Method for processing acidic wastewater and alkaline wastewater of viscose fiber industry

A technology of acidic wastewater and viscose fiber, applied in chemical instruments and methods, filtration treatment, precipitation treatment, etc., can solve the problems of insufficient recycling of wastewater, achieve good industrial application prospects, save production costs, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

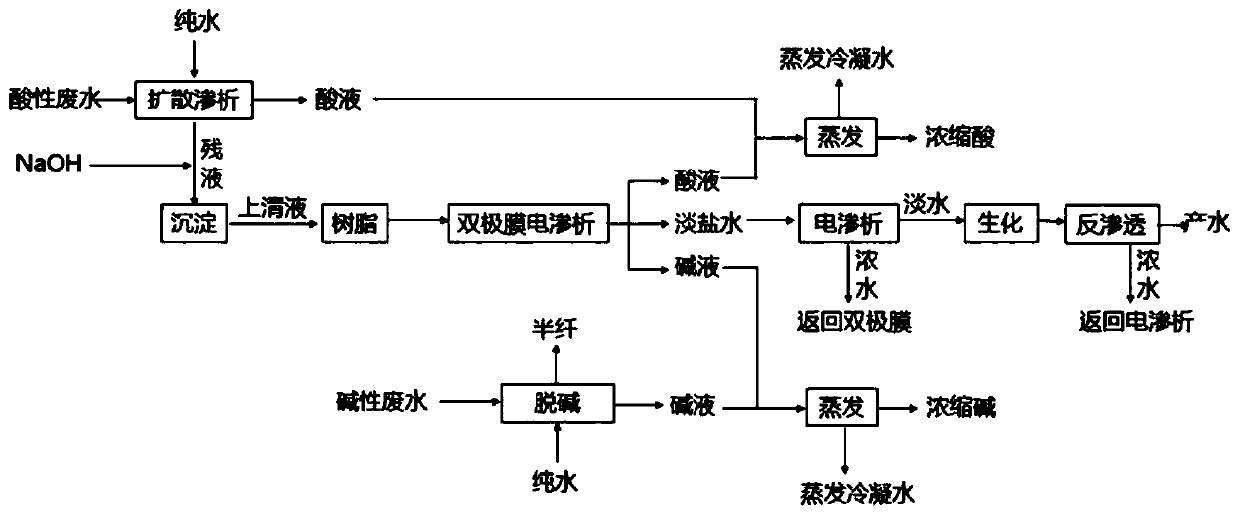

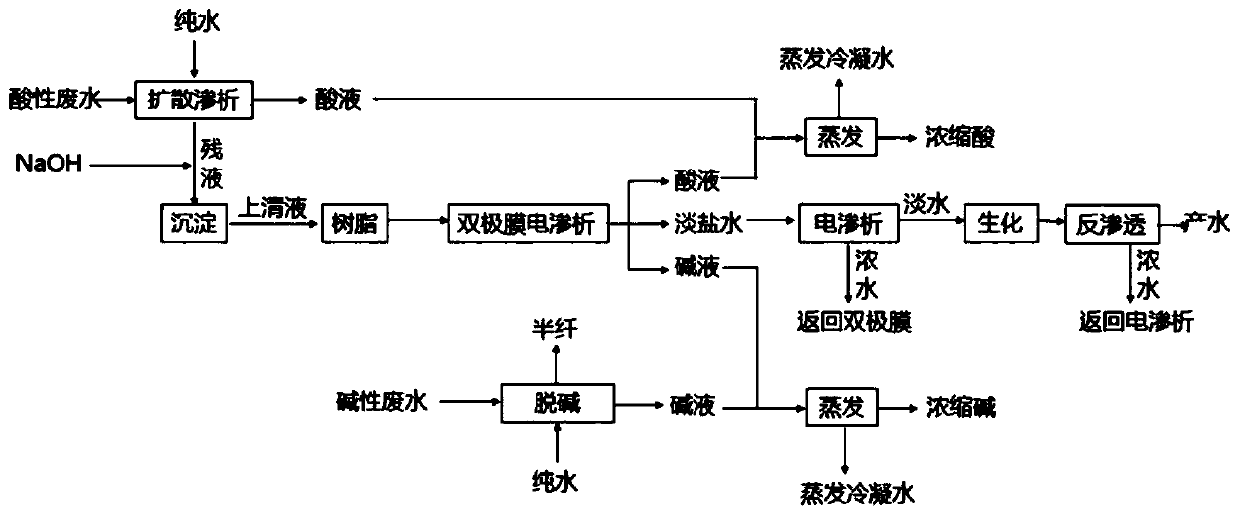

[0037] Such as figure 1 As shown, the method for treating acidic wastewater and alkaline wastewater in the viscose fiber industry in this embodiment includes a treatment method for acidic wastewater and a treatment method for alkaline wastewater.

[0038] Wherein: acid waste water containing mass fraction is 10% sulfuric acid, 12% sulfate, and the treatment method of acid waste water comprises the steps:

[0039] S11. Acidic wastewater and pure water are fed into the diffusion dialysis device at the same time. The acid in the acidic wastewater migrates to the pure water, and the acidic wastewater becomes a raffinate. The main components are salt and a small amount of acid. After receiving the acid, the pure water becomes an acid recovery solution. The mass fraction of sulfuric acid in the acid recovery liquid is 8%, wherein the mass fraction of sodium sulfate is 0.3%; the mass fraction of each substance in the raffinate is: 2% sulfuric acid, 12% sulfate;

[0040] S12, add 5mo...

Embodiment 2

[0051] Such as figure 1 As shown, the method for treating acidic wastewater and alkaline wastewater in the viscose fiber industry in this embodiment includes a treatment method for acidic wastewater and a treatment method for alkaline wastewater.

[0052] Wherein: acid waste water containing mass fraction is 4% sulfuric acid, 10% sulfate, and the treatment method of acid waste water comprises the steps:

[0053] S11. Acidic wastewater and pure water are fed into the diffusion dialysis device at the same time. The acid in the acidic wastewater migrates to the pure water, and the acidic wastewater becomes a raffinate. The main components are salt and a small amount of acid. After receiving the acid, the pure water becomes an acid recovery solution. The sulfuric acid mass fraction of acid recovery liquid is 3.2%, wherein the mass fraction containing sodium sulfate is 0.3%; The mass fraction of each substance in raffinate is: 0.8% sulfuric acid, 10% sulfate;

[0054] S12, add 5mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com