A manufacturing process of an electronic heater for an electronic thermostat

An electronic thermostat and manufacturing process technology, which is applied in the field of auto parts, can solve the problems of short life, long warm-up time, and low sensitivity, and achieve the effects of short response time, improved life, and simplified processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

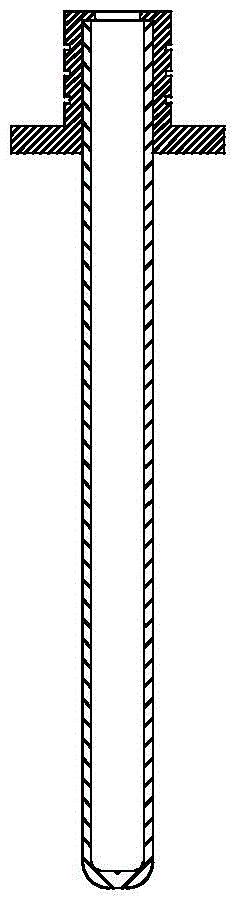

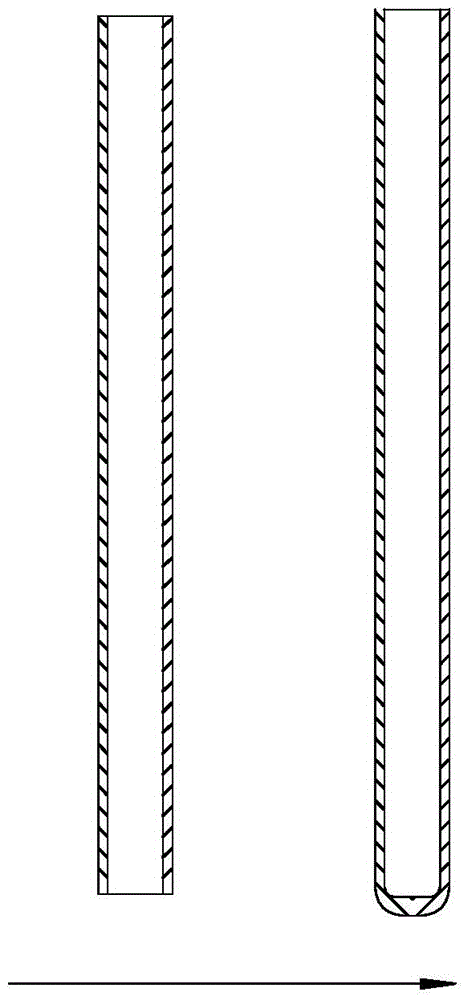

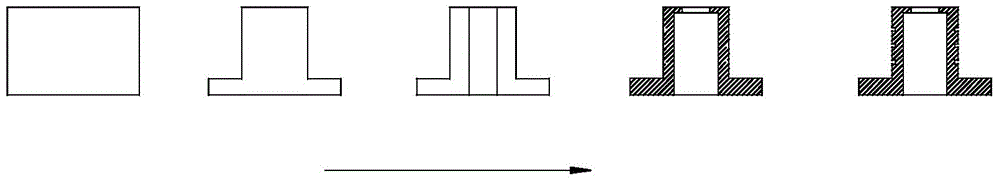

[0015] Such as figure 1 , 2 1. The manufacturing process of an electronic heater for an electronic thermostat shown in 3. First select a hollow tube with a diameter of 3 mm, cut the hollow tube into 100 mm by a cutting machine, and process the lower end of the cut hollow tube through a Baotou machine Form a cold-extruded Baotou, and then use an ultrasonic cleaning machine to clean the oil inside and outside the hollow tube; select a round steel with a diameter of 12mm and a length of 12mm, and form a circular step on the outer diameter of the car, and the horizontal width of the circular step gap is 2mm, and then drill the hole. The inner diameter is 3mm, that is, the diameter of the through hole formed by the inner circle step of the round steel is 3mm, and the hole is expanded again. Then cut off the lower part of the round steel by 2mm, so that the bottom of the finished product is smoother and flatter. Next, the hollow tube is pressed into the round steel to make close co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com