Technology for removing mercury in contaminated acid wastewater

A technology for the removal of polluted acid wastewater, applied in the field of lead and zinc smelting, can solve the problems of inability to treat suspended particulate mercury and colloidal mercury in water, Hg fluctuation of polluted acid wastewater, low Hg compliance rate of wastewater, etc., and achieves simple production control. Easy to operate, improve the cohesion effect, and the effect of high Hg compliance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

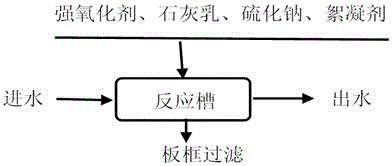

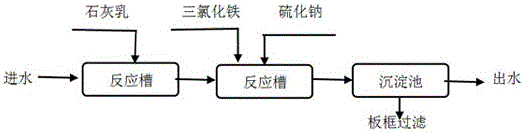

Method used

Image

Examples

Embodiment 1

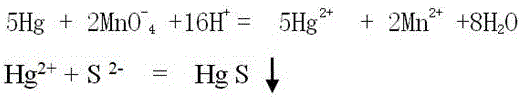

[0022] (1) The total mercury concentration generated during the sulfuric acid dynamic wave washing process is 20mg / L, and the volume is 33m 3 The dirty acid wastewater is pumped into the reaction tank, and the mass percent concentration is added to be 5%, and the volume is 4.18L metered KMnO 4 React for 15-20 minutes, then add the Baume degree to 3-4, the volume is 8m 3 Lime milk reacted for 10 minutes, adjusted pH value to 3-4, Hg in wastewater 2+ When the ion concentration is 20mg / L, add sodium sulfide with a mass percentage concentration of 5% and a volume of 14.63L, and react for 30-45 minutes.

[0023] (2) Add flocculant polyacrylamide with a mass per thousand concentration of 3‰ and a volume of 1-1.5L to the pulp after mercury removal, and pump the liquid into a plate-and-frame filter after reacting for 5 minutes to obtain filtrate and filter residue. The Hg content in the filtrate is less than 0.03mg / L, and the mercury content in the filter residue is 0.264%, which is...

Embodiment 2

[0025] (1) The total mercury concentration produced during the sulfuric acid dynamic wave washing process is 650mg / L, and the volume is 33m 3 The dirty acid wastewater is pumped into the reaction tank, and the mass percentage concentration is 5%, and the volume is 136L of KMnO 4 React for 15-20 minutes, then add the Baume degree to 3-4, the volume is 8 m 3 Lime milk reacted for 10 minutes, adjusted pH value to 3-4, Hg in wastewater 2+ When the ion concentration is 650mg / L, add sodium sulfide with a concentration of 5% and a volume of 475L, and react for 30-45 minutes.

[0026] (2) Add flocculant polyacrylamide with a mass per thousand concentration of 3‰ and a volume of 1-1.5L to the pulp after mercury removal, and pump the liquid into a plate-and-frame filter after reacting for 5 minutes to obtain filtrate and filter residue. The Hg content in the filtrate is less than 0.03mg / L, and the mercury content in the filter residue is 7.82%, which is comprehensively recovered.

Embodiment 3

[0028] (1) The total mercury concentration produced during the sulfuric acid dynamic wave washing process is 2000mg / L, and the volume is 33m 3 The dirty acid wastewater is pumped into the reaction tank, and the mass percentage concentration is 5%, and the volume is 418L of KMnO 4 React for 15-20 minutes, then add the Baume degree to 3-4, the volume is 8m 3 Lime milk reacted for 10 minutes, adjusted pH value to 3-4, Hg in wastewater 2+ When the ion concentration is 2000mg / L, add sodium sulfide with a mass percentage concentration of 5% and a volume of 1463L, and react for 30-45 minutes.

[0029] (2) Add flocculant polyacrylamide with a mass per thousand concentration of 3‰ and a volume of 1-1.5L to the pulp after mercury removal, and pump the liquid into a plate-and-frame filter after reacting for 5 minutes to obtain filtrate and filter residue. The Hg content in the filtrate is less than 0.03mg / L, and the mercury in the filter residue is 20.33%, which is comprehensively reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com