Digital constant-temperature control concrete ultra-low-temperature construction maintenance system

A constant temperature control and maintenance system technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of unable to pour concrete on bridge piers, cracks on the concrete surface, and large temperature difference between inside and outside, so as to prevent heat loss and low manufacturing cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

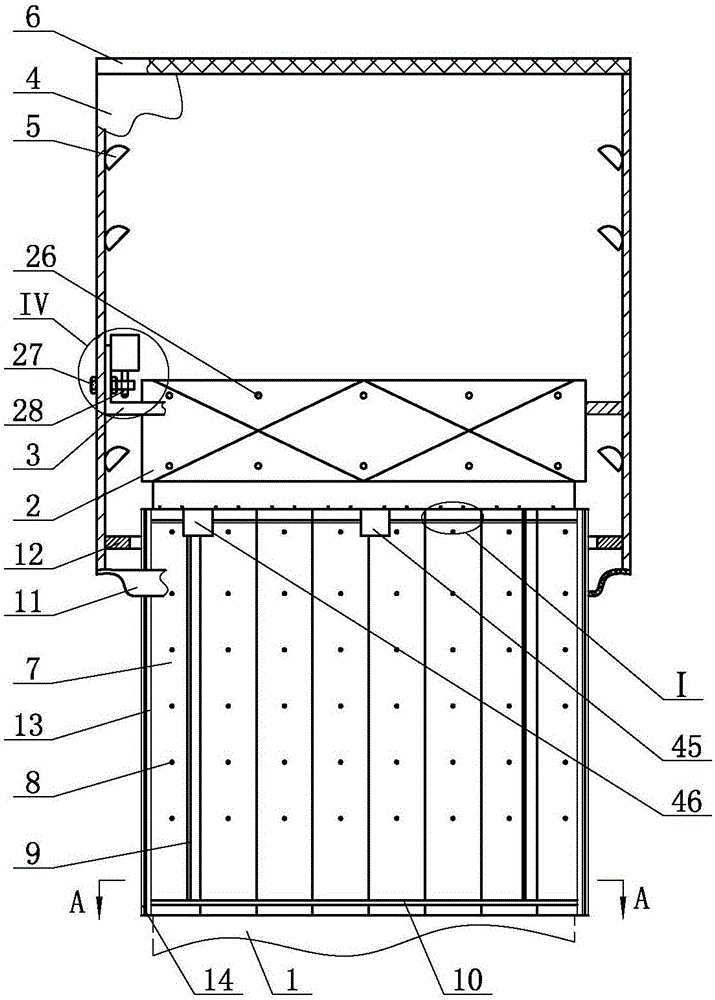

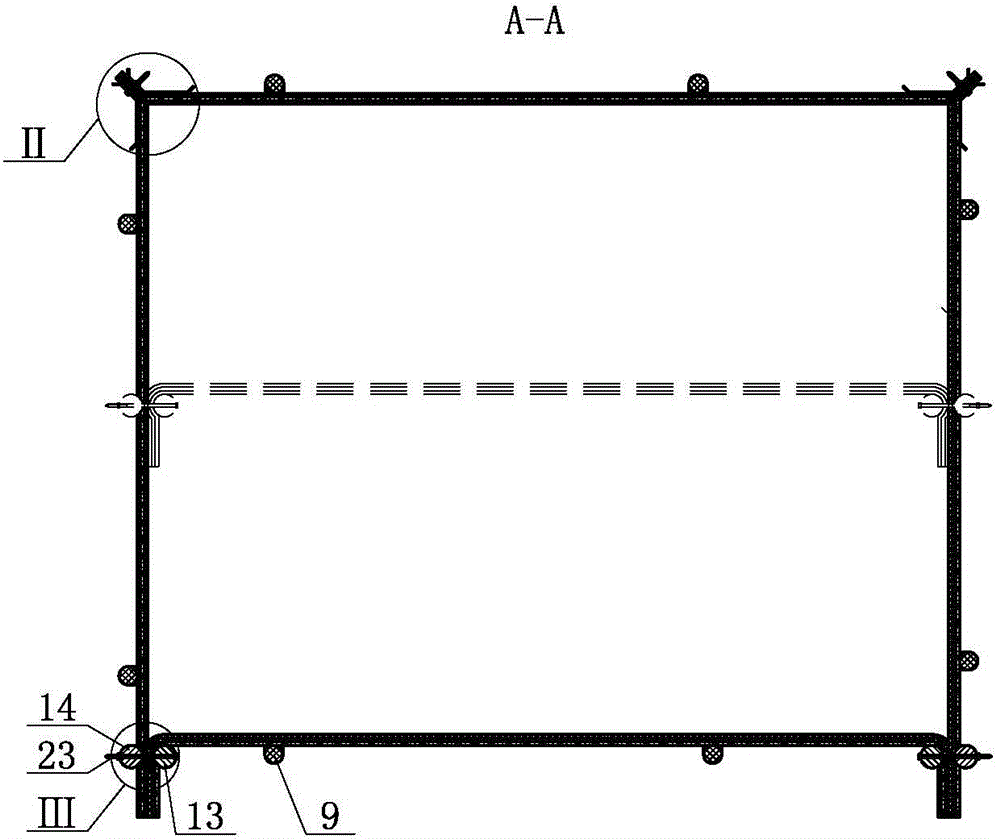

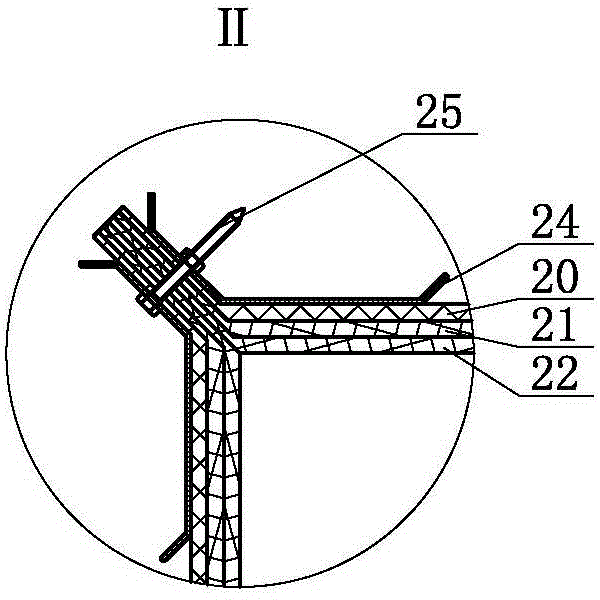

[0009] The digital constant temperature control concrete ultra-low temperature construction and maintenance system of the present invention includes a sliding formwork 2, a data acquisition device, a wireless transmission device and a heating control device. Such as figure 1 As shown, the insulation shed 4 is installed on the periphery of the sliding formwork 2. The steel pipe hanger 19 is installed on the bottom of the sliding template 2, and four electronic heating quilts 7 are suspended on the steel pipe hanger 19. Four pieces of electronic heating are surrounded by 7 to form a barrel-shaped airtight heat preservation cover. Such as Image 6 As shown, each piece of electronic heating quilt 7 is sequentially connected by high-strength glass fiber layer 22 , heating cable 21 and thermal insulation cotton layer 20 from inside to outside. The high-strength glass fiber layer 22 has the advantages of wear resistance, good toughness and strong tensile strength, and can bear the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com