Patents

Literature

40 results about "Electron heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electron Heat is a process for heating and curing thermoset composites. Using high-voltage radio frequency (RF) energy Electron Heat controls the profile of a material’s curing temperature and has reduced some curing cycles by more than 95%.

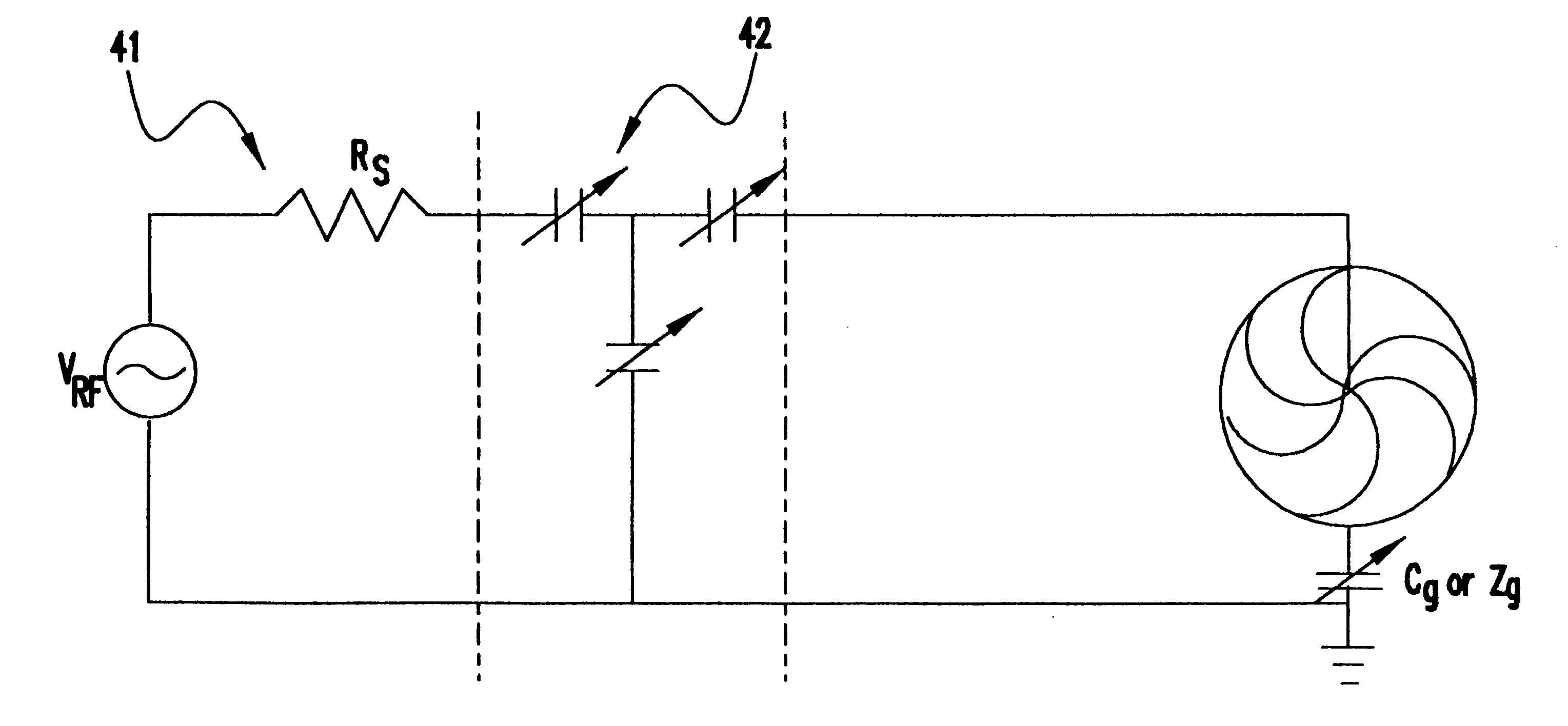

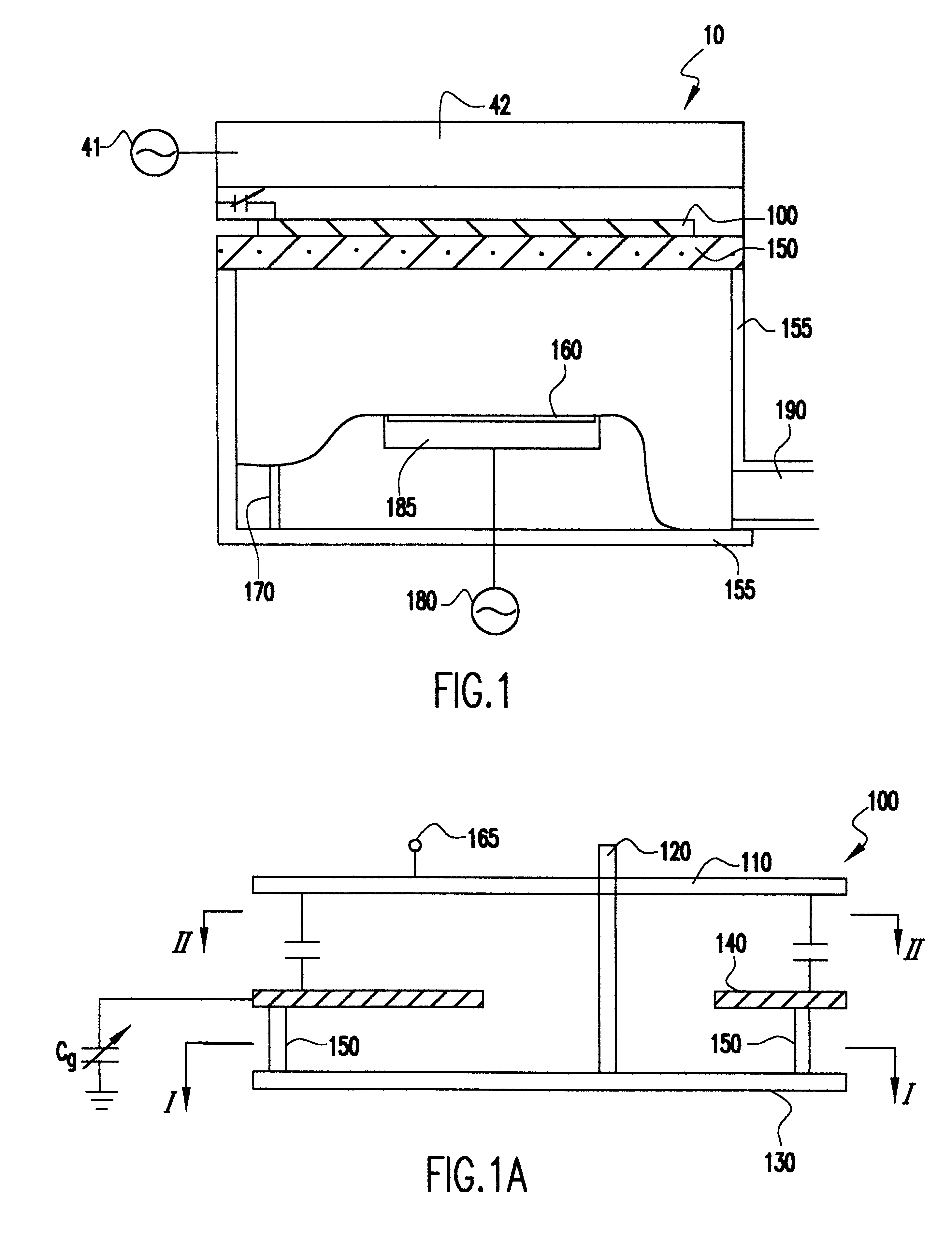

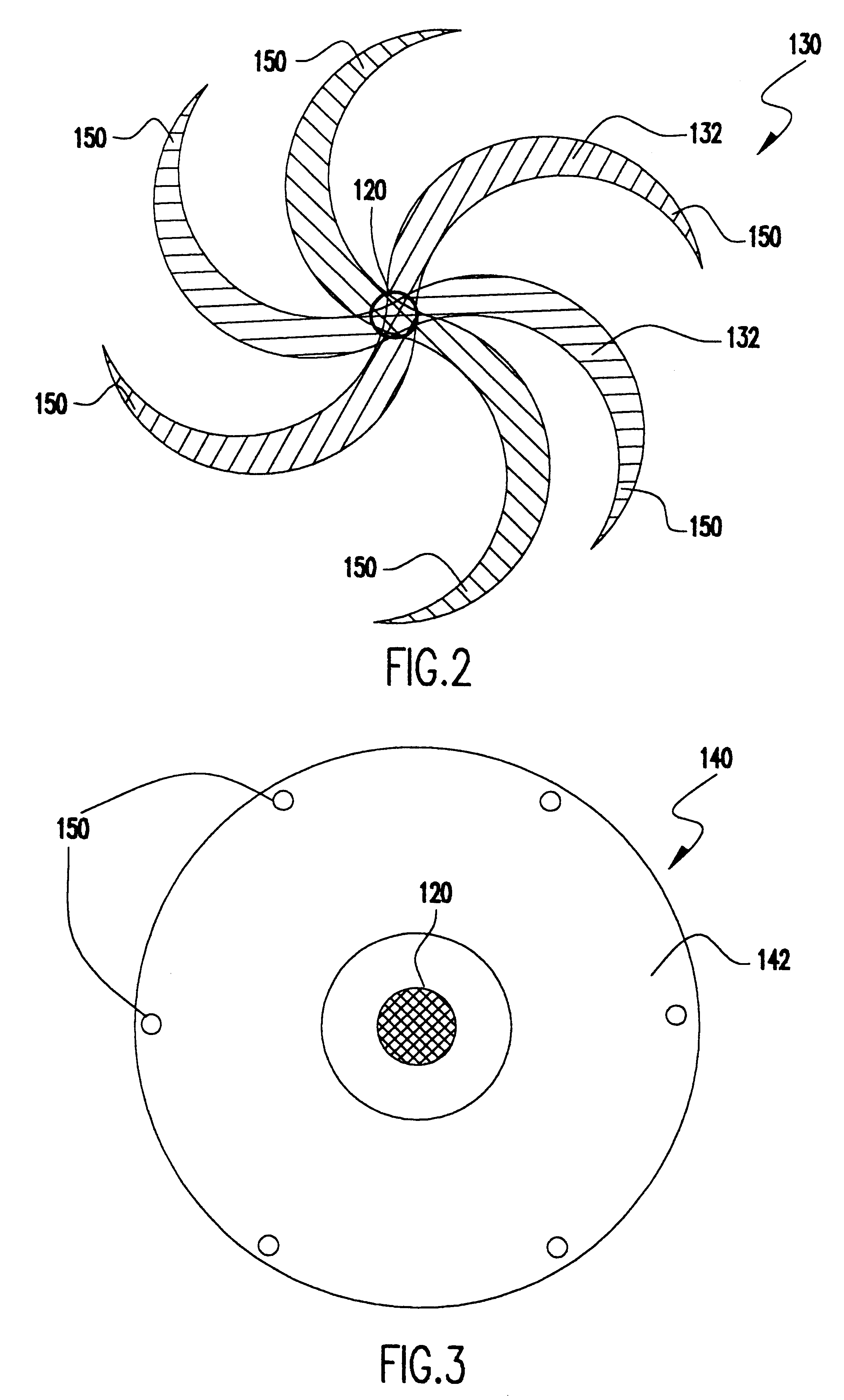

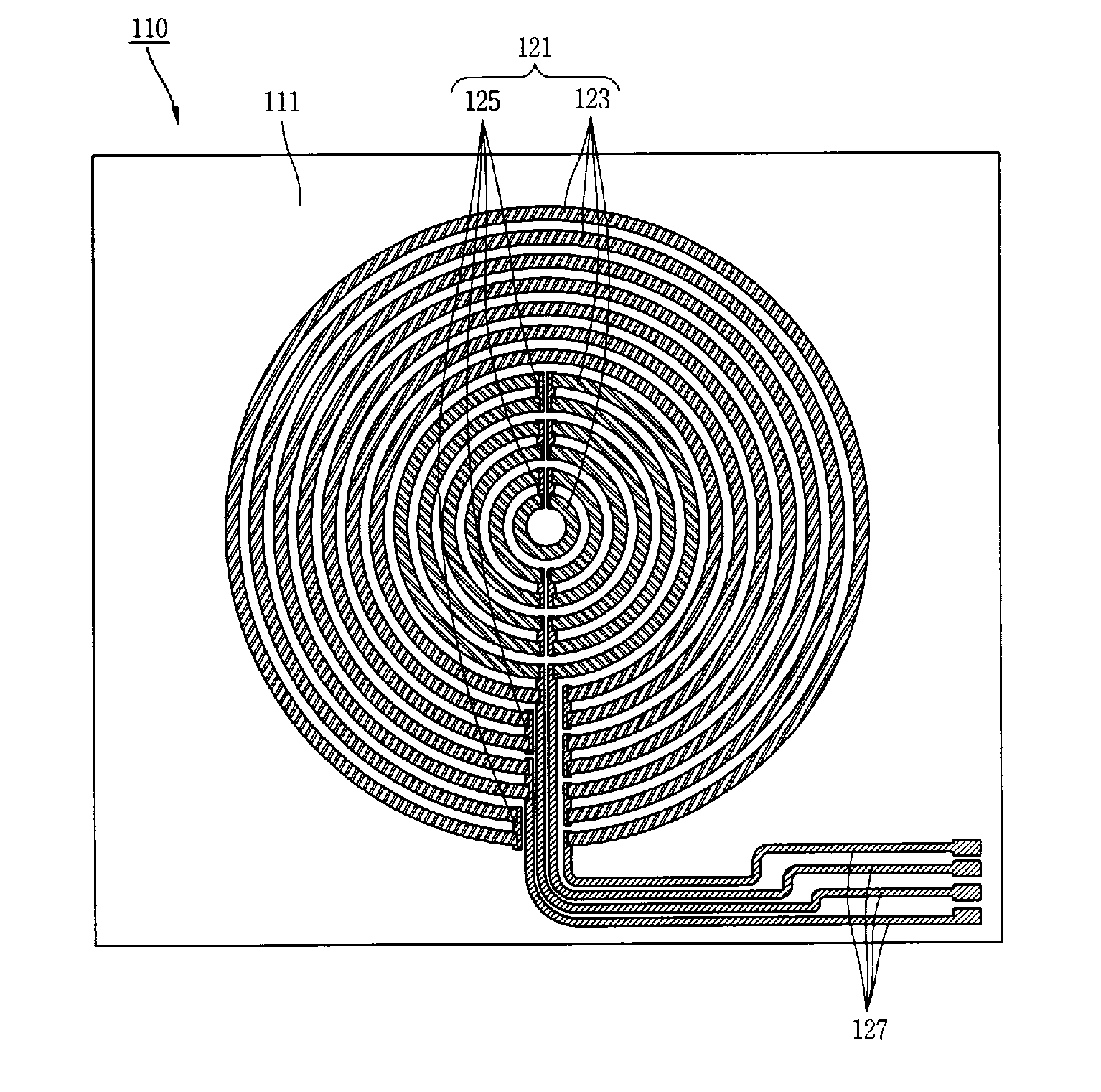

High density plasma tool with adjustable uniformity and stochastic electron heating for reduced gas cracking

InactiveUS6262538B1Increase chanceDevoid of excess gas cracking effectsElectric discharge tubesElectric arc lampsCapacitanceEtching

VHF / UHF power having a frequency of about 40 MHz or higher is applied across generally radial elements of an antenna and the phase of a standing wave component of the voltage in the generally radial elements is adjusted to provide relatively uniform density of a high density plasma across an area of at least the size of a semiconductor wafer being processed. Capacitive coupling of power to the plasma enhances the hot tail distribution of electron energies which is associated with low levels of gas cracking and the production of radicals such as fluorine which are not material-selective in semiconductor processing operations such as oxide etching. Accordingly, material-selectivity of processes may be maintained while the high density plasma accelerates the process to significantly improve tool throughput.

Owner:IBM CORP

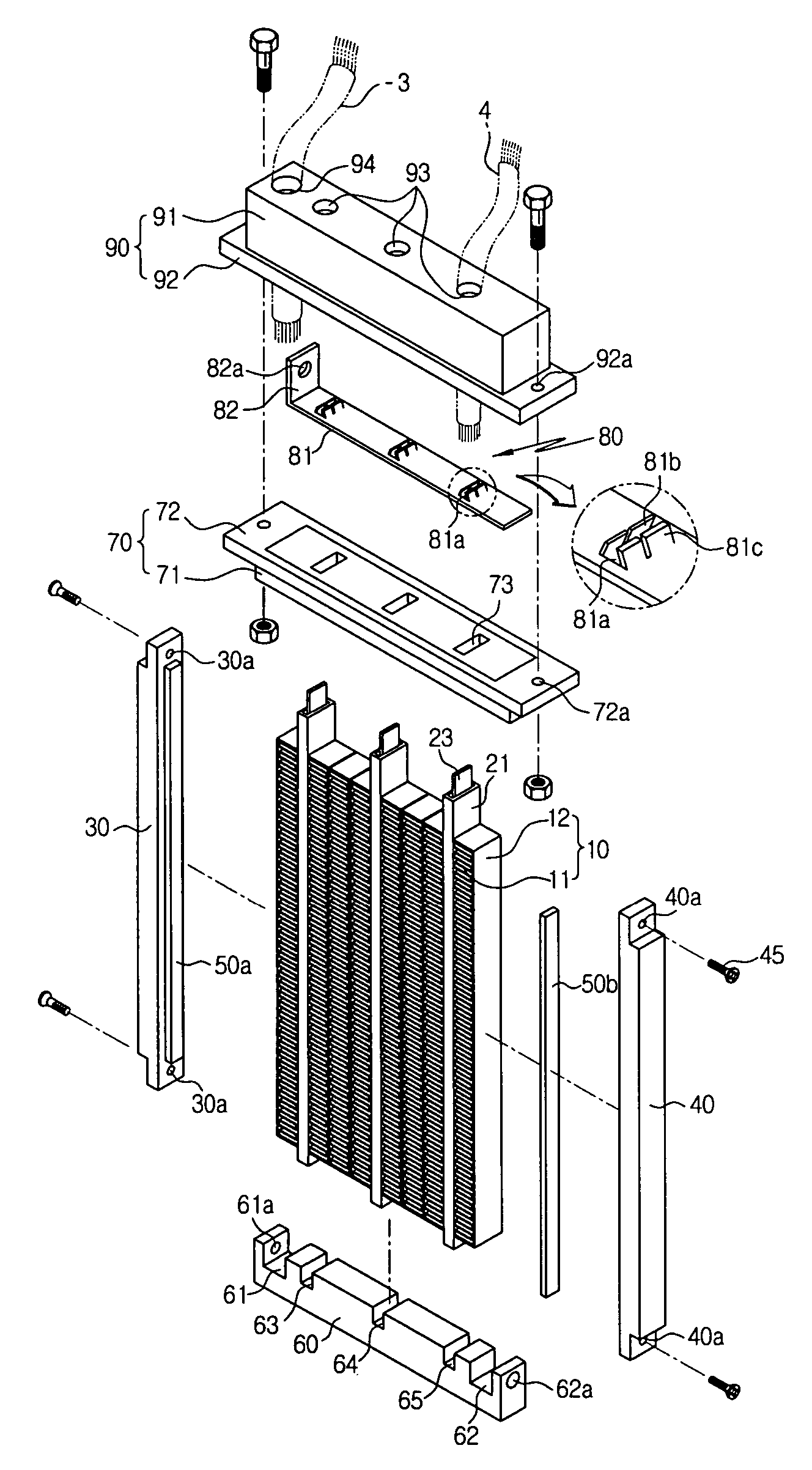

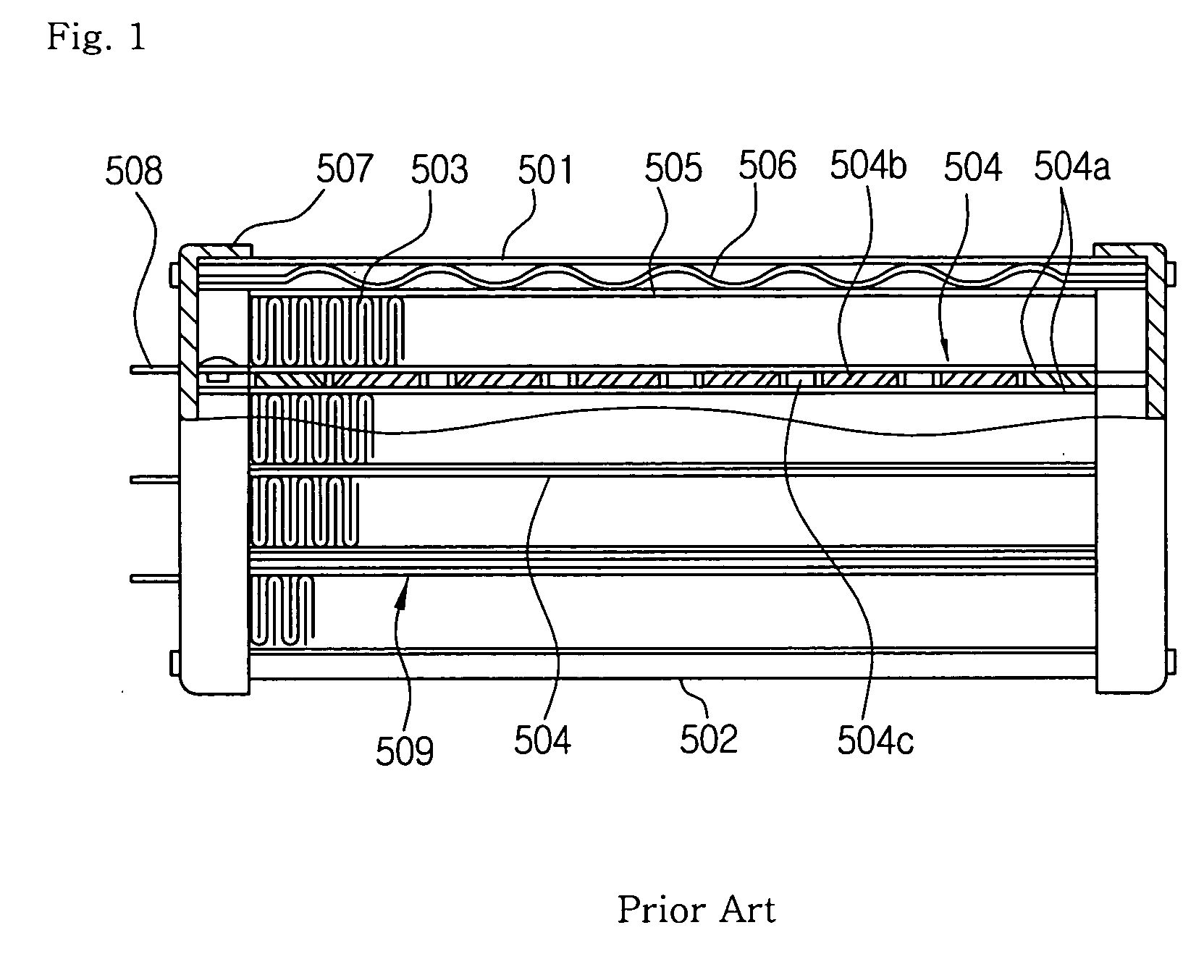

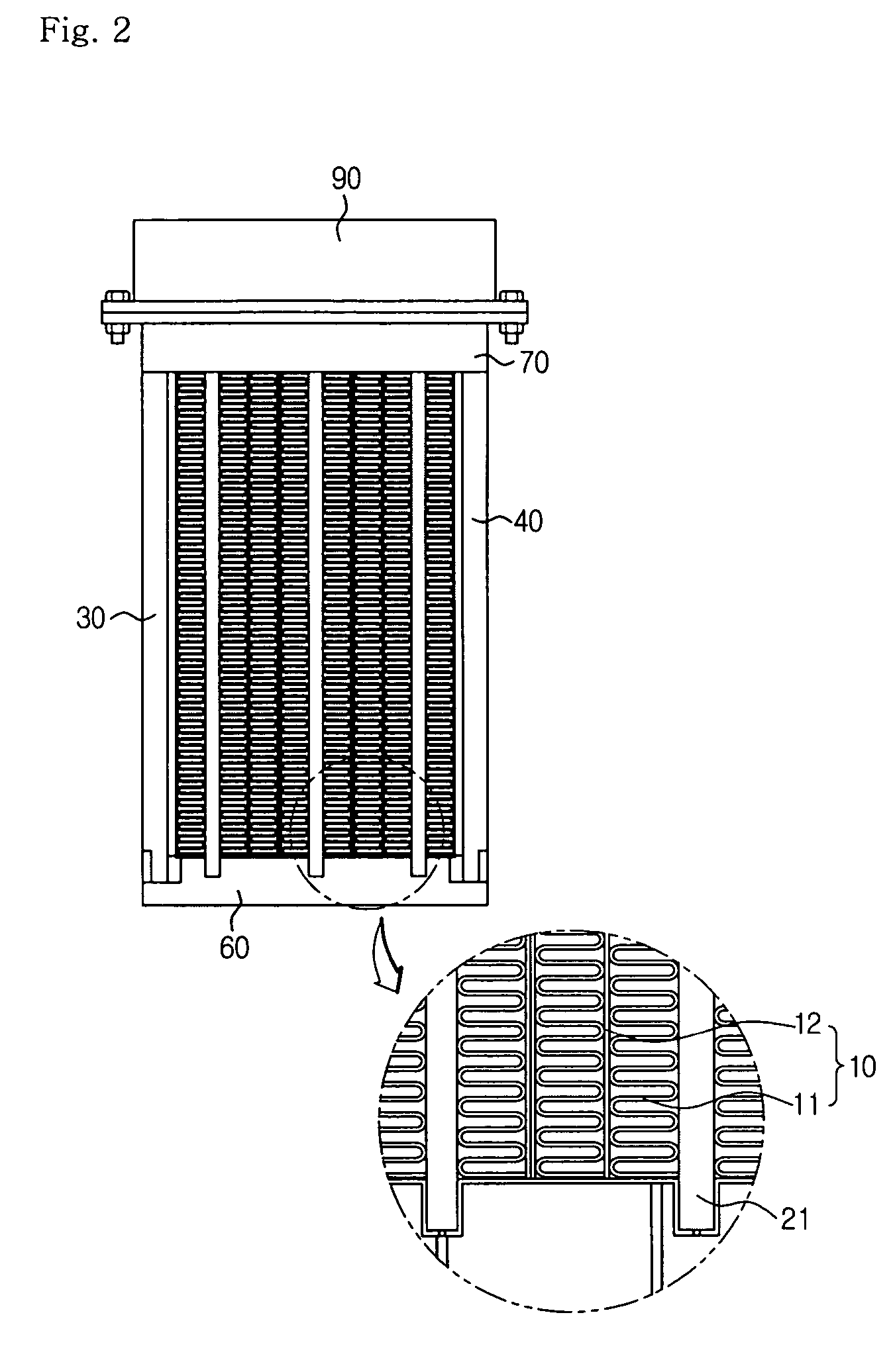

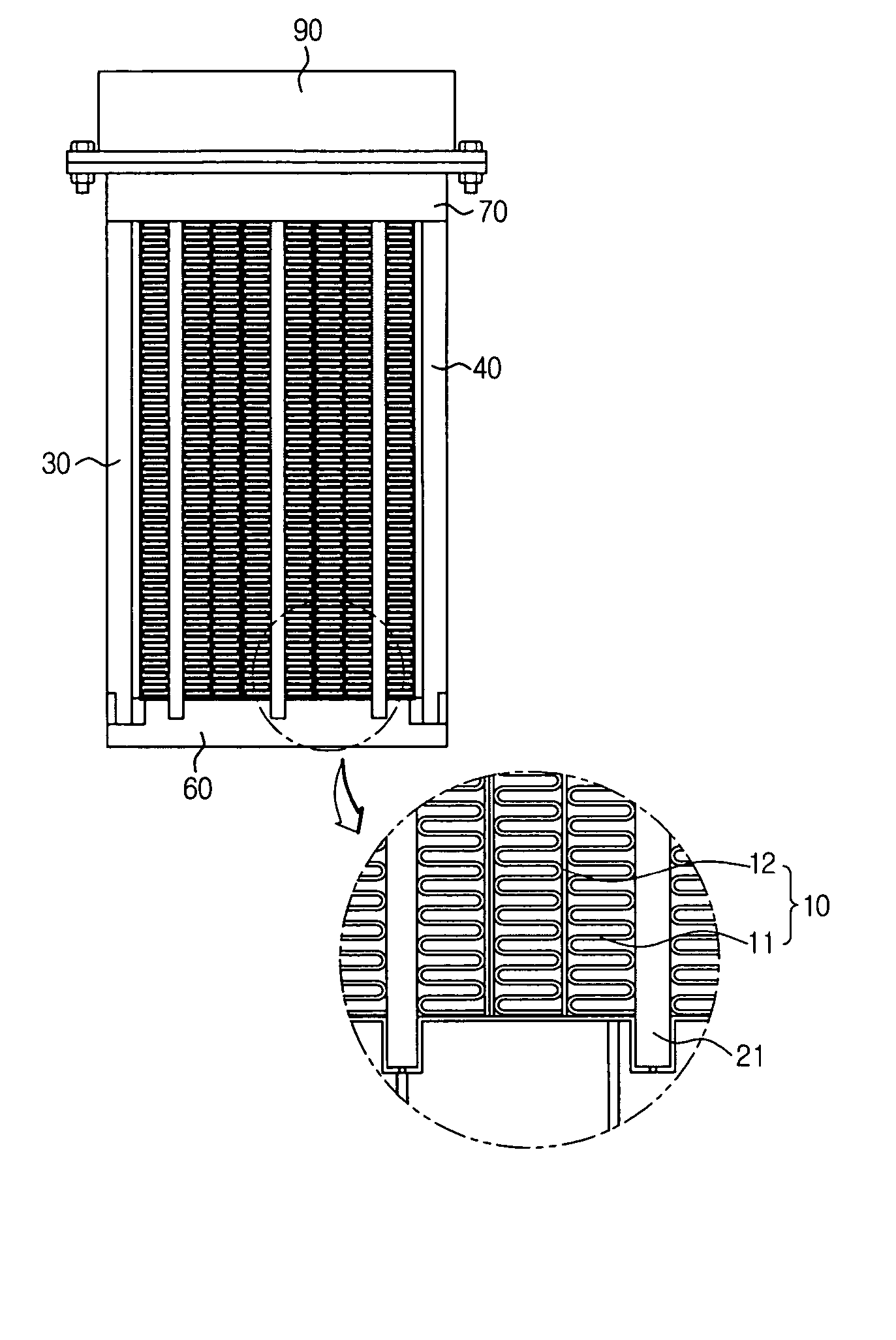

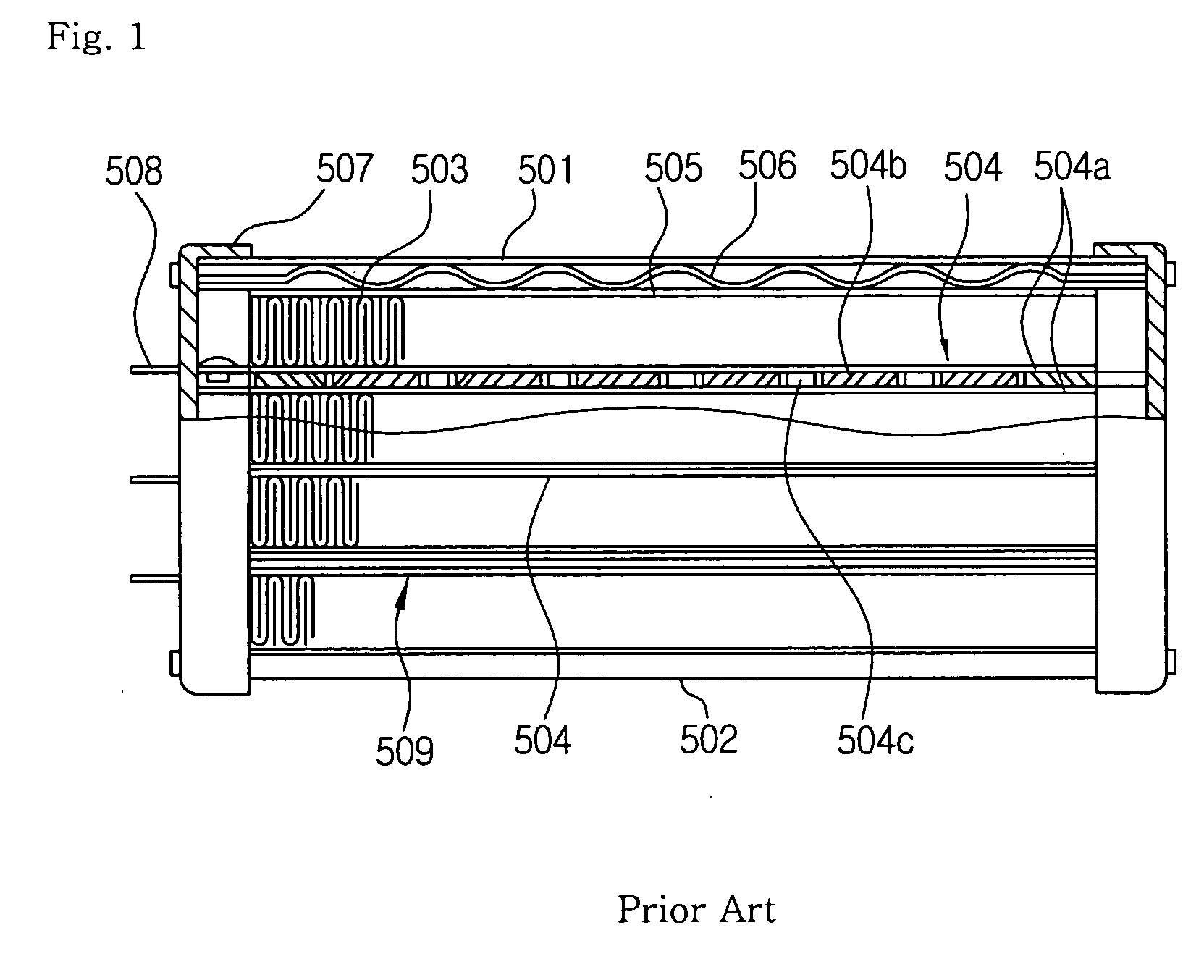

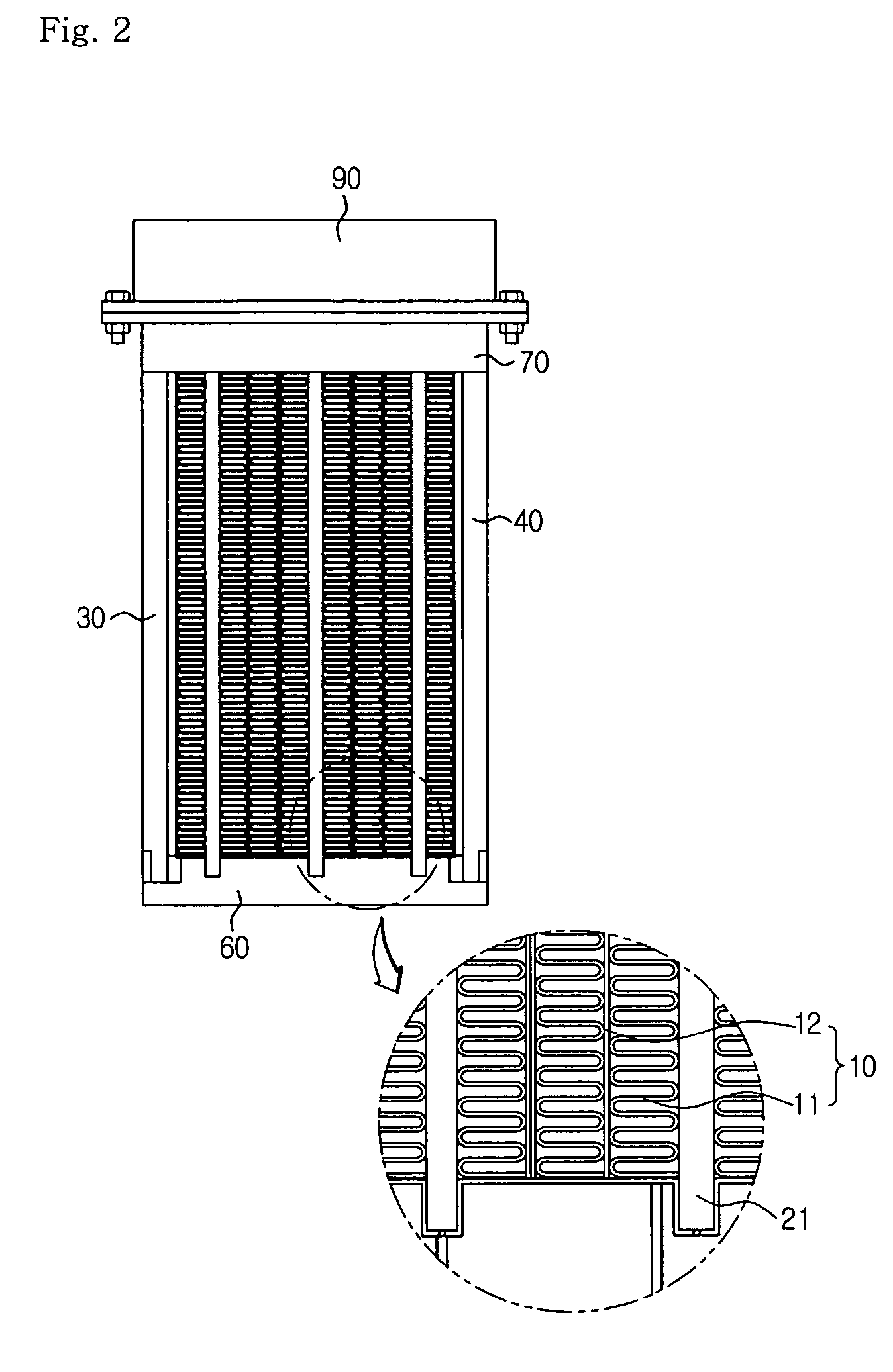

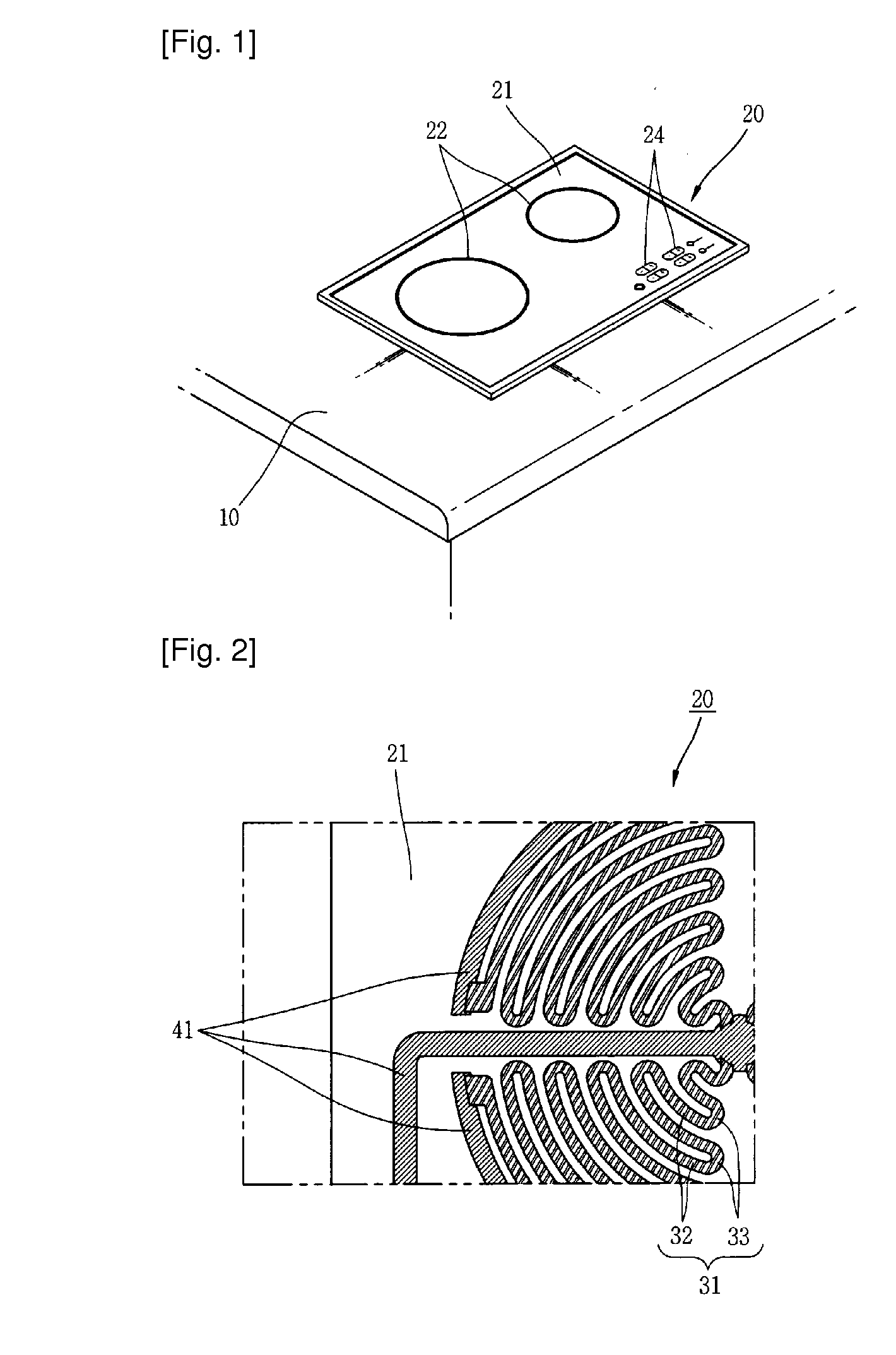

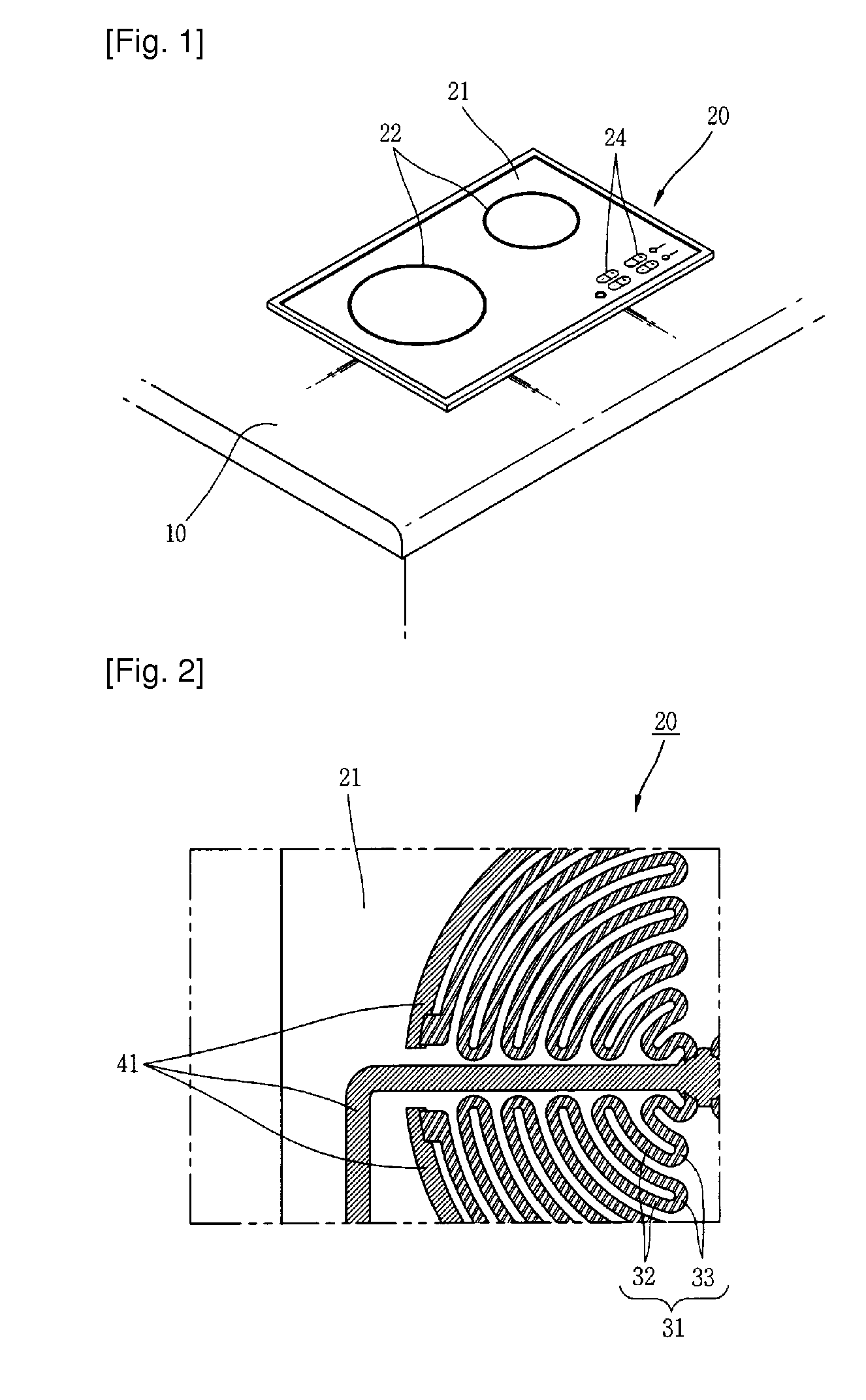

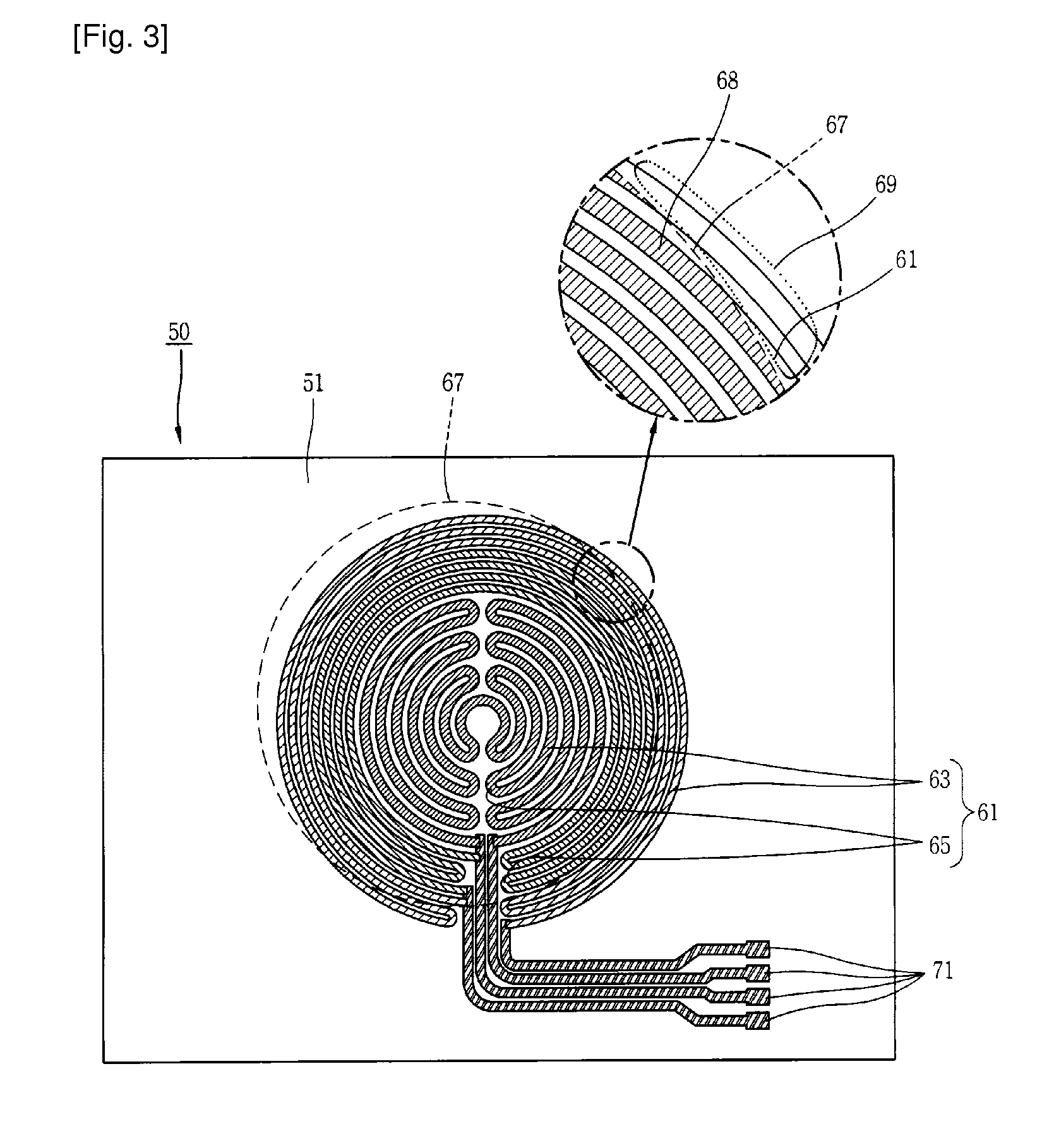

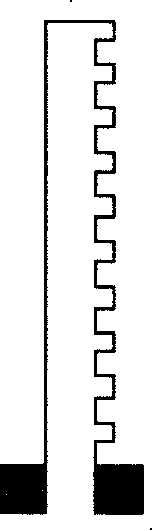

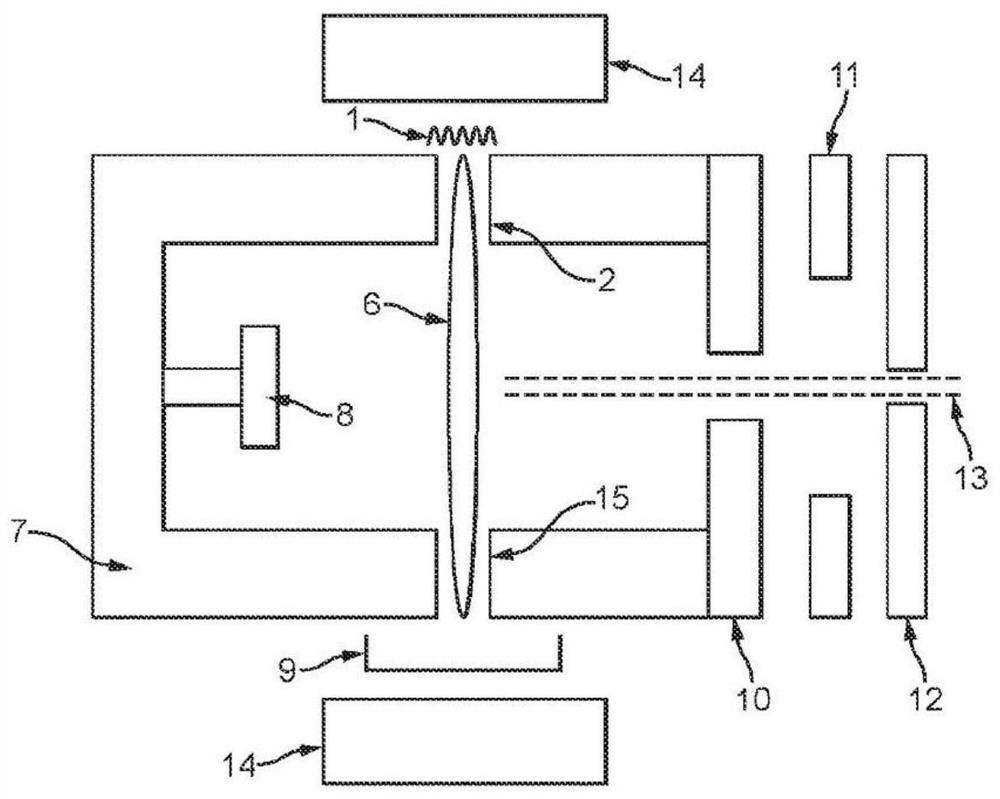

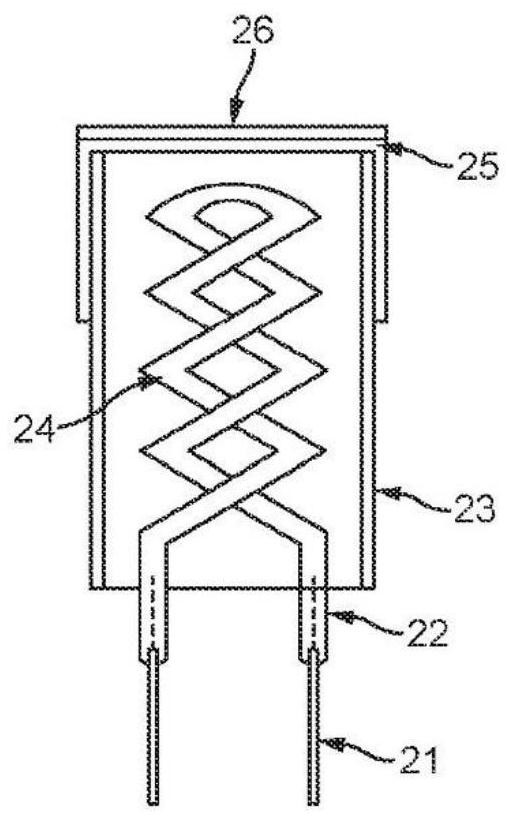

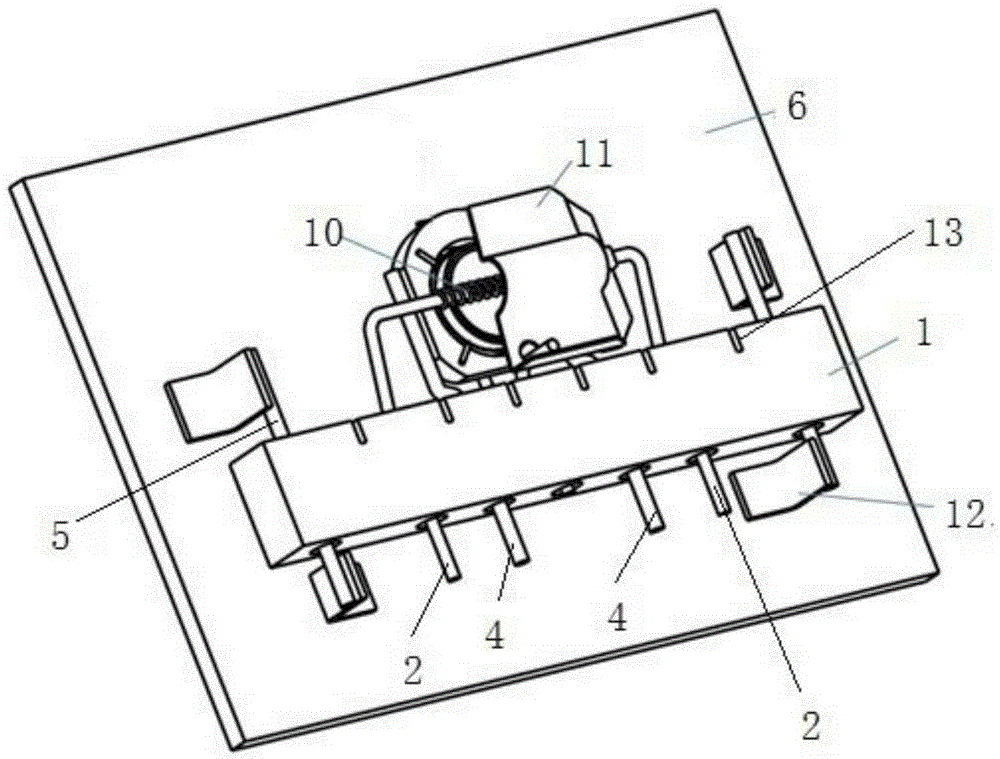

Electric heater

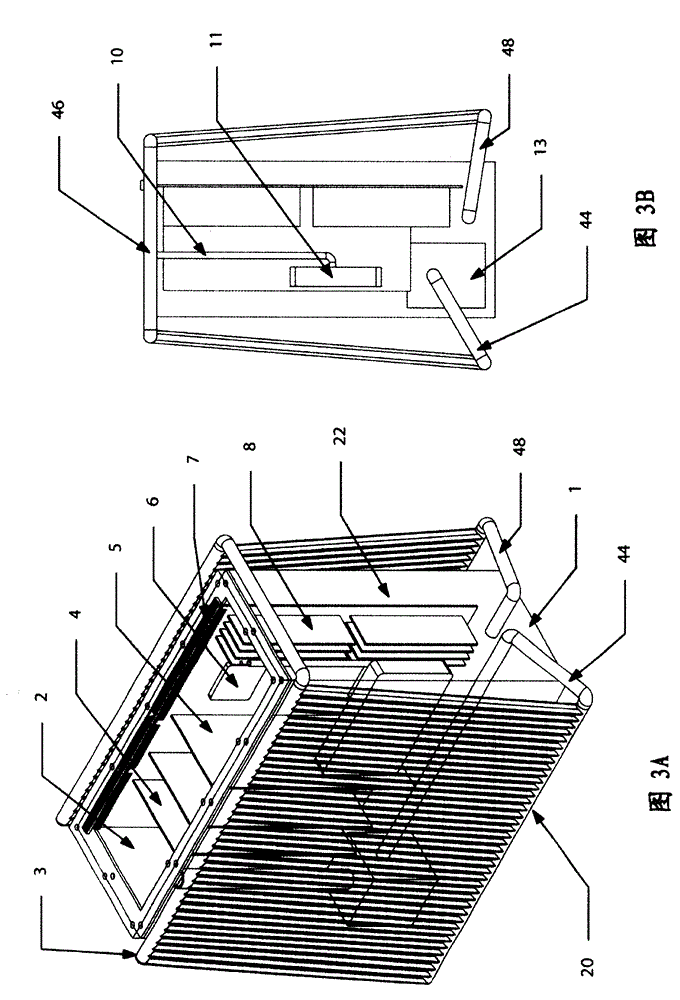

ActiveUS7064301B2Improve thermal conductivityIncrease valueAir-treating devicesOhmic-resistance electrodesEngineeringElectron heating

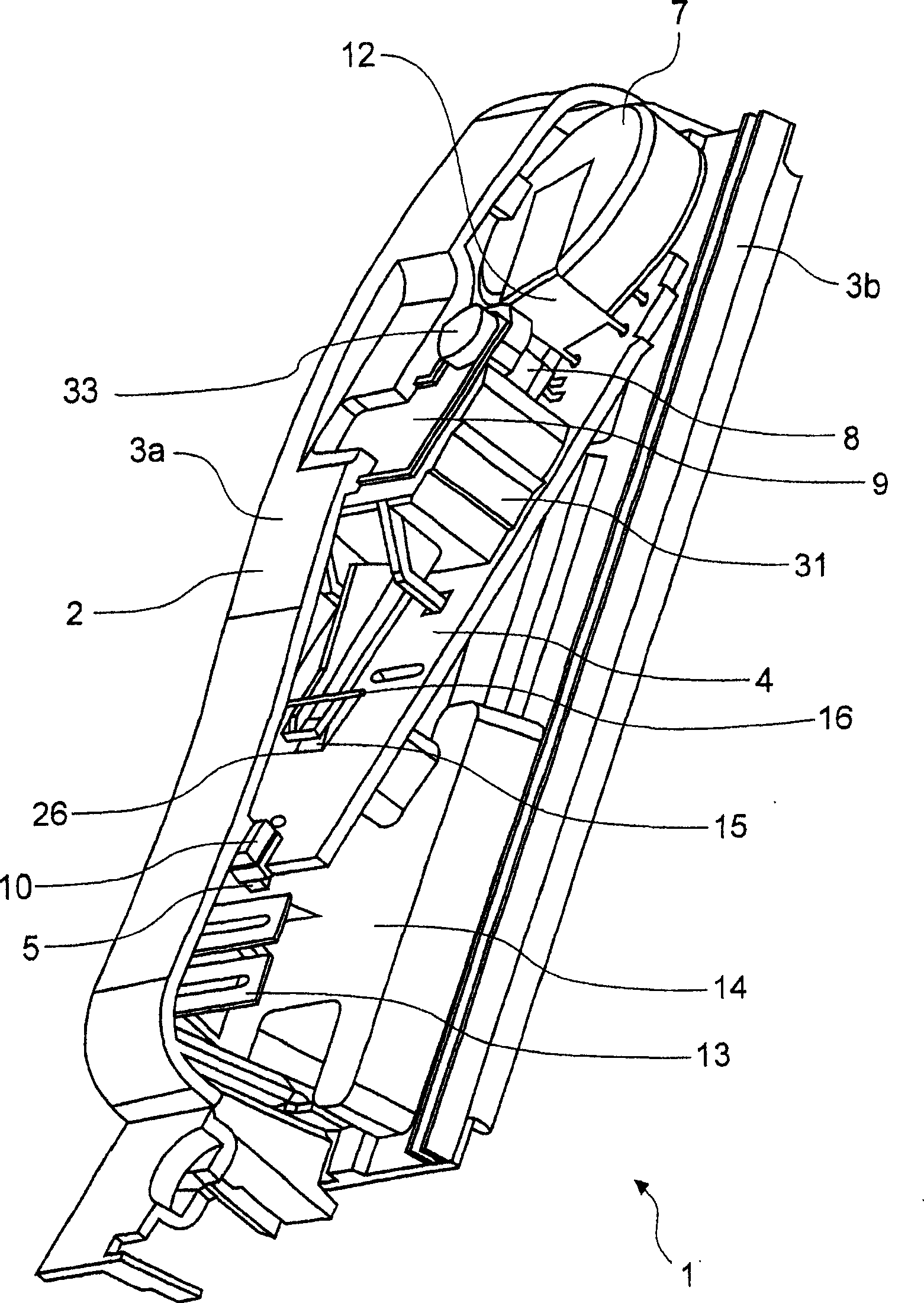

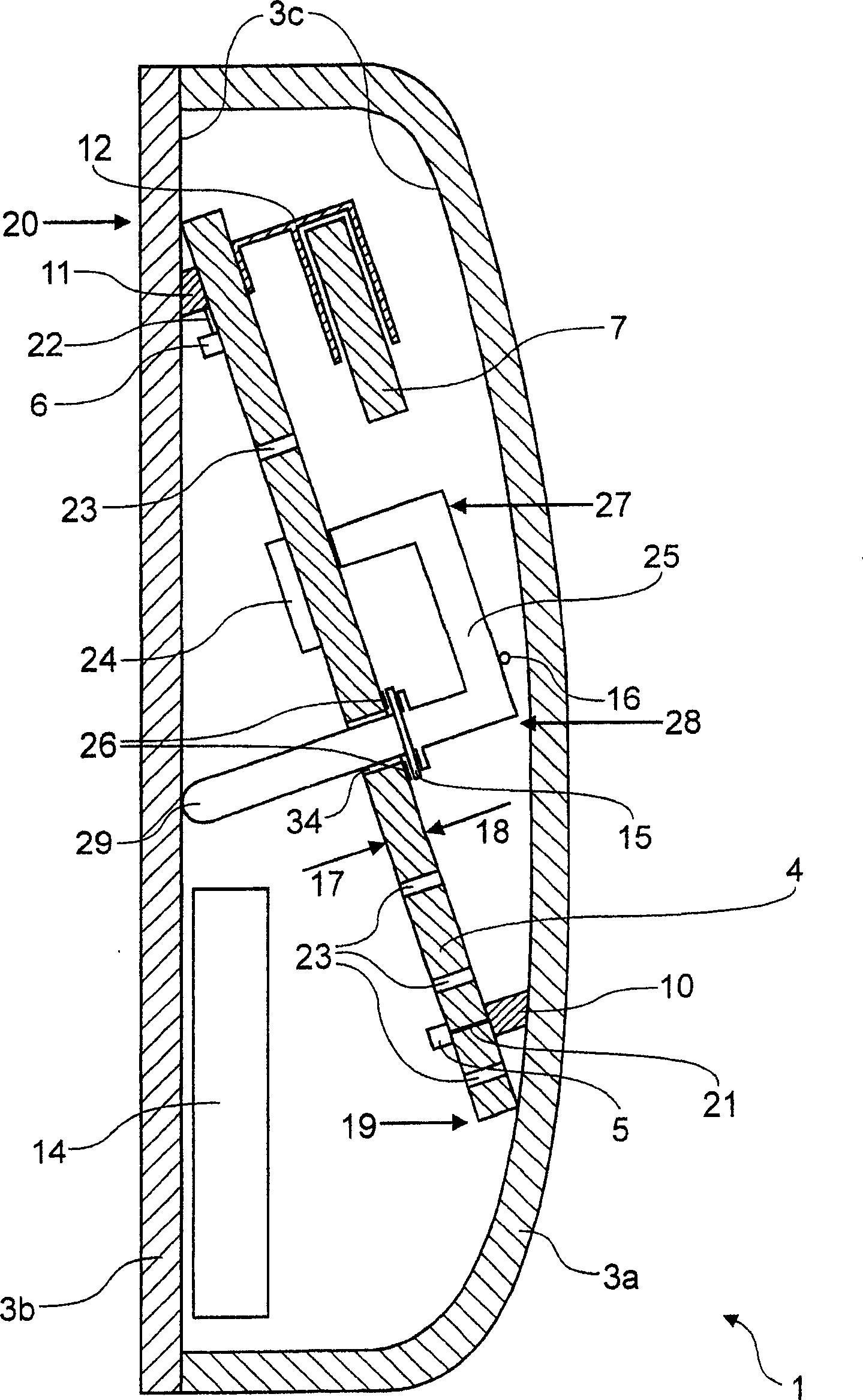

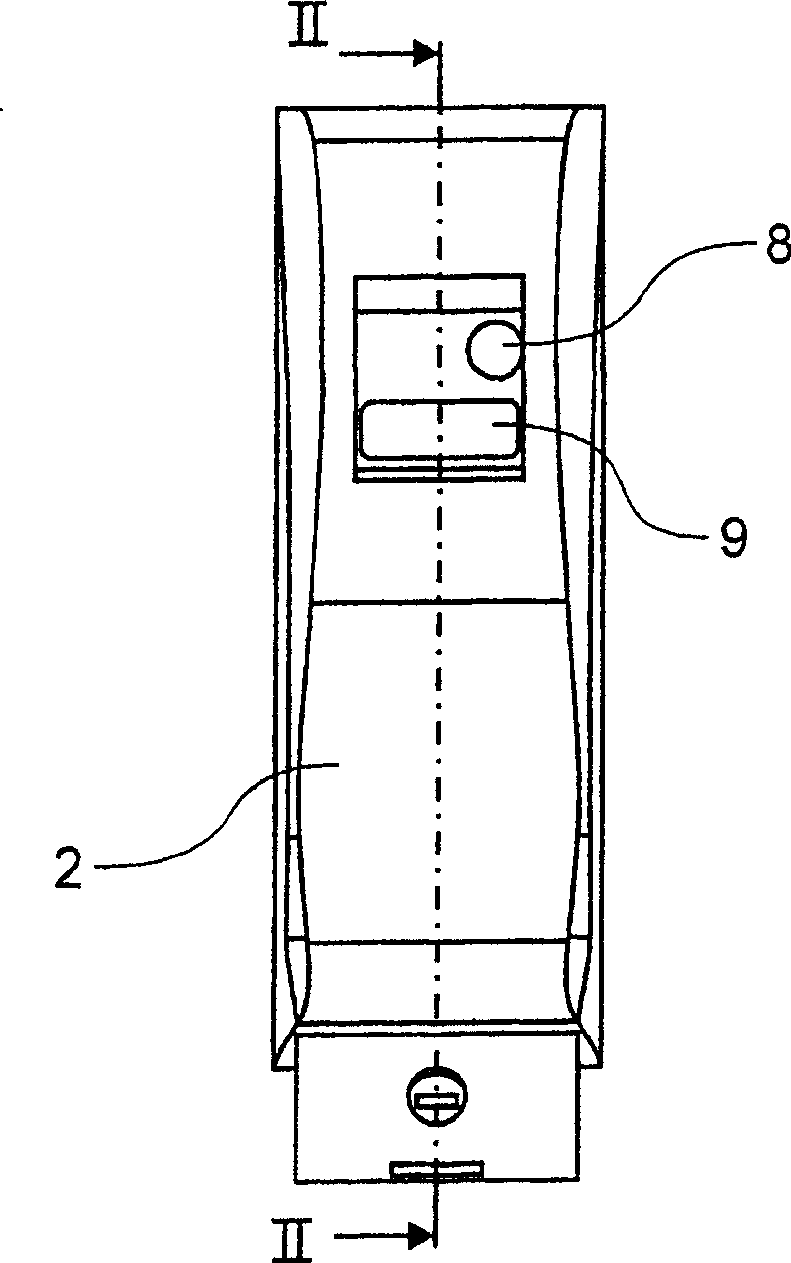

The present invention relates to an electric heater, which electrically and mechanically protects heating means from the outside, increases heating value and thermal conductivity by increasing contact efficiency among components, and improves assembly efficiency and productivity. The electric heater includes: a plurality of radiation members, each having a radiation fin and a radiation fin supporting plate surrounding the radiation fin and formed integrally with the radiation fin by brazing; a plurality of flat tubes arranged between the radiation members and having heating means therein for generating heat when electric power is supplied; first and second support frames oppositely arranged at sides of the outermost radiation members for supporting and fixing the radiation members and the flat tubes; and first and second caps for supporting both end portions of the first and second support frames and both end portions of the flat tubes.

Owner:JAHWA ELECTRONICS +1

Electric heater

ActiveUS20050205552A1Increase heat valueImprove thermal conductivityAir-treating devicesOhmic-resistance electrodesEngineeringElectron heating

The present invention relates to an electric heater, which electrically and mechanically protects heating means from the outside, increases heating value and thermal conductivity by increasing contact efficiency among components, and improves assembly efficiency and productivity. The electric heater includes: a plurality of radiation members, each having a radiation fin and a radiation fin supporting plate surrounding the radiation fin and formed integrally with the radiation fin by brazing; a plurality of flat tubes arranged between the radiation members and having heating means therein for generating heat when electric power is supplied; first and second support frames oppositely arranged at sides of the outermost radiation members for supporting and fixing the radiation members and the flat tubes; and first and second caps for supporting both end portions of the first and second support frames and both end portions of the flat tubes.

Owner:JAHWA ELECTRONICS +1

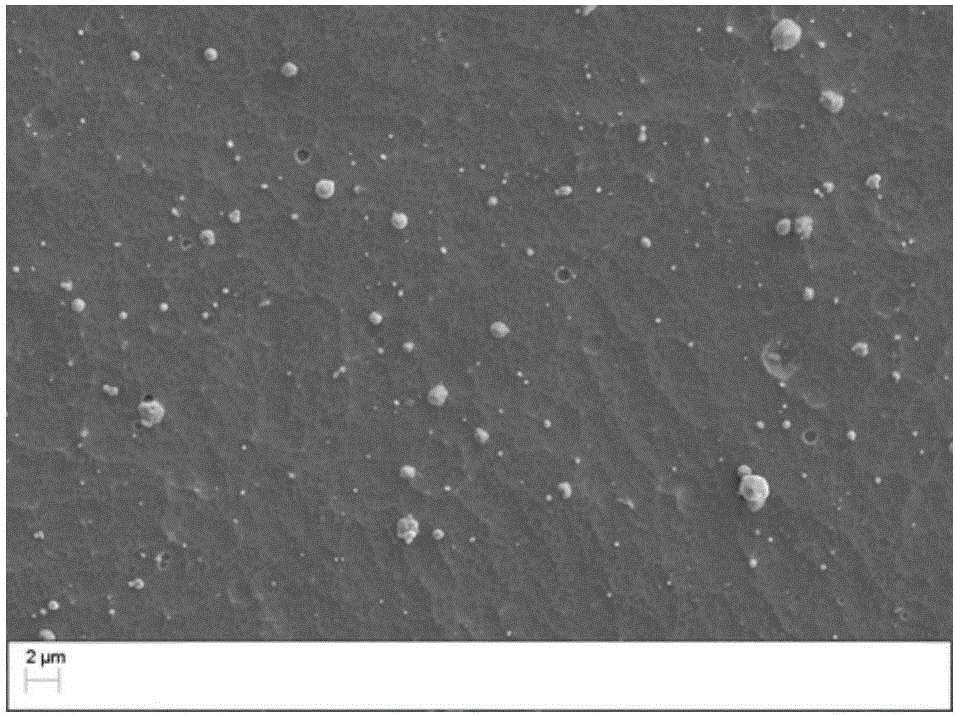

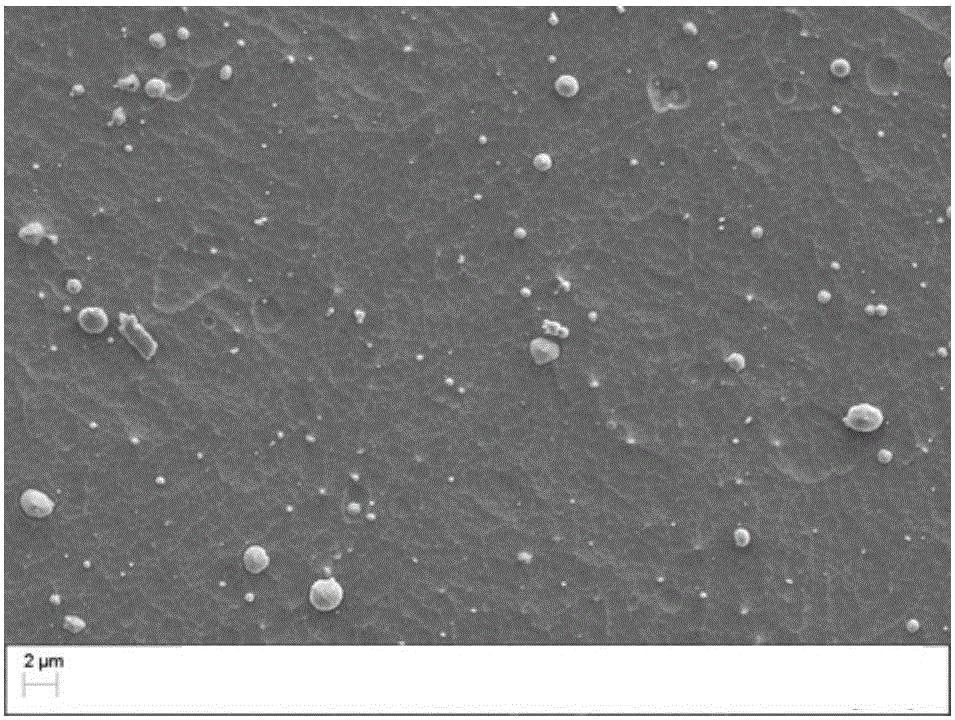

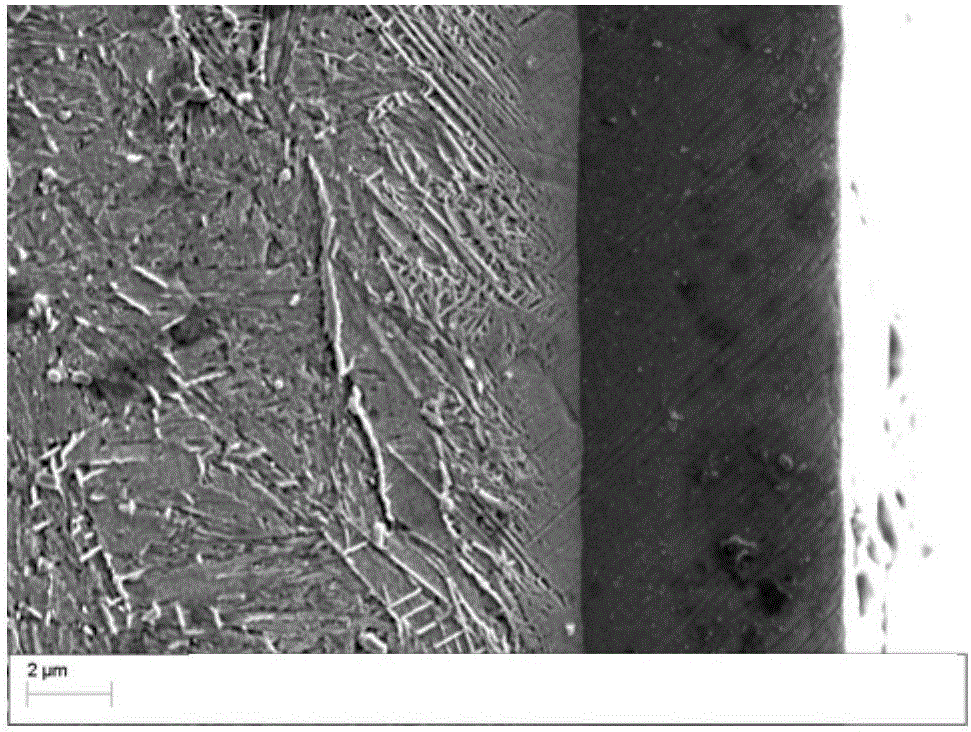

Integrated composite treatment method for in-situ PVD film coating after alloy steel surface nitriding

InactiveCN106399930AEfficient removalPlay a role in preprocessingVacuum evaporation coatingSputtering coatingMetallurgyElectron heating

The invention discloses an integrated composite treatment method for in-situ PVD film coating after alloy steel surface nitriding. Firstly, a matrix is ground, polished and subjected to ultrasonic cleaning, and then the surface of the matrix is subjected to plasma cleaning and etching through an arc enhanced type glow discharge technology; then, ion nitriding treatment is performed, and a nitriding layer is obtained; and finally, under the conditions of similar temperature and pressure, advanced plasma auxiliary arc film coating treatment is performed in situ, negative bias voltage is applied to the matrix, and a hard film is obtained on the nitriding layer. According to the method, due to the fact that storage and programming summarizing are performed on the same device, under the conditions of similar temperature and pressure, a PN-PVD composite treatment process is integrally performed, high-density plasma performs cleaning and etching on the matrix in the nitriding process, the nitriding speed is increased, and an electronic heating effect is also generated on the early growth stage of a film layer; and by means of the composite treatment process, the adhesiveness between a coating and the matrix is remarkably improved, the abrasion-resistant performance of the coating is improved, and the comprehensive performance of coating tools, molds and mechanical parts is effectively improved.

Owner:SOUTH CHINA UNIV OF TECH

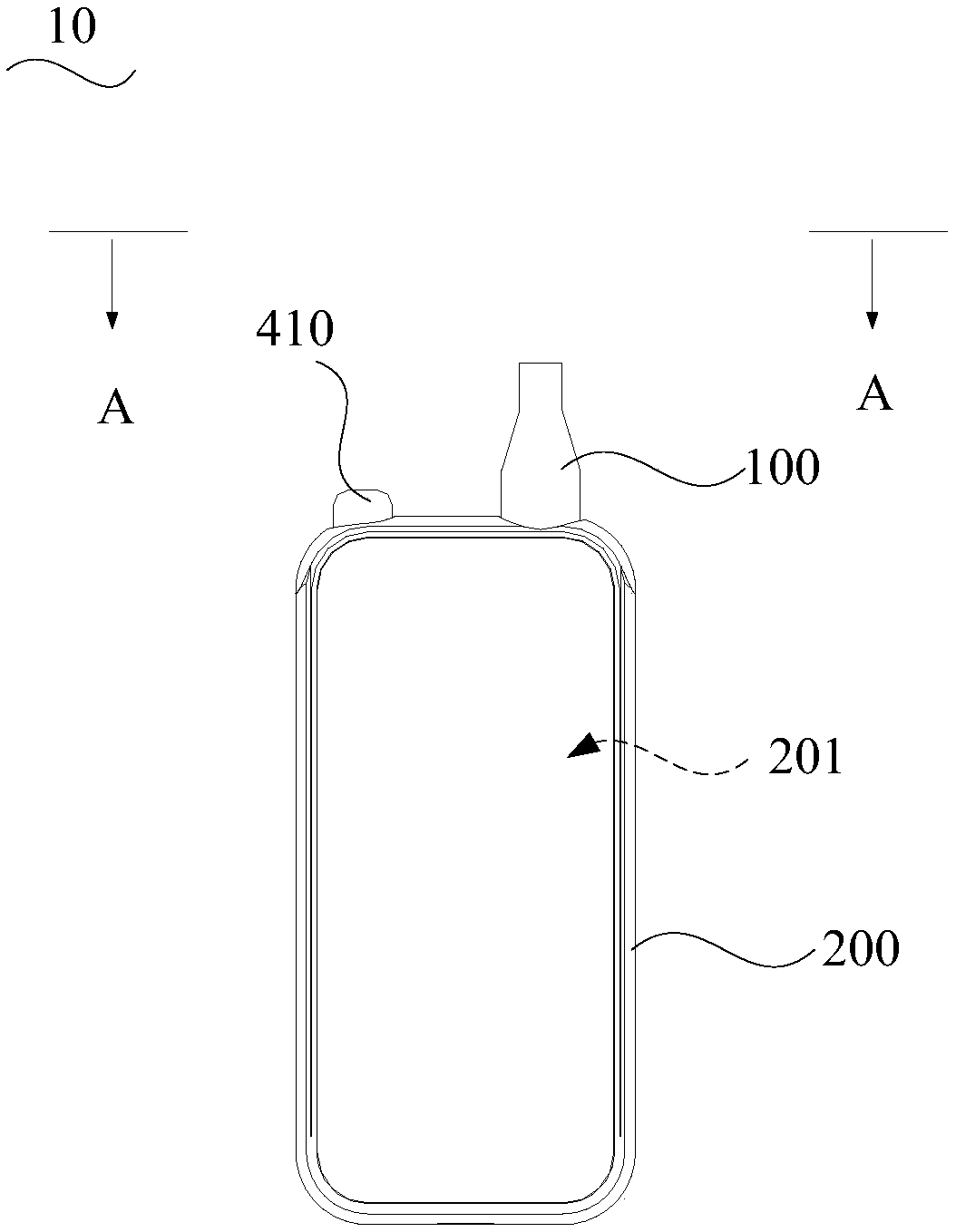

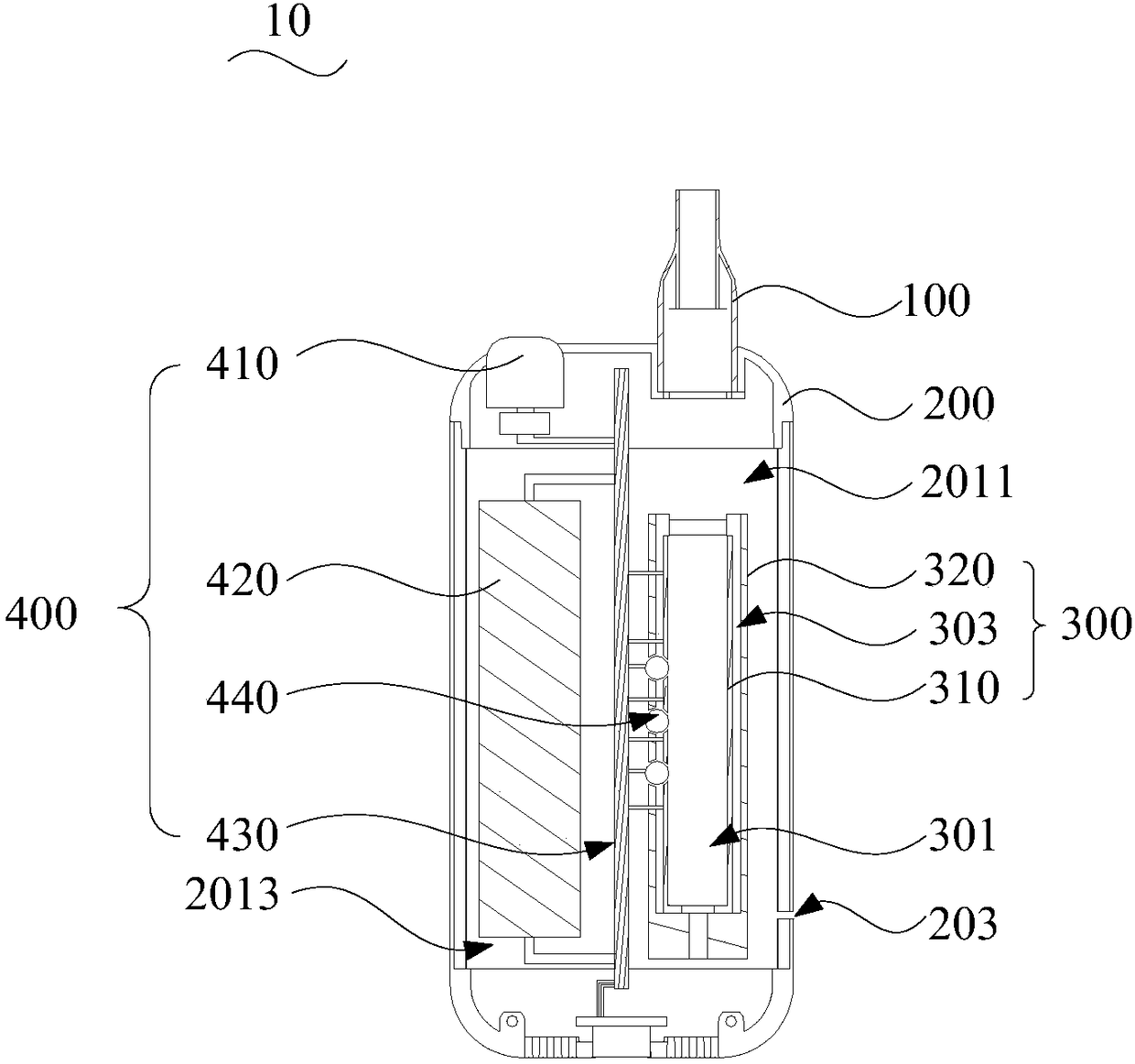

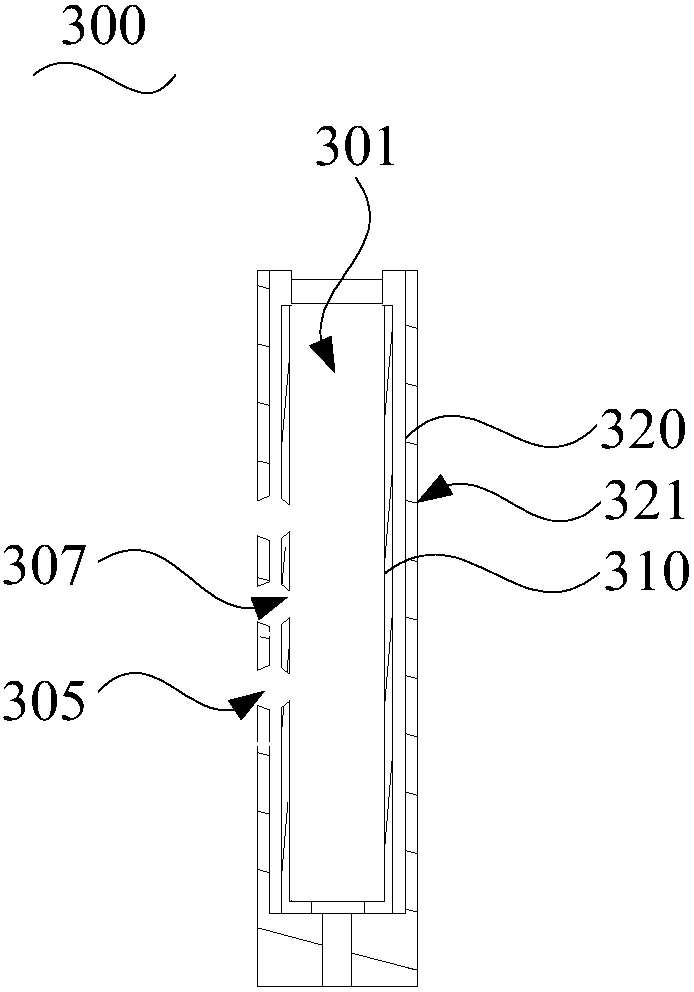

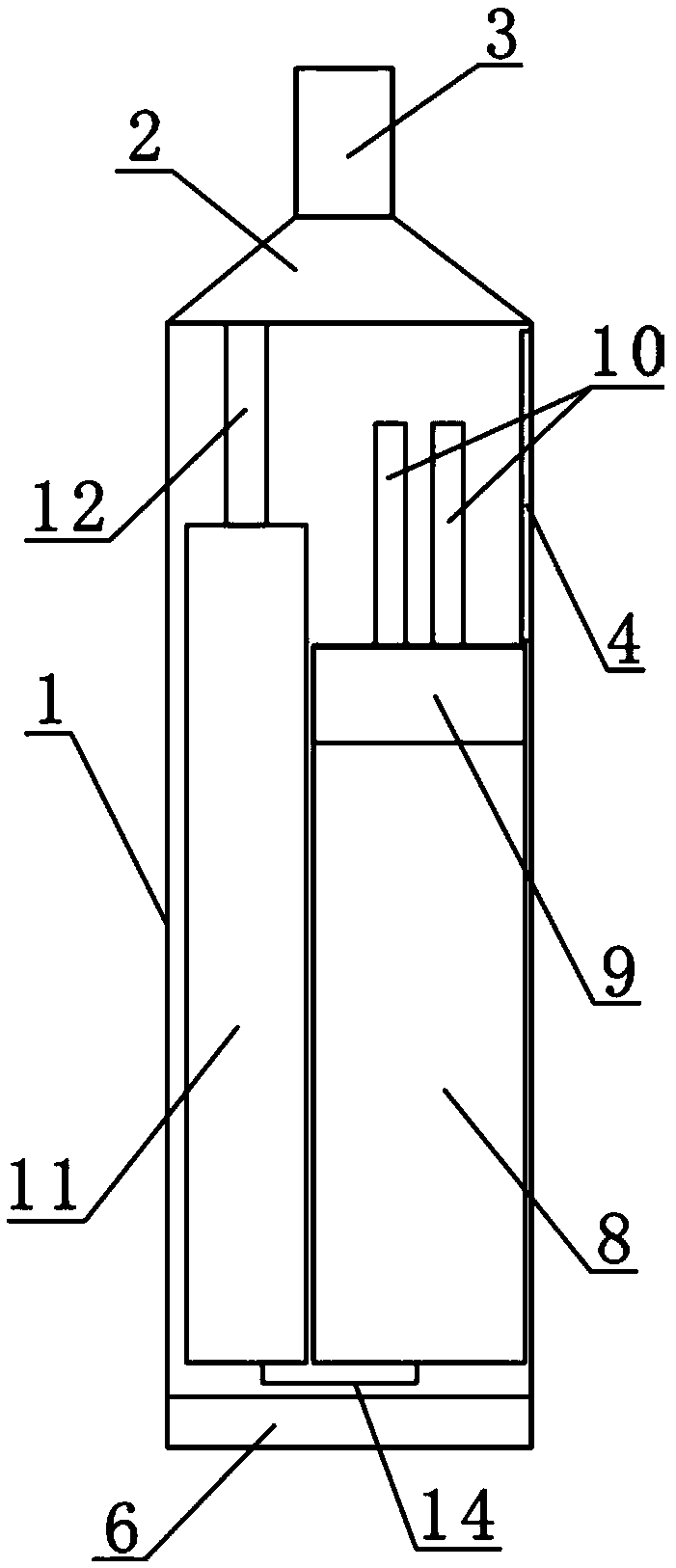

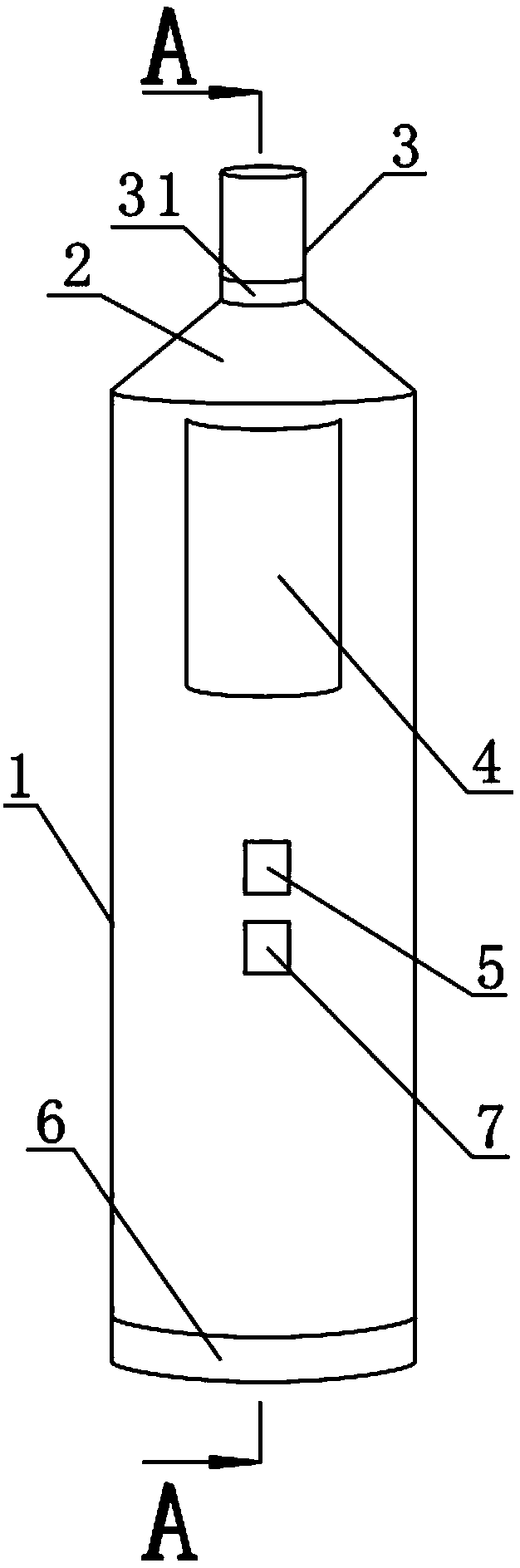

Electronic heating device

ActiveCN108208944ASimple structureGood heat insulationTobacco devicesReflecting/signal paintsCooking & bakingCold air

The invention relates to an electronic heating device, comprising a suction nozzle, a housing, a heating component and a power component. The heating component includes a heating pipe and a heat-insulating pipe; a baking cavity is arranged in the heating pipe; the wall of the heat-insulating pipe is coated with a heat-insulating coating layer; the heating pipe is sleeved with the heat-insulating pipe; a gap passage is formed between the heat-insulating pipe and the heating pipe in mutually spaced manner; the heat-insulating pipe is provided with a gas guide hole whereby a receiving cavity is communicated with the gap passage. The heat-insulating coating layer can reflect thermal radiation of the heating pipe so that heat in the baking cavity is avoided being directly transmitted to the housing. A gap is provided between the heat-insulating pipe and the heating pipe, external cold air can enter the receiving cavity from a gas inlet and may enter the gap passage via the gas guide hole, and the temperature of the heating pipe and the heat-insulating pipe is reduced during suction. The cooling design measures such as the heat-insulating coating layer and flow promotion enable the electronic heating device is simple in structure and good in heat-insulating effect.

Owner:SHENZHEN HANGSEN STAR TECH

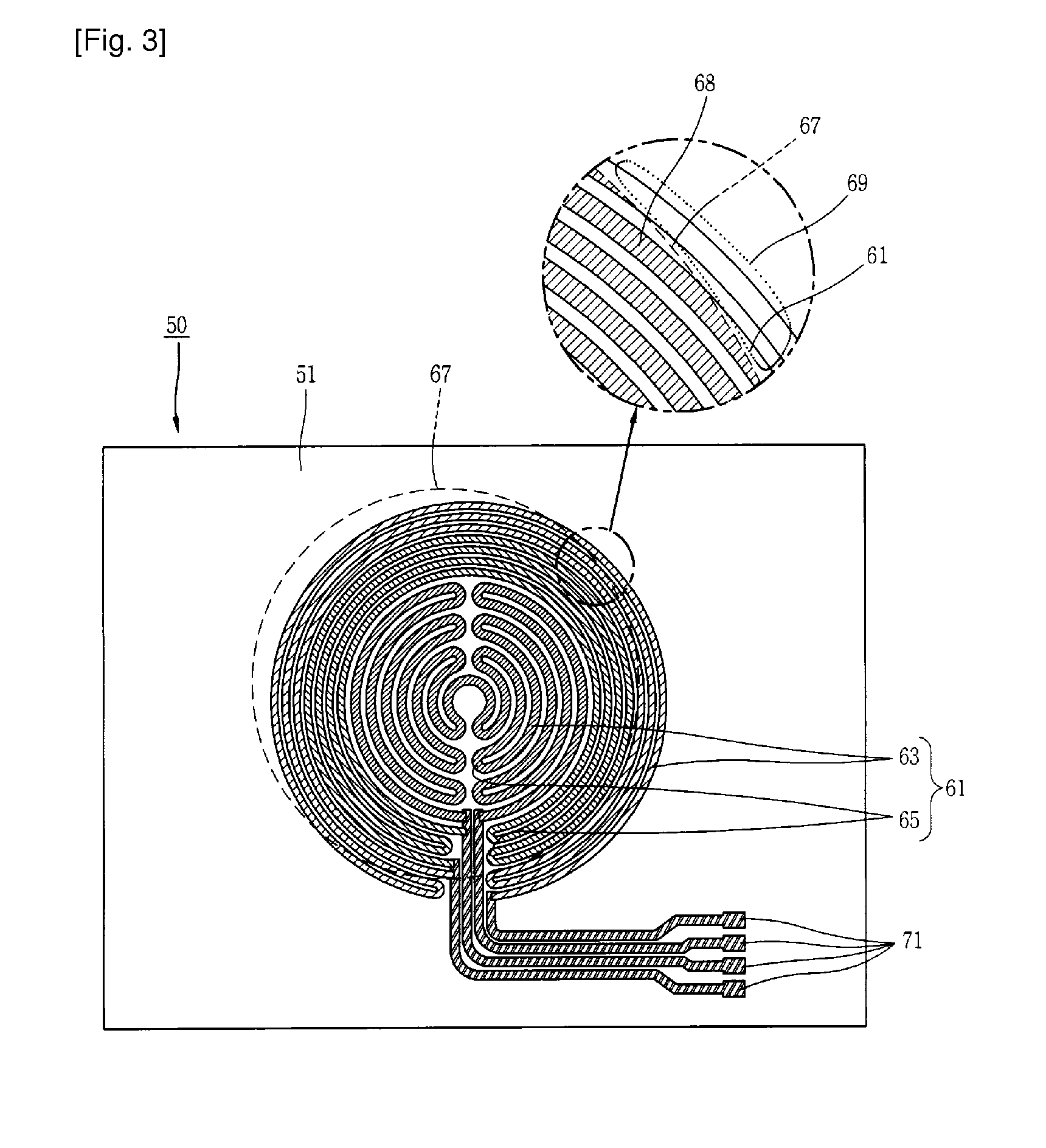

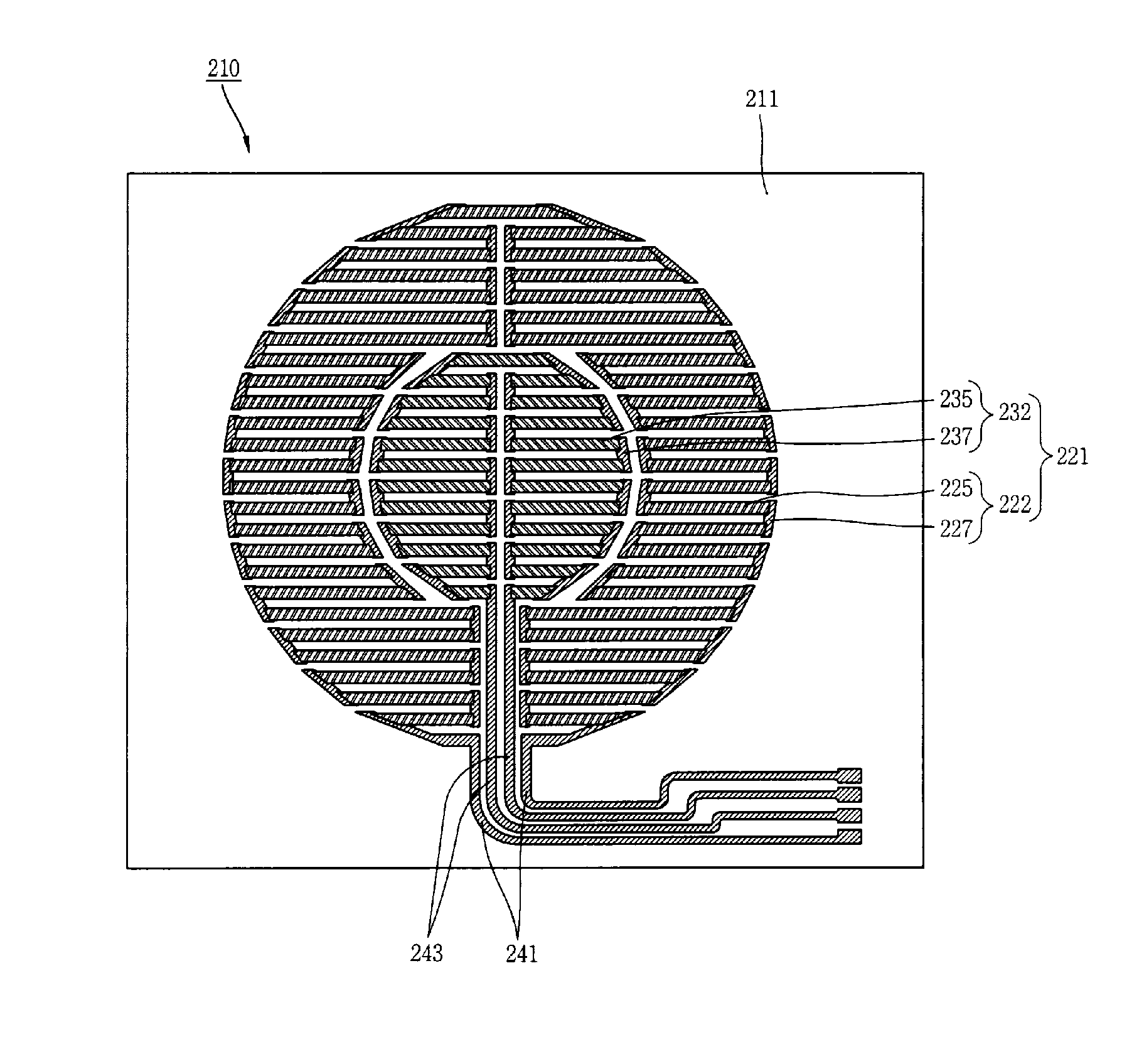

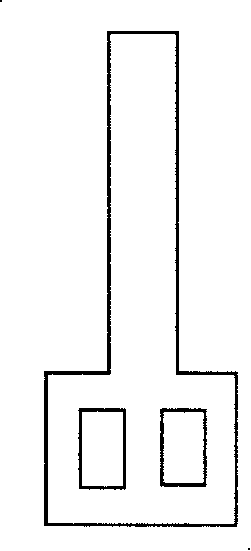

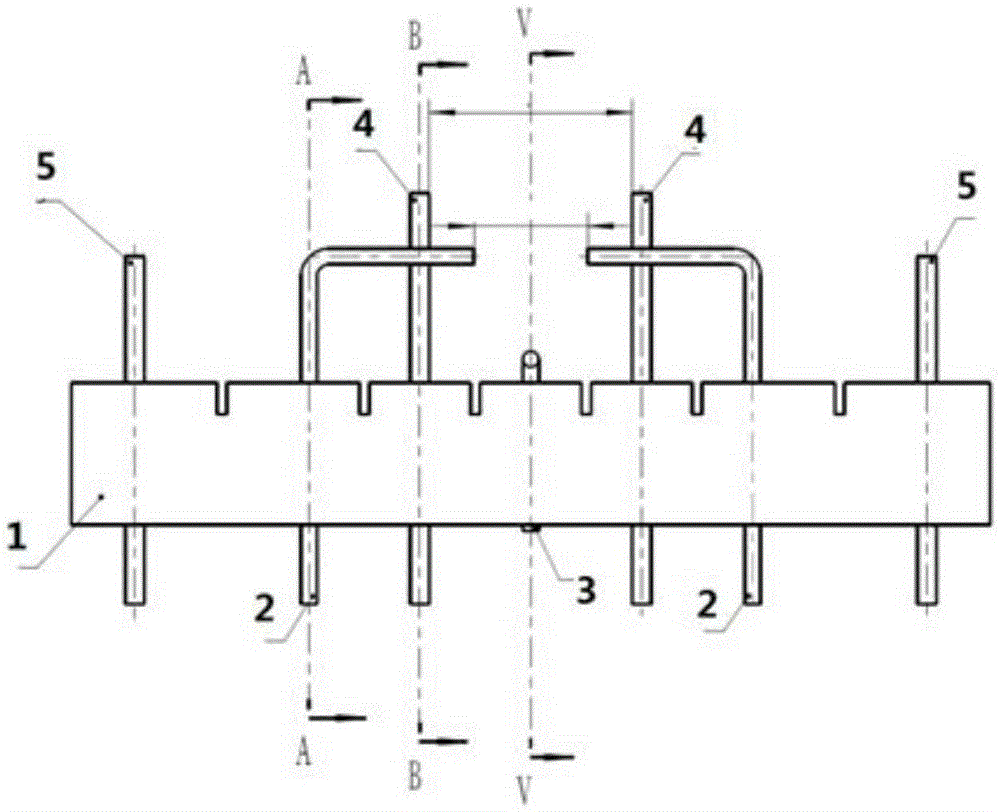

Electric heater

ActiveUS20100193502A1Avoid damageIncrease productionHeater elementsHot plates heating arrangementsStress concentrationElectron heating

Disclosed is the electric heater including a base, and a heating unit having a plurality of unit heating elements disposed on a plate surface of the base and at least one of heating connection portions configured to heat and conductively connecting the unit heating elements to each other and non-heating connection portions configured not to heat and conductively connecting the unit heating elements to each other, thereby preventing a thermal stress concentration, thus to prevent damage to the heating unit and to enhance its output.

Owner:LG ELECTRONICS INC

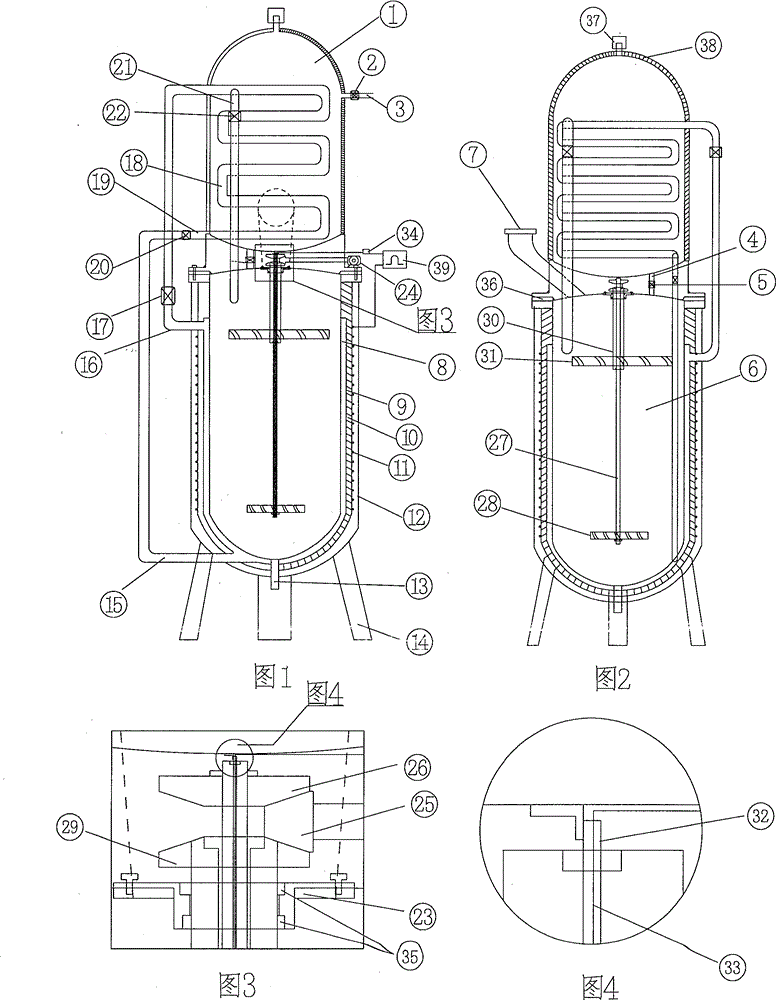

Fluid heating stirring equipment

ActiveCN104437165ARotary stirring mixersTransportation and packagingPlate heat exchangerIntegrated operations

The invention provides fluid heating stirring equipment, wherein a preheating container tank is arranged at the upper part of the equipment, a heat exchanger is arranged in the container, and a solution enters a reaction kettle after being heated. A dry powder feed opening is arranged on the upper side of the reaction kettle. A concentric and non-coaxial a thermocouple stirrer capable of being used for reversely shearing and stirring and capable of being installed for measuring the internal bottom temperature is arranged at the center. The reaction kettle is designed as an interlayer container, heat transfer oil in the interlayer is heated by a peripheral electromagnetic heating device, when raw materials in the reaction kettle are fully sheared and stirred by the stirrer to reach a set temperature, an electromagnetic heater automatically stops heating, at the time, a booster pump is started to pump the heat transfer oil into the heat exchanger of the preheating container to exchange the heat of the raw materials into the preheated solution, in order to preheat the solution and cool the raw materials. Then, a discharge pipe at the bottom of the reaction kettle is opened to discharge, and the work is finished. Since an electronic heating temperature control device and integrated operation technology of reverse shearing and stirring and afterheat utilization are adopted, the working efficiency and the product quality are greatly improved, and effects of safe production, environmental friendliness and energy conservation are achieved.

Owner:黎亚文

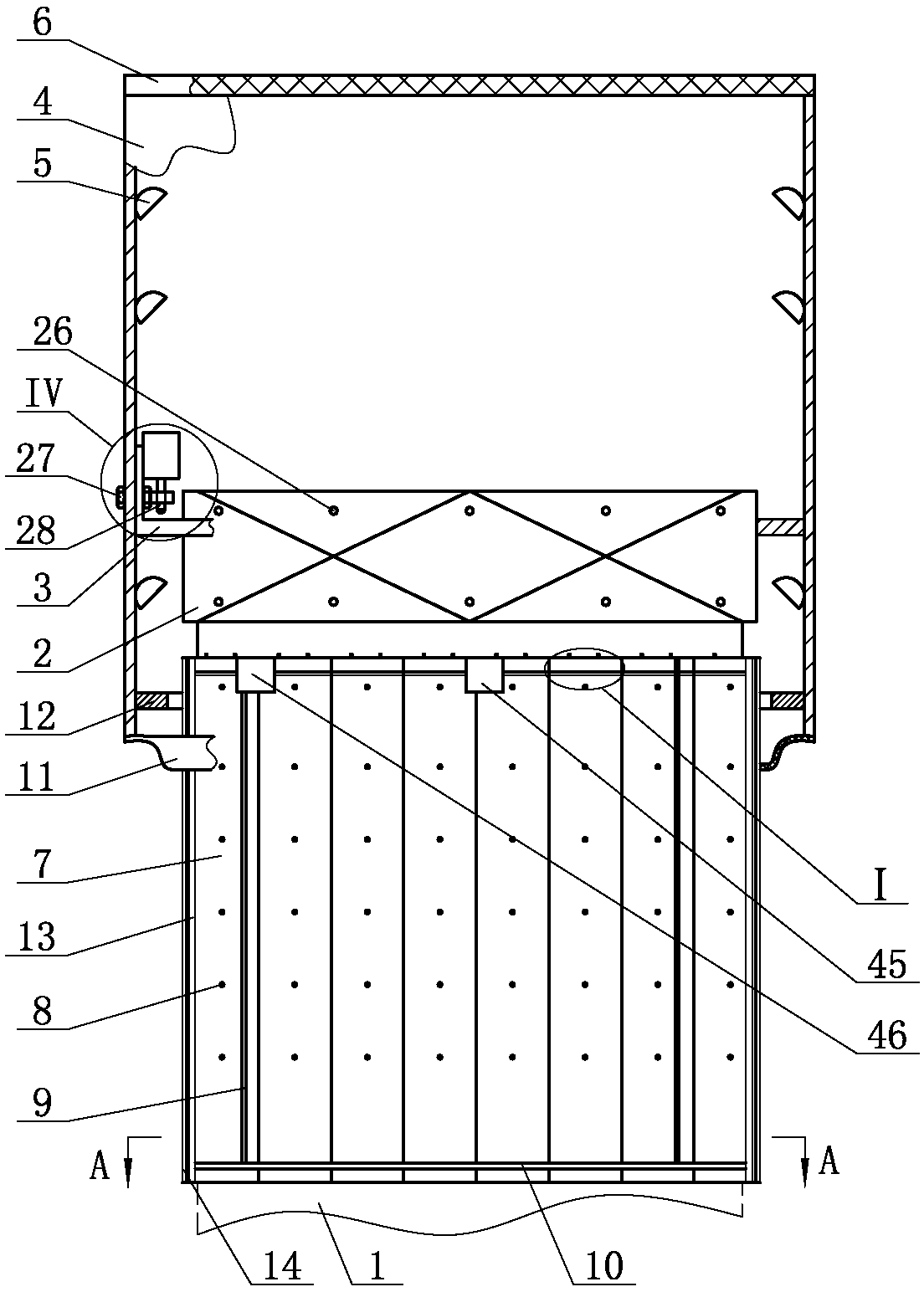

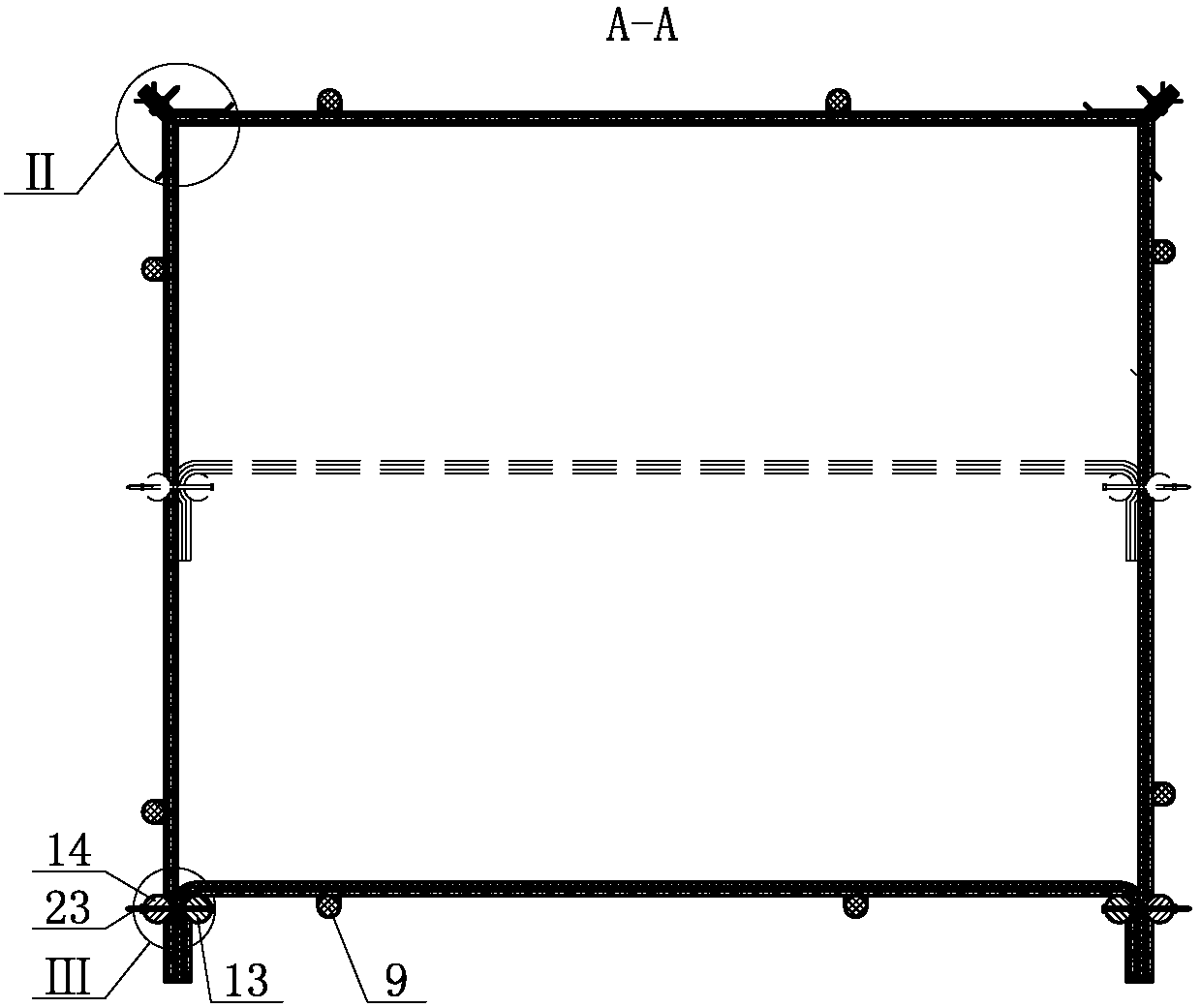

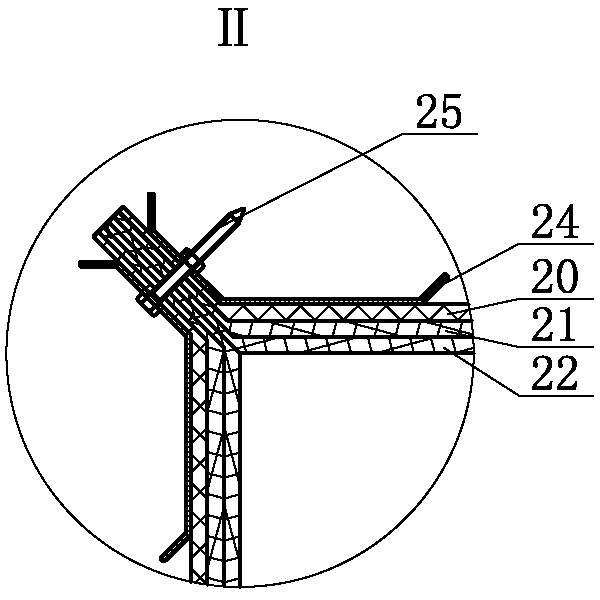

Digital constant-temperature control concrete ultra-low-temperature construction maintenance system

InactiveCN103074852AAvoid getting lostEnsure normal coagulationBridge erection/assemblyData acquisitionSteel frame

The invention discloses a digital constant-temperature control concrete ultra-low-temperature construction maintenance system, which comprises a sliding template, a data collecting device, a wireless transmission device and a heating control device, wherein a heat insulation shed is arranged on the outer periphery of the sliding template, a steel plate hanging frame is arranged at the lower part of the sliding template, four electronic heating quilts are suspended on the steel frame hanging frame, the four electronic heating quilts are surrounded into a barrel-shaped sealing head insulation cover, each electronic heating quilt is respectively and sequentially formed by connecting a high-intensity glass fiber layer, a heat tape and a heat insulation cotton layer from inside to outside, a plurality of temperature sensors are arranged on each electronic heating quilt, and all temperature sensors and heat tapes are respectively connected with the data collecting device, the wireless transmission device and the heating control device. Good heating and heat insulation effects can be realized, and the heat loss during the concrete casting can be effectively prevented. When the environment temperature is minus 30 DEG C, the temperature on the surface of the concrete can be enabled to be higher than 5 DEG C, so the cold damage and the crack occurrence on the surface of the concrete can be prevented, and the casting quality of bridge piers can be ensured.

Owner:山东黄河工程集团有限公司

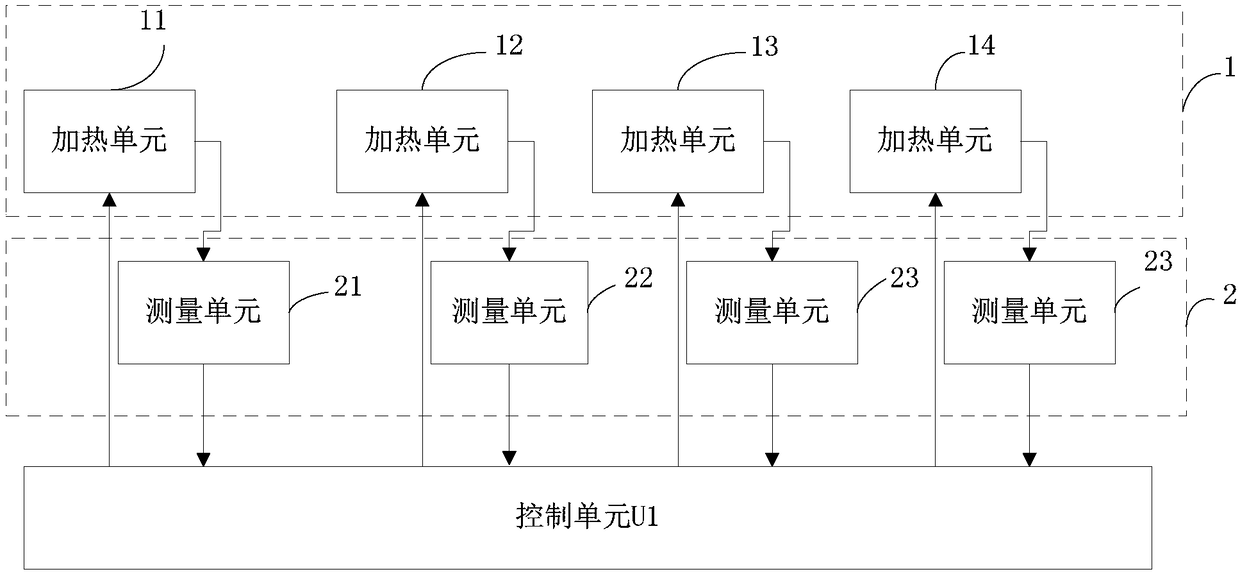

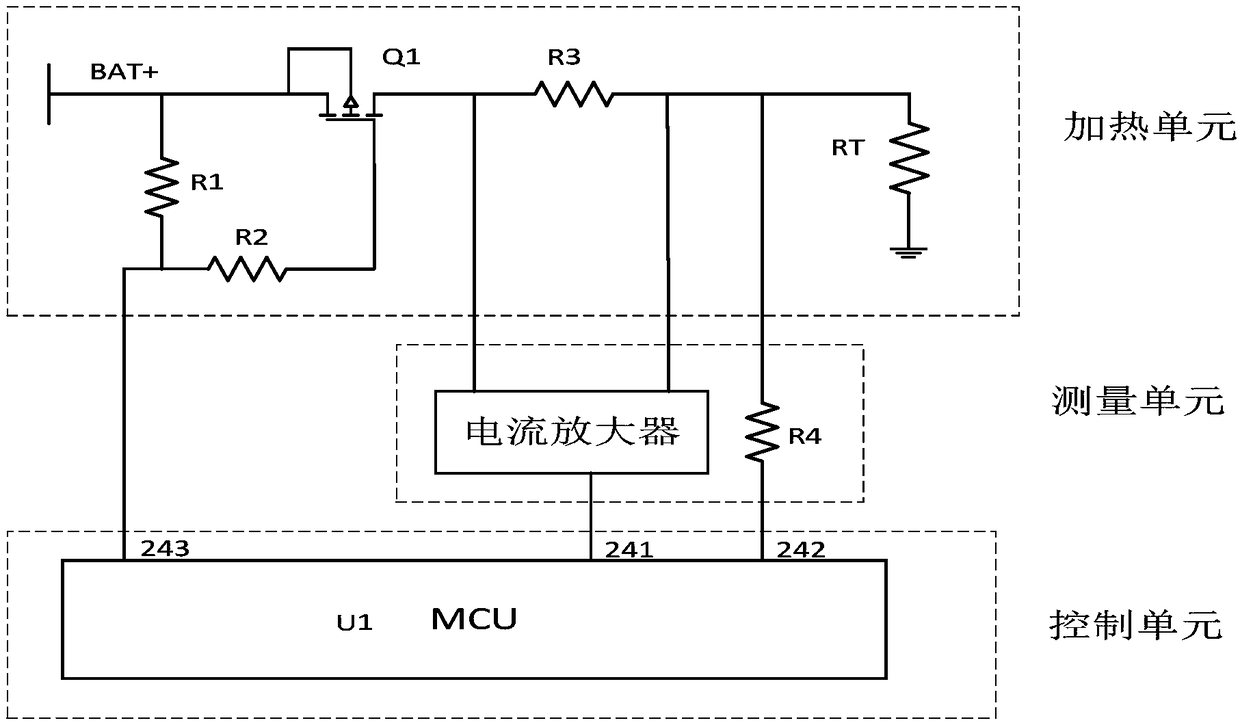

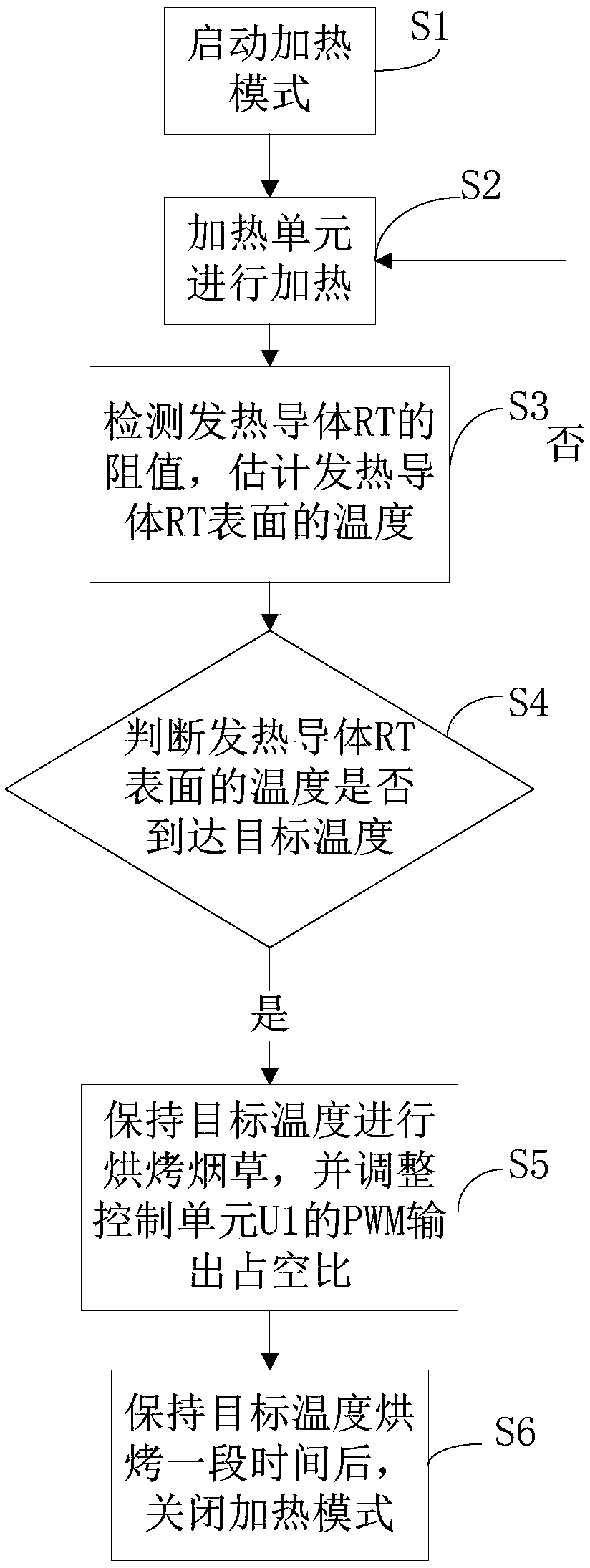

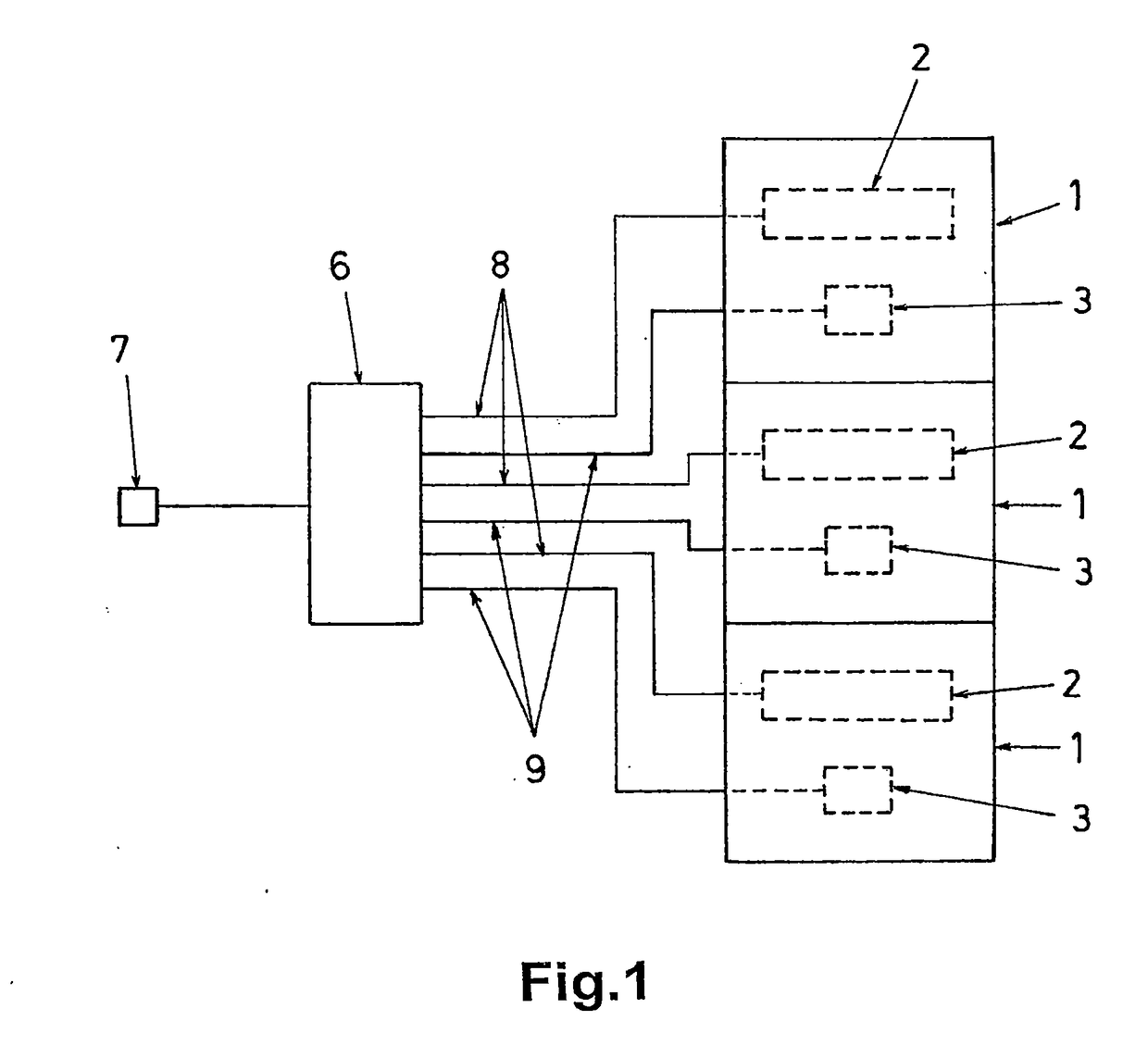

Electronic heating device and heating method

PendingCN108770084ARealize direct baking heatingSmooth releaseTobacco devicesOhmic-resistance heatingCooking & bakingPower flow

The present invention relates to an electronic heating device and a heating method. The device comprises a control unit U1, a plurality of heating modules and a plurality of measuring modules. The control unit U1 is used for outputting control signal(s) to drive the heating modules to work or shut down. The heating modules are used for heating a cigarette. The measuring modules are used for collecting voltage information and current information of the heating modules and converting the voltage(s) and the current(s) into resistance information to transmit into the control unit U1, so that the control unit U1 can adjust the control signal(s) and keep the voltage(s) and the current(s) within an allowable range of the control unit U1 when the heating modules work. According to the device, by providing the heating modules and the measuring modules, the control unit can control the heating temperature of the heating modules to a target temperature according to the data transmitted by the measuring modules, the direct heating and baking on the ordinary cigarette is realized, smoke is uniformly released, the heating modules are arranged at intervals around the cigarette, so that the bakingis more sufficient, the release of the cigarette smoke is more uniform, and the energy is saved.

Owner:SHENZHEN HANGSEN STAR TECH

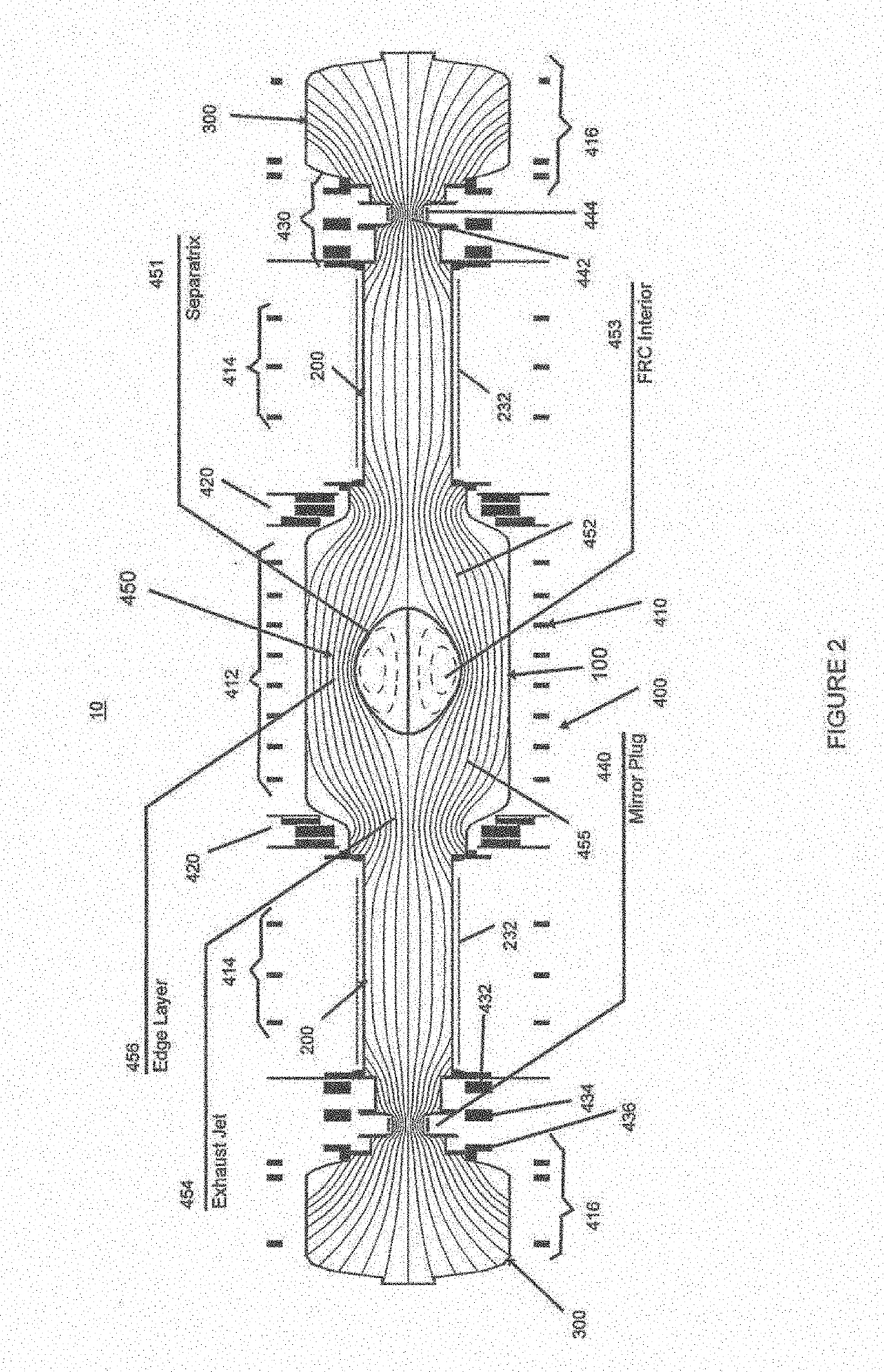

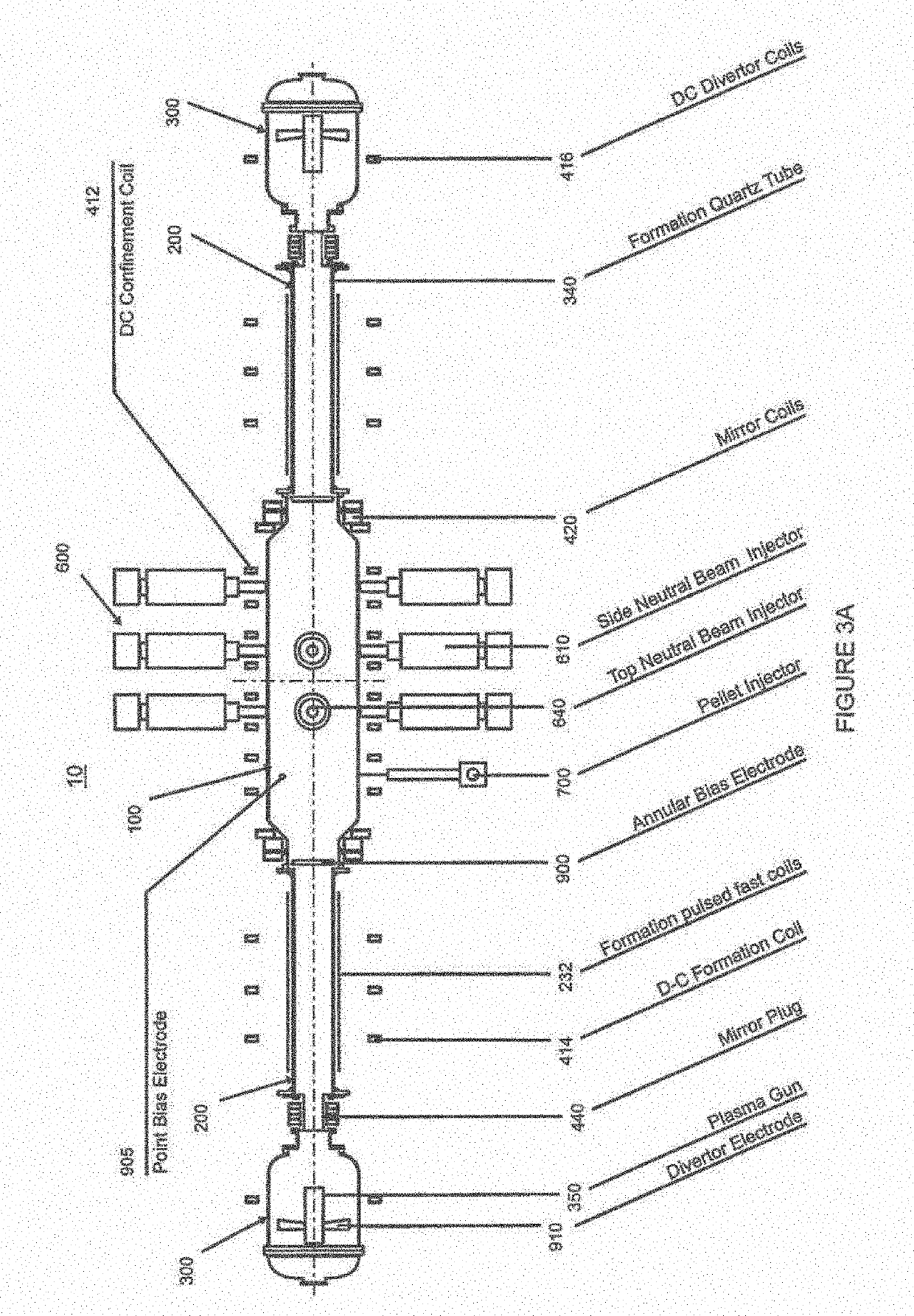

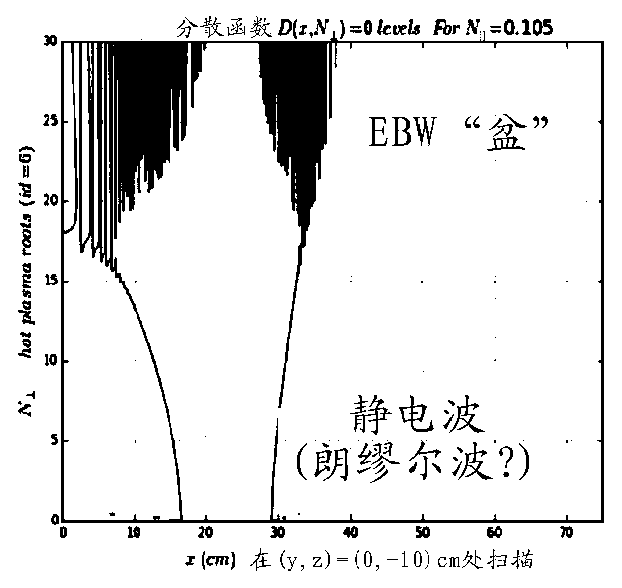

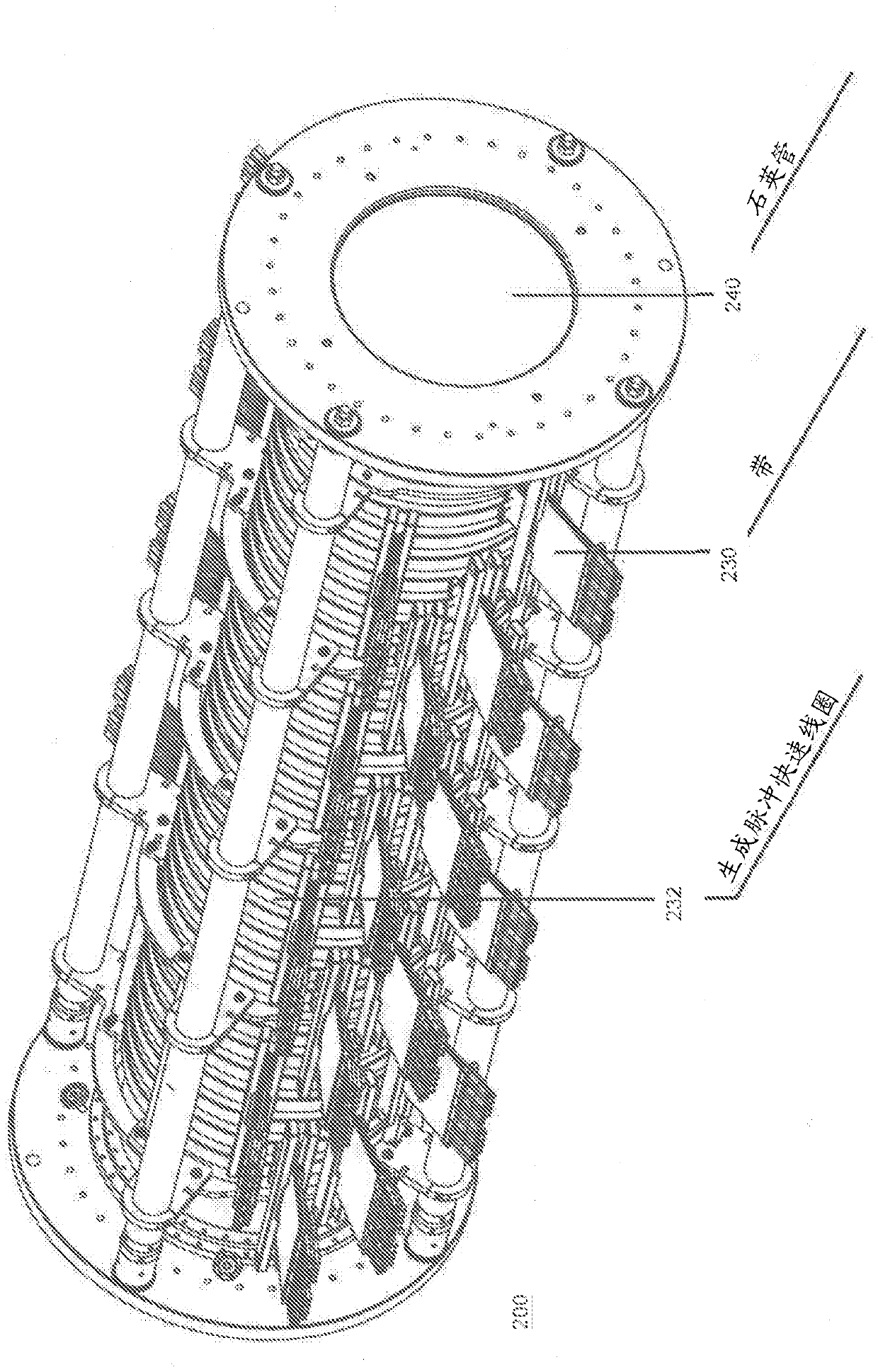

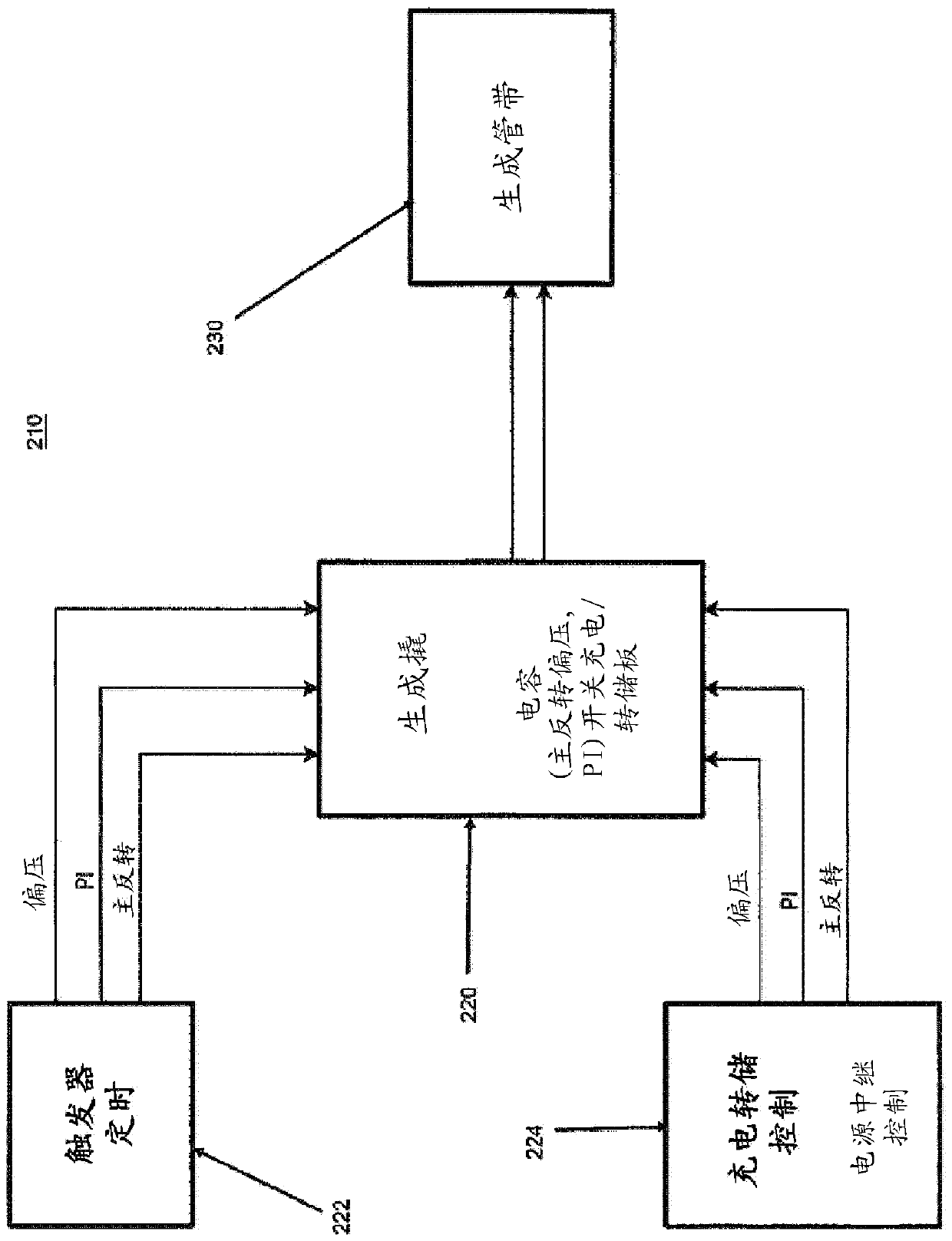

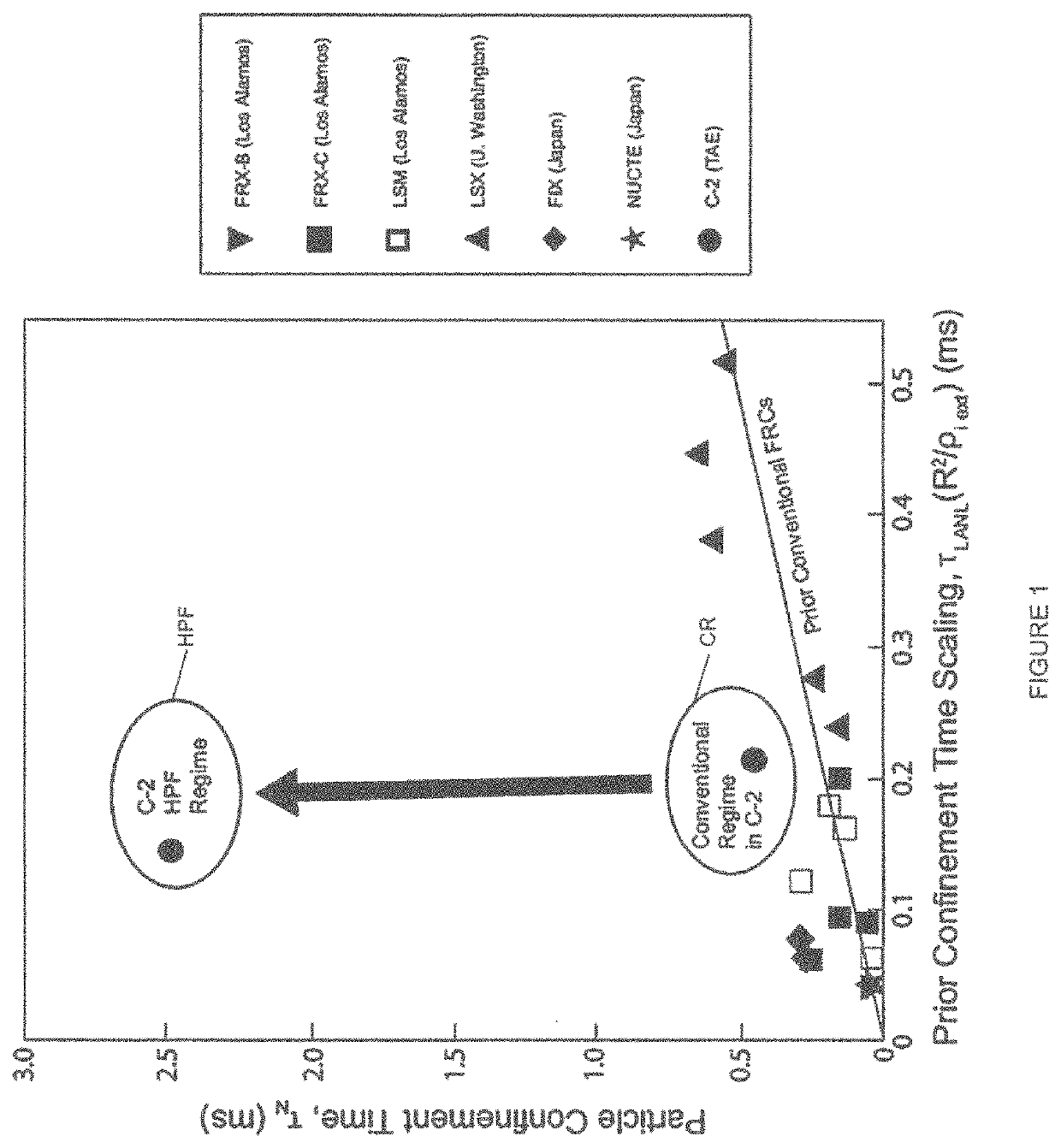

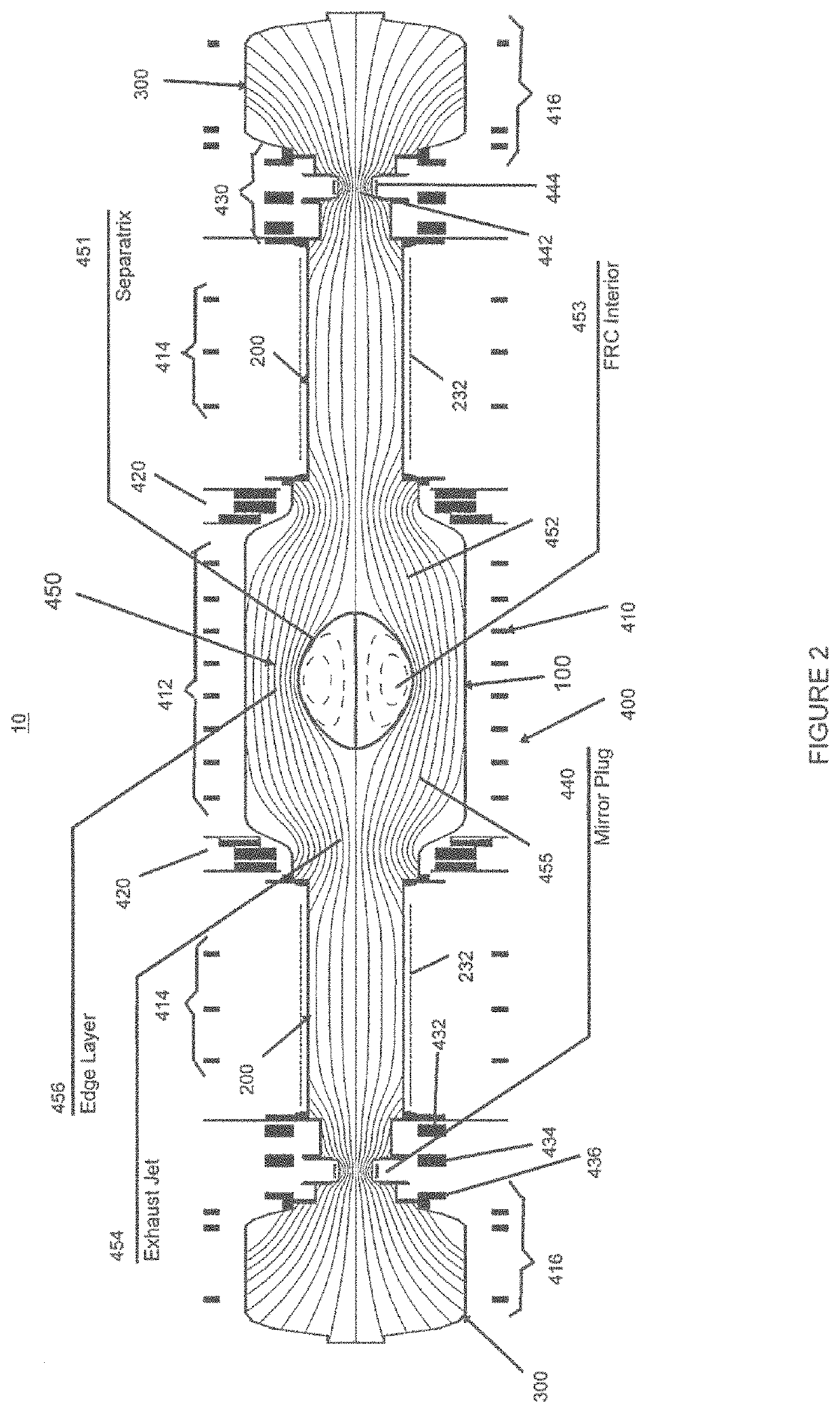

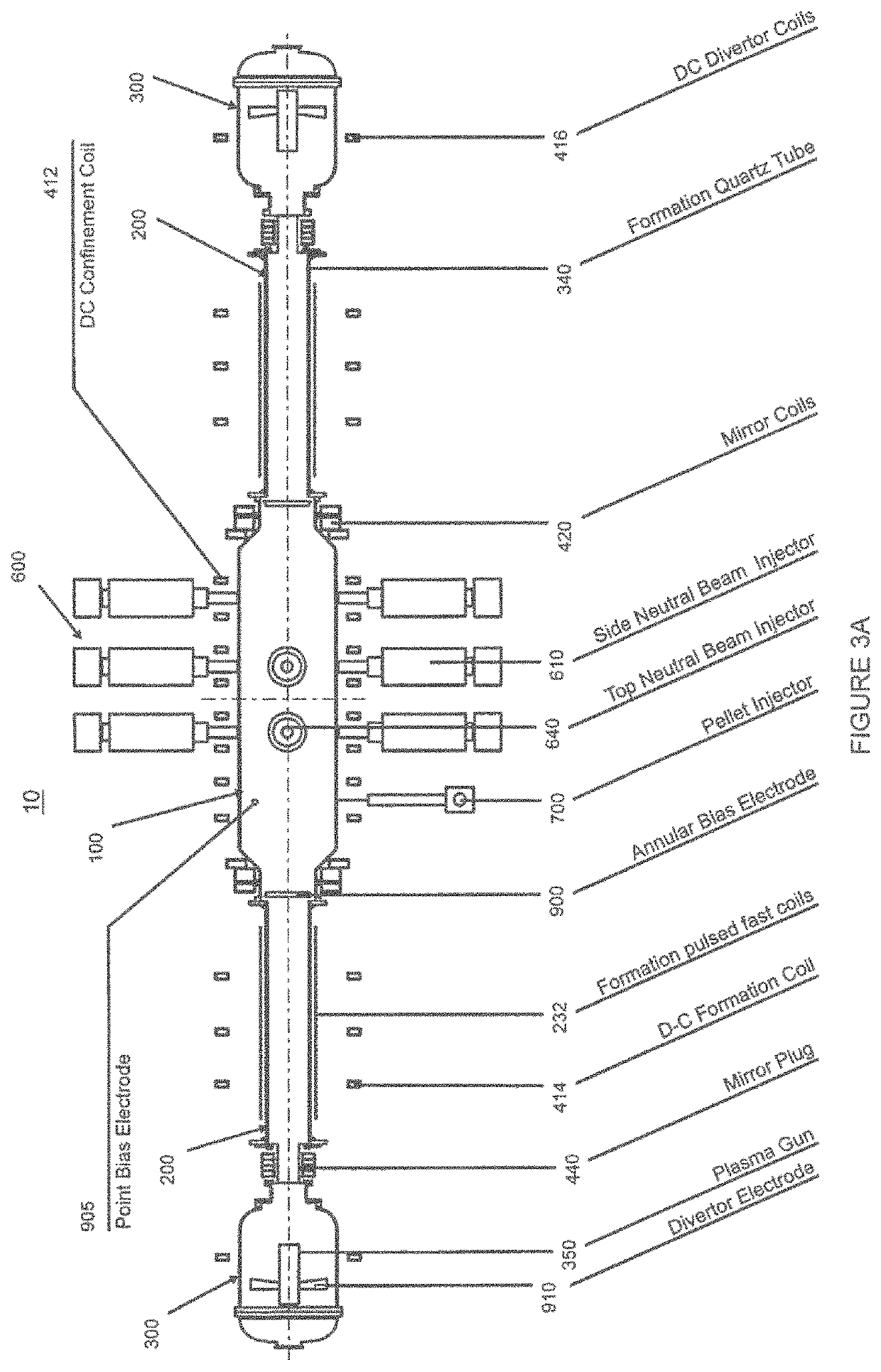

Systems and methods for improved sustainment of a high performance frc and high harmonic fast wave electron heating in a high performance frc

ActiveUS20190326023A1Reduces fast ion charge-exchange lossImproves plasma confinementNuclear energy generationPlasma techniqueHarmonicElectron heating

Systems and methods that facilitate forming and maintaining FRCs with superior stability as well as particle, energy and flux confinement and, more particularly, systems and methods that facilitate forming and maintaining FRCs with elevated system energies and improved sustainment utilizing neutral beam injection and high harmonic fast wave electron heating.

Owner:TAE TECH INC

Method for heating liquid in an electric kettle

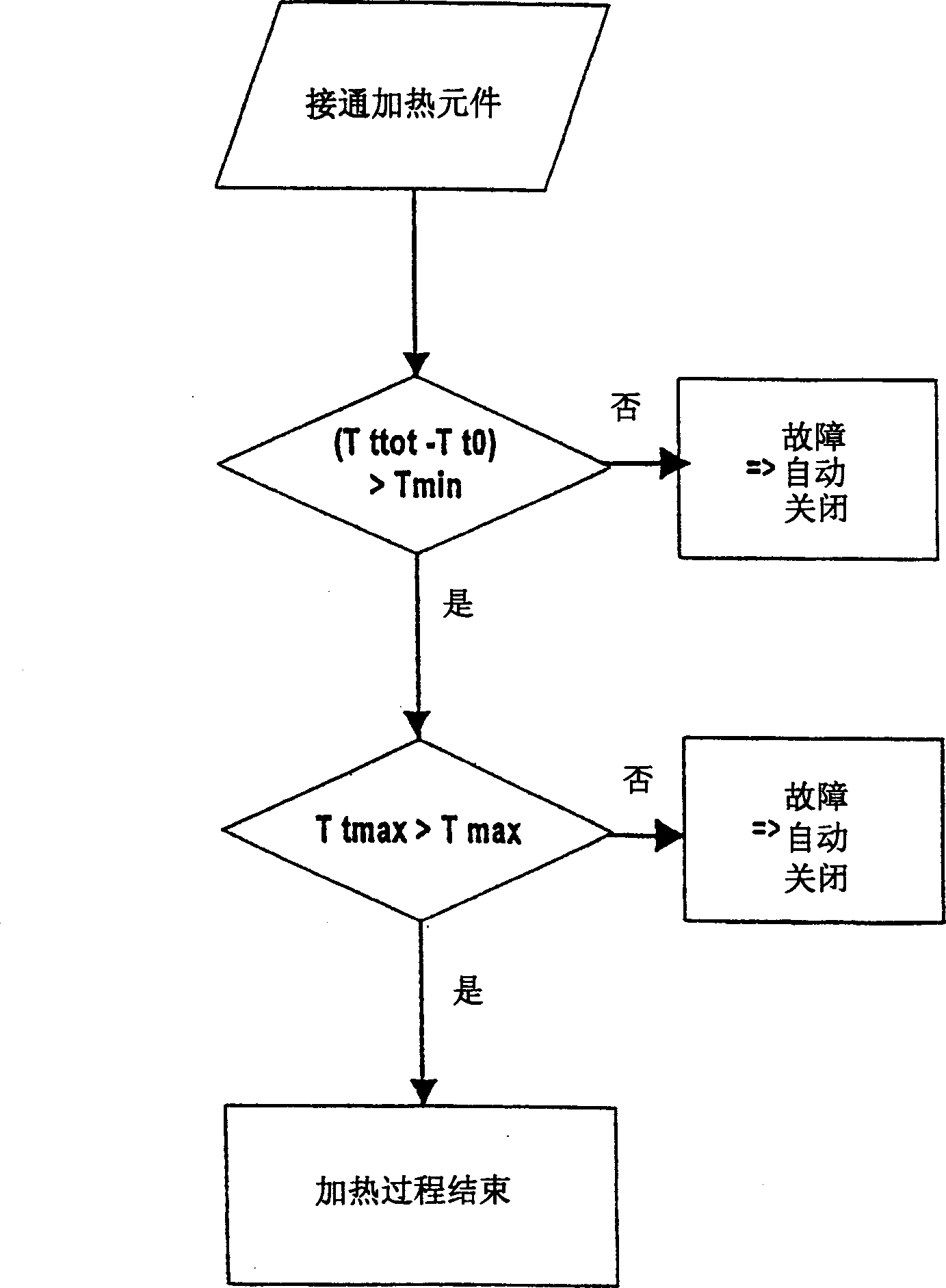

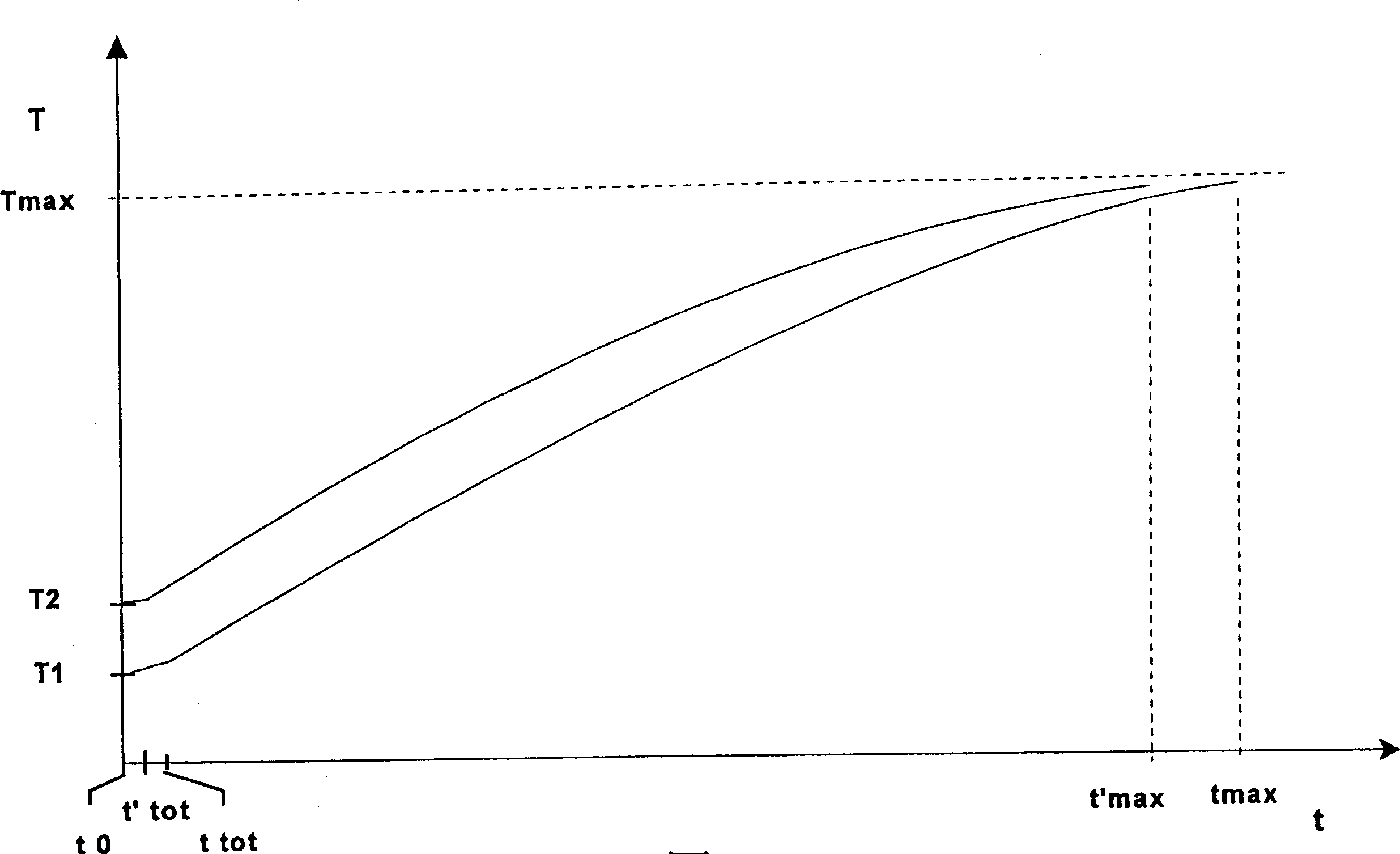

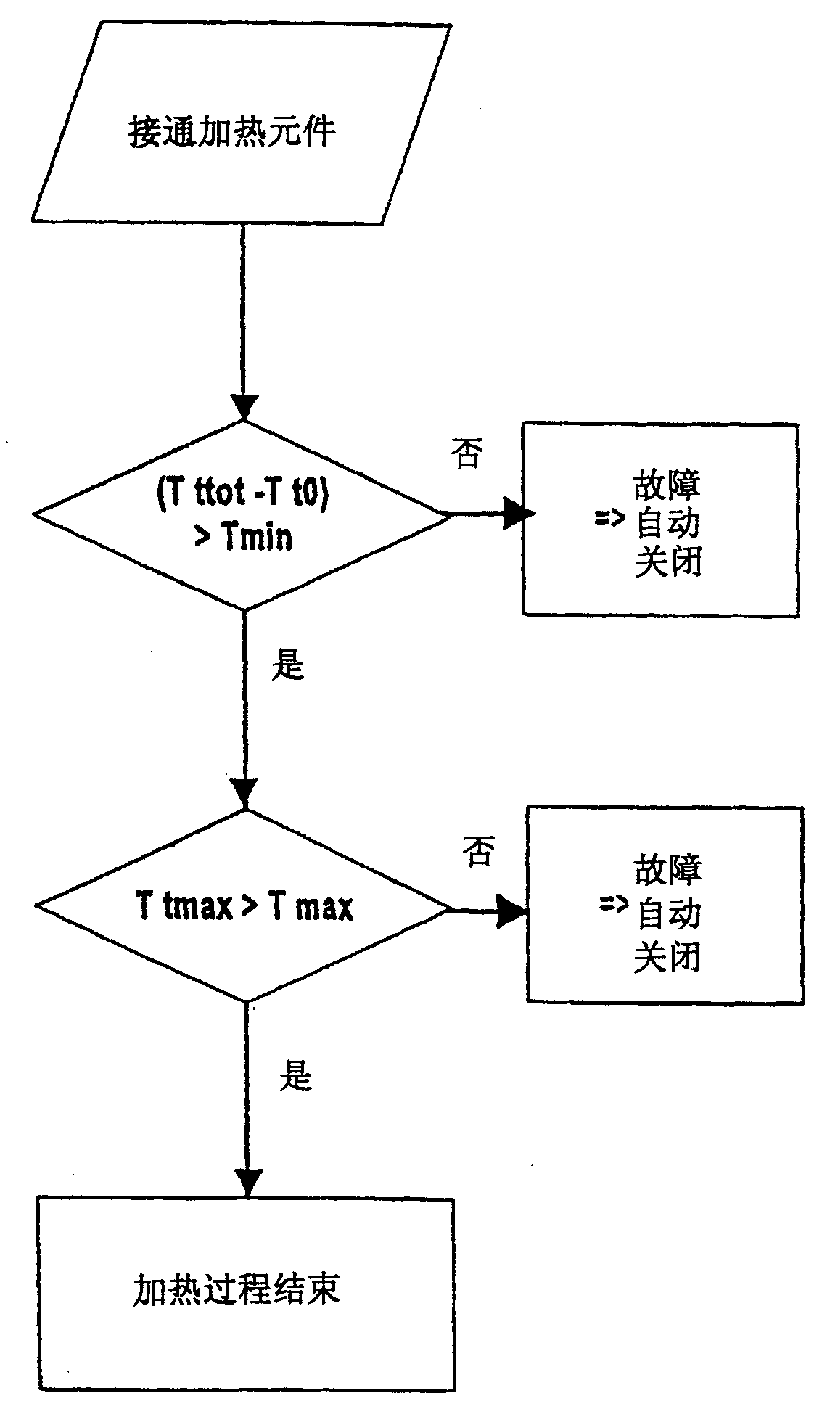

The invention relates to an electric kettle for heating water whereby the kettle has an electric heating element with an electronic regulator which detects the temperature and the duration of heating via sensors. The kettle comprises a non volatile electronic memory wherein predefined characteristic data is stored for verifying the sensor information. The invention also relates to a method for regulating a heating process for a kettle of said type, comprising the following steps: switching on a heating element; measuring the increase in temperature DELTA T at a predetermined time interval ttot-to; switching off the heating element if the measured temperature increase DELTA T is less than or equal to Tmin; measuring the temperature T at the time tmax; switching off the heating element if the measured temperature Ttmax is greater than the stored temperature Tmax; regular completion of the heating process. The invention enables a simple and secure detection of and response to an error function occurring in the heating element or the electronic regulator in the electric kettle.

Owner:BRAUN GMBH

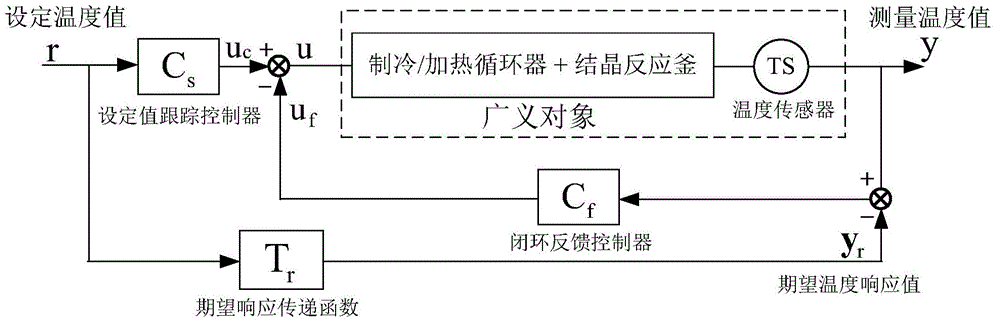

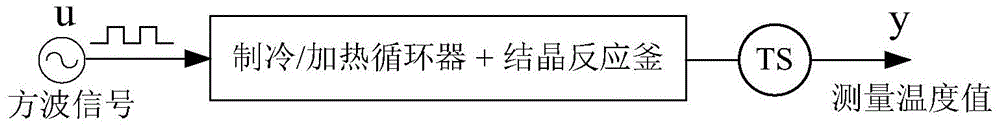

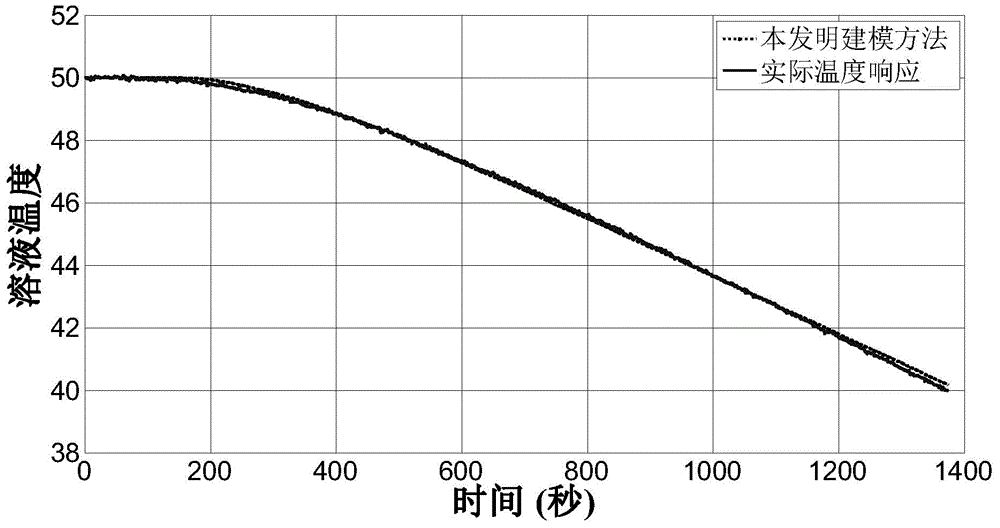

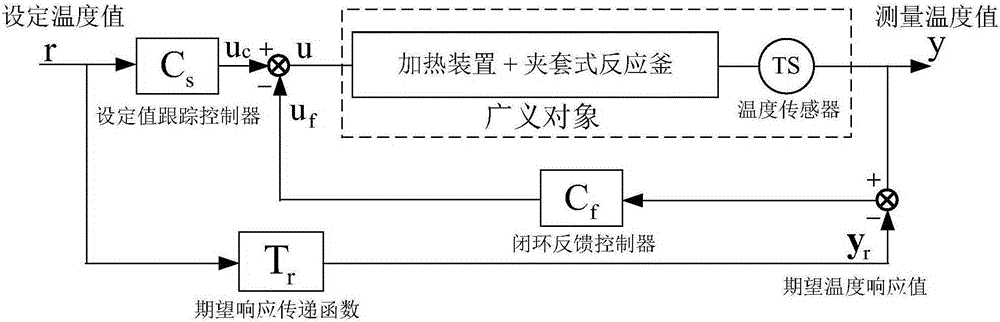

Quick and overregulation-free cooling crystallization reaction kettle temperature control method

ActiveCN104881062AOvercoming time-varying uncertaintyNo overshoot cooling control effectTemperature control using electric meansRefrigeration compressorAutomatic control

Provided is a quick and overregulation-free cooling crystallization reaction kettle temperature control method. According to the method, a refrigeration compressor with a variable-frequency power regulation function, an electronic heating tube based on pulse width modulation power, a programmable controller and a monitoring computer are used to construct a temperature control system. First, a square wave excitation experiment is adopted, namely, the temperature change of a crystallization reaction kettle is detected by periodically changing the power of the refrigeration compressor, and a cooling response transfer function model of the crystallization reaction kettle is established according to experimental data; then, a robust closed-loop control system and the form of the controller are designed based on the response model; and finally, the suitable range of the parameters of the controller is set according to the actual executable power of the refrigeration compressor and the electronic heating tube and the working condition constraints of the reaction kettle. By adopting the method of the invention, the cooling rate of solution in the reaction kettle can be regulated quantitatively to ensure no overregulation and reach a specified target value of cooling. Thus, a convenient and reliable method of automatic control is provided for cooling regulation of the crystallization process.

Owner:DALIAN UNIV OF TECH

Electric heater

ActiveUS8269150B2Avoid damageIncrease productionHeater elementsHot plates heating arrangementsStress concentrationEngineering

Disclosed is the electric heater including a base, and a heating unit having a plurality of unit heating elements disposed on a plate surface of the base and at least one of heating connection portions configured to heat and conductively connecting the unit heating elements to each other and non-heating connection portions configured not to heat and conductively connecting the unit heating elements to each other, thereby preventing a thermal stress concentration, thus to prevent damage to the heating unit and to enhance its output.

Owner:LG ELECTRONICS INC

Systems and methods for improved sustainment of a high performance frc and high harmonic fast wave electron heating in a high performance frc

ActiveCN110024489ANuclear energy generationReaction to electrical energyParticle physicsElectron heating

Systems and methods that facilitate forming and maintaining FRCs with superior stability as well as particle, energy and flux confinement and, more particularly, systems and methods that facilitate forming and maintaining FRCs with elevated system energies and improved sustainment utilizing neutral beam injection and high harmonic fast wave electron heating.

Owner:TRI ALPHA ENERGY INC

Electrothermal actuator and technique of producing the same

InactiveCN101195472AReduce heat dissipationHigh coefficient of thermal expansionMicromanipulatorDecorative surface effectsElectrothermal actuatorMicro actuator

The invention relates to an applied technology of micro-robots in the fields of cell operation and cell separation, in particular to a micro-actuator driven by heating from electricity and a process for preparation. The micro-actuator driven by heating from electricity is composed of a polymeric material of Parylene C and electron-heating materials of titanium and platinum and is capable of realizing the operation of clamping cells under the fluid environment. The actuator is a multiple cantilever beam structure and is fixed on a silicon substrate, and each cantilever beam is a three-layer structure of parylene C clamping the electron-heating materials. The processing technique employs screen-printing technology of MEMS (micro-electro-mechanism system). The invention is capable of being electrically driven, and parylene C is taken as heat / electricity / fluid isolation material, then a heater formed by electron-heating materials is not exposed in the fluid, thereby having good biological adaptability and fluid environment adaptability, being capable of realizing cell operation and cell separation by controlling the temperature and providing automatic operation and application of localization detection, injection and measuring of cells.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

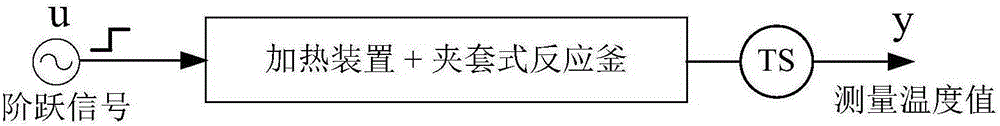

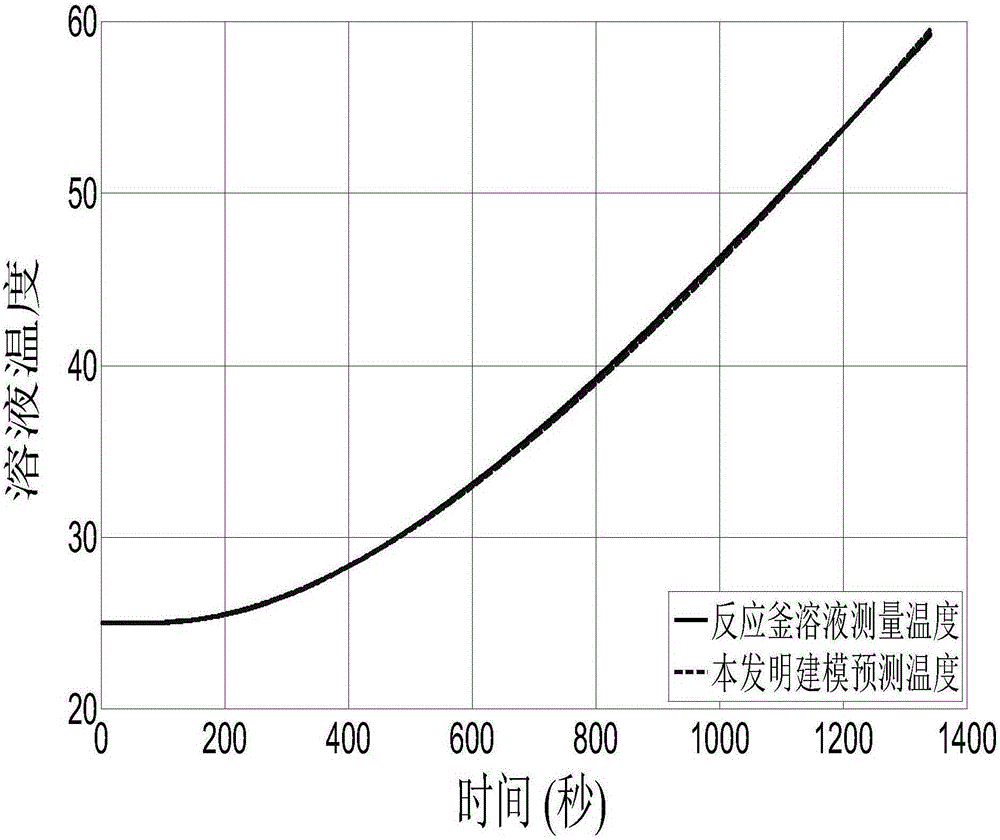

Temperature control method of rapid non-overshooting heating jacket type heating reaction kettle

The invention discloses a temperature control method of a rapid non-overshooting heating jacket type heating reaction kettle. The method comprises the steps that a temperature control system is composed of an electronic heating pipe based on pulse width modulation power, a programmable logic controller (PLC) and a monitoring computer; an open loop step response test is carried out in a full-power heating mode, and a heating response transfer function model of the jacket type heating reaction kettle is built according to the test detection temperature data; the forms of a robust closed-loop control system and a controller are designed based on a response model; finally, controller parameters are set to be in an appropriate range according to the actual power of a heating device and working condition constraint conditions of the reaction kettle. By the adoption of the temperature control method, the heating speed of a solution of the jacket type reaction kettle can be quantitatively adjusted, it is ensured that a heating target value is achieved in a non-overshooting mode, and therefore a convenient and reliable automatic control method is provided for heating adjustment of chemical polymerization, distillation separation, biological fermentation and other technologies.

Owner:DALIAN UNIV OF TECH

Systems and methods for improved sustainment of a high performance FRC and high harmonic fast wave electron heating in a high performance FRC

ActiveUS11335467B2Reduces fast ions charge-exchange lossImproves plasma confinementNuclear energy generationReaction to electrical energyParticle physicsElectron heating

Owner:TAE TECH INC

An electron source

PendingCN111868880AHigh emissivityReduce decreaseTube electron sourcesIon sources/gunsElectron sourceThermal electron

An electron source in a gas-source mass spectrometer the electron source comprising: an electron emitter cathode presenting a thermionic electron emitter surface in communication with a gas-source chamber of the gas-source mass spectrometer for providing electrons there to; a heater element electrically isolated from the electron emitter cathode and arranged to be heated by an electrical current therein and to radiate heat to the electron emitter cathode sufficient to liberate electrons thermionically from said electron emitter surface, therewith to provide a source of electrons for use in ionising a gas the gas-source chamber.

Owner:ISOTOPX LTD

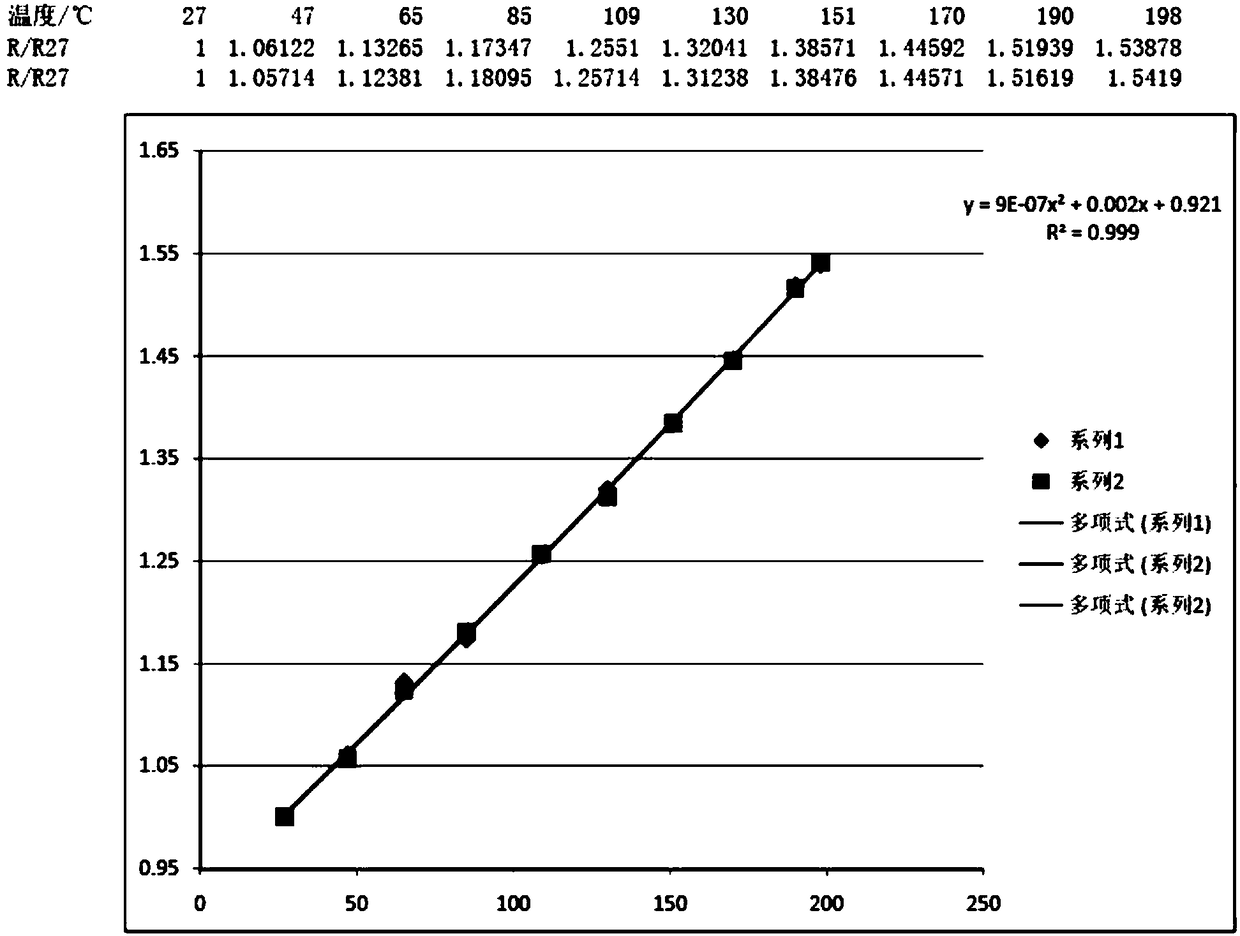

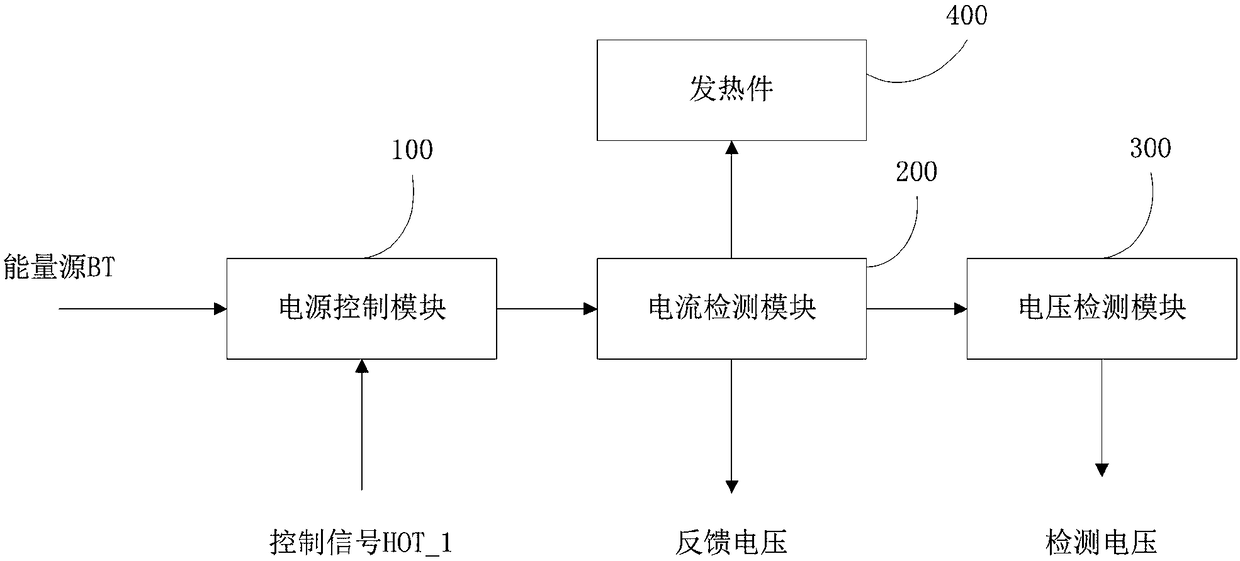

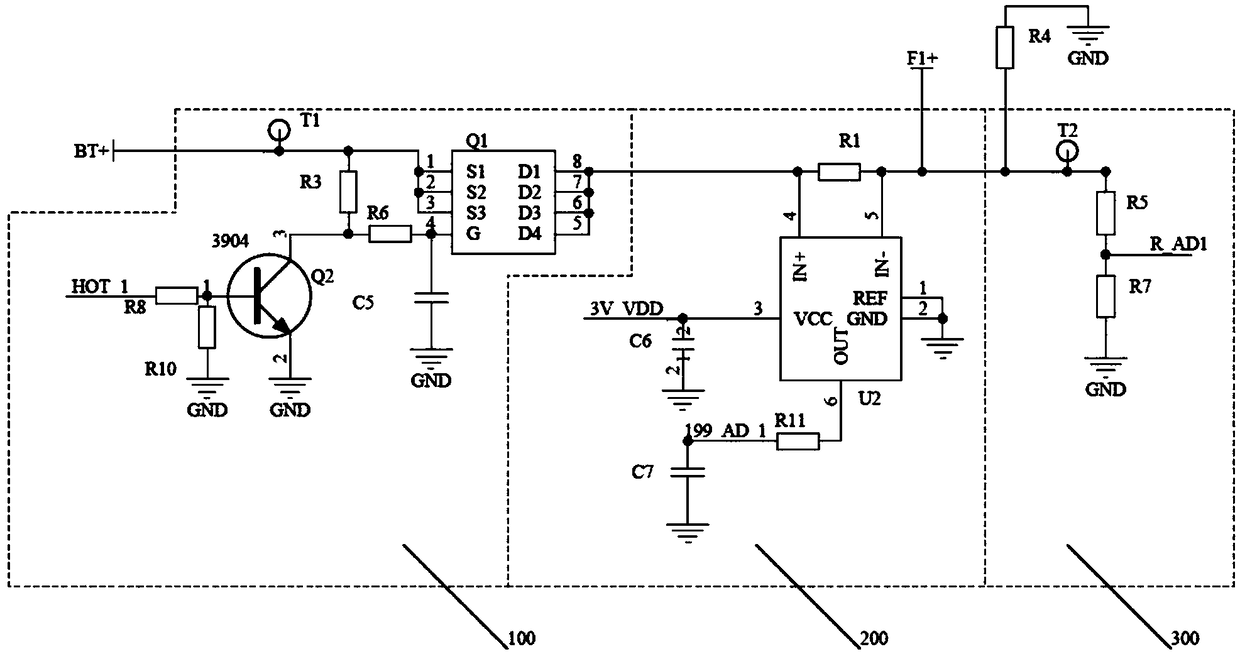

Electronic heating control system, electronic heating device and heating control method thereof

PendingCN108391856AImplement current sensingAchieve constant temperature effectElectrical measurement instrument detailsTobacco devicesCooking & bakingControl signal

The invention relates to an electronic heating control system, an electronic heating device and a heating control method thereof. The electronic heating control system comprises a power control module, a current detecting module and a voltage detecting module; the input end of the power control module is connected with an energy source, the output end of the power control module is electrically connected with the input end of the current detecting module, and the enabled end of the power control module is externally connected with a control signal; the output end of the current detecting module is electrically connected with the input end of the voltage detecting module; the output end of the current detecting module is further electrically connected with a heating piece. The heating pieceadopting a ceramic heating tube adopts a differential amplification circuit, current detection is achieved, the constant temperature effect is achieved, and the ceramic heating tube is cylindrical and is better suitable for common cigarettes on the market; sectional type baking is adopted, and the heating effect is better.

Owner:SHENZHEN HANGSEN STAR TECH

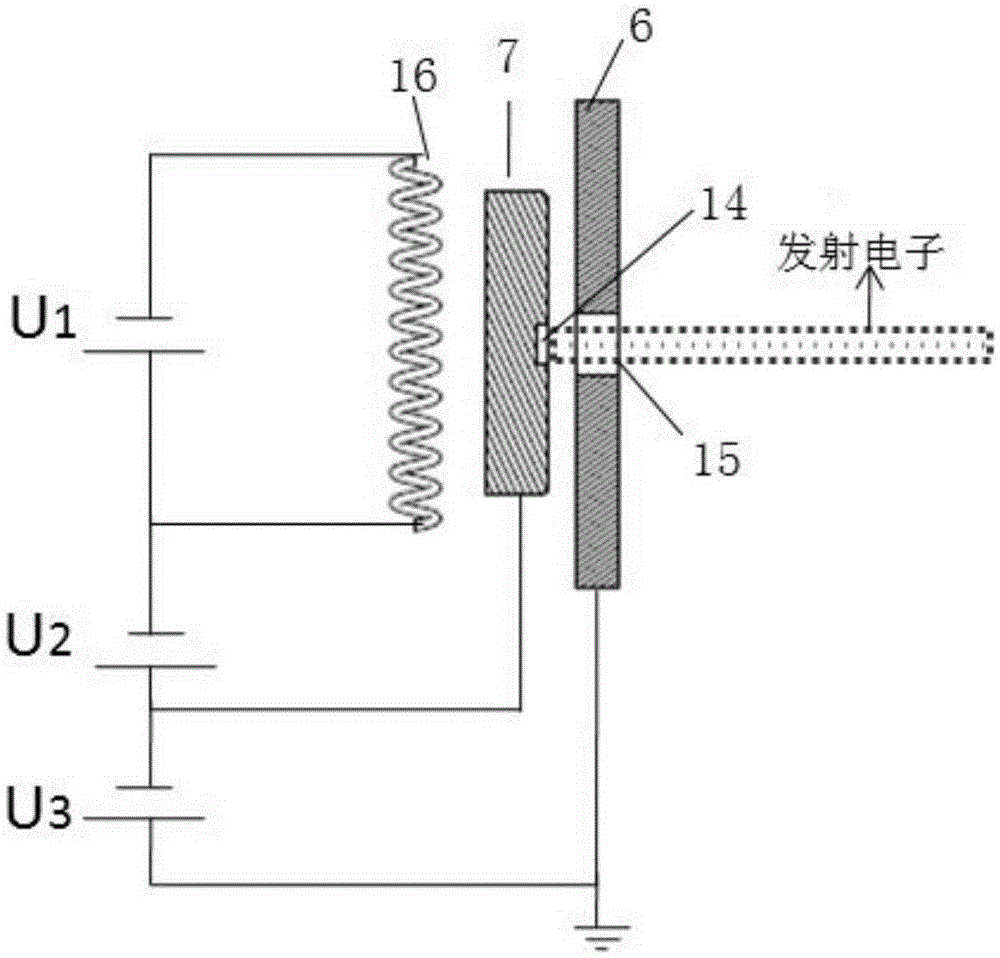

Radiation electron heating electron gun

InactiveCN105280461AAvoid high temperature contactQuality improvementElectrode assembly support/mounting/spacing/insulationThermionic cathodesPlanar electrodeElectron heating

The present invention discloses a radiation electron heating electron gun. The radiation electron heating electron gun comprises insulator components, an anode plate successively arranged, a cathode component configured to emit electrons and a filament component configured to perform electronic heating of the cathode component. The anode plate is provided with an anode hole configured to lead out emitting electrons; and the anode plate, the cathode component and the filament component are fixedly connected with each other through the insulator components. According to the invention, the electron heating mode of a cathode, with a long life, a short switch response time, a short length of an axis, a simple process and the like, is used. Moreover, a planar electrode structure is adopted to form fine electron beams, especially banding electron beams, wherein the banding electron beams may effectively avoid electron disturbance and the electron beam edge vortex layer containing few electrons and improve the quality of electrons emitted by an electron gun provided by the invention.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

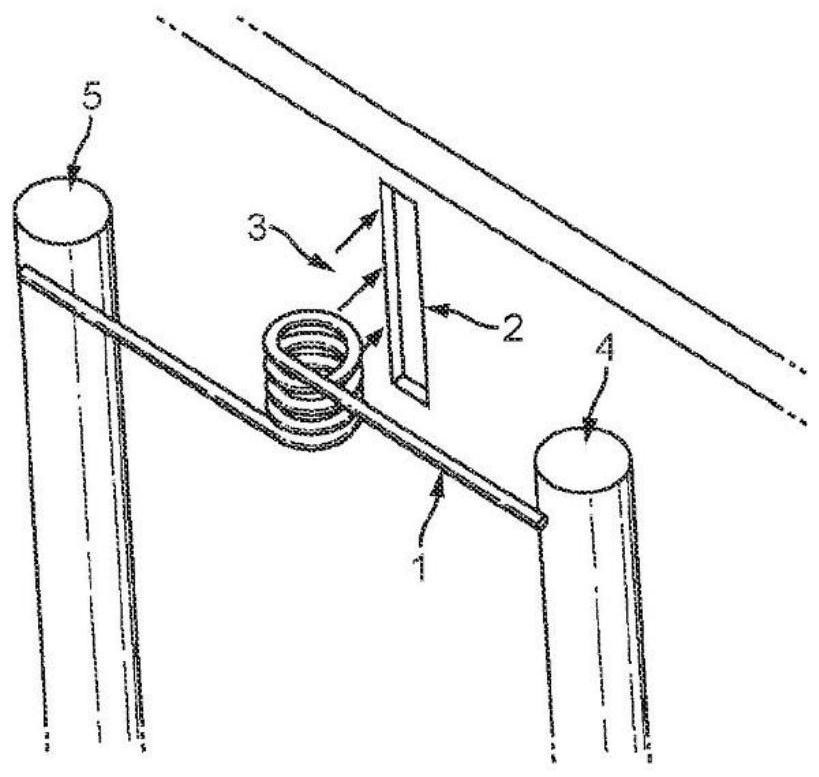

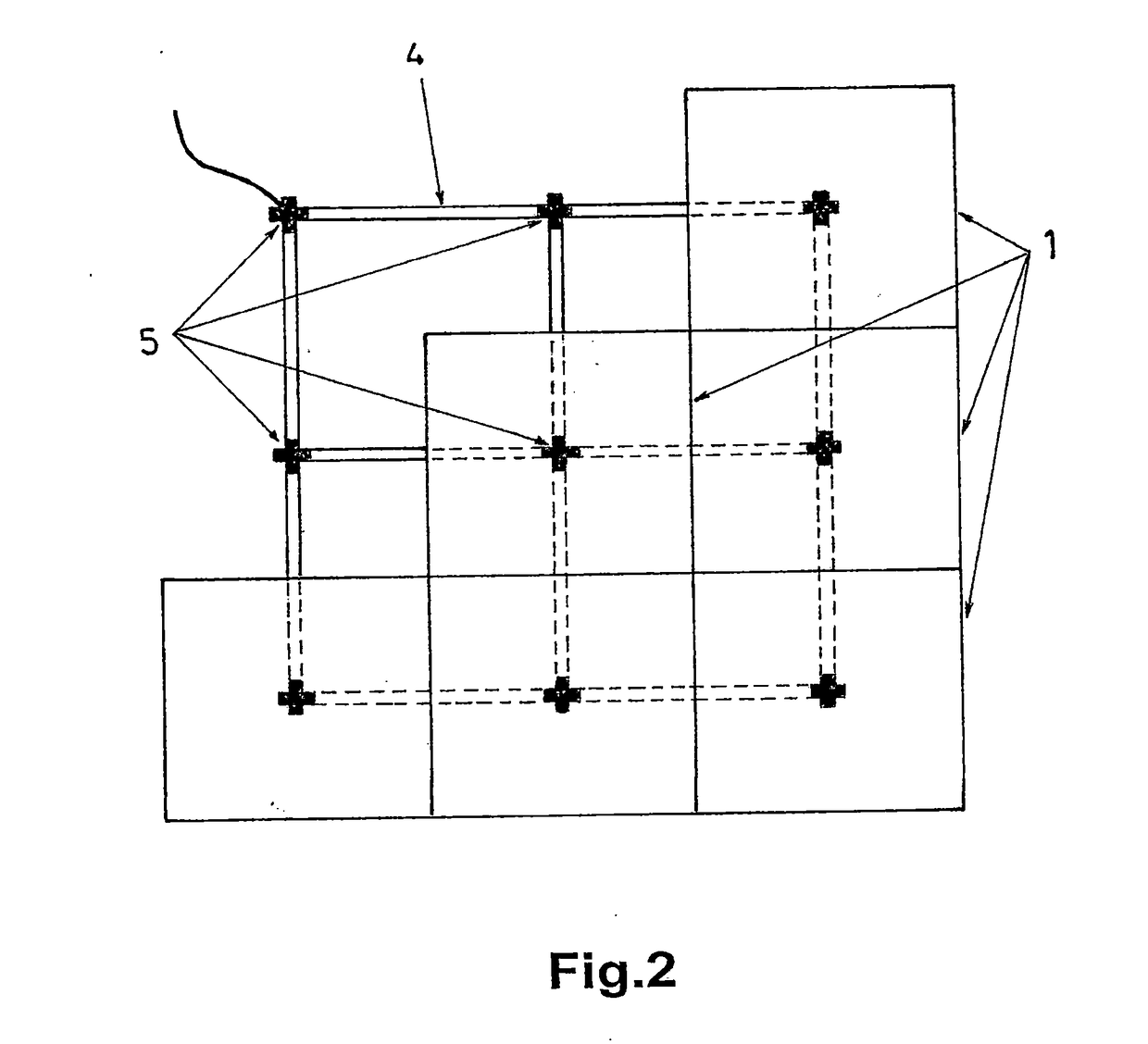

Dynamic heating system

InactiveUS20170191675A1Increase or decrease the heat generation of said elementsLighting and heating apparatusElectric heating systemElectron heatingData transmission

The invention relates to a dynamic heating system in the form of a radiant surface, comprising a covering formed by tiles (1), each tile (1) containing at least one electrical heating resistance (2) and a thermal temperature-measuring sensor (3), a connection network (4) being arranged below the covering in the form of a grid, the tiles (1) being connected to the nodes of said grid electrically and via data transmission, while said connection network (4) is connected to a programmable controller (6) which establishes an individual electric power supply to each of the tiles (1) according to the temperature.

Owner:EXPLODED VIEW SL

Anti-electromagnetic radiation glue used for carbon crystal and carbon fiber electronic heaters and preparation method

InactiveCN104312511AReduce radiationSolve the hazards to human healthNon-macromolecular adhesive additivesOhmic-resistance heating detailsEpoxyFiber

The invention discloses anti-electromagnetic radiation glue used for carbon crystal and carbon fiber electronic heaters. The anti-electromagnetic radiation glue comprises the following components in percentage by weight: 20-50% of epoxy resin,10-20% of conductive carbon powder, 5-10% of graphite, 10-20% of tourmaline, 5-10% of copper powder, 5-10% of nickel powder, 1-3% of a curing agent and 9-12% of magnesium hydroxide, and the sum of the weight percentage of each component is 100%. The preparation method is as follows: epoxy resin and dicyandiamide are dissolved, conductive carbon powder, tourmaline and magnesium hydroxide are added sequentially, graphite, copper powder and nickel powder are added, even stirring is performed, the surface of an electronic heating plates is coated with the glue, and the glue is cured to form an electromagnetic radiation shield and absorption layer. The glue solves the problem that the present carbon crystal and carbon fiber electronic heaters generate electromagnetic radiation which harms human health in the use process, the cost is low, the shield is tight, the absorbability is strong, and the glue can reduce electromagnetic radiation to be lower than the stand of 100muT and within a lower range.

Owner:郭长奇

An electronic heating-cost distributor

InactiveCN100465597CReliable measurementSolve the real problemElastomeric polymer dielectricsPrinted circuit non-printed electric components associationThermodynamicsEngineering

The electronic heating costs distributor (1) incorporates sensors (5, 6) which measure the temperature respectively of the room air and the heater body, and are provided with thermally conductive and elastically deformable elements (10, 11).

Owner:DIEHL METERING SYST

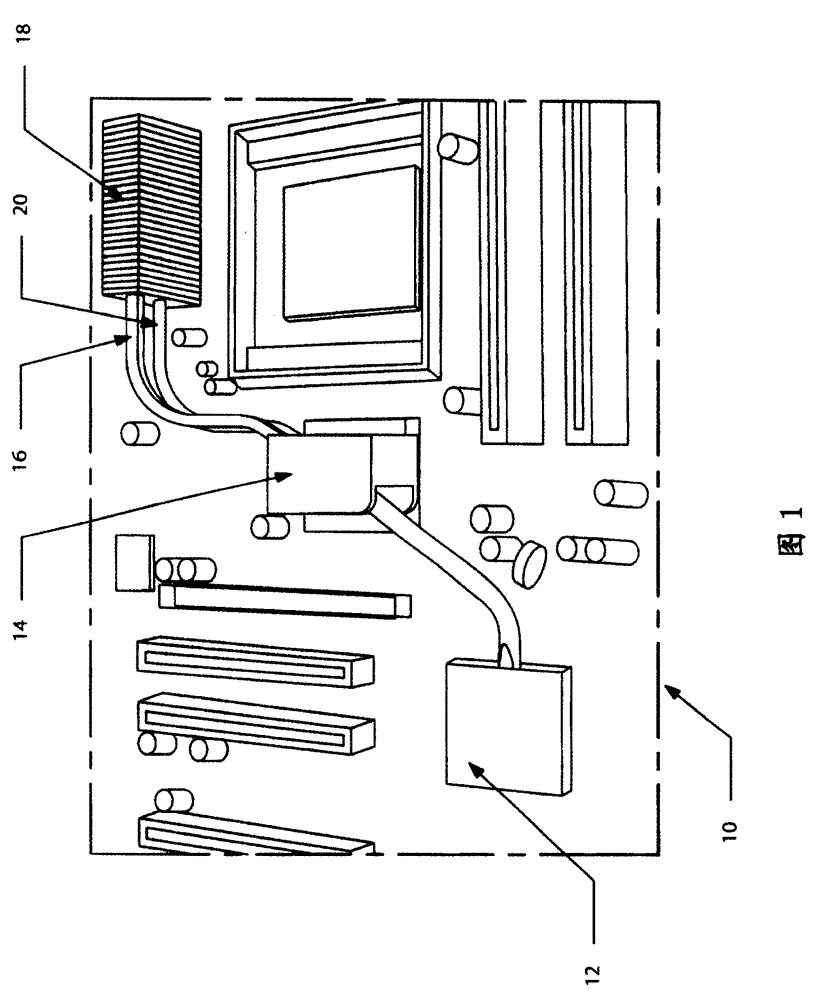

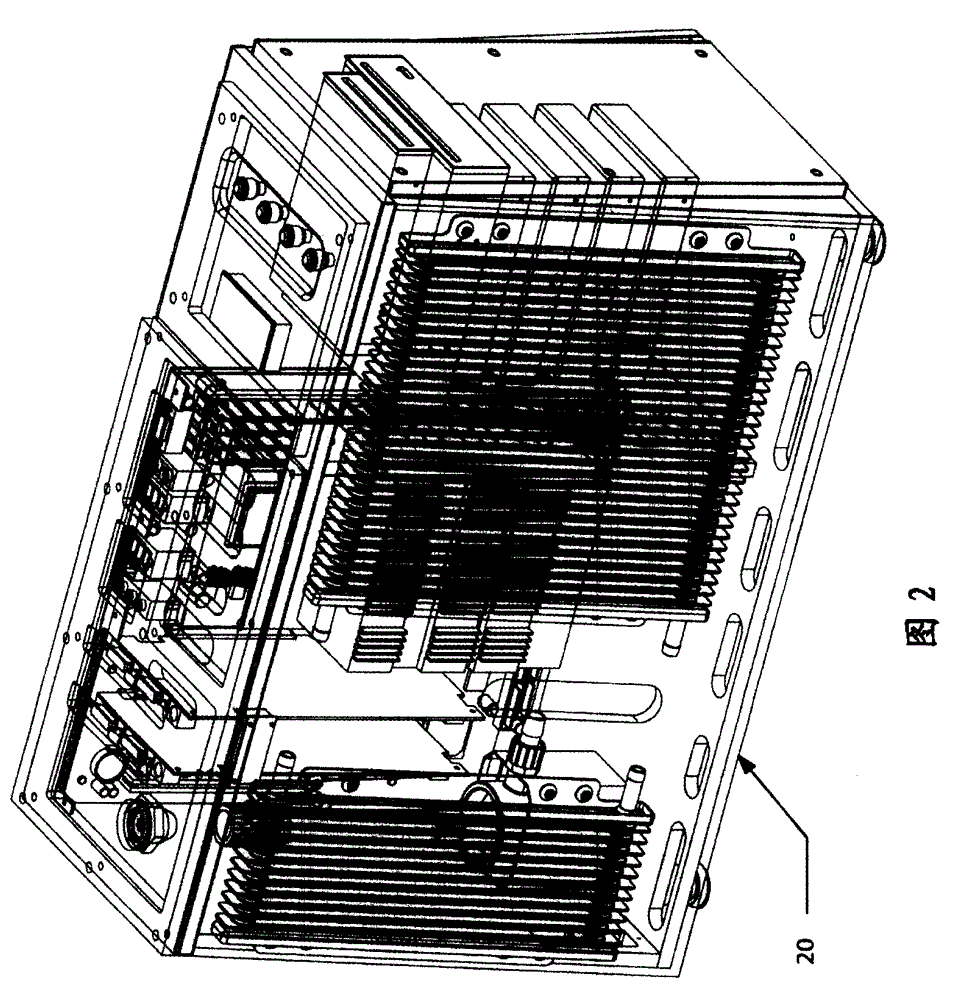

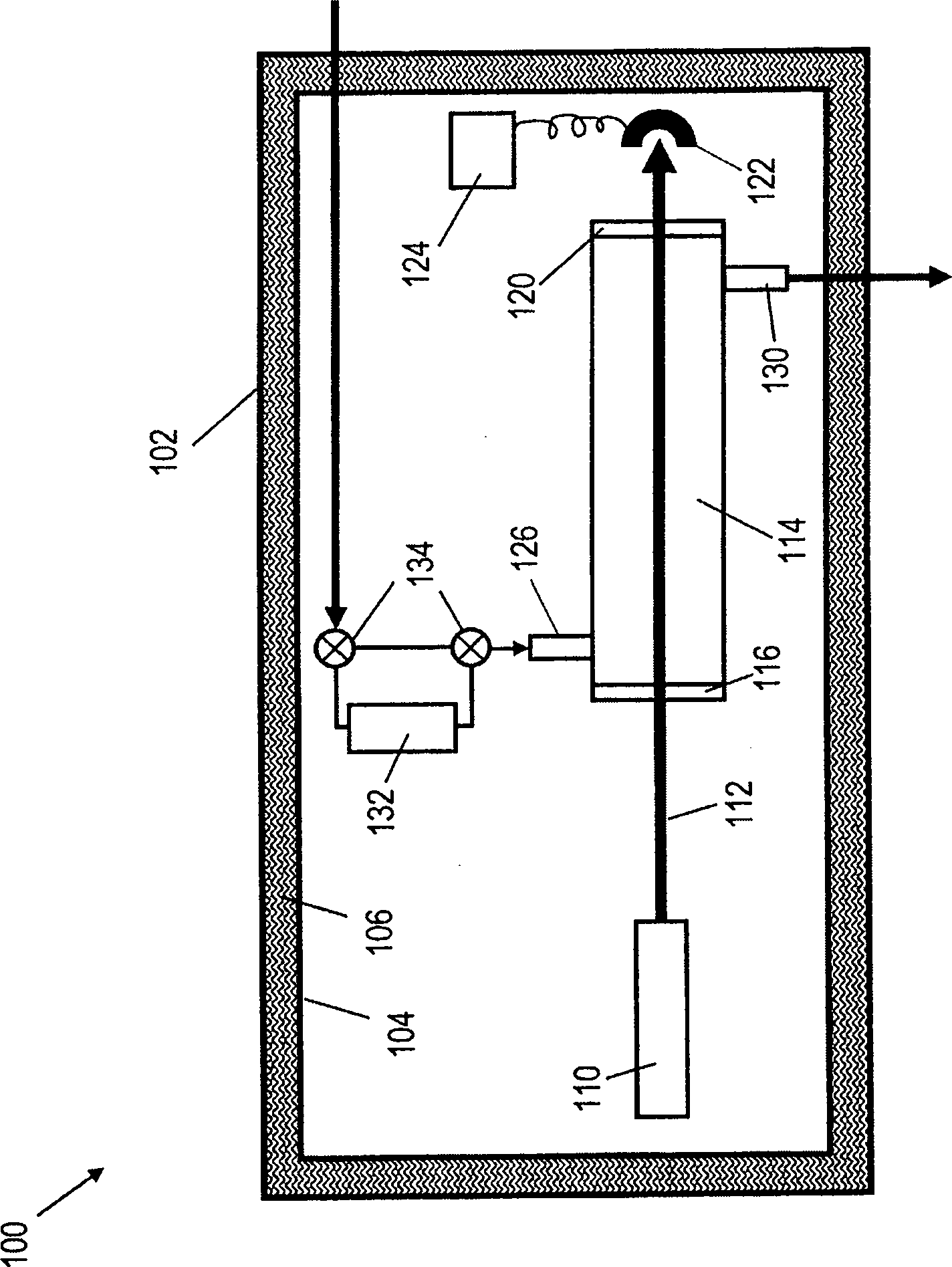

Liquid Immersion Cooling System

A self-contained portable liquid immersion cooling system suitable for cooling a variety of electronic devices, including cooling heat-generating components in computer systems and cooling other systems that use electronic heat-generating components. The electronic device includes a housing with an internal space, an electrically insulating cooling liquid in the internal space, an electronic heating component disposed in the internal space and immersed in the electrically insulating cooling liquid, and a pump, the pump is used for cooling Liquid is fed into or out of this interior space, and cooling liquid is fed into or out of a heat exchanger fixed outside the interior space. The heat exchanger includes a cooling liquid inlet, a cooling liquid outlet, and a flow channel for the cooling liquid to flow from the cooling liquid inlet therethrough to the cooling liquid outlet. Air supply devices such as fans can be used to flow air through the heat exchanger to improve heat transfer.

Owner:LIQUIDCOOL SOLUTIONS

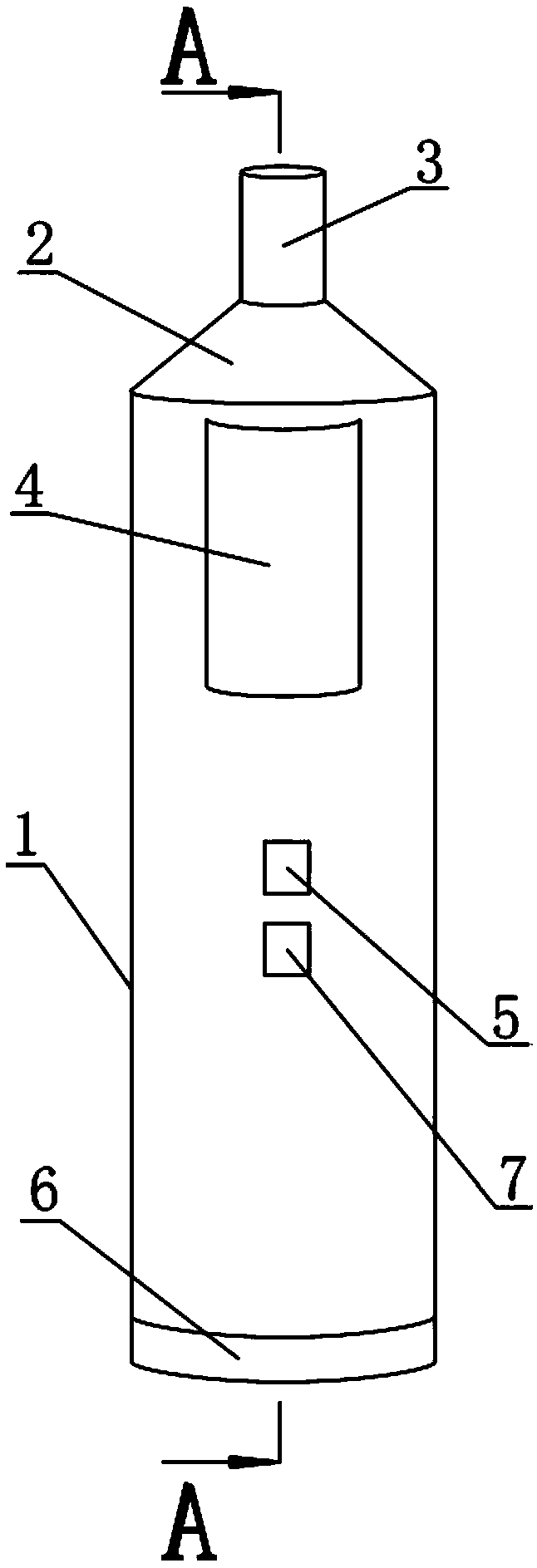

Novel electronic heating atomizing instrument

The invention discloses a novel electronic heating atomizing instrument. The electronic instrument comprises a housing, a suction nozzle is arranged at the front end of the housing, an installing cavity is formed in the housing, the front end of the housing is provided with a conical temperature reduction cavity, an inner cavity of the suction nozzle is communicated with the conical temperature reduction cavity, and an atomizing heating device, a battery and a plurality of electric heating pieces are installed in the installing cavity of the housing; the atomizing heating device comprises an atomizing liquid chamber, an atomizing gas outlet end and an atomizing liquid atomizing heating device, a gas inlet of the atomizing gas outlet end is connected with a gas outlet end of the atomizing liquid chamber, and the atomizing liquid atomizing heating device and the electric heating pieces are electrically connected with the battery; the circumferential space of the electric heating pieces is filling heating space, and the filling heating space and the gas outlet end of the atomizing gas outlet end are connected with the conical temperature reduction cavity. The novel electronic heatingatomizing instrument has the advantages that the advantage of two technologies of heating non-burning and electronic atomizing liquid atomizing are obtained so that a better smoke experiencing effectcan be obtained, mixed smoke is concentrated and abundant, and the taste is better.

Owner:何书杰 +1

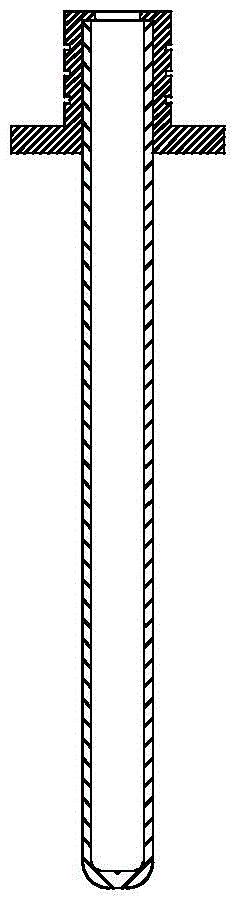

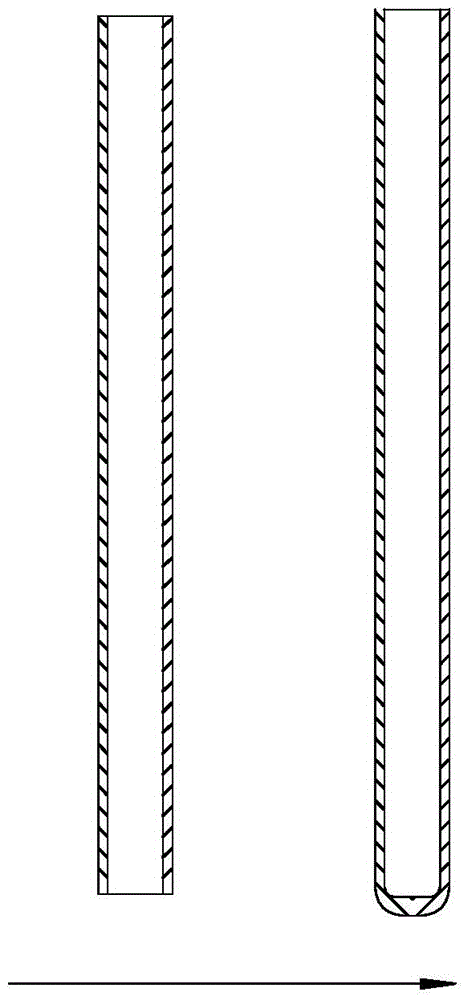

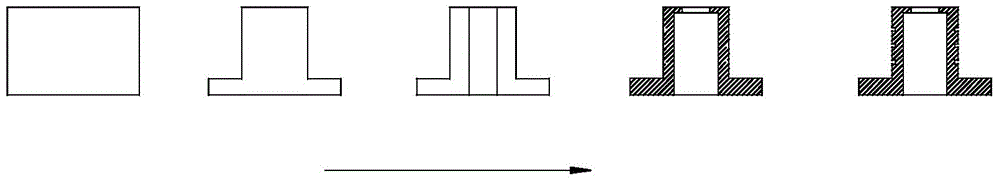

A manufacturing process of an electronic heater for an electronic thermostat

ActiveCN103737272BSimplify the shell processing processSimple processElectronic temperatureMegasonic cleaning

The invention relates to the field of auto parts, in particular to a manufacturing process of an electronic heater for an electronic thermostat. A manufacturing process of an electronic heater for an electronic thermostat. Firstly, a hollow tube with a diameter of 2mm-5mm is selected, and the hollow tube is cut into 80mm-120mm by a cutting machine, and the lower end of the cut hollow tube is formed by Baotou machining Cold extrude the Baotou, and then use an ultrasonic cleaning machine to clean the oil stains inside and outside the hollow tube; select a round steel with a diameter of 6mm-16mm and a length of 10mm-20mm, and make a circular step on the outer diameter of the car, and drill a through hole. The inner diameter is equal to the hollow tube The diameter of the inner diameter is used for reaming. The reaming diameter is equal to the outer diameter of the hollow tube, and the reaming length is equal to the pressing length of the hollow tube to form an inner circular step. Next, the hollow tube is pressed into the round steel to tightly contact with the inner circular step. The invention has the advantages of simplifying the processing technology, saving raw materials, high temperature resistance, insulation, fast heat conduction and short response time.

Owner:NINGBO XINGCI THERMAL ELECTRIC APPLIANCES

Multi-layer food container allowing food to be heated easily

The invention belongs to a multi-layer structure lunch box capable of simply heating food, relates to the field of tableware, in particular to a tableware that is convenient to carry out. The purpose of the present invention is to provide a multi-layer structure meal tube that can easily heat meals. Three-layer short lunch tube and top cover of the lunch tube, among them: the interior of the simple electric heating substrate contains an electrothermal guide wire and a section of power plug less than 60CM, and the top edge of the top edge and the bottom edge of the top cover of the lunch tube belong to interference fit A number of detachable structural beams are attached between the simple electric heating base plate and the top cover of the dining tube. The inner side of the simple electric heating base plate of the dining tube is connected with the top cover of the dining tube through the water vapor outlet attached to the structural beam frame; The side wall of the structural beam frame and the tray attached to the top of the side wall of the structural beam frame, and the steam outlet is attached to the tray. In summary, the present invention has the advantage of being able to temporarily and simply heat food.

Owner:廖华勇

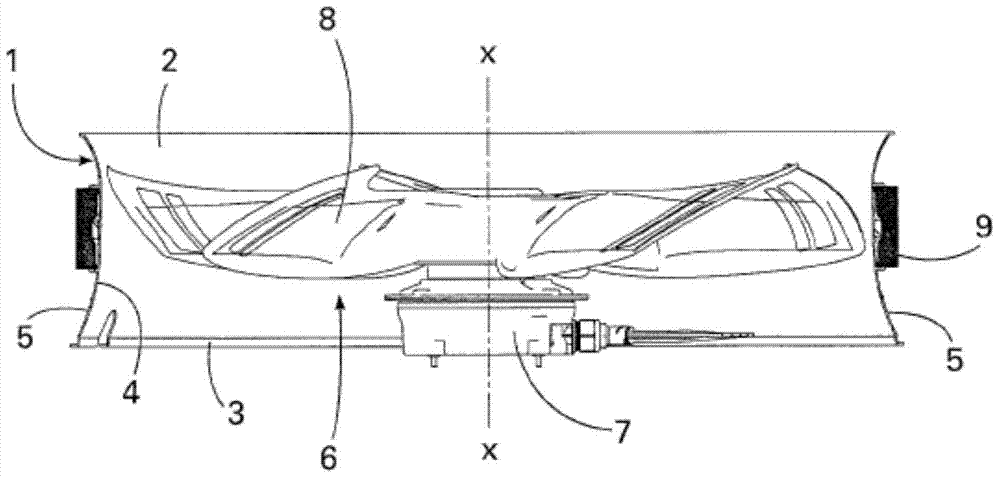

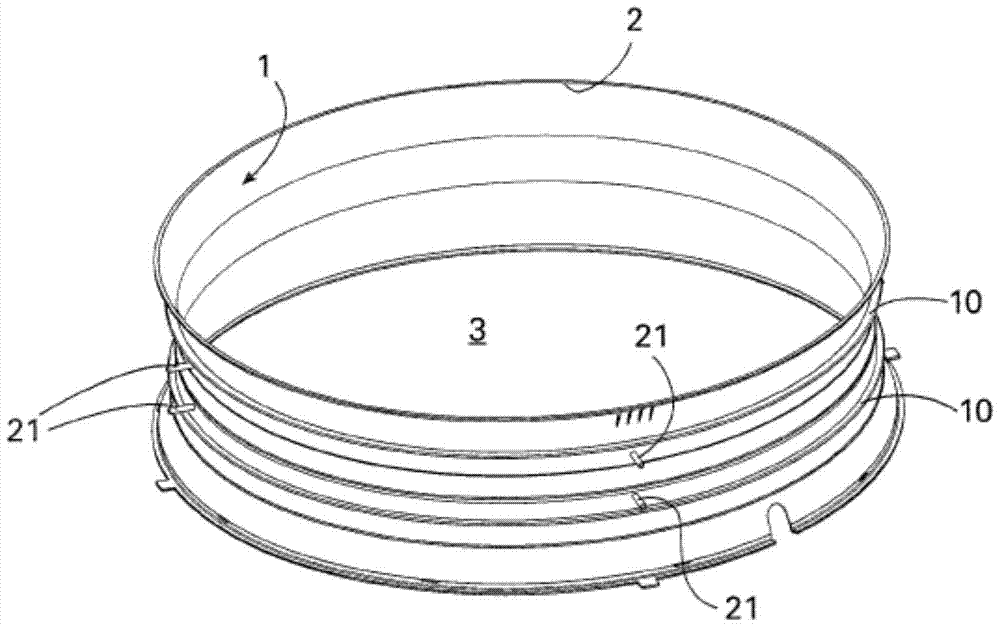

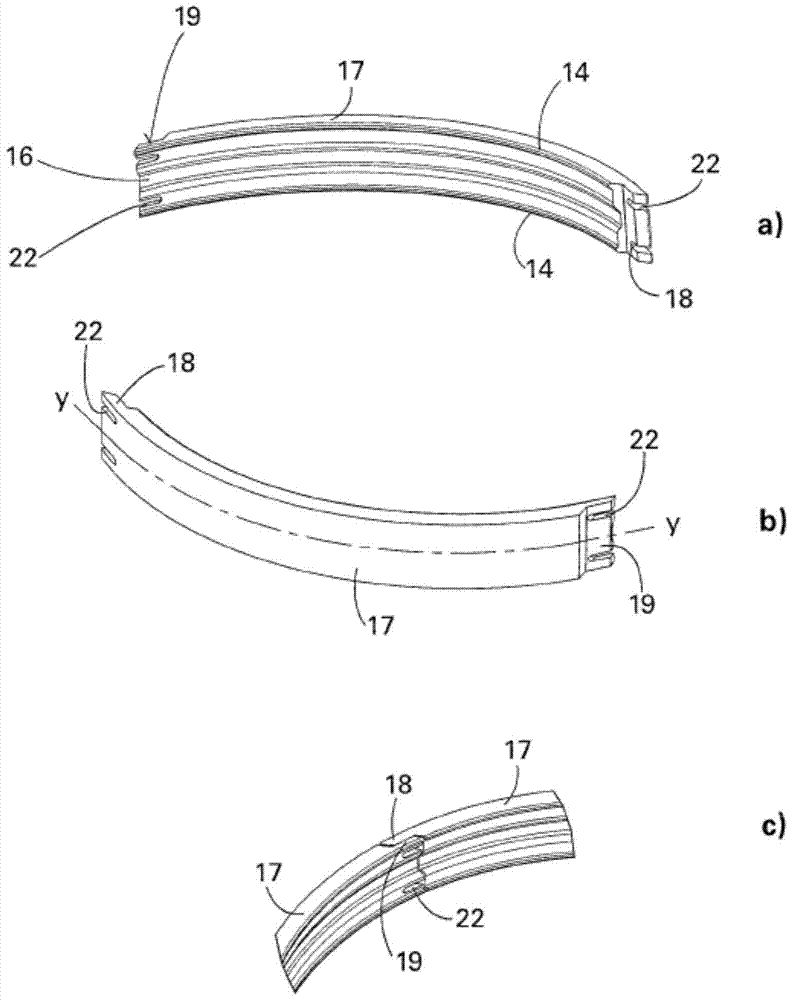

Wall rings for axial fans with wall ring heaters

ActiveCN104736851BAchieve decentralizationDisperse thoroughlyPump componentsEngine fuctionsEngineeringElectron heating

Owner:EBM PAPST MULFINGEN GMBH & CO KG

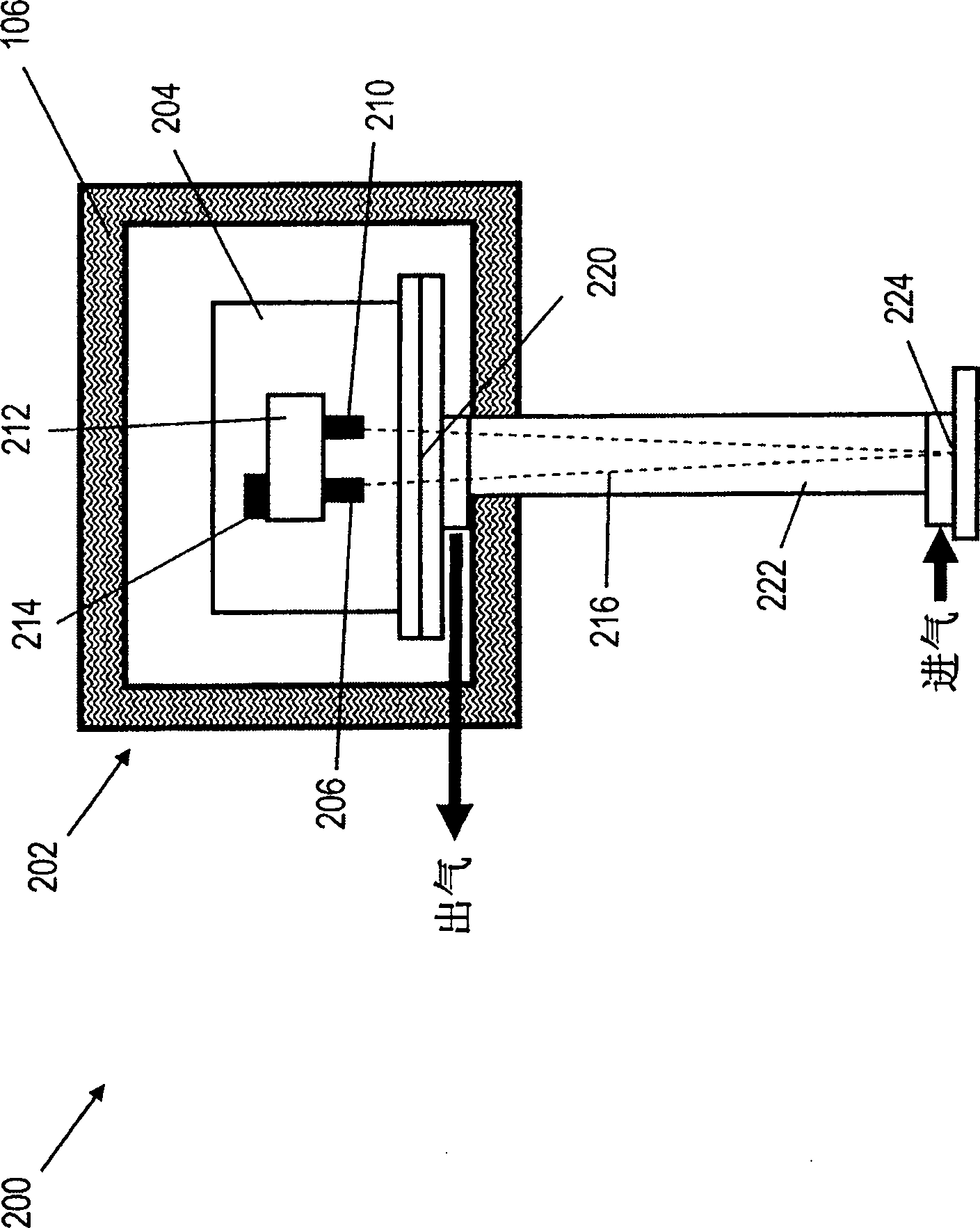

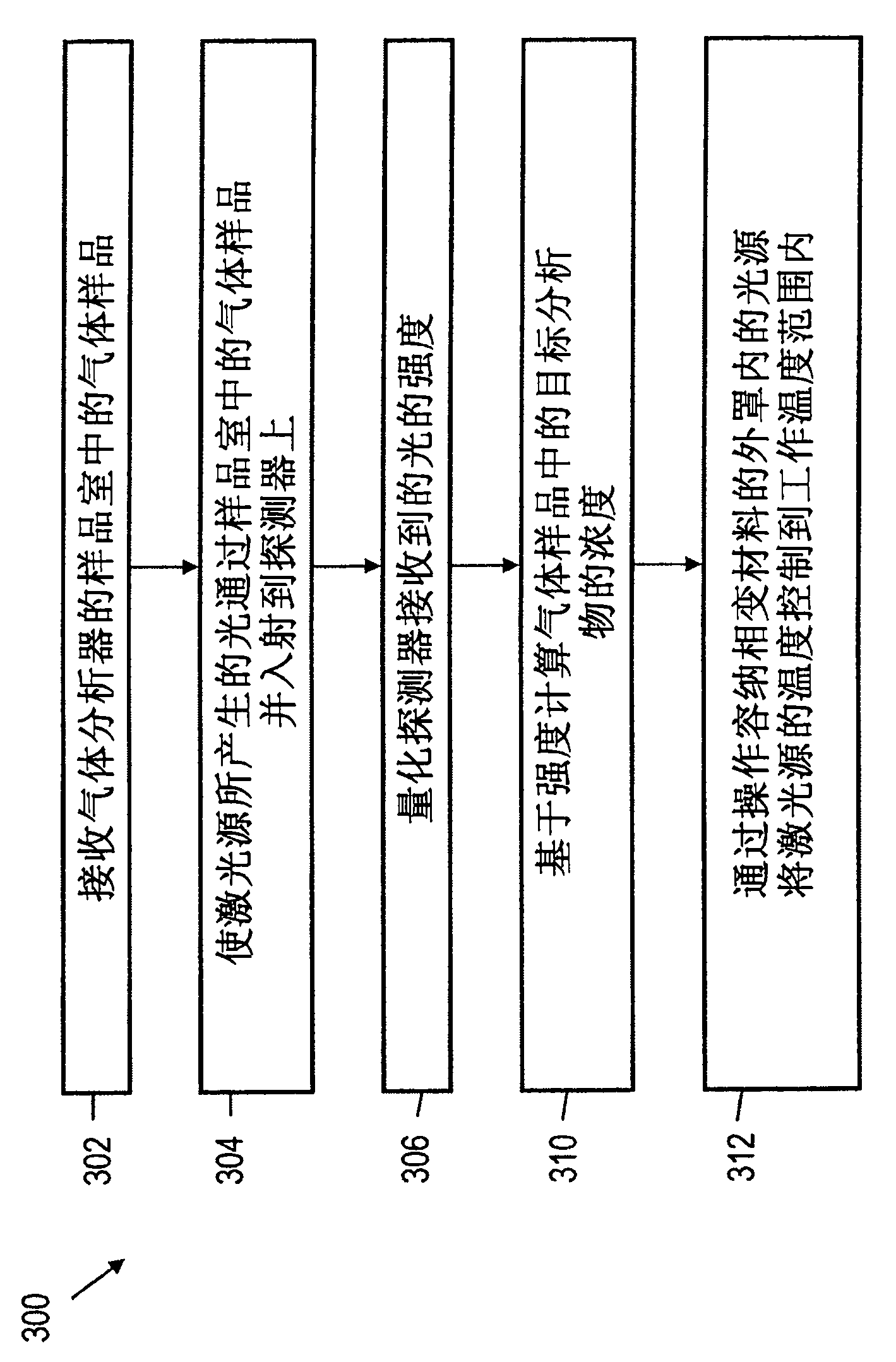

Analytical equipment enclosure incorporation phase changing materials

InactiveCN102265139BMinimize energy consumptionImprove stabilityScattering properties measurementsColor/spectral properties measurementsProcess engineeringProduct gas

Thermally controlled enclosures that can be used with gas analyzers are described. The enclosures incorporate one or more phase changing materials that buffer ambient and internal heat loads to reduce the power consumption demand of mechanical or electronic heating apparatus. Maintenance of gas analyzer equipment at a consistent temperature can be important to achieving stable and reproducible results. Related systems, apparatus, methods, and / or articles are also described.

Owner:SPECTRASENSORS INC

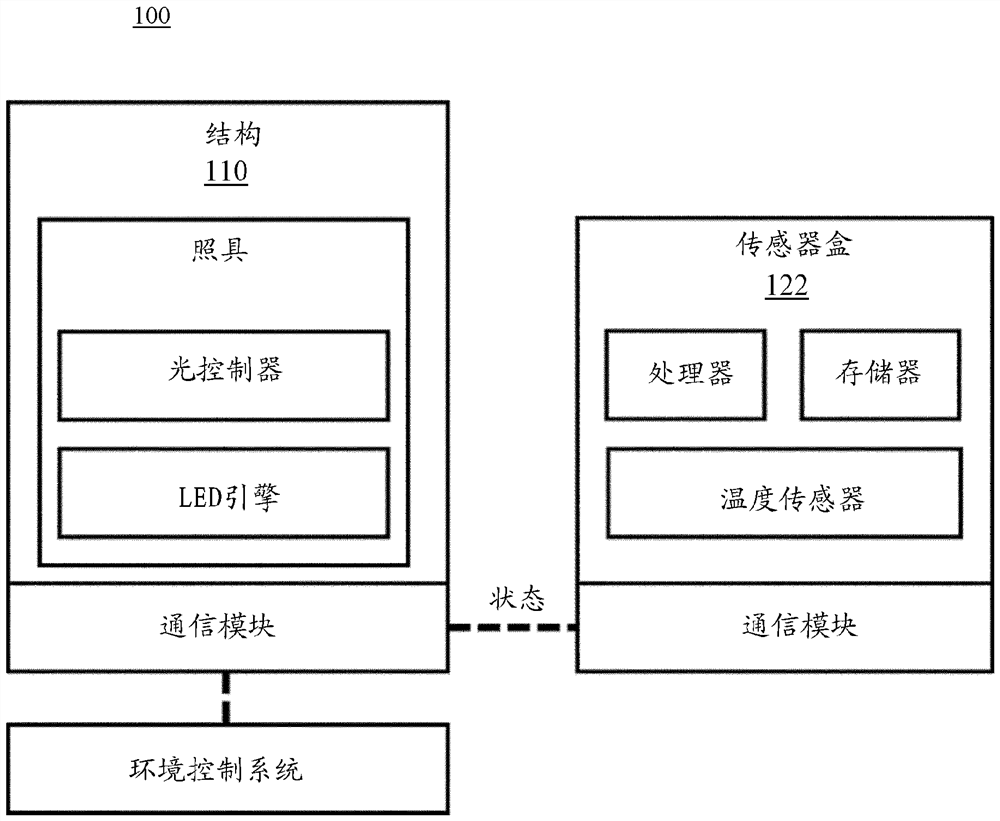

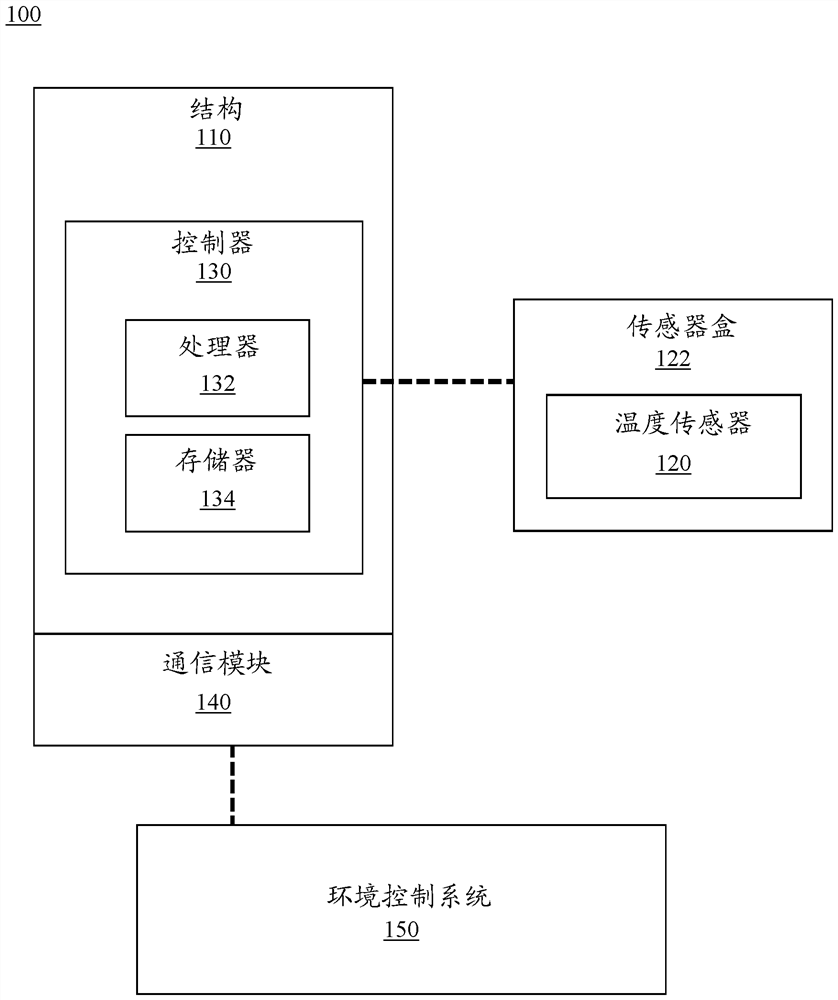

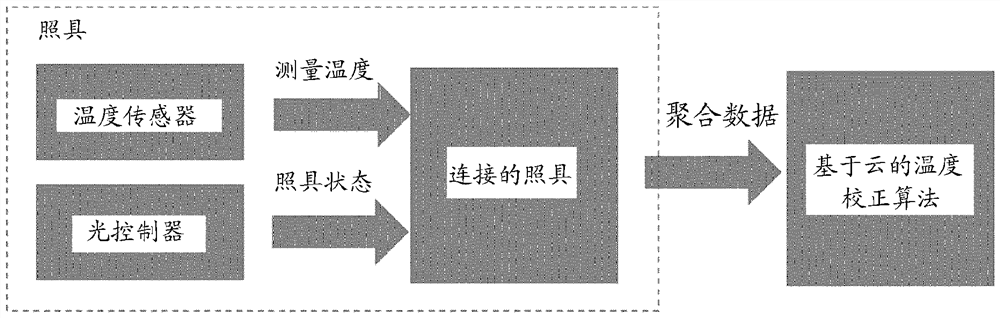

System and method for measuring occupant-level temperature

A method (300) for determining temperature in a region (220 / 230) of an environment (200) by compensating for heat-up of a temperature sensor caused by ambient air and / or electronic heating, using a system (100) comprising: (i) a structure (110); (ii) a controller (130); and (iii) a temperature sensor (120), the method comprising: obtaining (320) first temperature measurements while the structure is in a first operating mode; changing (330) the first operating mode of the structure to a second operating mode; obtaining (340) second temperature measurements while the structure is in the second operating mode; determining (350) a temperature correction comprising an effect of the second operating mode on the temperature sensor; obtaining (360) a new temperature measurement during operation of the structure in the second operating mode; and adjusting (370), using the temperature correction, the new temperature measurement to generate a compensated temperature measurement.

Owner:SIGNIFY HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com