Electronic heater for electronic thermoregulator

An electronic thermostat, using electronic technology, applied to the shape of heating elements, etc., can solve the problems of long warm-up time, low sensitivity, short life, etc., and achieve the effects of short response time, simplified processing technology, and improved life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

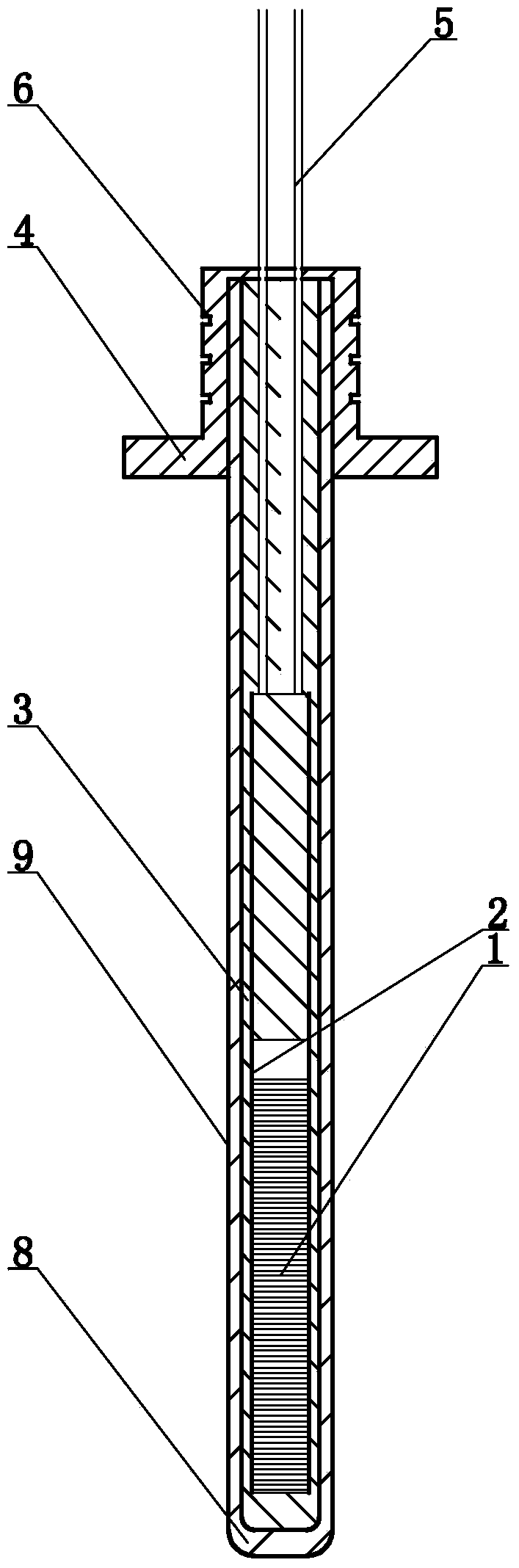

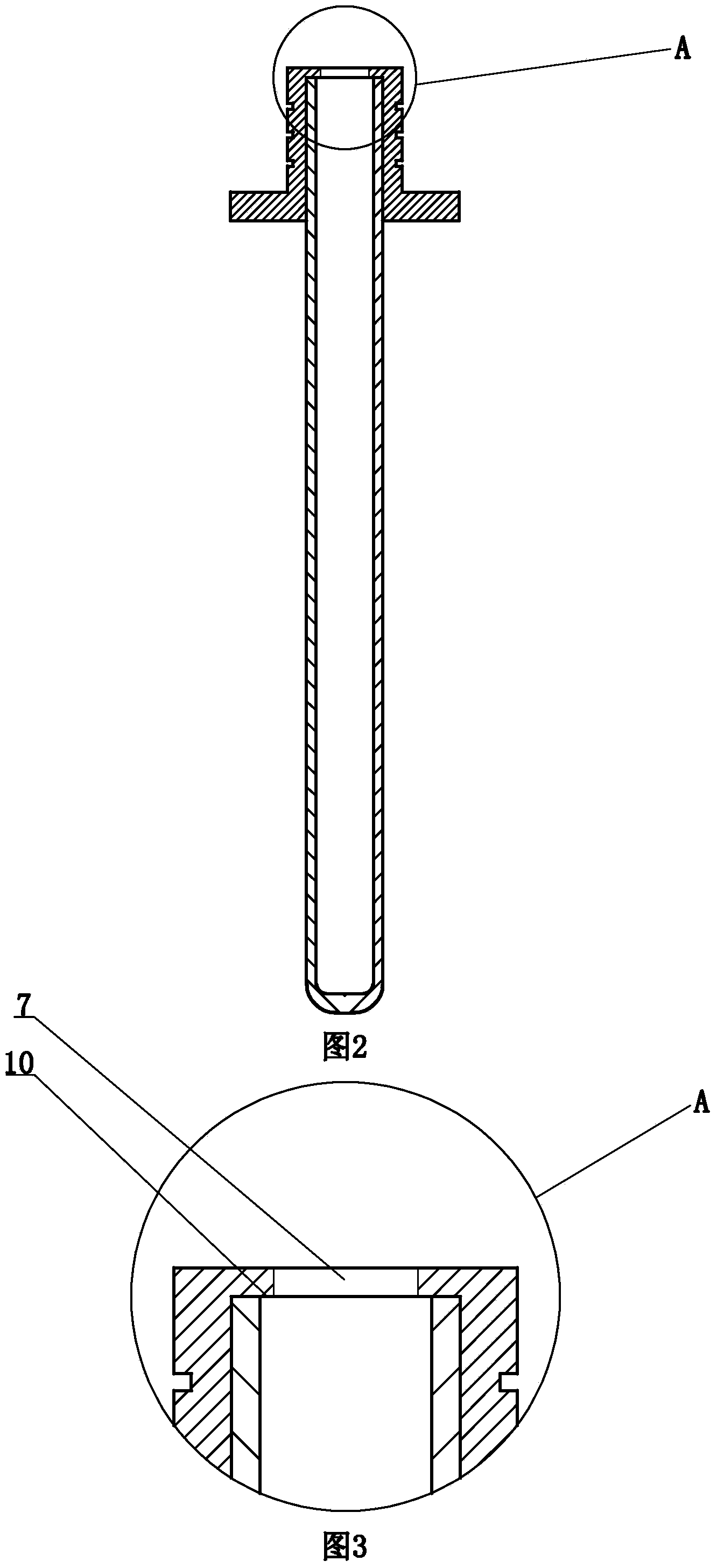

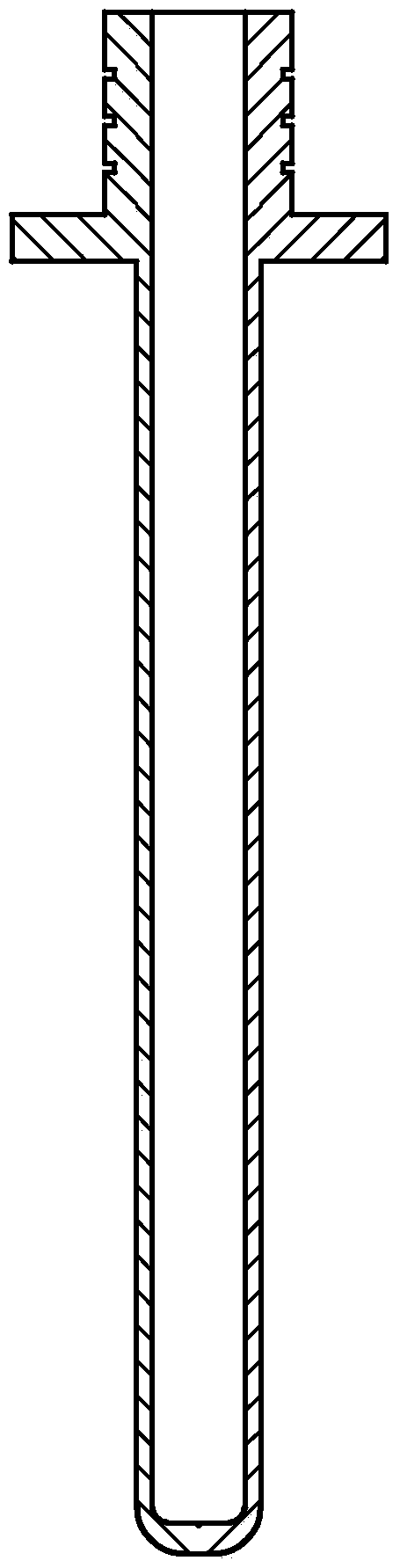

[0016] Such as figure 1 , 2 1. An electronic heater for an electronic thermostat shown in 3, comprising a metal shell tube 9 that is hollow up and down, the diameter between the inner walls of the metal shell tubes 9 is 3 mm, the length is 100 mm, and the diameter between the inner walls of the upper sleeve 4 is 4 mm. The lower end of the tube 9 is sealed and connected to the cold extruded head 8, and the inner wall of the metal shell tube 9 is provided with a layer of high-temperature insulating material 3, and the bottom of the inner wall of the high-temperature insulating material 3 is provided with an upper and lower hollow magnetic tube 2, and the lower part of the inner wall of the magnetic tube 2 is provided with There is a heating wire 1, a high-temperature insulating material 3 is arranged above the heating wire 1, and an upper cover 4 is set on the upper end of the metal shell tube 9. The outer wall step diameter of the upper cover 4 is 12 mm and the length is 24 mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com