Glass polishing equipment

A glass and equipment technology, applied in the field of glass polishing equipment, can solve the problems of difficult and uniform polishing of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

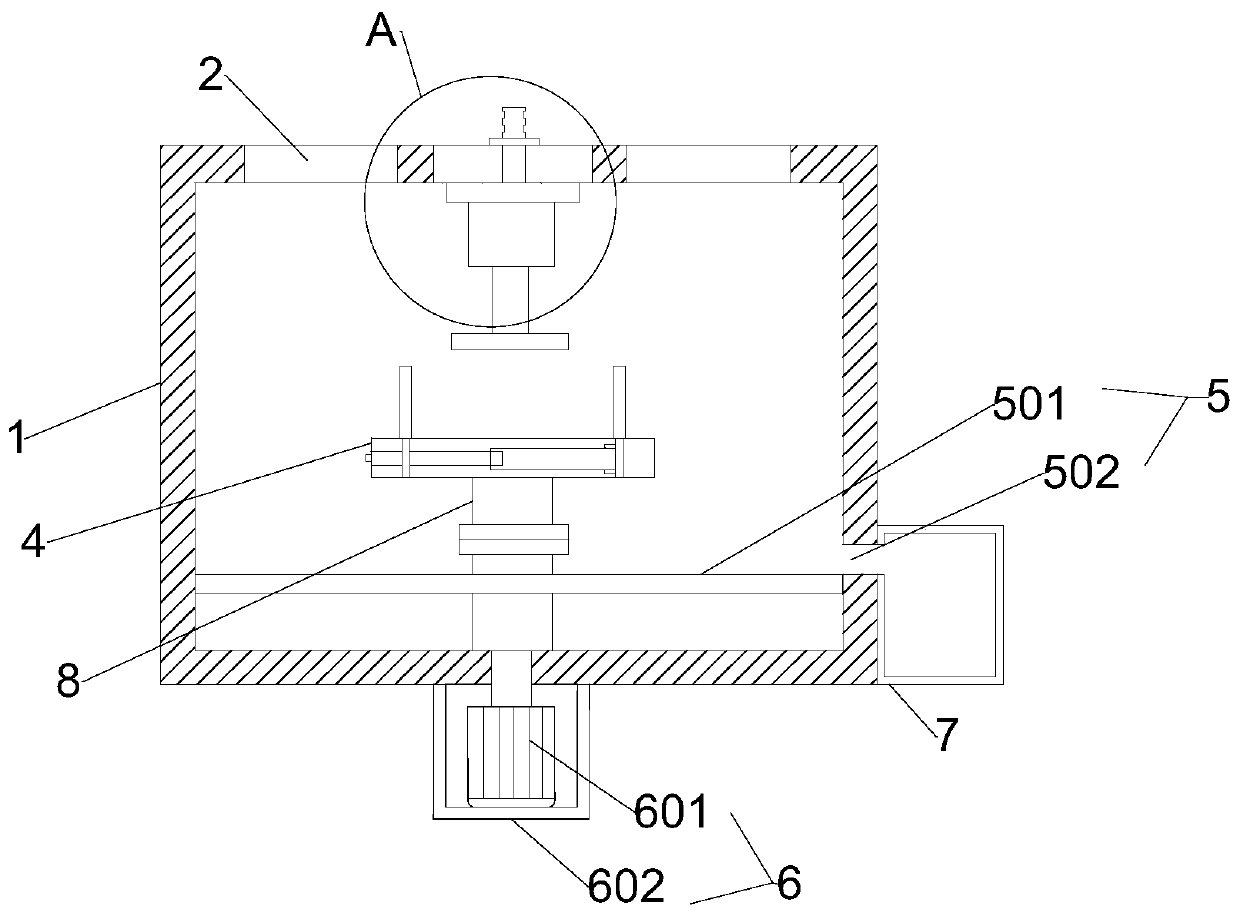

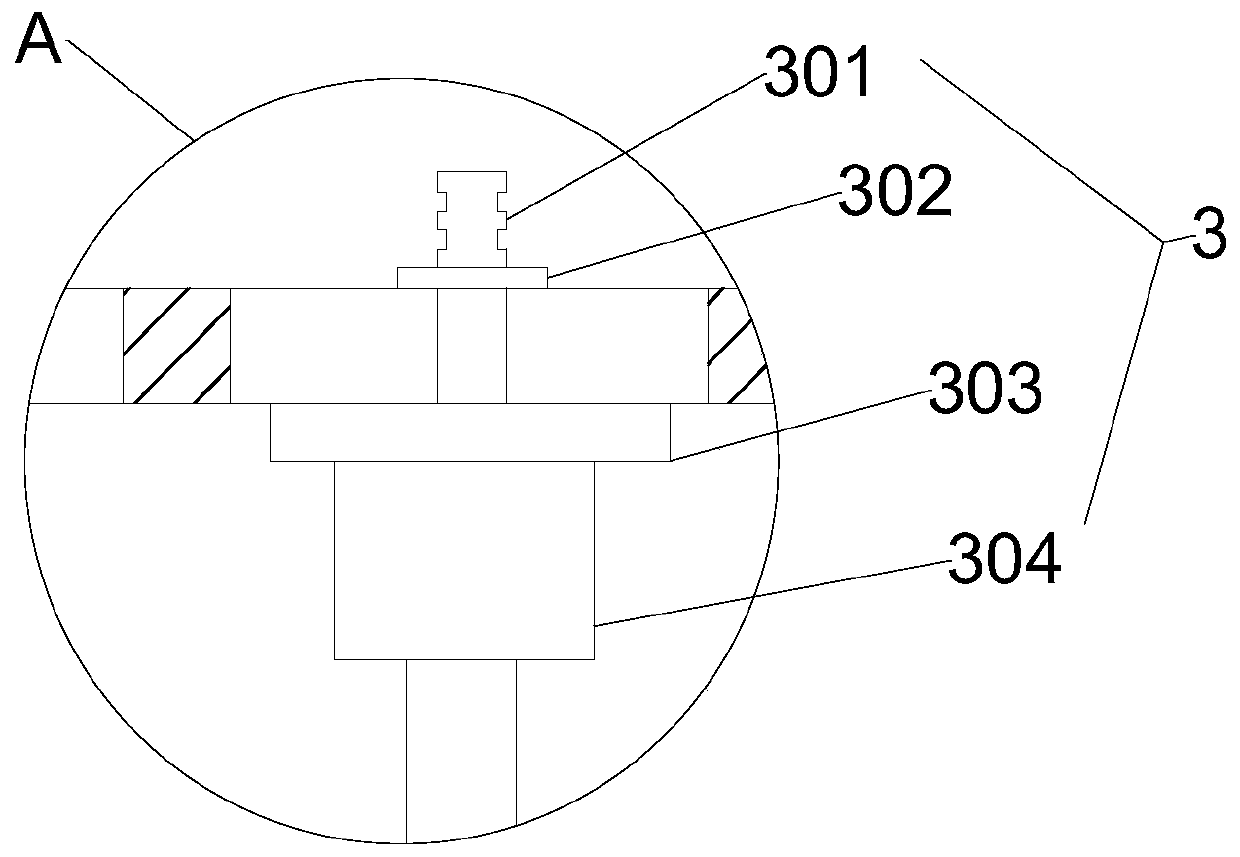

[0033] figure 1 It is a schematic structural diagram of a polishing device for glass provided in Embodiment 1 of the present invention; figure 2 for figure 1 The schematic diagram of the enlarged structure of A; such as Figure 1-Figure 2 , a glass polishing device, comprising a housing 1, a see-through window 2, a polishing mechanism 3, a fixing mechanism 4, a rotating mechanism 5, a driving mechanism 6, a dust collection box 7 and a rotating rod 8, the top of the housing 1 A polishing mechanism 3 is arranged in the middle, and the top of the housing 1 is symmetrically fixed on both sides of the polishing mechanism 3 with see-through windows 2 for observation, and the polishing mechanism 3 is provided with a fixing mechanism 4 directly below the inside of the housing 1. The bottom of the fixing mechanism 4 is fixedly connected with the rotating mechanism 5 through the rotating rod 8, and the lower end of the rotating rod 8 passes through the rotating mechanism 5 and is fix...

Embodiment 2

[0046] Such as Figure 6 , Figure 6 A schematic structural diagram of a polishing device for glass provided by Embodiment 2 of the present invention. The difference between Embodiment 2 and Embodiment 1 is that the drive mechanism 6 is replaced by a fan 9. Others are the same as Embodiment 1. This embodiment Among them, the bolts of the fan 9 are arranged on the top of the fixing mechanism 4 and the left side wall of the housing 1, so that under the action of the fan 9, dust etc. will be blown into the dust collection box 7 by the wind.

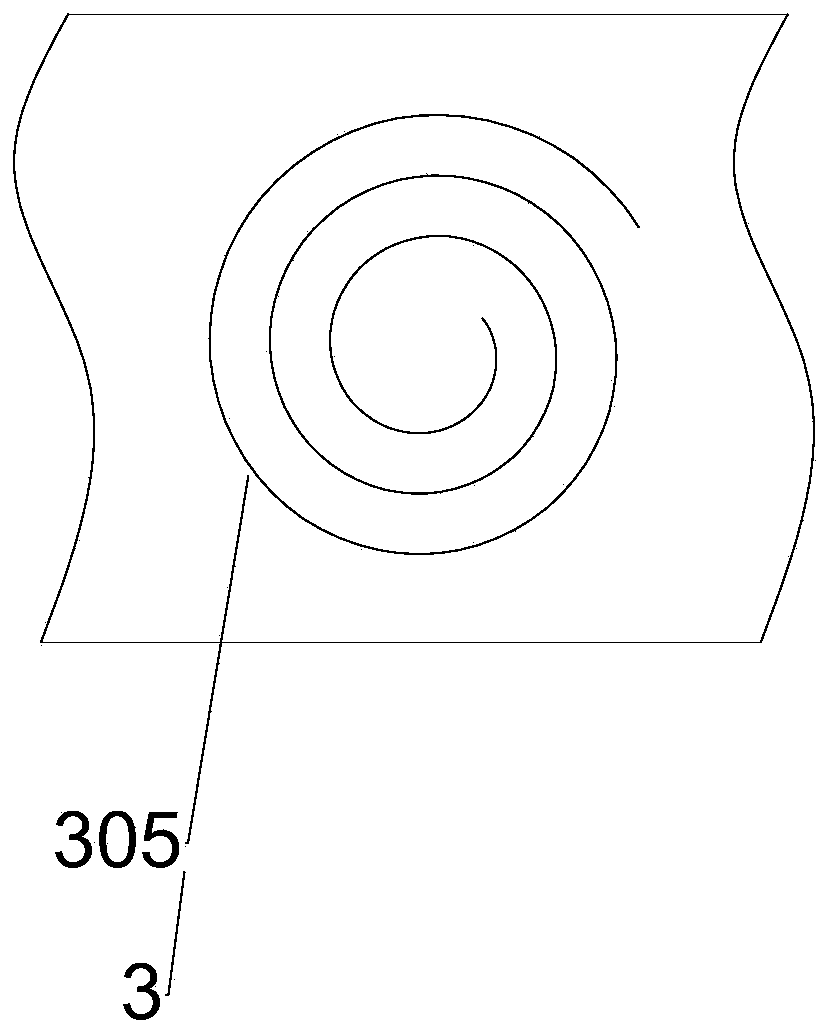

[0047] Working principle: adjust the height in advance, then manually hold the upper end of the connecting rod 301, and then move the connecting rod 301 along the spiral track 305. At this time, the polishing machine 304 will be polished under the drive of the connecting rod 301. 4051, drives the first rotating rod 4052 to rotate, and the external thread 4053 cooperates with the internal thread. When the first rotating rod 4052 rotates cloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com