Integrated composite treatment method for in-situ PVD film coating after alloy steel surface nitriding

A composite treatment, alloy steel technology, applied in the field of material surface processing, can solve problems such as failure, cracking, peeling, etc., and achieve the effect of activating the matrix, enhancing the adhesion performance, and improving the comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

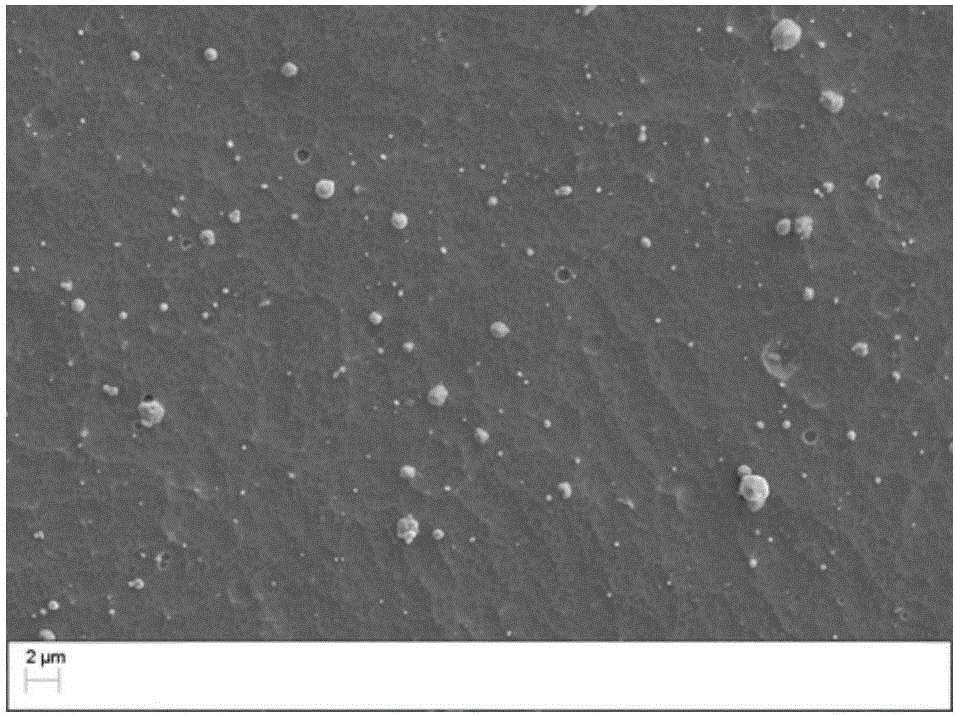

[0035] Example 1: In-situ preparation of TiN hard coating on the surface of H13 hot work die steel after nitriding

[0036] 1. Substrate surface pretreatment: (1) Grinding and polishing: Roughly grind and finely grind H13 hot work die steel on sandpaper of 200 mesh, 400 mesh, 600 mesh, 800 mesh, and 1000 mesh respectively, and the time of coarse and fine grinding is controlled at After 10 minutes of fine grinding, the sample was ultrasonically cleaned, and the cleaning agent was absolute ethanol to remove the abrasive debris generated during the grinding process. The ultrasonic cleaning time was 5 minutes, and dried in an oven. After the sample is ground, it is polished with W2.5 diamond polishing powder for 15 minutes. After polishing, the surface roughness Ra value of the sample reaches 0.3 μm. (2) Ultrasonic cleaning: The polished substrate was ultrasonically cleaned with absolute ethanol for 15 minutes, and then dried.

Embodiment 2

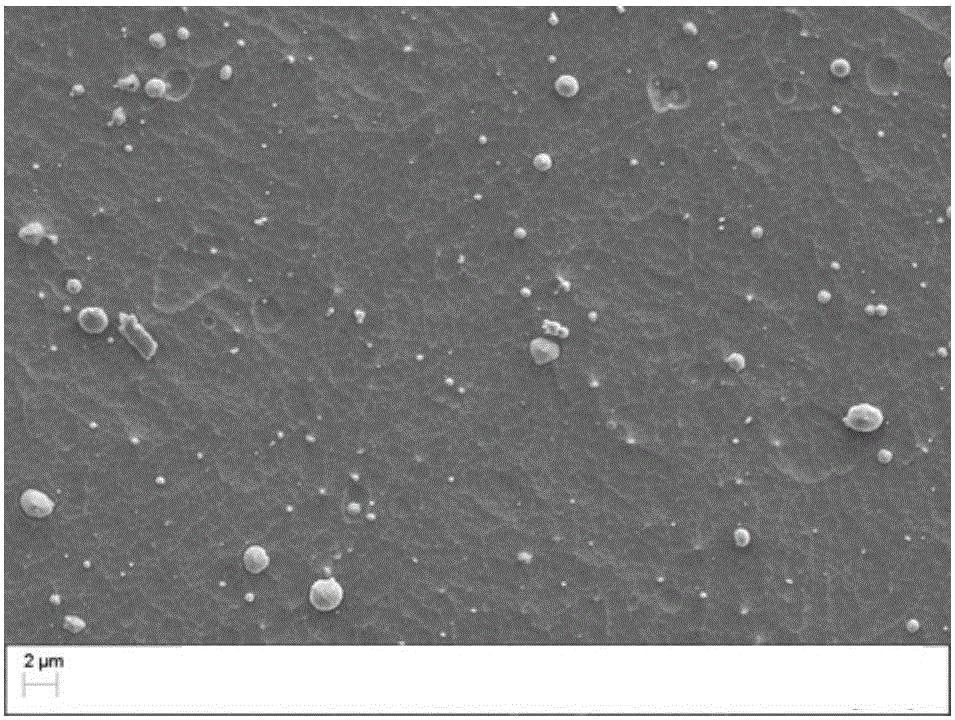

[0044] Example 2: In-situ preparation of Al after surface nitriding of H13 die steel 55 Ti 45 N hard coat

[0045] 1. Substrate surface pretreatment: with embodiment 1

[0046] 2. Ion cleaning and etching on the substrate surface: same as in Example 1.

[0047] 3. Plasma-assisted nitriding on the surface of the substrate: After ion cleaning and etching on the surface of the substrate, high-purity N is continuously introduced into the reaction furnace 2 , high purity H 2 and high-purity Ar, target current, substrate bias, temperature and pressure in the furnace are the same as above, N 2 The flow rate is 25sccm, H 2 The flow rate is 50 sccm, the Ar flow rate is controlled by air pressure, and plasma-assisted nitriding treatment is performed for 120 min.

[0048] 4. Coating evaporation deposition: After plasma-assisted nitriding of the substrate surface, TiN hard coating is deposited in situ. The deposition method is carried out in two stages: (1) The first stage uses hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com