A mold for wheel casting

A mold and wheel technology, applied in the field of casting, can solve problems such as limited cooling capacity, uneven cooling, uneven temperature distribution, etc., and achieve the effects of improving product production efficiency, ensuring normal solidification, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

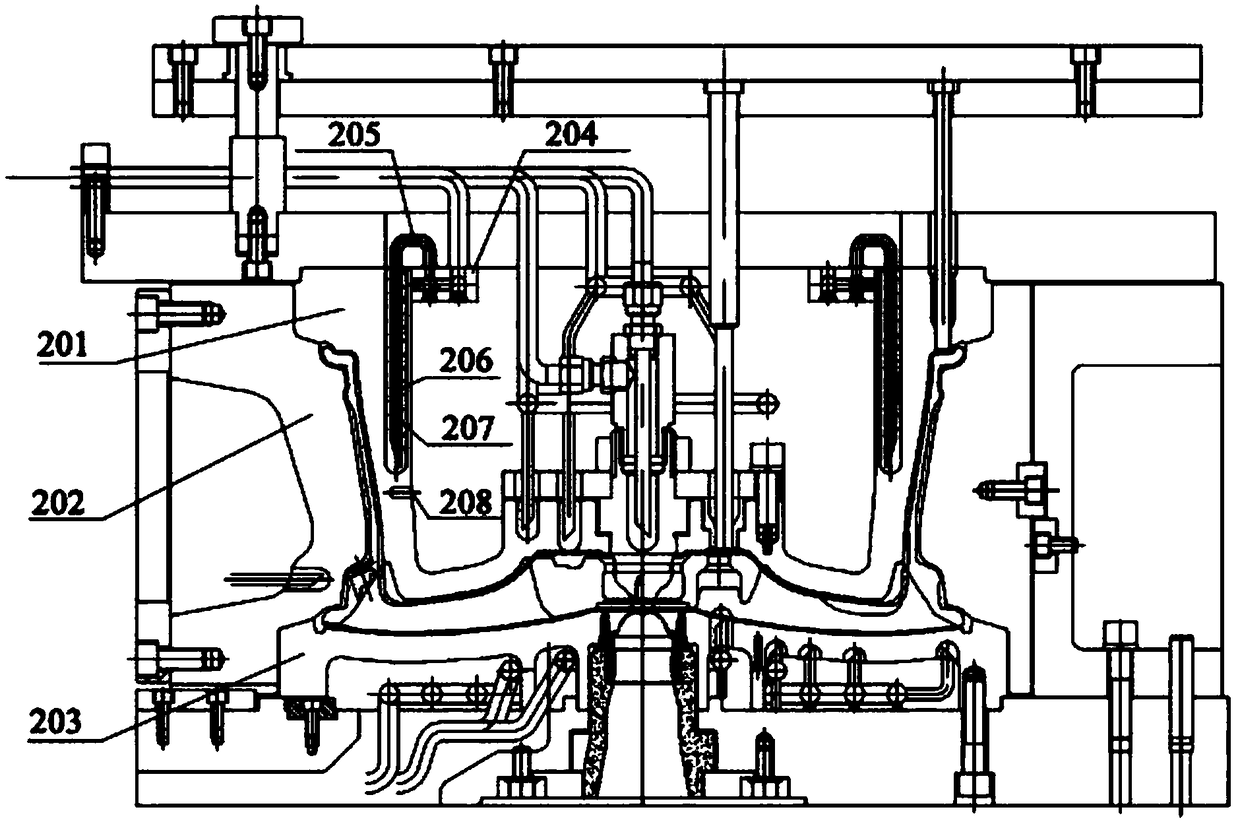

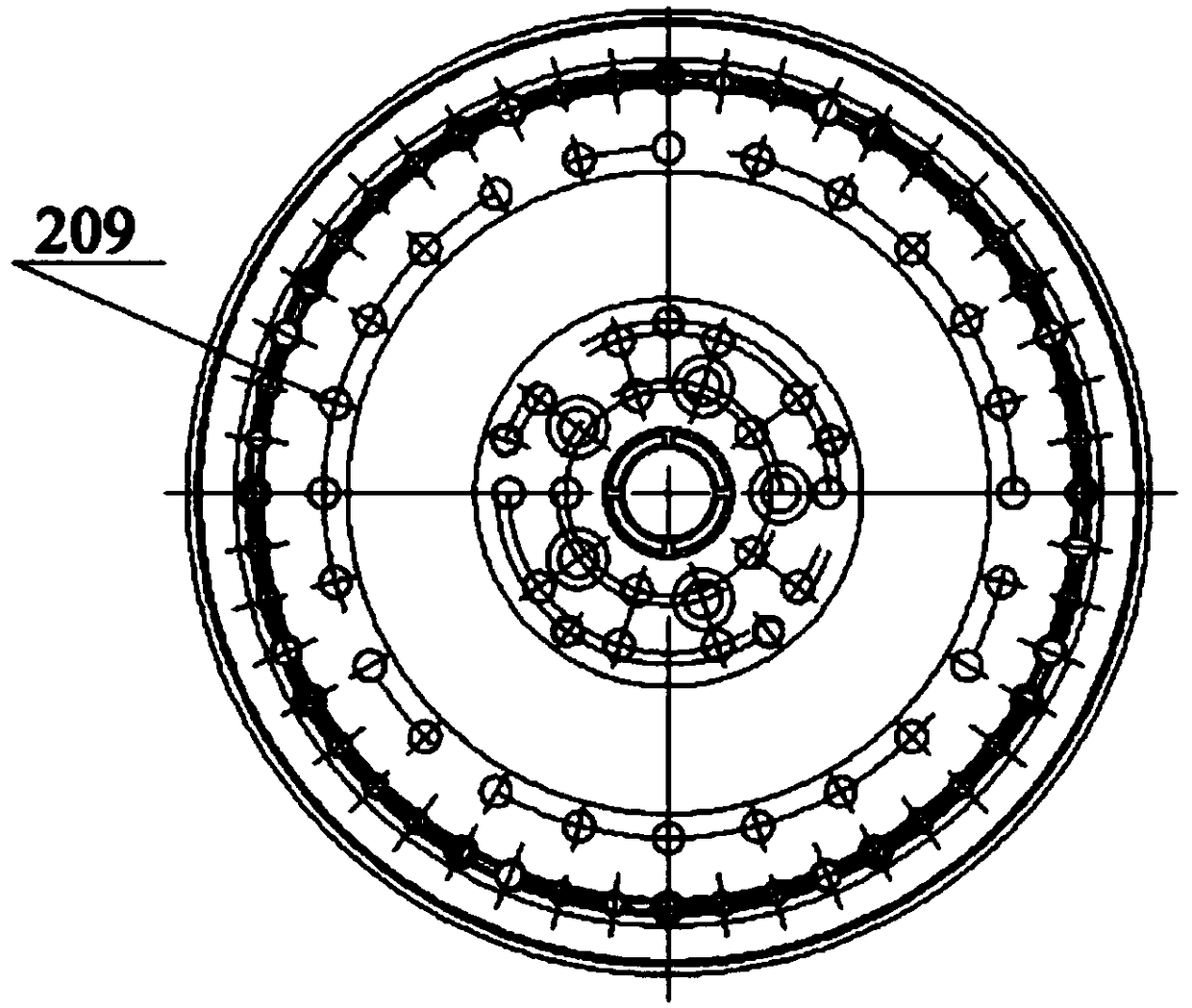

[0029] Test group: the mold includes an upper mold 201, a side mold 202 and a lower mold 203, wherein the upper mold 201 includes a rim cooling hole 206 on the upper surface; the rim cooling hole is a blind hole, And there is a water mist cooling pipe 205 therein; and the water mist outlet 207 of the water mist cooling pipe 205 is located at the end of the water mist cooling pipe 205 and the bottom of the rim cooling hole 206 . Process a group of rim cooling holes 206 (blind holes) on the upper mold of the low-pressure casting mold. The blind holes are located on the pitch circle where the center of the upper mold is the center of the circle. The distance between the inner rim and the side wall of the blind hole is about 22mm, and the number of blind holes is 24. Insert the water mist cooling pipe 205 into the blind hole 206. The water mist cooling pipe 205 is made of stainless steel with a diameter of 8mm. The side wall of the mist cooling hole is drilled with small holes wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com