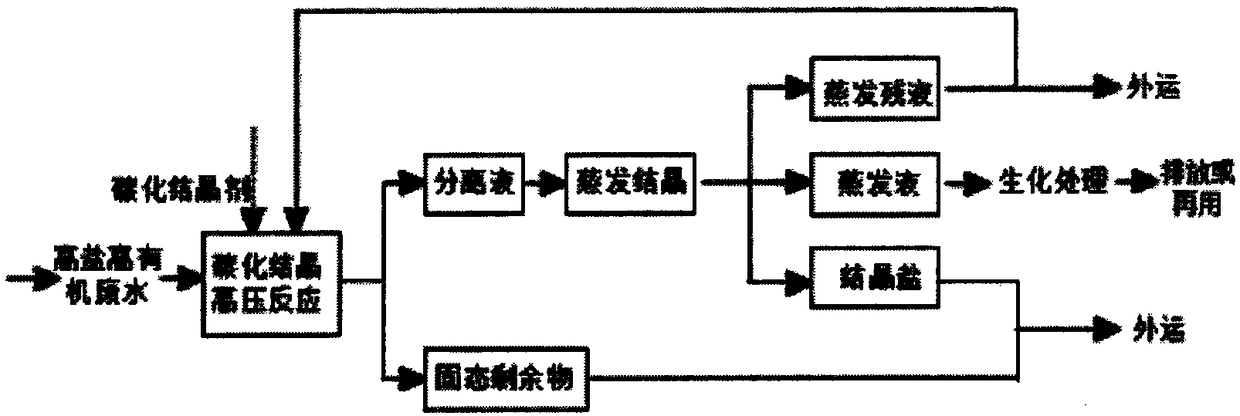

Carbonization and crystallization method for treating high-salt high-organic waste water

A technology for crystallization treatment and organic wastewater, applied in chemical instruments and methods, special compound water treatment, water/sewage treatment, etc. The effect of difficulty, lower energy consumption, and reduced organic concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for treating high-salt and high-organic wastewater by carbonization and crystallization:

[0032] (1) Configure 10mL carbonized crystallization agent: hydrochloric acid 15%, malonic acid 25%, ferric sulfate 3%, zinc nitrate 5% and deionized water 52% by volume percentage, get hydrochloric acid 1.5mL, malonic acid 2.5mL, 0.3mL of iron sulfate, 0.5mL of zinc nitrate and 5.2mL of deionized water are mixed together and stirred evenly to make a metal salt carbide crystallization agent;

[0033] (2) Measure 25mL of high-salt and high-organic wastewater, filter and remove impurities, and add it to a 100mL special high-pressure reactor. Next, take 5 mL of the carbonized crystallization agent configured in step (1) and add it to the reaction kettle, stir at a temperature of 30° C. at a speed of 80 r / min for 20 minutes, and close the reaction kettle after the wastewater and the carbonized crystallization agent are fully mixed;

[0034] (3) Heating the reactor to hydroth...

Embodiment 2

[0038] A method for treating high-salt and high-organic wastewater by carbonization and crystallization:

[0039] (1) Configure 10mL carbonization crystallization agent: by volume percentage, sulfuric acid 10%, hydrochloric acid 10%, succinic acid 15%, glutaric acid 15%, ferric sulfate 5%, potassium nitrate 10% and deionized water 35%, take respectively Sulfuric acid 1mL, hydrochloric acid 1mL, succinic acid 1.5mL, glutaric acid 1.5mL, ferric sulfate 0.5mL, potassium nitrate 1mL and deionized water 3.5mL, mix them together, stir evenly, make metal salt carbonization crystallization agent;

[0040] (2) Measure 25mL of high-salt and high-organic wastewater, filter and remove impurities, and add it to a 100mL special high-pressure reactor. Next, take 5 mL of the carbonized crystallization agent configured in step (1) and add it to the reaction kettle, stir at a temperature of 50° C. at a speed of 120 r / min for 40 minutes, and close the reaction kettle after the wastewater and the...

Embodiment 3

[0045] A method for treating high-salt and high-organic wastewater by carbonization and crystallization:

[0046] (1) Configure 50mL carbonization crystallization agent: 15% sulfuric acid, 20% hydrochloric acid, 25% succinic acid, 5% copper chloride, 5% potassium nitrate, 1% palladium nitrate and 29% deionized water by volume percentage, take respectively Mix 7.5mL of sulfuric acid, 10mL of hydrochloric acid, 12.5mL of succinic acid, 2.5mL of copper chloride, 2.5mL of potassium nitrate, 0.5mL of palladium nitrate and 14.5mL of deionized water, mix them together, and stir them evenly to make metal salt carbide crystals agent;

[0047] (2) Measure 50mL of high-salt and high-organic wastewater, filter and remove impurities, and add it to a 100mL special high-pressure reactor. Next, take 20 mL of the carbonized crystallization agent prepared in step (1) and add it to the reactor, stir at a temperature of 50° C. at a speed of 160 r / min for 60 minutes, and close the reactor after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com