive power compensation device SVG H And terminal dynamic reactive power compensation device SVG E connected to the controller;

[0029] B. The temperature sensor monitors the temperature of catenary T. When the detected temperature is lower than 0°C, the controller controls the dynamic reactive power compensation device SVG at the head end and end end. H , SVG E Entering the anti-icing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com