Wide-surface copper plate of crystallizer for high-efficiency slab caster

A slab continuous casting machine and crystallizer technology, applied in the field of continuous casting molds, can solve problems such as uneven heat transfer, slab cracks, recrystallization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

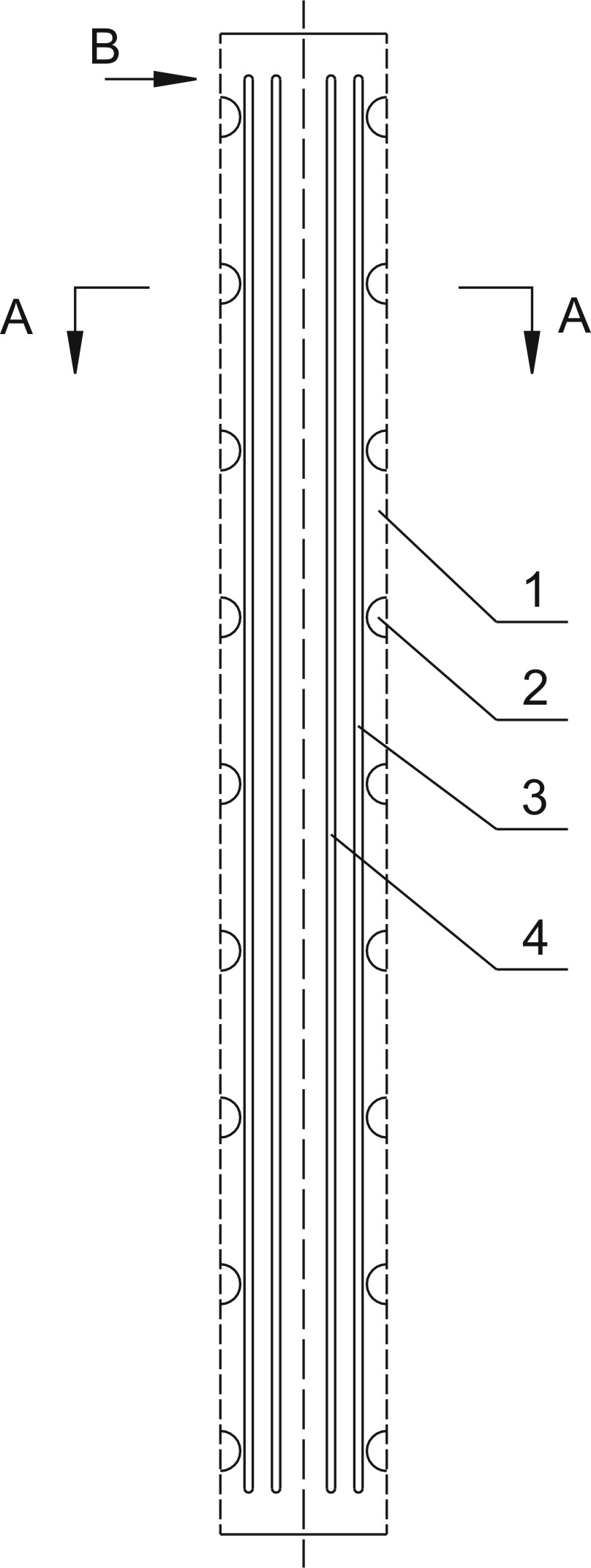

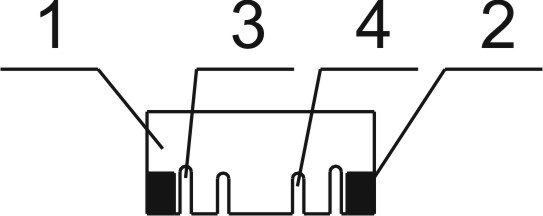

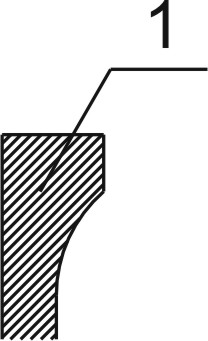

[0015] Such as Figure 1 to Figure 3 As shown, a kind of crystallizer wide-faced copper plate used for high-efficiency slab continuous casting machine of the present invention includes wide-faced copper plate body 1, several rows of screw holes 4 on the wide-faced copper plate body 1 and the cold surface of wide-faced copper plate body 1 The cooling water tank set on the figure 1 Schematically shows the structure of a repeating cycle of the wide-faced copper plate body 1. It can be seen from the figure that the cooling water tank of this embodiment includes two deeper deep water tanks 3 and two shallower shallow water tanks 4, deep water tank 3 and shallow water tank 4 The depths are 21mm and 16mm respectively. Between two adjacent columns of screw holes 4, two deep water tanks 3 are arranged symmetrically close to the screw holes 4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com