Analytical equipment enclosure incorporation phase changing materials

A phase-change material and cover technology, which is applied in the direction of analyzing materials, instruments, and measurement of scattering characteristics, can solve problems such as difficulties, and achieve the effects of reliability, intrinsic safety, high reliability, and enhanced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

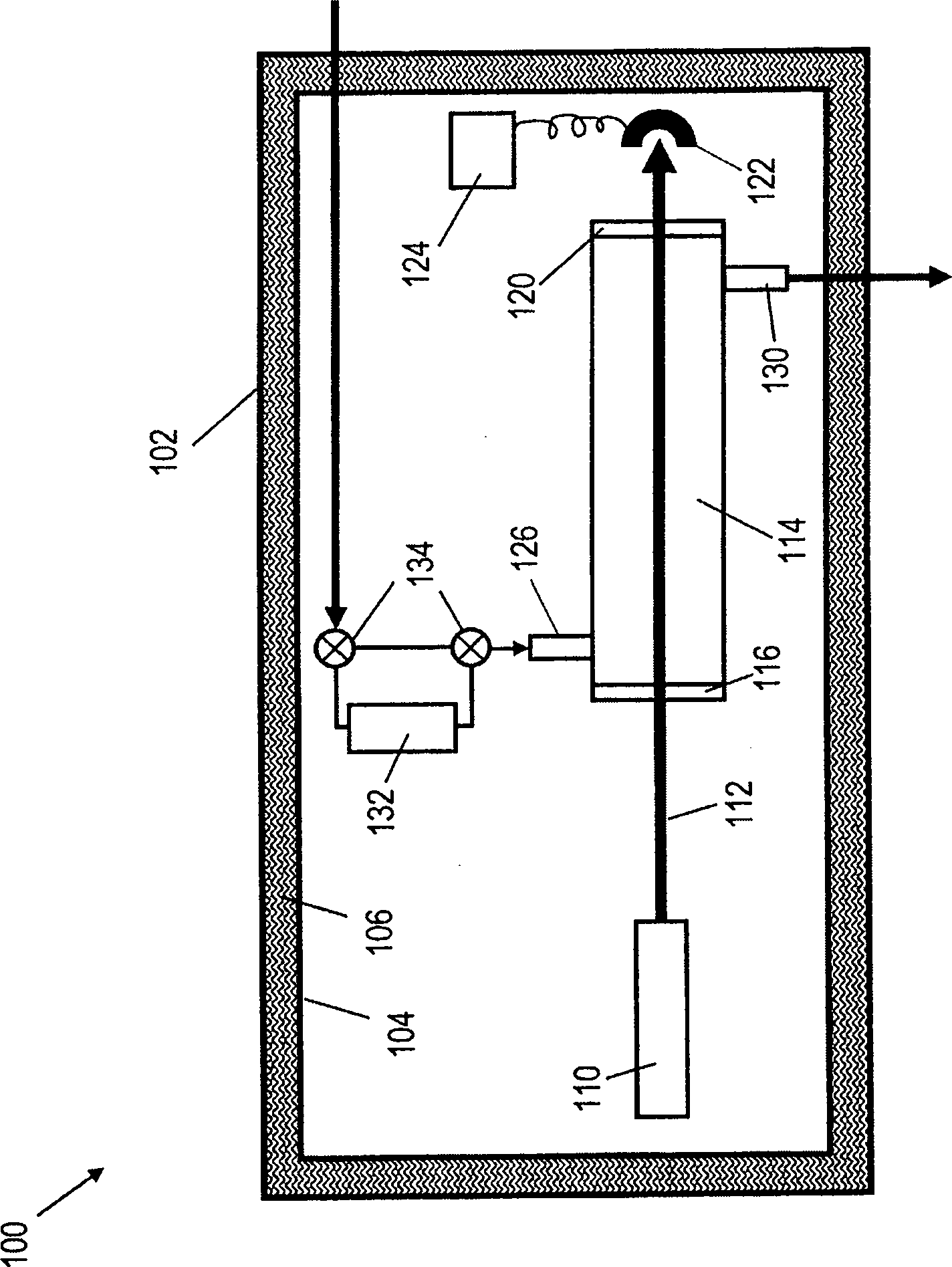

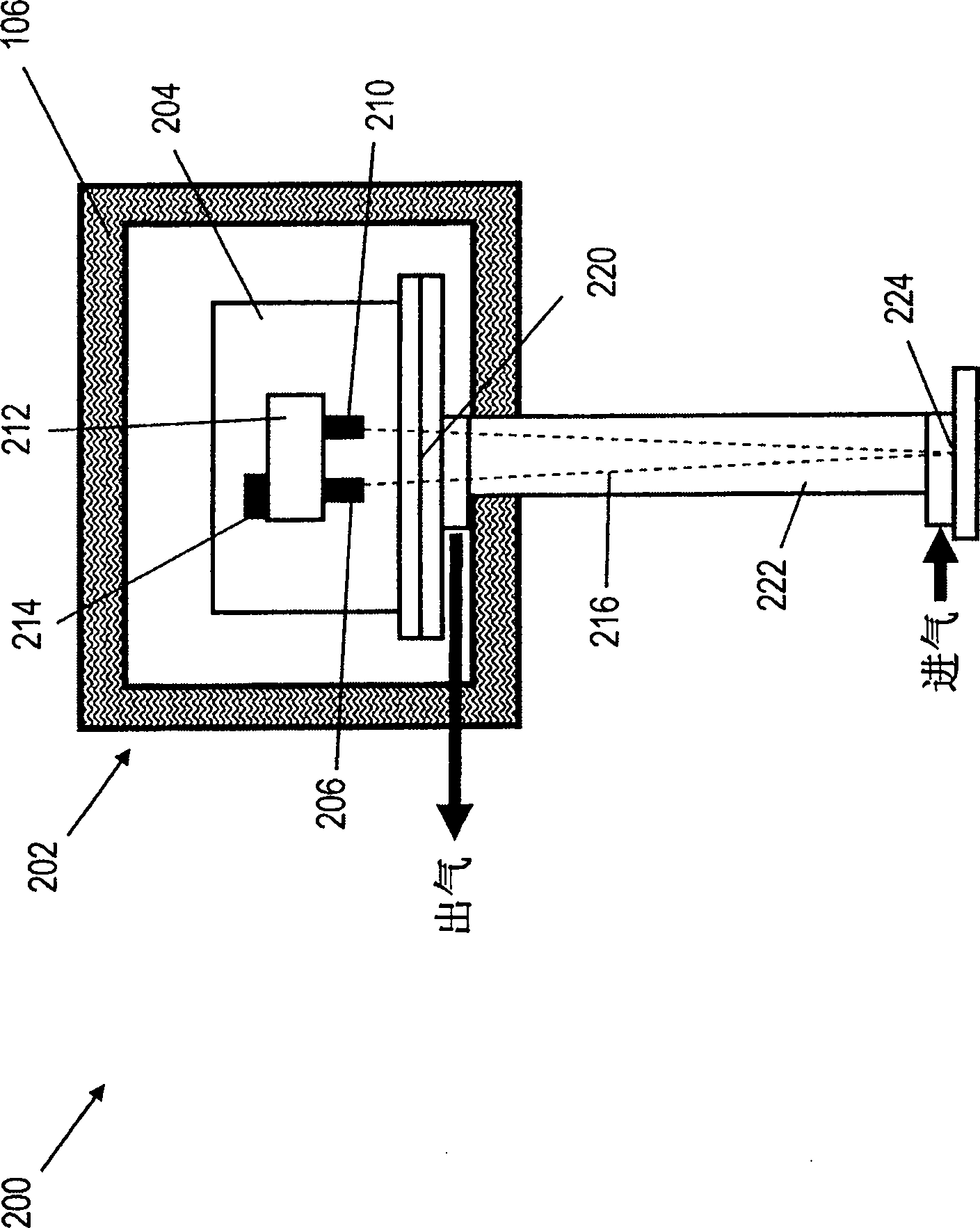

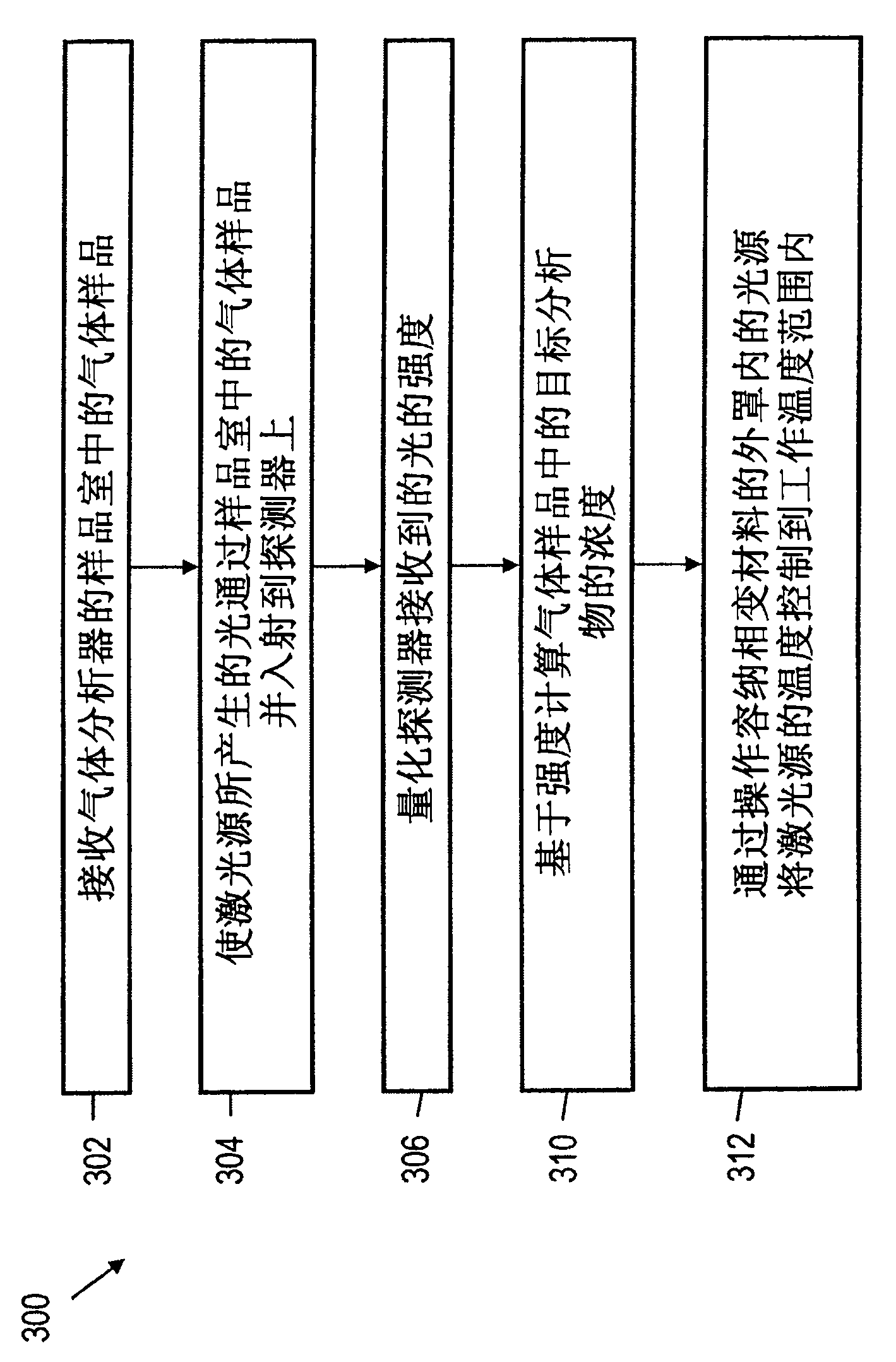

[0023] The presently disclosed subject matter provides methods, systems, techniques, devices, and articles of manufacture for maintaining a stable temperature for analyzers, such as tunable diode laser-based gas analyzers. A certain mass of phase change material (PCM) is incorporated into the design of the housing for the analyzer. The PCM mass provides a thermal buffer at the phase transition temperature due to the absorption of latent heat when the PCM transitions to a higher entropy state (ie gas or liquid) or the release of latent heat when the PCM transitions to a lower entropy state (ie liquid or solid). Since the phase transition occurs at a fixed phase transition temperature, a large latent buffer heat exchange with the surrounding environment is performed, thereby isolating the analyzer element within the enclosure from changes in the ambient temperature to which the enclosure is exposed. This will help ensure the accuracy and repeatability of the analyzer readings. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com