High-strength thermal-shock-resistant refractory brick

A technology of thermal shock resistance and refractory bricks, which is applied in the field of refractory bricks, can solve the problems of low softening temperature, poor thermal shock resistance, and short service life of loads, and achieve high mechanical strength, strong thermal shock resistance, and shock resistance. The effect of hot and cold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

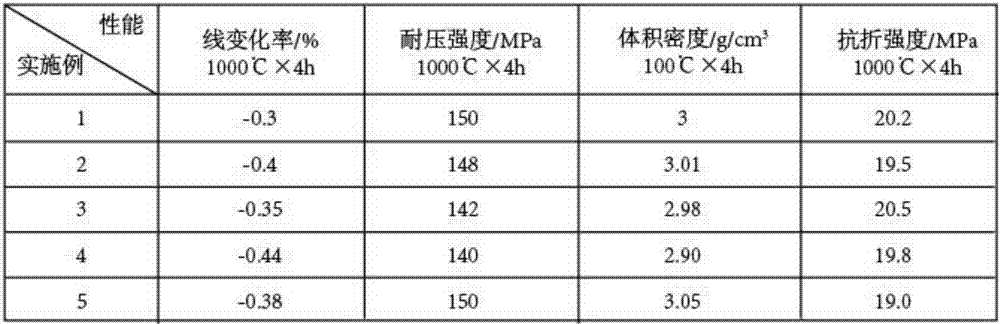

Examples

Embodiment 1

[0020] Example 1: A high-strength thermal shock-resistant refractory brick, comprising the following raw materials in weight percentages: 16 parts of fused corundum powder, 12 parts of tabular corundum, 48 parts of alumina micropowder, 2 parts of magnesia fine powder, zirconia powder 2 parts, 1 part of silicon carbide, 1 part of silica powder, 2 parts of sodium silicate, 2 parts of andalusite powder, 1 part of titanium boride additive, 5 parts of sillimanite fine powder, 5 parts of Guangxi clay, 10 parts of scrap iron ditch Parts, 10 parts of waste silicon bricks. The particle diameter of the andalusite fine powder and the sillimanite fine powder is 40 μm; the particle diameter of the silicon micropowder is ≤5 μm. Described waste silica molybdenum brick is the waste silica molybdenum brick that getting particle size is 2mm after crushing and screening. The waste iron trench material is scrap iron trench material with a particle size of 1 mm after being crushed and screened. ...

Embodiment 2

[0021] Example 2: A high-strength thermal shock-resistant refractory brick, comprising the following raw materials in weight percentages: 20 parts of fused corundum powder, 16 parts of tabular corundum, 52 parts of alumina micropowder, 6 parts of magnesia fine powder, zirconia powder 6 parts, 4 parts of silicon carbide, 4 parts of silica powder, 6 parts of sodium silicate, 6 parts of andalusite powder, 6 parts of titanium boride additive, 15 parts of sillimanite fine powder, 8 parts of Guangxi clay, 15 parts of scrap iron ditch Parts, 15 parts of waste silicon bricks. The particle diameter of the andalusite fine powder and the sillimanite fine powder is 80 μm; the particle diameter of the silicon micropowder is ≤5 μm. Described waste silica molybdenum brick is the waste silica molybdenum brick that getting particle size is 12mm after crushing and screening. The waste iron trench material is scrap iron trench material with a particle size of 10mm after being crushed and screen...

Embodiment 3

[0022] Example 3: A high-strength thermal shock-resistant refractory brick, comprising the following raw materials in weight percentages: 18 parts of fused corundum powder, 14 parts of tabular corundum, 50 parts of alumina micropowder, 4 parts of magnesia fine powder, zirconia powder 4 parts, 2 parts of silicon carbide, 2 parts of silica powder, 4 parts of sodium silicate, 4 parts of andalusite powder, 1 part of titanium boride additive, 10 parts of sillimanite fine powder, 7 parts of Guangxi clay, 12 parts of scrap iron ditch Parts, 12 parts of waste silicon bricks. The particle diameter of the andalusite fine powder and the sillimanite fine powder is 60 μm; the particle diameter of the silicon micropowder is ≤5 μm. Described waste silica molybdenum brick is the waste silica molybdenum brick that getting particle size is 6mm after crushing and screening. The scrap iron ditch material is the scrap iron ditch material with a particle size of 5 mm after being crushed and screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com