Fluid heating stirring equipment

A technology of heating, stirring and equipment, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., which can solve problems such as difficult temperature measurement, many heat-saving links, and low efficiency of stirring and dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

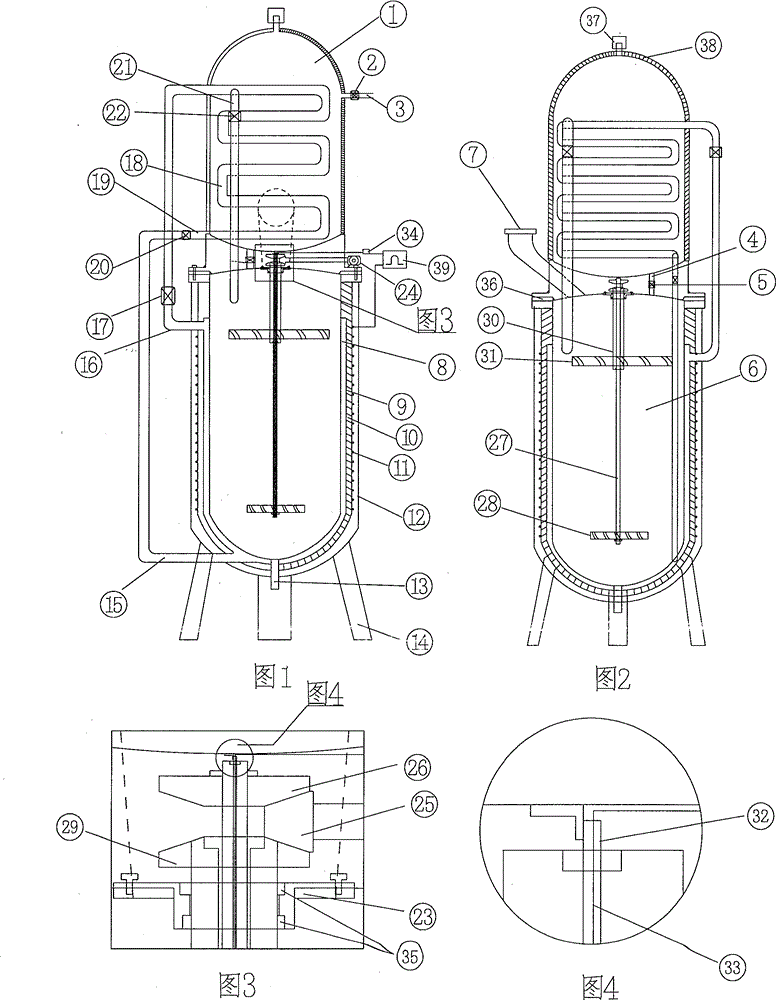

[0014] In this tower type stirring equipment, the heat storage tank 1 and the metering pump 2 are arranged on the solution feed pipe 3, the bottom of the heat storage tank is provided with a discharge pipe 4, and the discharge pipe is equipped with a solenoid valve 5, and a sandwich reactor 6. The kettle is provided with a dry powder feed port 7, a reaction kettle interlayer 8, an electromagnetic heating layer 9, an electromagnetic coil 11 wound on an insulating layer 10, the electromagnetic coil 11 is connected to the electromagnetic heater, a protective cover 12, and a reactor discharge pipe 13. The support base 14, the heat transfer oil input pipe 15 is set on the lower side of the reaction kettle and enters the interlayer 8 of the reaction kettle, the heat transfer oil output pipe 16 is output from the upper side of the reaction kettle interlayer 8, and communicates with the heat exchanger 18 in the heat storage tank through the booster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com