Electronic heating device

An electronic heating and heating tube technology, which is applied in the field of electronic cigarettes, can solve the problems of high cost of PEEK materials and fiber cotton, plastic melting, and unsatisfactory heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Phosphoric acid and Al(OH) 3 The reaction generates aluminum dihydrogen phosphate solution, phosphoric acid and MgO react to generate magnesium dihydrogen phosphate solution, the aluminum dihydrogen phosphate solution and the magnesium dihydrogen phosphate solution are mixed in a certain proportion to form a mixed solution, and distilled water is added to dilute to make the dihydrogen phosphate in the solution. The concentration of aluminum was 89 g / L, and the concentration of magnesium dihydrogen phosphate was 9.5 g / L. Add a certain amount of CrO to the mixture 3 , so that CrO 3 The concentration of 2.5g / L. Then react with a certain amount of reactive pigment aluminum powder in a ball mill to obtain an orange suspension which is the base material of the coating. A certain amount of aluminum powder was added to the base material of the coating so that the concentration of the aluminum powder was 1.2 g / L. Disperse with high-speed stirring for about half an hour to ob...

Embodiment 2

[0066] Phosphoric acid and Al(OH) 3 The reaction generates an aluminum dihydrogen phosphate solution, and the aluminum dihydrogen phosphate solution is added to distilled water to dilute, so that the concentration of the aluminum dihydrogen phosphate in the solution is 98.5 g / L. Then add a certain amount of CrO 3 , so that CrO 3 The concentration is 3g / L. Then react with a certain amount of reactive pigment aluminum powder in a ball mill to obtain an orange suspension which is the base material of the coating. A certain amount of aluminum powder was added to the base material of the coating so that the concentration of the aluminum powder was 1.5 g / L. Disperse with high-speed stirring for about half an hour to obtain phosphate aluminum powder coating. Before use, water is used as a diluent to adjust the viscosity to 25cp, and it is coated on the pipe wall of the aluminum pipe to form a thermal insulation pipe.

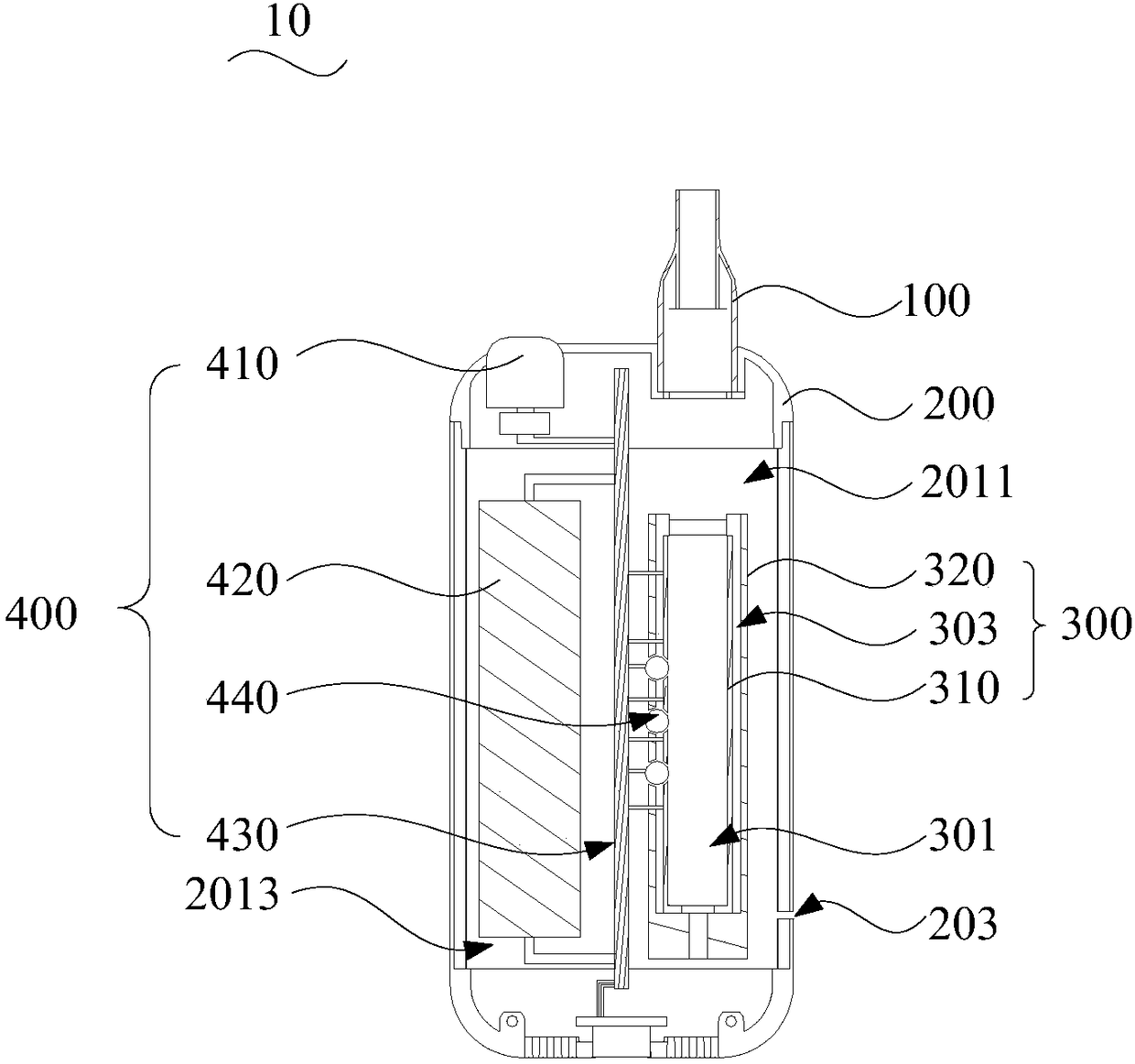

[0067] according to figure 2 As shown in the structure sho...

Embodiment 3

[0069] Preparation of raw materials for thermal insulation coating

[0070] Phosphoric acid and Al(OH) 3 The reaction generates aluminum dihydrogen phosphate solution, phosphoric acid and MgO react to generate magnesium dihydrogen phosphate solution, the aluminum dihydrogen phosphate solution and the magnesium dihydrogen phosphate solution are mixed in a certain proportion to form a mixed solution, and distilled water is added to dilute to make the dihydrogen phosphate in the solution. The concentration of aluminum was 96 g / L, and the concentration of magnesium dihydrogen phosphate was 3.5 g / L. Add a certain amount of CrO to the mixture 3 , so that CrO 3 The concentration of 3.25g / L. Then react with a certain amount of reactive pigment aluminum powder in a ball mill to obtain an orange suspension which is the base material of the coating. A certain amount of aluminum powder is added to the base material of the coating, so that the concentration of the aluminum powder is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com