Electrothermal actuator and technique of producing the same

A technology of micro-actuator and preparation process, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, manufacturing tools, etc., can solve problems such as cell manipulation limitations, killing cells, etc. , to achieve the effect of not easy to break, reduce heat dissipation, and large displacement output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

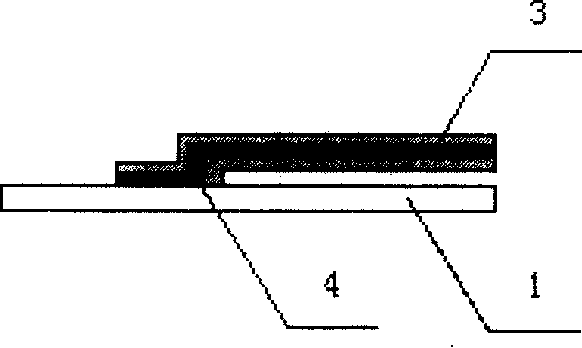

[0035] Such as figure 1 As shown, the electrothermally driven microactuator of the present invention has the effect of electrothermal braking, and can be designed and processed to have multiple cantilever beam structures (fingers) to complete microoperations such as cell capture and clamping. Each cantilever beam is installed on a silicon substrate and has a three-layer structure. Titanium and platinum are used as resistance heating materials, and titanium and platinum are placed between parylene C (a polymer material); that is, titanium and platinum are clamped by parylene C. The three-story structure constitutes a cantilever beam. This embodiment is 4 cantilevers (or fingers), see Figure 4 .

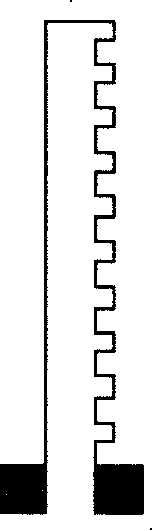

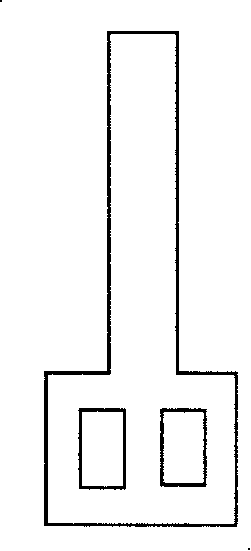

[0036] Among them: the resistance heating material can be a few-shaped structure or any shape (see figure 2 , 3 ).

[0037] The maximum working temperature of the thermally driven micro-actuator cantilever beam of the present invention is 70°C, and the voltage when it is fully b...

Embodiment 2

[0051] This embodiment is 2 cantilevers (or fingers, see Figure 8 ). Its processing technology differs from embodiment 1 in that:

[0052] used on silicon chips Silicon oxide is grown under the same light conditions as the substrate 1; the thickness of photoresist is 1.0 μm on the desired part of the silicon substrate; the thickness of parylene C as the first layer 3 is 0.35 μm; the thickness of the electrothermal material titanium is 0.055 μm , the platinum thickness is 0.195 μm. The thickness of parylene C as the third layer 3 is 0.24 μm;

Embodiment 3

[0054] The present embodiment is 6 cantilever beams, and its processing technology differs from embodiment 1 in that:

[0055] used on silicon chips Silicon oxide is grown under the same light conditions as the substrate 1; the thickness of photoresist is 1.8 μm on the desired part of the silicon substrate; the thickness of parylene C as the first layer 3 is 0.35 μm; the thickness of the electrothermal material titanium is 0.045 μm , the titanium thickness is 0.205 μm. The thickness of parylene C as the third layer 3 is 0.26 μm;

[0056] The two usage states of the six-finger gripper in this embodiment are as follows: Figure 7-1 , 7-2 shown. The index of the present invention should be determined according to the actual application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com