Radiation electron heating electron gun

An electronic heating and electron gun technology, applied in the direction of thermionic cathode, electron emission electrode/cathode, electrode assembly support/installation/spacing/insulation, etc., can solve the difficulty of cathode temperature control, increase the temperature of cathode filament assembly, and electron gun High scrap rate and other issues, to avoid high temperature contact, improve cathode electric field strength, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

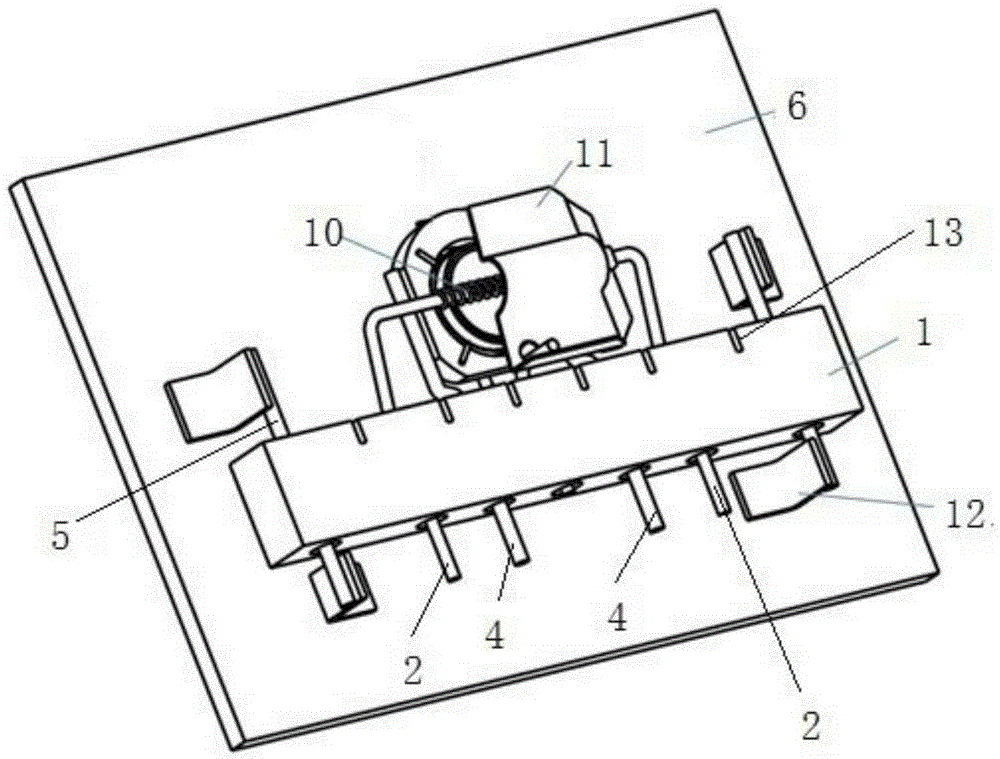

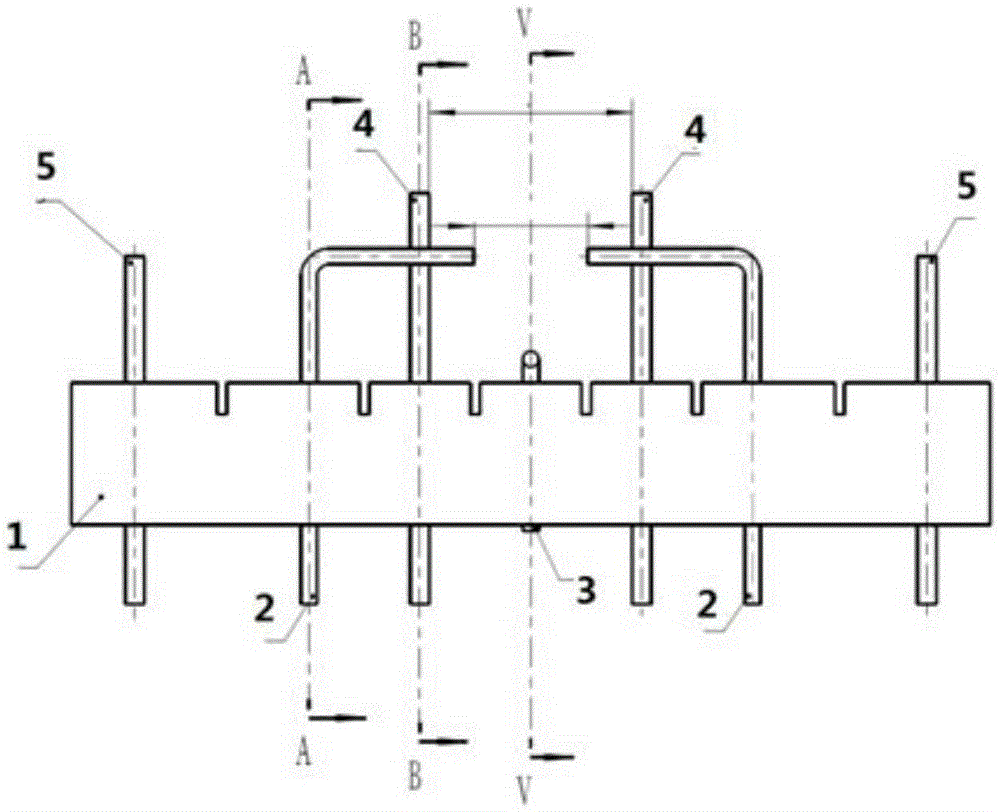

[0033] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

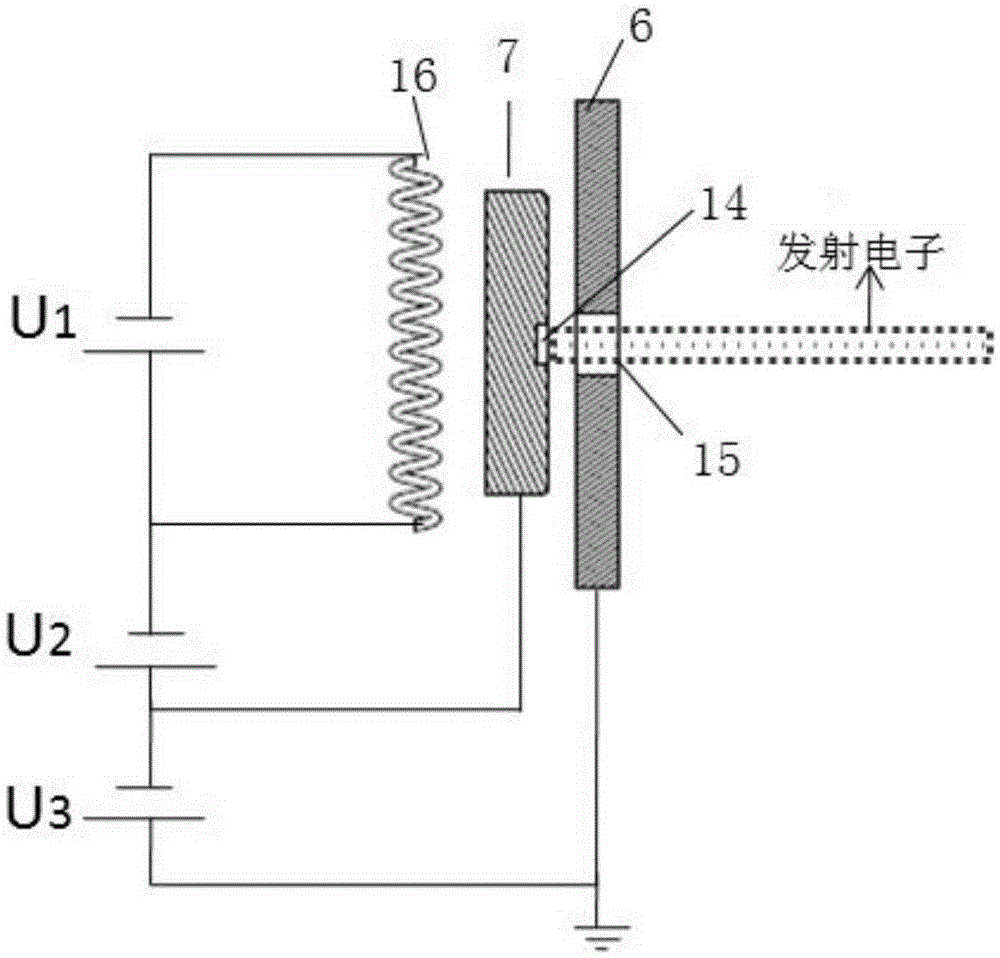

[0034] Such as Figure 1 to Figure 13 As shown, the present invention is a radiation electron heating type electron gun. The electron gun includes an insulator assembly, an anode plate 6 arranged in sequence, a cathode assembly for emitting electrons, and a filament assembly for electronically heating the cathode assembly. The anode plate is provided with a The anode hole 15 from which the electrons are emitted, the anode plate 6, the cathode assembly and the filament assembly are fixedly connected by an insulator assembly.

[0035] A device for accelerating the emitted electrons at high voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com