Refining agent for atmosphere protected electro-slag re-melting

A technology of electroslag remelting and refining agent, applied in the field of electroslag remelting, can solve the problems of difficulty in dissolved oxygen, restriction of purity of alloy products, poor stability, etc., to improve metallurgical quality, reduce the content of non-metallic inclusions, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

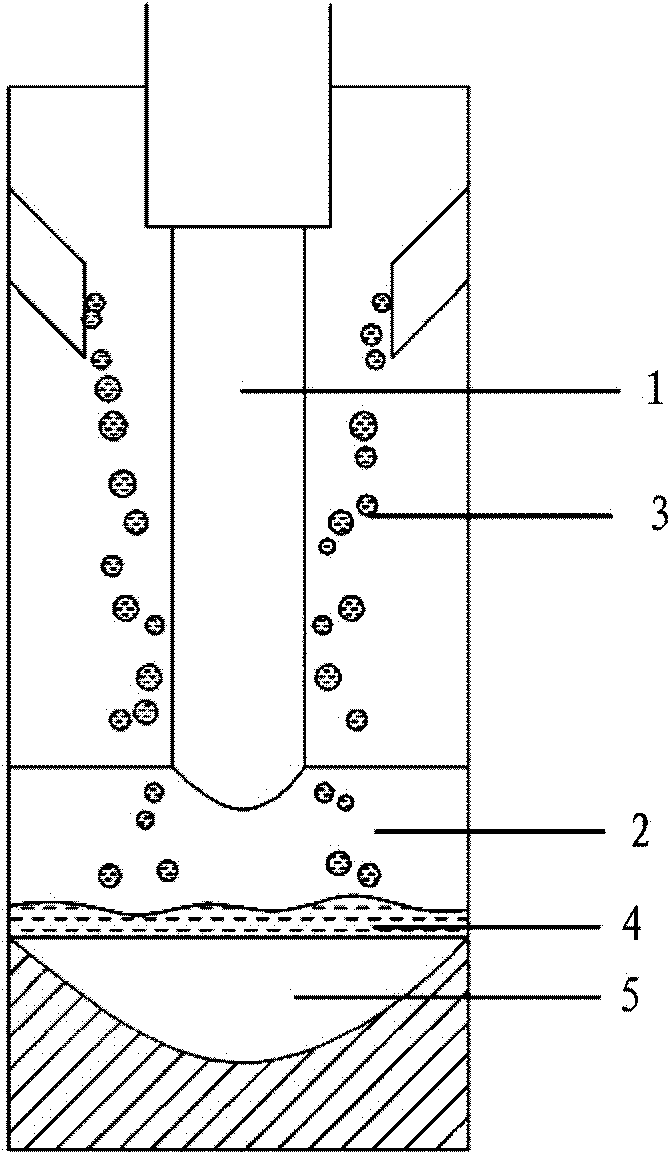

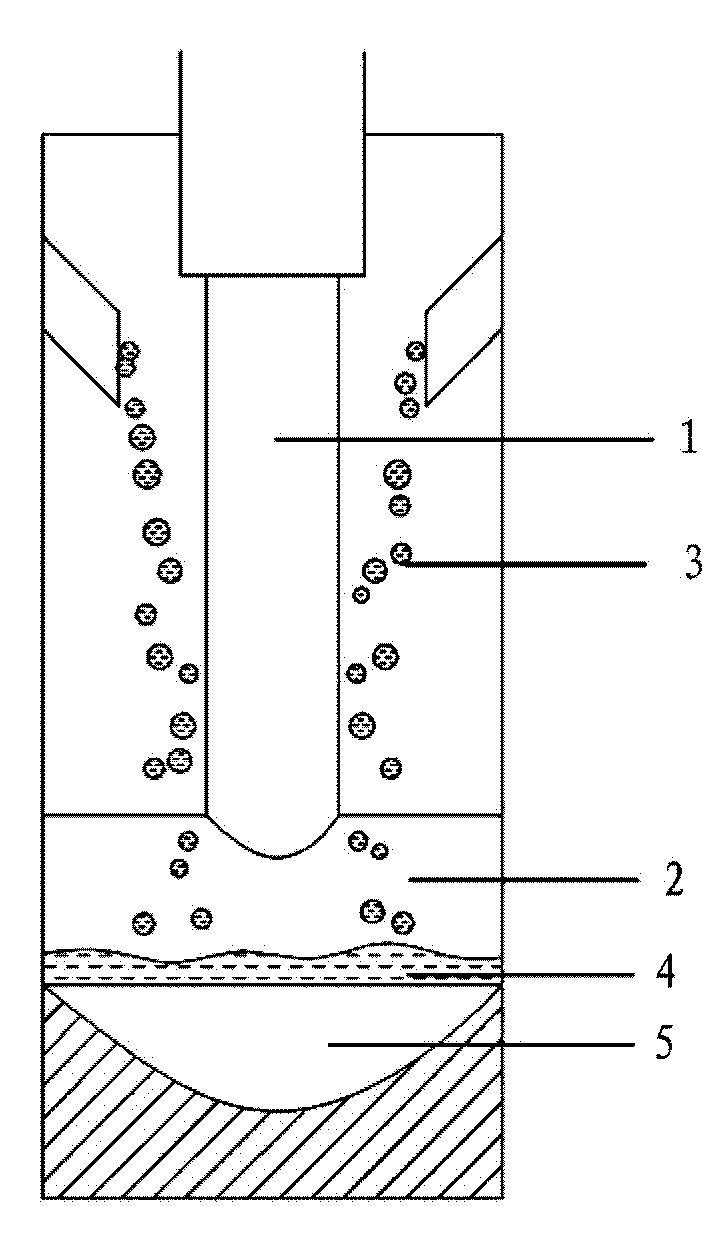

Image

Examples

Embodiment 1

[0037] In this example, the raw material to be refined is H13 steel, and its specific gravity is about 7.8g / cm 3 , the total oxygen content is 30ppm, the sulfur content is 88ppm, and the phosphorus content is 120ppm. H13 steel is a hot work die steel, which implements the standard GB / T1299-2000. The slag is composed of 60% calcium fluoride (CaF 2 ), 20% calcium oxide (CaO) and 20% aluminum oxide (Al 2 o 3 ) composition, at 1600°C, the specific gravity of the slag is about 2.7g / cm 3 . Mix metal calcium powder, metal aluminum powder, H13 steel powder and slag in a ratio of 1:1:3:1 by weight, then put it into a designated mold, and use a cold isostatic press to extrude at a pressure of 150MPa for 1 Hours, after forming, it is baked under argon protection at 700°C for 24 hours to form a granular refining agent with a particle size of 0.1mm. In this example, the specific gravity of the prepared refining agent is 3g / cm 3 . The specific gravity value is greater than the speci...

Embodiment 2

[0040] In this example, the raw material to be refined is H13 steel, and its specific gravity is about 7.8g / cm 3 , the total oxygen content is 30ppm, the sulfur content is 70ppm, and the phosphorus content is 100ppm. Slag consists of 70% CaF 2 and 30% Al 2 o 3 composition, at 1600°C, the specific gravity of the slag is about 2.8g / cm 3 . Mix metal calcium powder, metal aluminum powder, H13 steel powder and slag in a ratio of 2:1:5.3:1 by weight, then put it into a designated mold, and use a cold isostatic press to extrude at 180MPa for 1 Hours, after forming, it is baked under argon protection at 700°C for 24 hours to form a granular refining agent with a particle size of 10mm. In this example, the specific gravity of the prepared refining agent is 5g / cm 3 . The specific gravity value is greater than the specific gravity of the slag liquid in the electroslag remelting process and smaller than the specific gravity of the alloy liquid formed from the molten H13 steel after...

Embodiment 3

[0043] In this example, the raw material to be refined is S136 steel, and its specific gravity is about 7.8g / cm 3 , the total oxygen content is 28ppm, the sulfur content is 62ppm, and the phosphorus content is 92ppm. Slag consists of 60% CaF 2 , 20% CaO and 20% Al 2 o 3 Composition, at 1600°C, the specific gravity of the slag is 2.7g / cm 3 . Mix metal calcium powder, metal aluminum powder, S136 steel powder and slag according to the ratio of 1:2:6.6:0.8 by weight, then put it into a designated mold, and use a cold isostatic press to extrude 1.2 Hours, after forming, it is baked under argon protection at 720°C for 24 hours to form a granular refining agent with a particle size of 3mm. In this example, the specific gravity of the prepared refining agent is 6g / cm 3 . The specific gravity value is greater than the specific gravity of the slag liquid in the electroslag remelting process and smaller than the specific gravity of the alloy liquid formed by melting the S136 steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com