Method for treating wastewater containing polyvinyl alcohol

A polyvinyl alcohol and treatment method technology, which is applied in the reduction water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of large area, poor biodegradability, complicated management, etc. To achieve the effect of recycling, short time and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

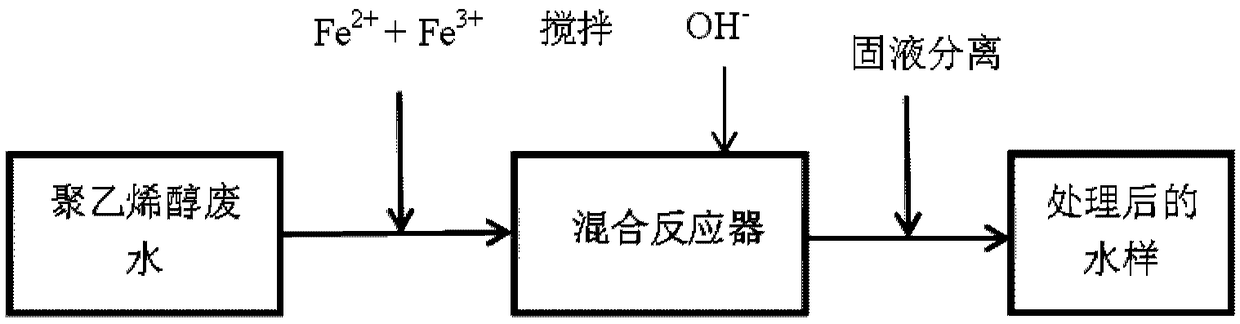

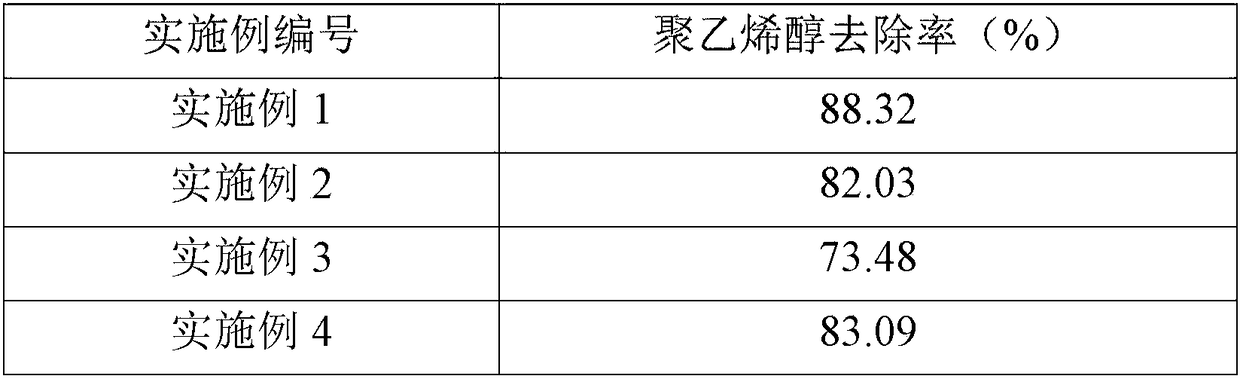

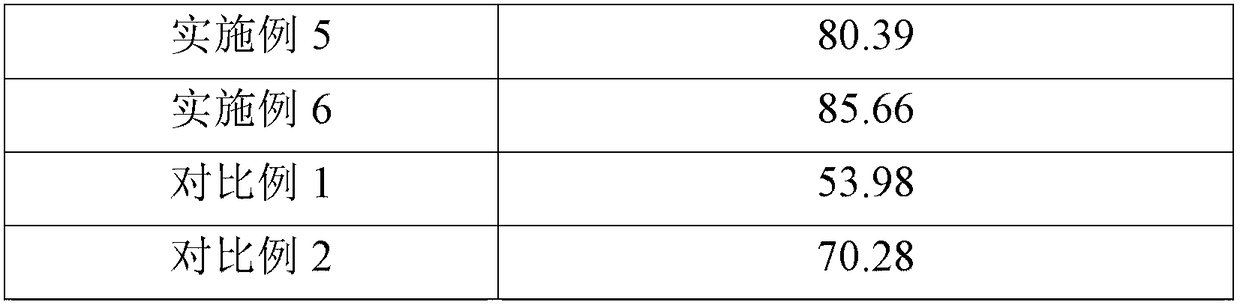

[0038] Such as figure 1 As shown, it shows a schematic flow chart of the treatment method of polyvinyl alcohol-containing wastewater of the present invention. Get 100mL of polyvinyl alcohol (polymerization degree is 2500) solution containing 500mg / L, add a certain amount of ferrous sulfate and ferric chloride wherein the molar ratio is 1:2, make Fe in the mixed solution 2+ The concentration is 5mmol / L, Fe 3+ The concentration of the mixture is 10mmol / L, after stirring evenly at a certain speed (50r / min) at 15°C, adjust the pH to 11 with sodium hydroxide, and react for 90min. After passing through the membrane, the concentration of polyvinyl alcohol in the mixed solution was measured by Finley spectrophotometry.

[0039] The measurement results are shown in Table 1.

Embodiment 2

[0041] Get 100mL of polyvinyl alcohol (polymerization degree is 2500) solution containing 1000mg / L, add a certain amount of ferrous chloride and ferric nitrate that the molar ratio is 1:2 to it, make Fe in the mixed solution 2+ The concentration is 10mmol / L, Fe 3+ The concentration of the solution is 20mmol / L. After stirring evenly at a certain speed (150r / min) at room temperature (25°C), adjust the pH to 11 with sodium hydroxide, and react for 30min. After magnetic separation, the concentration of polyvinyl alcohol in the mixed solution was measured by Finley spectrophotometry.

[0042] The measurement results are shown in Table 1.

Embodiment 3

[0044] Get 100mL of polyvinyl alcohol (polymerization degree is 2500) solution containing 3000mg / L, add a certain amount of ferrous sulfate and ferric chloride wherein the molar ratio is 1:2, make Fe in the mixed solution 2+ The concentration is 20mmol / L, Fe 3+ The concentration of the mixture is 40mmol / L. After stirring evenly at a certain speed (500r / min) at room temperature (25°C), adjust the pH to 11 with ammonia water and react for 60min. After static precipitation, the concentration of polyvinyl alcohol in the mixed solution was measured by Finley spectrophotometry.

[0045] The measurement results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com