Patents

Literature

42results about How to "Facilitate subsequent biochemical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

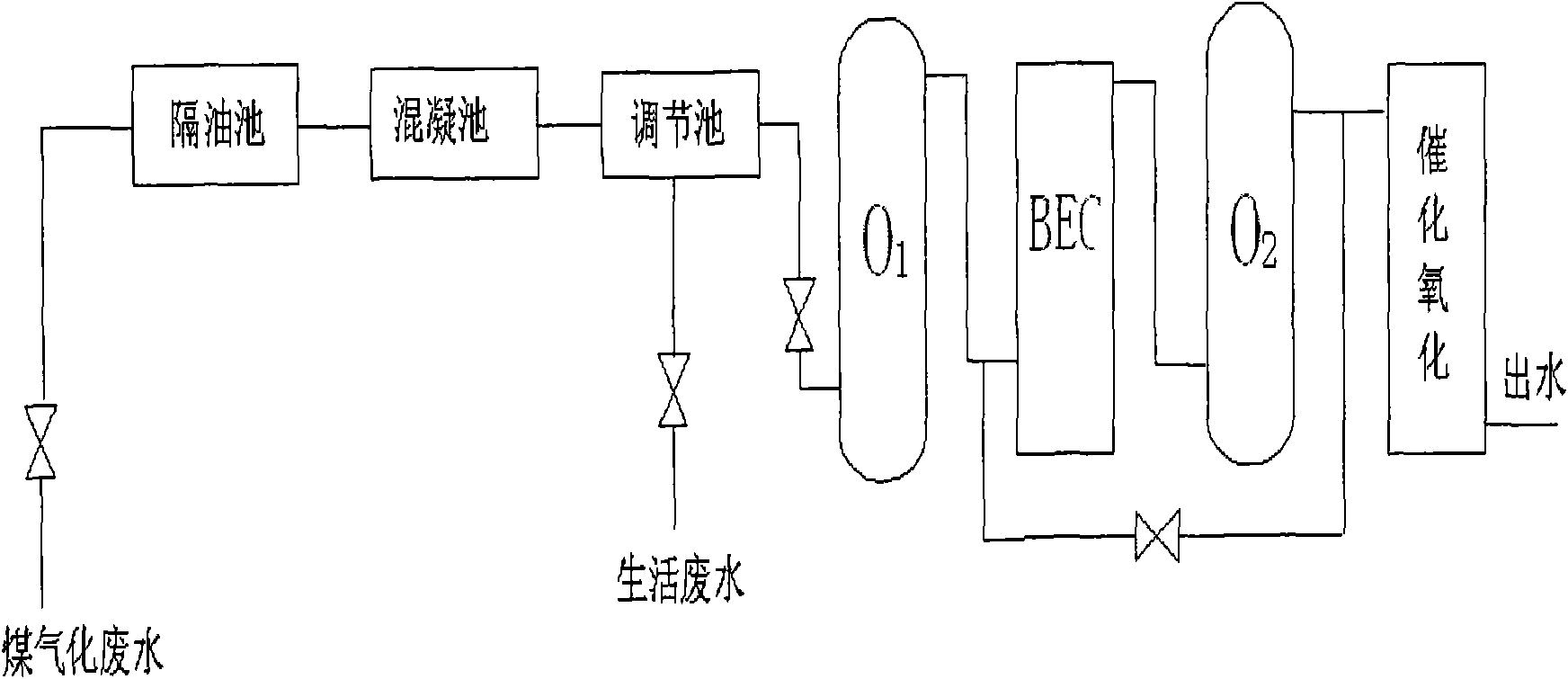

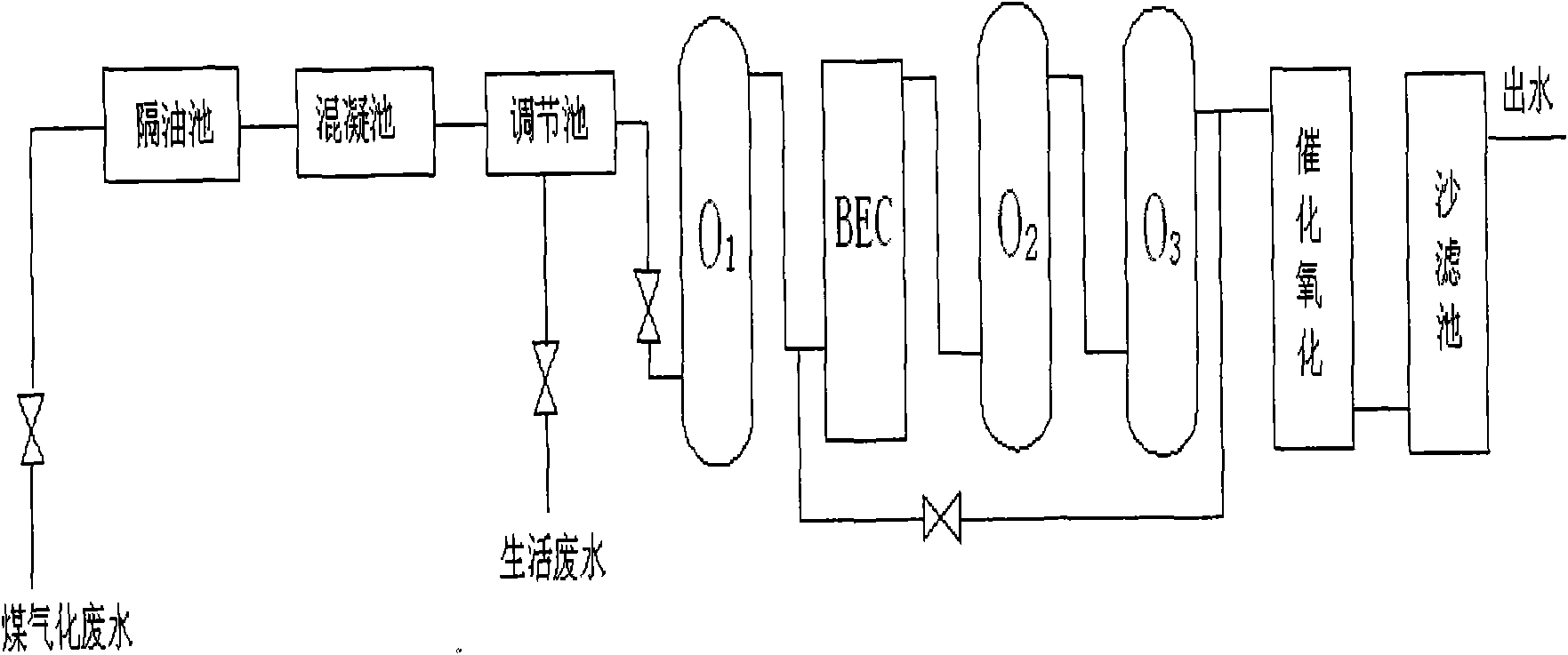

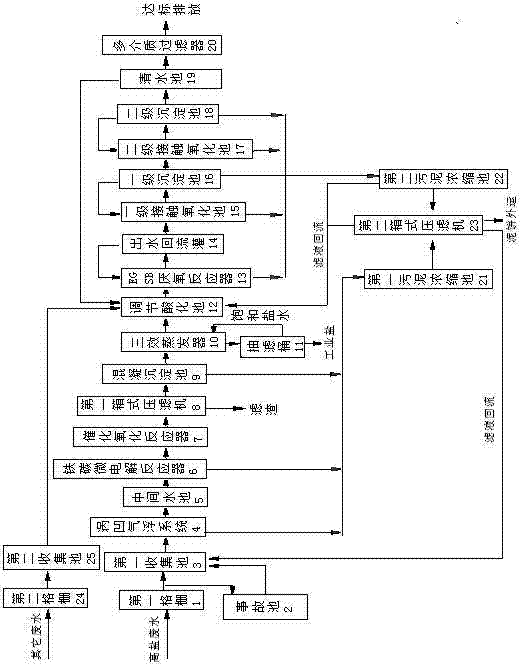

Method for processing coal gasification wastewater

ActiveCN101654316APromote degradationImprove nitrogen removal efficiencyWaste water treatment from gaseous effluentsMultistage water/sewage treatmentCoal gasification wastewaterCatalytic oxidation

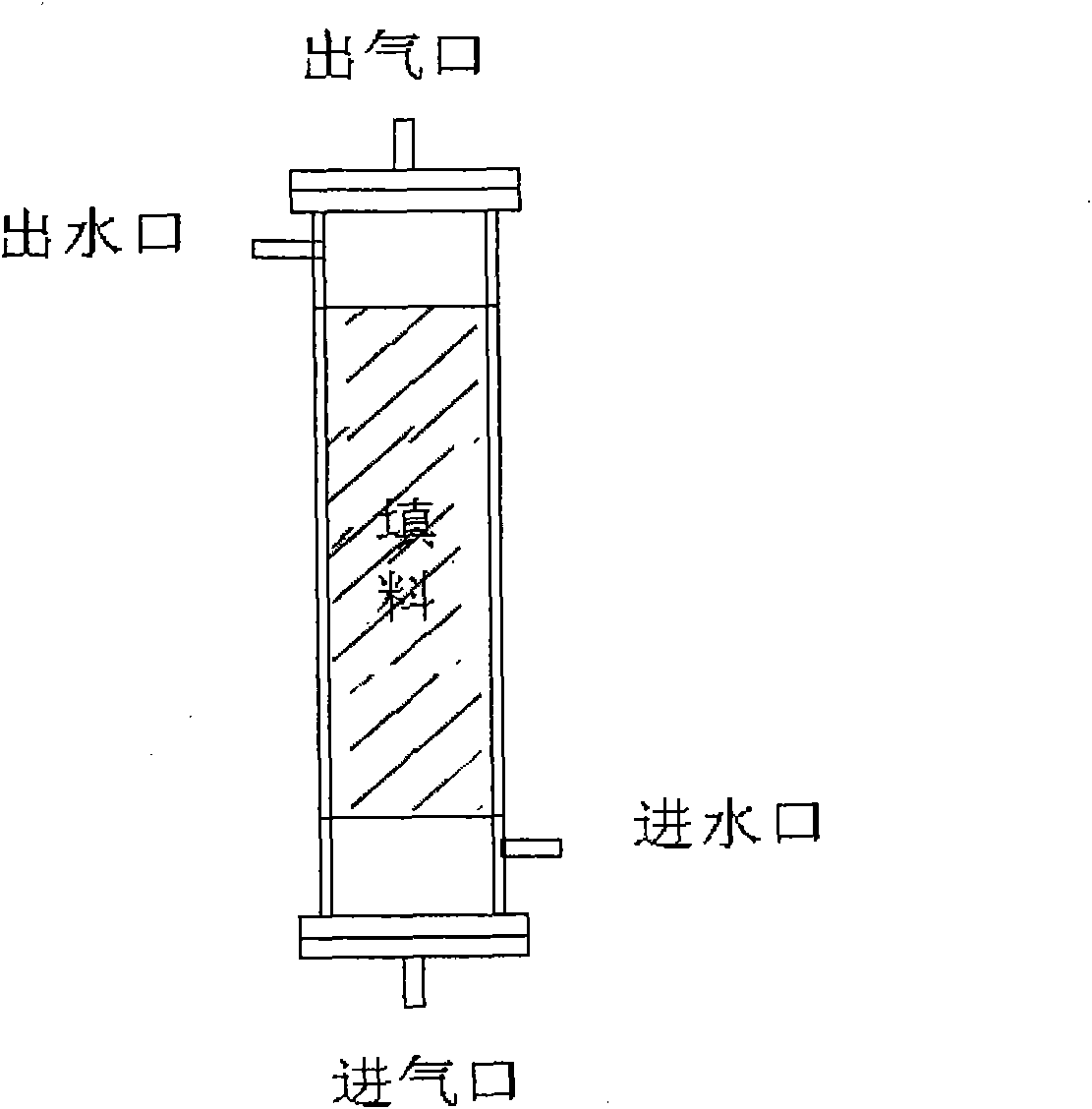

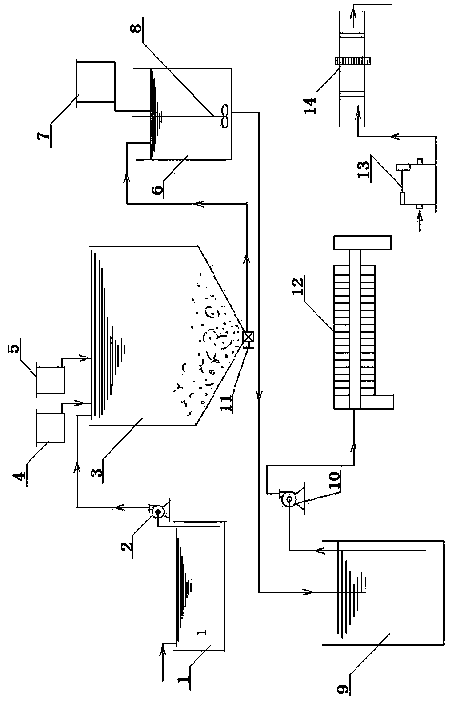

The invention discloses a method for processing coal gasification wastewater. The method sequentially comprises the following steps: a. carrying out preprocessing on the coal gasification wastewater in a preprocessing step comprising oil removal processing, coagulation processing and optional adjustment processing; then b. leading the preprocessed coal gasification wastewater to sequentially flowthrough a first-class bio-contact oxidation reactor, a biological electrochemical reactor, a second-class bio-contact oxidation reactor and an optional third-class or multi-class bio-contact reactor to carry out biological processing; and c. leading the biologically processed coal gasification wastewater to carry out catalytic oxidation processing in a catalytic oxidation reactor.

Owner:ENN ENVIROTECH CO LTD

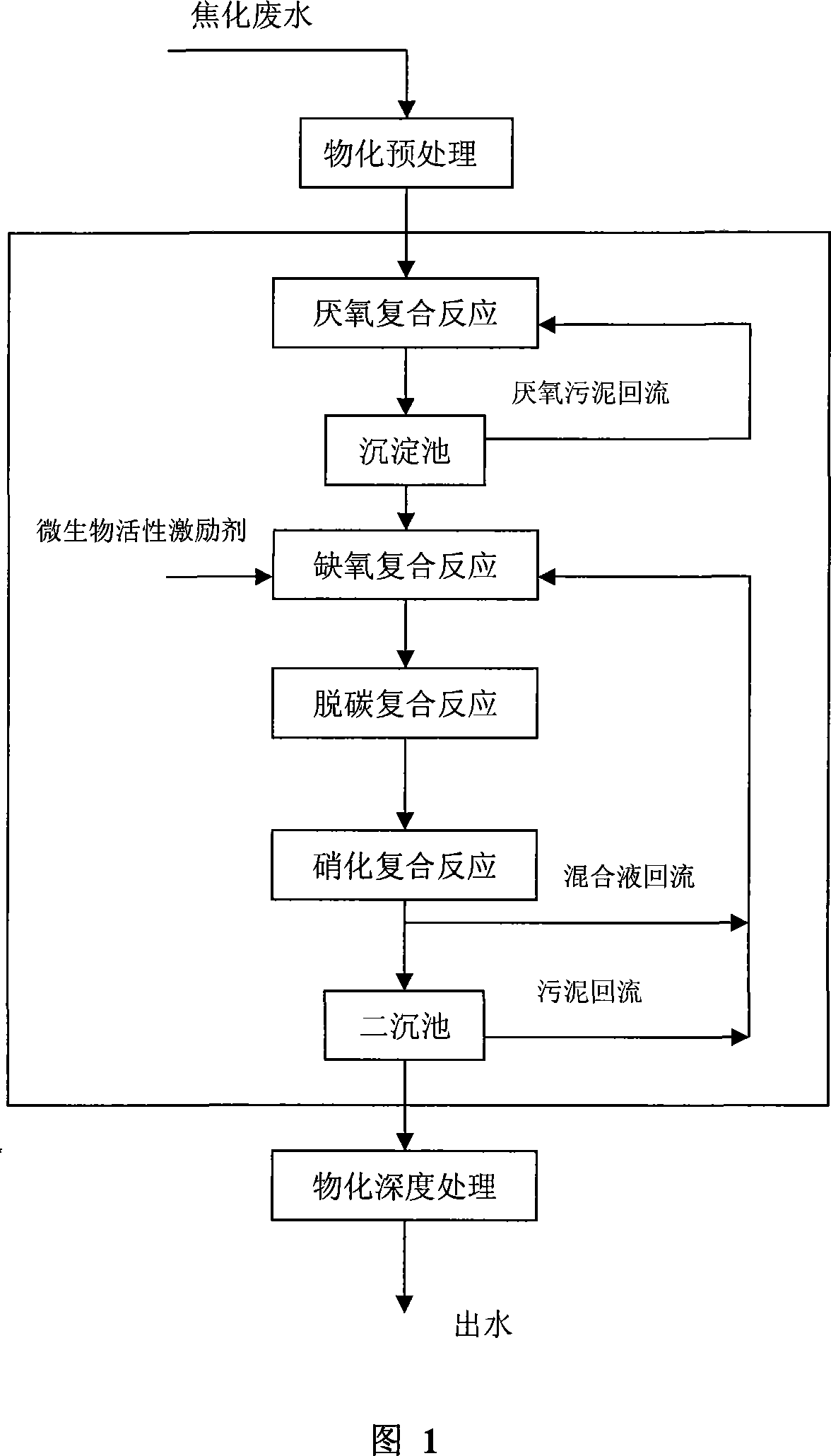

Impact-resistant multiplication combined type coking waste water treatment process

InactiveCN101113065AOptimize material compositionImprove biodegradabilityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater treatmentWater quality

An anti-impact multiplying combination coking wastewater treatment technique relates to a treatment method of coking wastewater. The coking wastewater is first qualified by a physical-chemical pretreatment to improve biodegradable property of wastewater; the composite technology of a biological carrier of active sludge is adopted to do anaerobic / hypoxia / aerobic decarbonization / aerobic nitrification biochemical combination treatment; suspended or floating folding ball-shaped fillings are arranged in biochemical reactors and when micro organism traits are abnormal or a great amount of foams existing in the reactor, micro organism active incentive agents are added to the reactor in interval to improve active sludge traits and organism film quantity; finally the water is treated by a physical-chemical advanced treatment to reach a top grade standard. The invention not only strengthens the removal of COD, ammonia-nitrogen, volatile phenol and other pollutants in the coking wastewater by biochemical treatment but also resists serious water quality impact and has the advantages of quick system startup, less foams in an aeration tank, small occupying space, low operation cost and stable and effective treatment to coking wastewater.

Owner:TONGJI UNIV +1

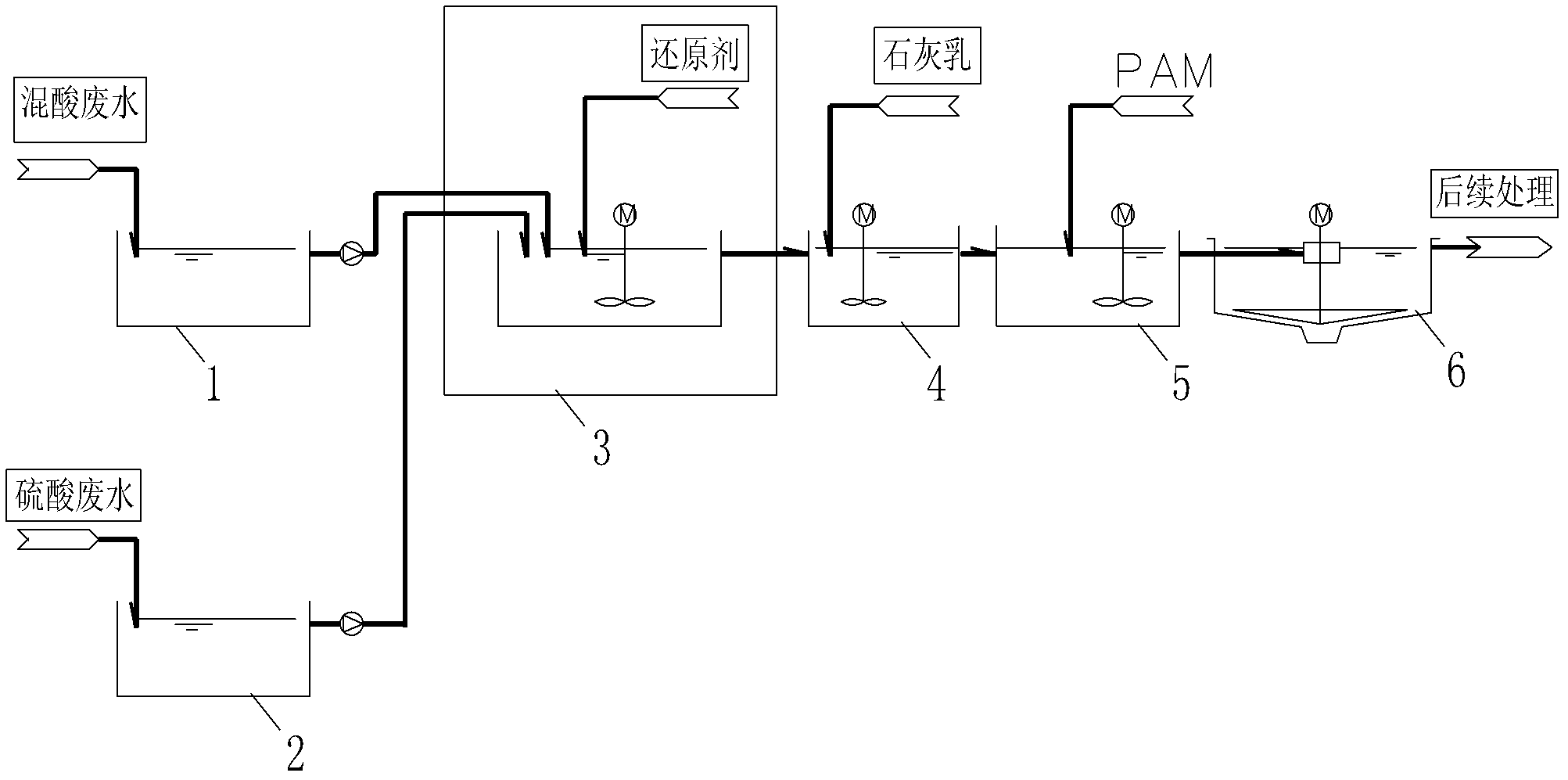

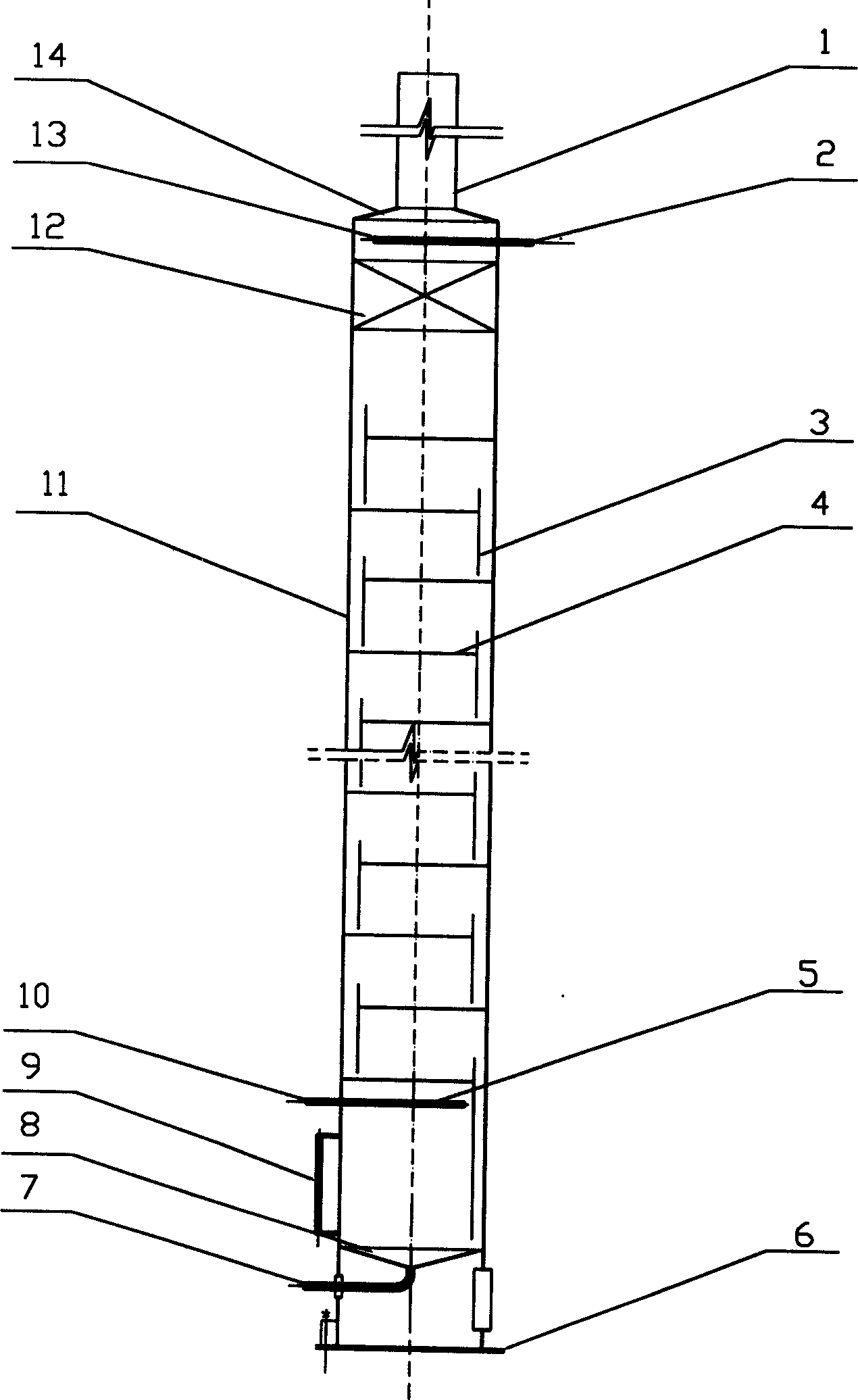

Treatment method for reducing Cr<6+> in stainless steel acid wastewater

InactiveCN102329024AMeet environmental protection requirementsFacilitate subsequent biochemical treatmentWater contaminantsMultistage water/sewage treatmentSludgeWastewater

The invention relates to a treatment method for reducing Cr<6+> in stainless steel acid wastewater. The treatment method comprises the following steps: feeding stainless steel mixed acid wastewater and sulfuric acid wastewater into a reducing pond; adding a reducing agent into the reducing pond and stirring, so that Cr<6+> in the wastewater is converted to Cr<3+> and leading effluent meeting an ORP (oxidation-reduction potential) requirement to flow into a neutralization pond; adding lime into the neutralization pond and carrying out oxygen blast aeration, so that Fe<2+> in the wastewater is oxidized to Fe<3+> and Cr(OH)3, CaF2, Fe(OH)3 and CaSO4 precipitates are formed; entering the effluent from the neutralization pond into a flocculation pond; adding 2-5 mg / l of PAM (polyacrylamide) into the flocculation pond so as to form large alum floc, and leading the effluent from the flocculation pond to flow into a precipitation pond for precipitation; and then entering the effluent after precipitation into a subsequent treatment facility so that the Cr<6+> in the effluent meets the emission requirement, and externally transporting sewage in the precipitation pond at regular intervals. The treatment method can meet environmentally-friendly requirement and is beneficial to subsequent biochemical treatment.

Owner:WISDRI ENG & RES INC LTD

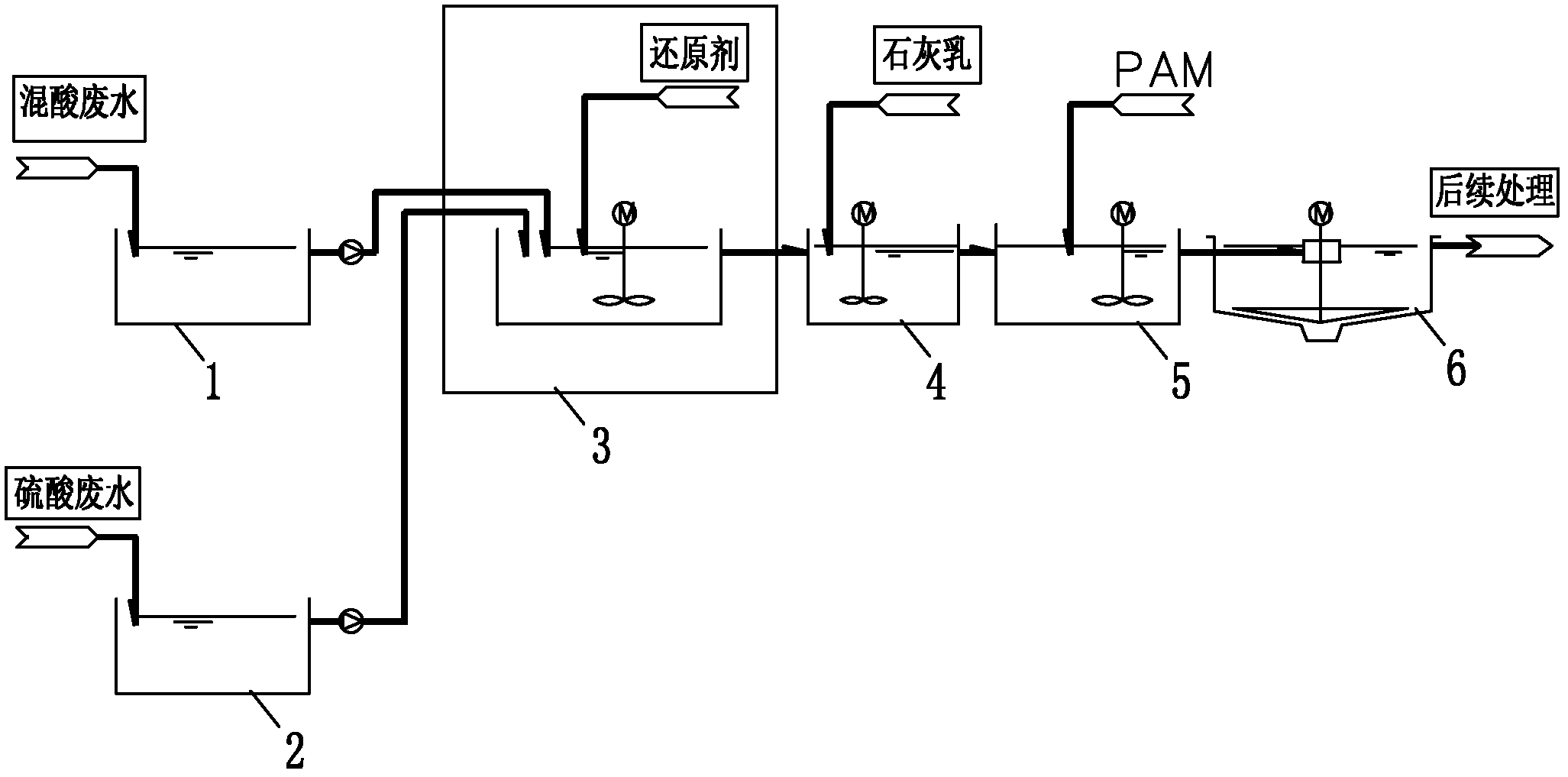

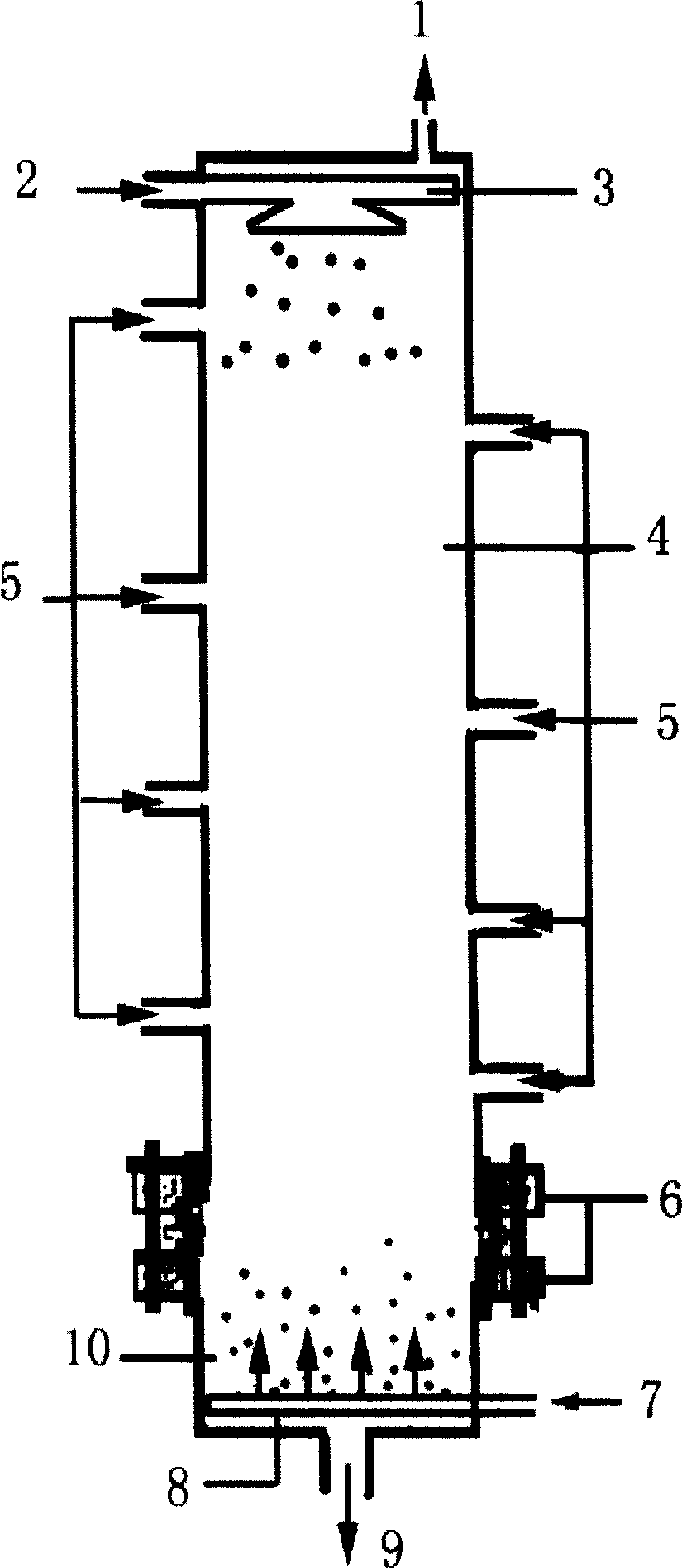

High performance tower for picking off ammonia nitrogen

InactiveCN1600693AFacilitate subsequent biochemical treatmentEasy to operateWater/sewage treatment by oxidationHigh densityNitrogen

The invention relates to a deammonia-nitrogen tower for processing industrial ammonia nitrogen waste water. It consists of tower, waste water entrance pipe fixed on the tower, processed water exit pipe, air charging pipe and spreading pipe. In the tower, there is liquid distribution pipe, anti-foaming unit, tower plate and air distribution unit arranged from above to below, the liquid distribution pipe and waste water entrance pipe are connected, the air distrbution unit is connected with air charging pipe, the processed water exit pipe is fixed on bottom sealing block of the tower, the spreading pipe is fixed on top sealing block. By the invention deammonia-nitrogen tower, high-density ammonia nitrogen waste water that density is more than 5000mg / L can be disposable deammonia and denitrogen to reach national discharging standard.

Owner:王小宁 +1

Process for treating epoxy resin production wastewater

ActiveCN103613244AEasy to handleHigh degree of automationMultistage water/sewage treatmentNature of treatment waterSuspended particlesEpoxy

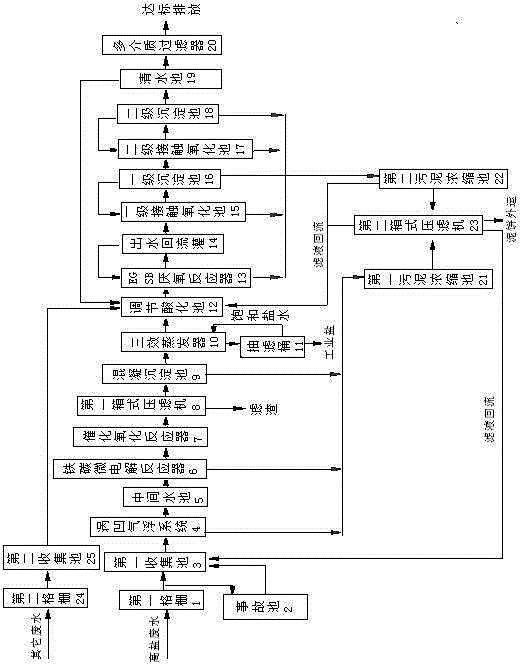

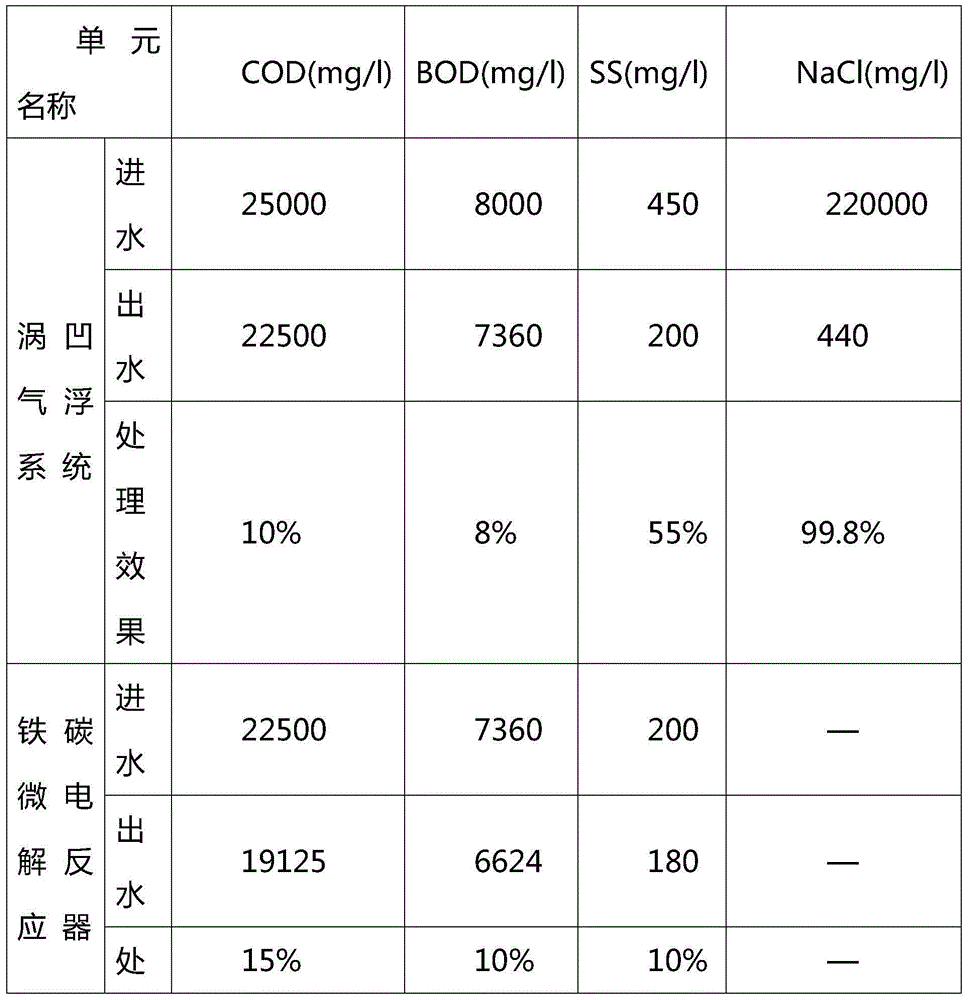

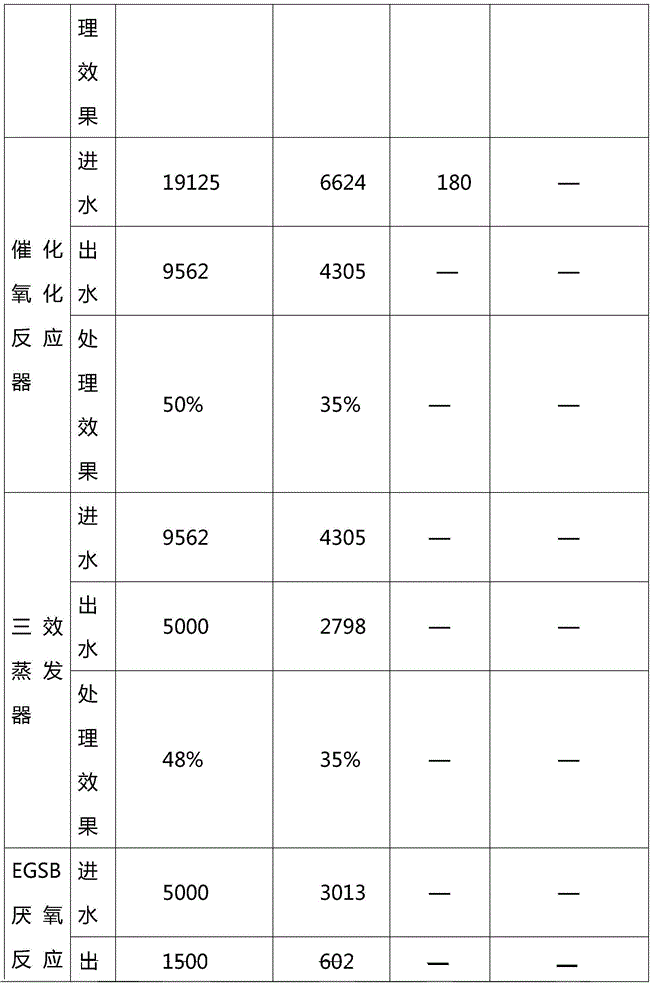

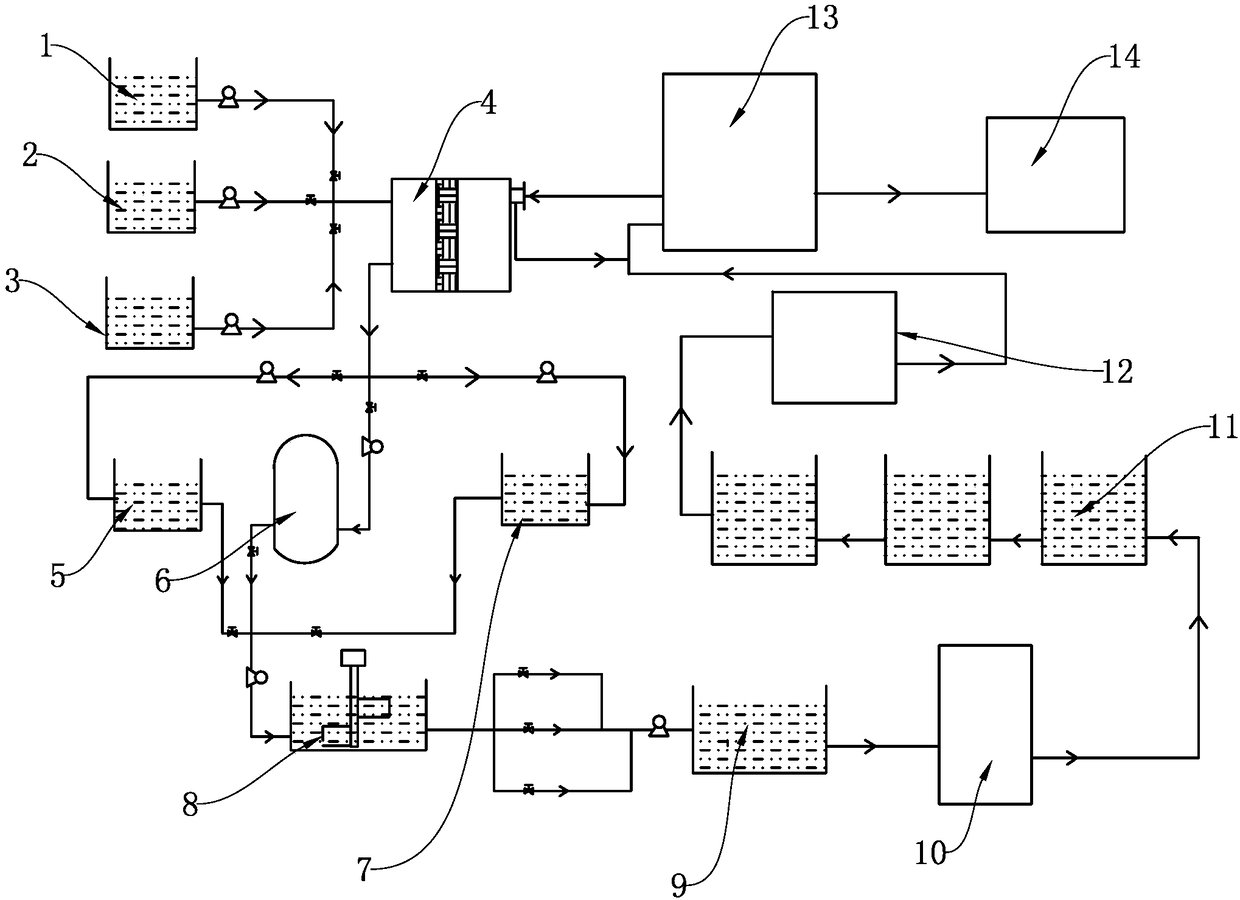

The invention discloses a process for treating epoxy resin production wastewater. The process comprises: removing oils, suspended particle organic matters, a part of high polymers and toluene in high-salinity wastewater through a cavitation air flotation system, transforming macromolecular organic matters in the wastewater into micromolecular organic matters through an iron-carbon micro-electrolysis reactor, then, oxidizing non-biodegradable and non-chemical oxidable organic matters in the wastewater through a catalytic oxidation reactor under the action of an Fenton reagent, carrying out anaerobic biochemical treatment to reduce the chemical oxygen demand and the biochemical oxygen demand in the wastewater, carrying out aerobic biochemical treatment to anaerobically degrade a part of aerobic organic matters incapable of being degraded by aerobiont into biochemically degradable organic matters, finally, conveying the wastewater into a clean-water reservoir, filtering the wastewater through a multi-medium filter, and discharging the wastewater after meeting the standard. The process disclosed by the invention has the advantages of small energy consumption, high removal load and capability of recycling biogas as an energy source, and the purified water quality meets the emission standard so as to protect the ecological environment.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

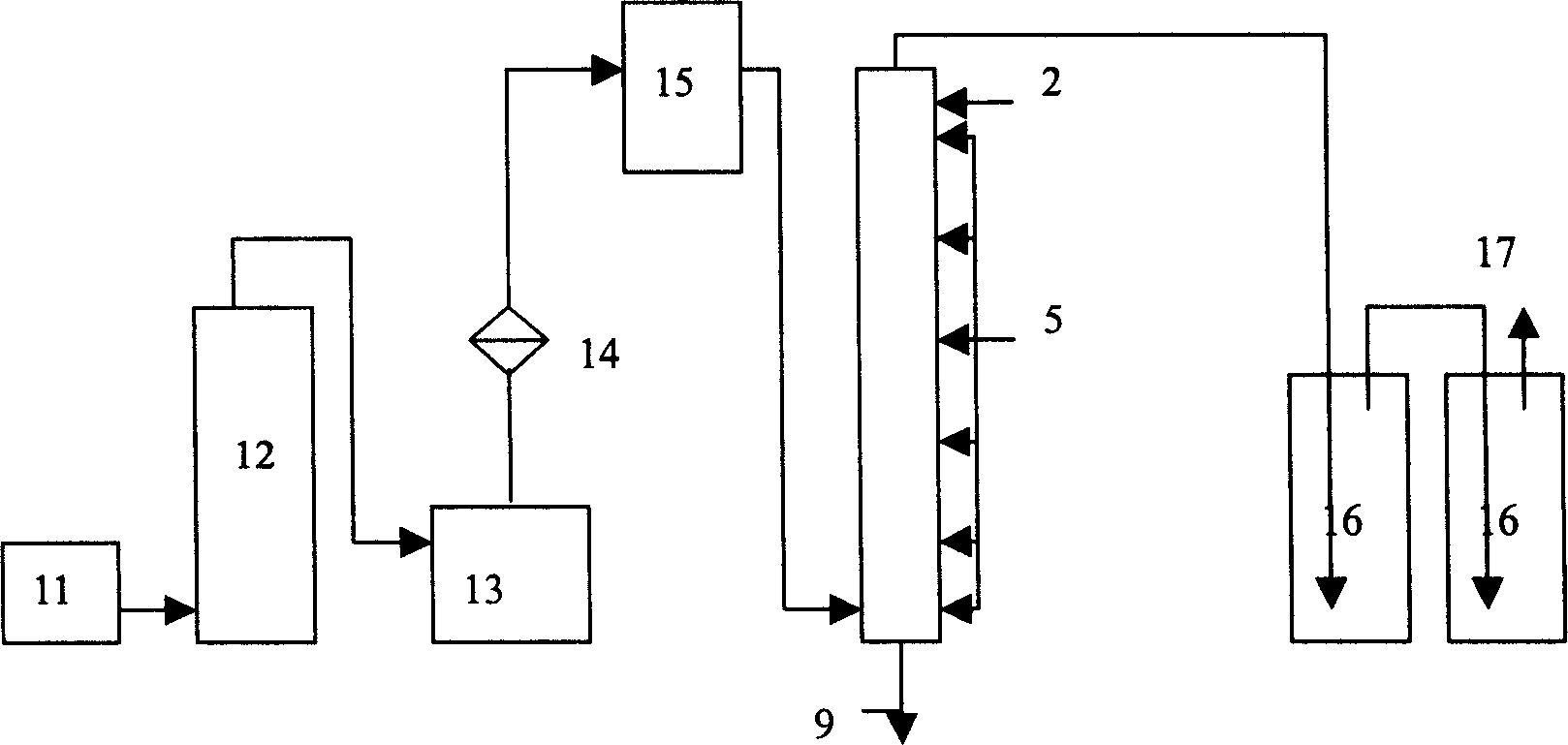

Apparatus and process for combined treating waste water containing pesticide with ozone/hydrogen peroxide solution

InactiveCN1644528APromote generationReduce concentrationWater/sewage treatment by oxidationWastewaterSewage

An ozone-oxydol combing treating device for pesticide waste water and its process are disclosed. The device consists of an ozone-oxydol mixed contacting reacting cavity as main part. The process is carried out by taking dried and purified air as material, ozone air with silent discharging method generation flowing by the bottom of ozone-oxydol mixed contacting reacting cavity, air scattering uniformly, oxydol solution and sodium hydroxide solution pumping into a feed liquid dog house of a contacting reacting cavity at low flowing speed, rapid oxidizing degrading small molecular organic compound under strong oxidative hydroxy radical action. It can be used for other organic sewage purifying treatment.

Owner:NANKAI UNIV

Method for processing membrane filtration concentrated solution of middle and late landfill leachate

InactiveCN101767896AReduce the degree of aggregationEasy loadingMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationAeration rateElectrolysis

The invention relates to a method for processing membrane filtration concentrated solution of middle and late leachate in a refuse landfill and belongs to the technical field of the environment protection. The method comprises the following steps: adjusting a pH value of the membrane filtration concentrated solution to between 4 and 6.5; adding polymeric aluminium salt or a composite coagulating / flocculating agent the main component of which is polymeric aluminium salt into the adjusted membrane filtration concentrated solution, wherein the adding amount of Al2O3 serving as the polymeric aluminium salt or the composite coagulating / flocculating agent is between 50 and 1,000 mg / L; stirring the mixture for 0.5 to 5 minutes at a speed of between 100 and 280 revolutions per minute, and stirring the obtained product for 3 to 30 minutes at a speed of between 20 and 100 revolutions per minute; after the membrane filtration concentrated solution reacts with the polymeric aluminium salt or the composite coagulating / flocculating agent, carrying out solid-liquid separation; putting clear solution in an iron-carbon bed with a mass ratio of iron to carbon of 1 to 4, wherein the aeration rate is between 100 and 250 cubic meter air per cubic meter water per hour; carrying out micro-electrolysis reaction for 10 to 30 minutes; then adding H2O2 the mass concentration of which is 30 percent to strength micro-electrolysis reaction, wherein the adding amount of H2O2 is between 0.05 and 0.5 L per cubic meter water and the reaction time is between 0.5 and 3 hours; and adjusting the pH of the effluent to between 7.5 and 9.0 to obtain the processed effluent after the solid and the liquid are separated. The method has the advantages of simple operation, relatively lower operation cost, better processing effect and the like.

Owner:KUNMING UNIV OF SCI & TECH

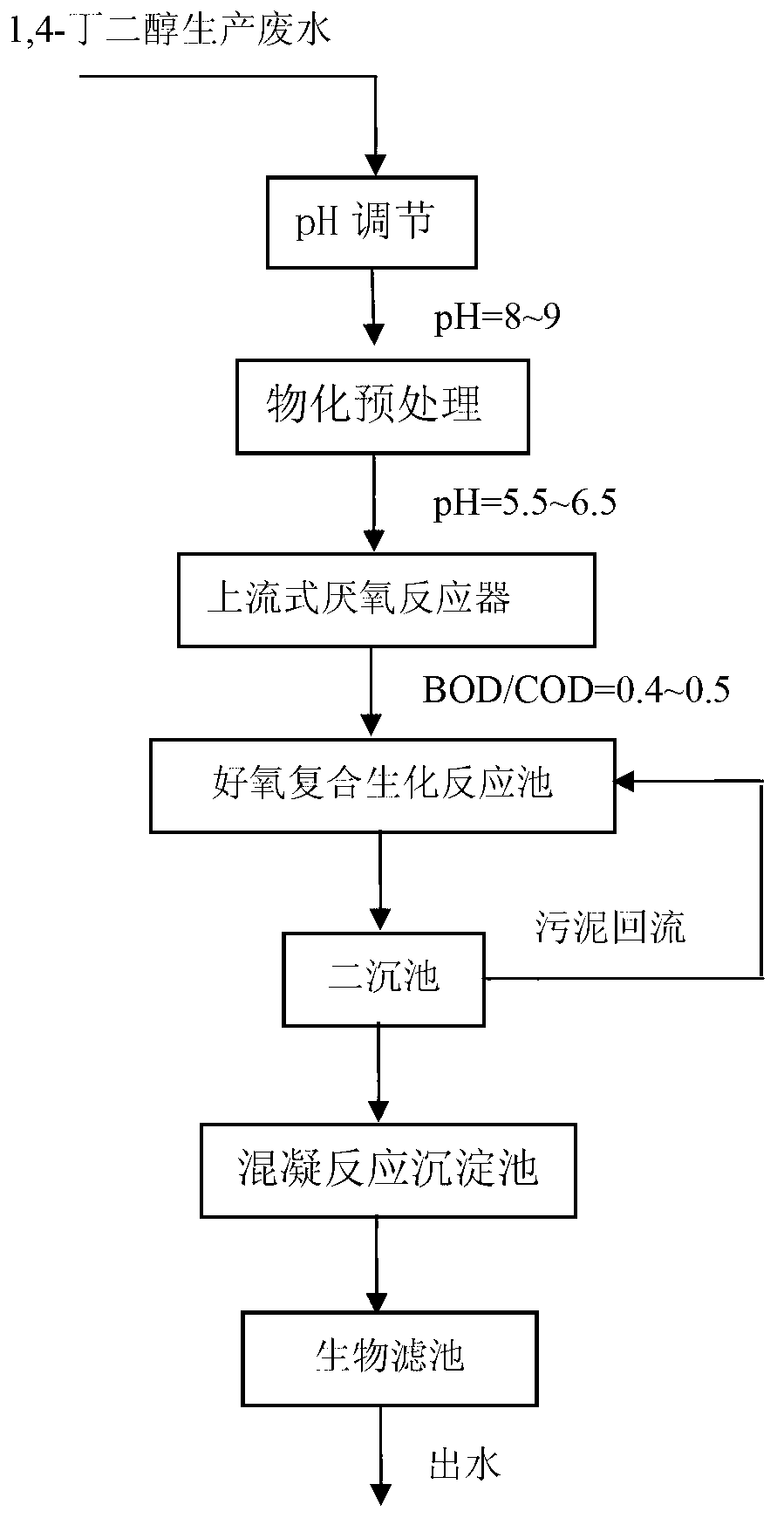

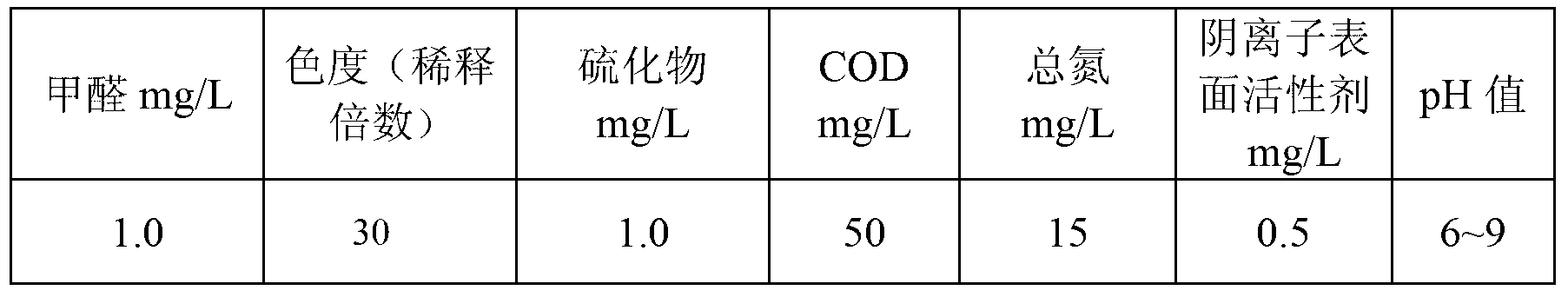

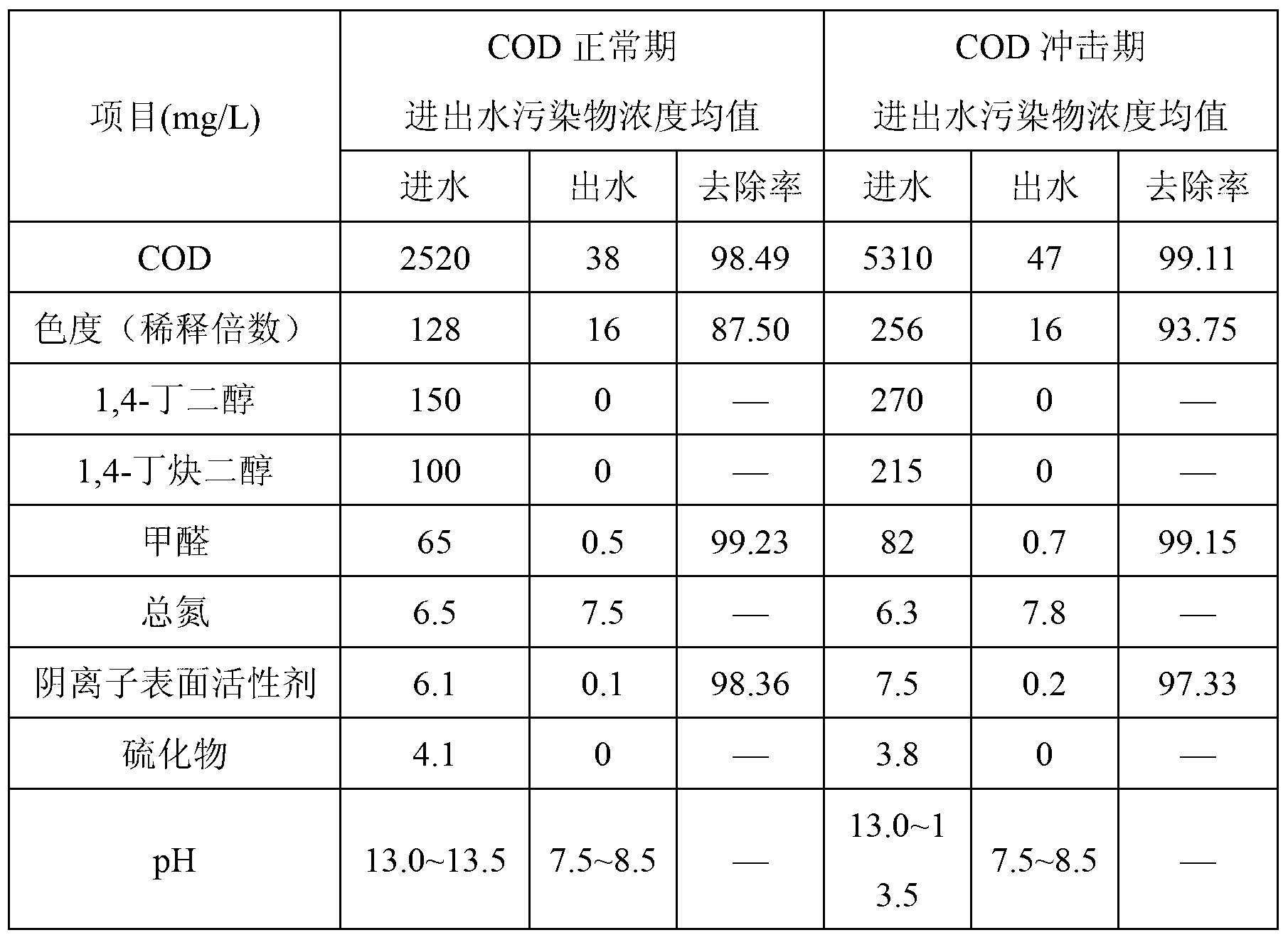

Combined treatment method of 1,4-butanediol production wastewater

InactiveCN103253827AReduce acidityWeak acidMultistage water/sewage treatmentNature of treatment waterHigh concentrationChemical oxygen demand

The invention relates to a combined treatment method of 1,4-butanediol production wastewater, which comprises the following steps: carrying out physical and chemical pretreatment on wastewater firstly so as to obtain pre-optimized wastewater; improving the biodegradability of the wastewater and further reducing the COD (chemical oxygen demand) concentration of the wastewater through an upflow anaerobic reactor and an aerobic combined biochemical reaction tank; and after the muddy water separation of the wastewater is realized through a secondary sedimentation tank, sequentially feeding the wastewater into a coagu-flocculation reaction settling pond and a biological filter, carrying out deep treatment on the wastewater, removing substances such as tiny suspended solids and colloids and the like in the wastewater through coagu-flocculation reaction and precipitation, and enabling discharged water to meet the requirements of one-class A standards in the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002) through the synergistic effect of adsorption and biodegradation of the biological filter. The method disclosed by the invention not only has a stable removal effect on COD in 1,4-butanediol production wastewater, but also can effectively resist violent water impacts; and the method has the characteristics of rapid system startup and the like. The method disclosed by the invention also can be applied to the treatment of other high-concentration toxic degradation-resistant organic wastewater with a water quality similar to that of 1,4-butanediol production wastewater.

Owner:TONGJI UNIV +1

Pretreatment technique for industrial bean clear water

InactiveCN101239760AReduce dosageGood flocculation effectMultistage water/sewage treatmentWater/sewage treatment by neutralisationAluminium chlorohydrateSewage

The present invention is a preprocessing technique of the industrial bean clear water, belongs to the field of the industrial sewage and is characterized in that the technique comprises the following technical procedures: when the bean clear water is adjusted with pH value, respectively adding the polyaluminium chloride solution and the polyacrylamide solution; after stewing separating the precipitate, adjusting pH of the residual solution and adding the polyaluminium chloride solution and polyacrylamide solution. The technique of the invention has the advantages of effectively eliminating the SS, BOD, COD and the like in the bean clear water with eliminating ratio higher than 88%; simple technique and excellent operability; effectively increasing the biochemical property and facilitating the subsequent biochemical treating.

Owner:胡志刚

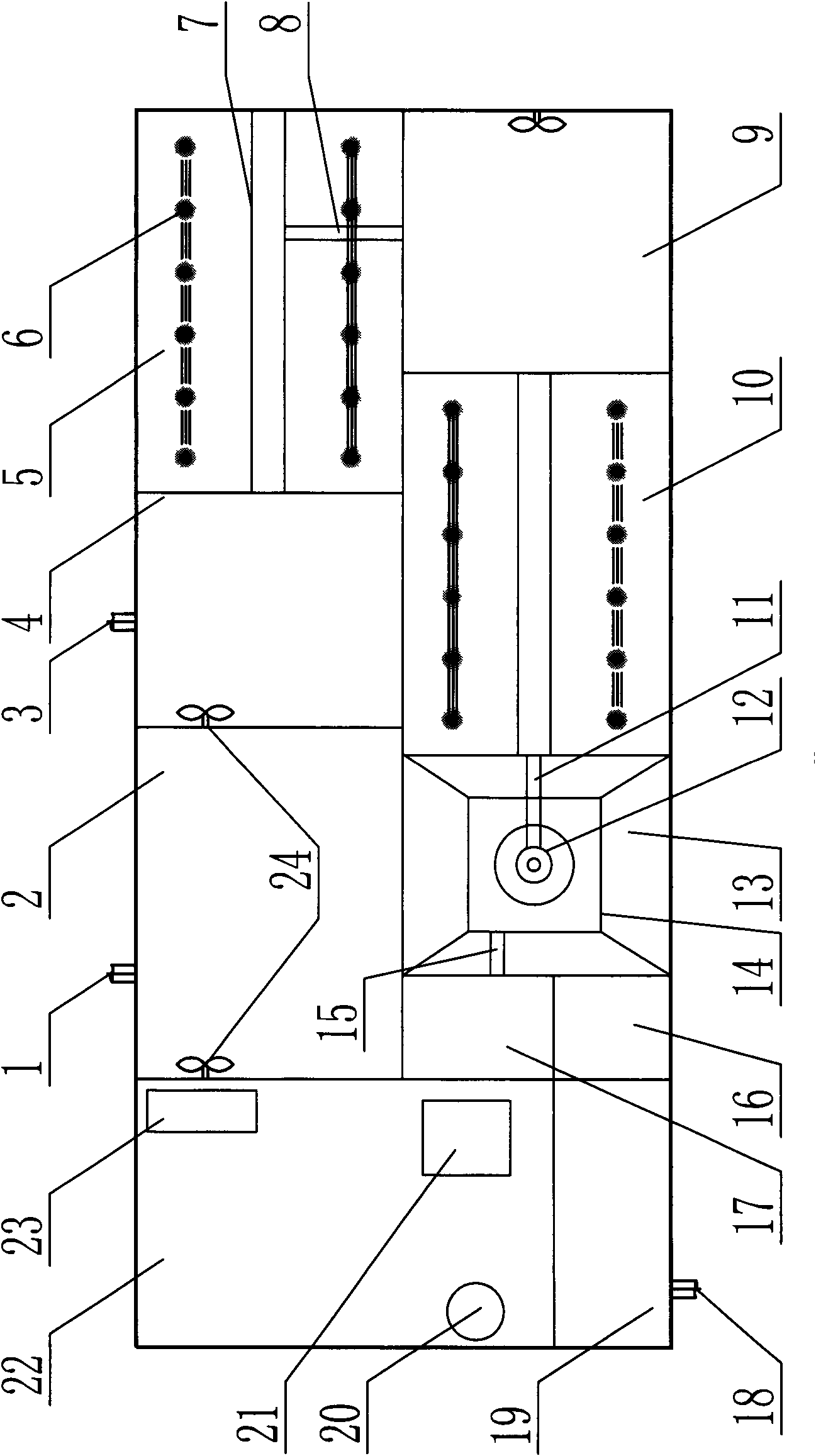

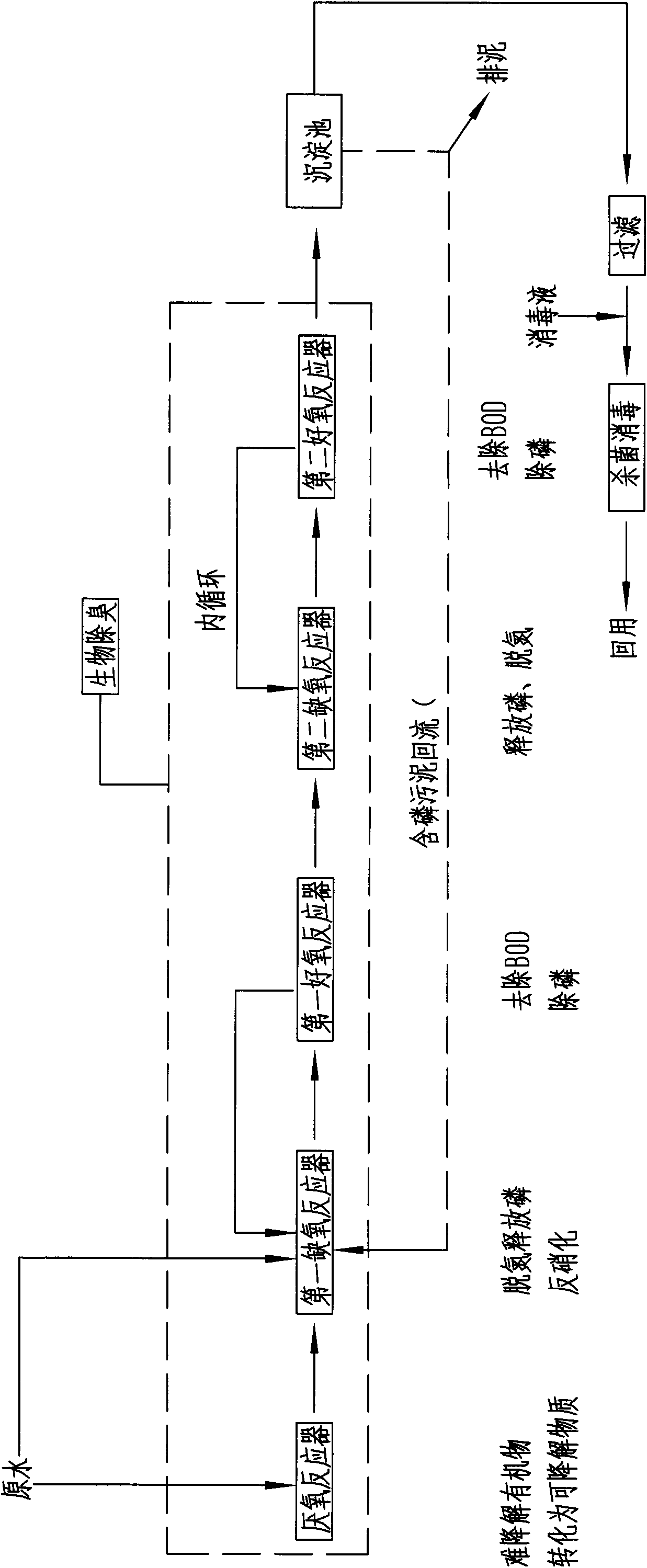

Three-stage anaerobic two-stage aerobic inner circulation reclaimed water treater

InactiveCN102101747AFacilitate subsequent biochemical treatmentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated carbon filtrationDisinfectant

The invention discloses a three-stage anaerobic two-stage aerobic inner circulation reclaimed water treater. Raw water is pumped into an anaerobic cavity and a first-stage anoxic cavity respectively through a water inlet by a lift pump, and a first-stage aerobic cavity is communicated with the first-stage anoxic cavity; effluent of the first-stage aerobic cavity enters a second-stage anoxic cavity through a water collecting weir, and the second-stage anoxic cavity is communicated with a second-stage aerobic cavity; the anaerobic cavity, the first-stage anoxic cavity and the second-stage anoxic cavity are provided with an underwater stirrer respectively; the first-stage and second-stage aerobic cavities are provided with more than two microporous aeration disks supplied with air by a Roots blower; water collecting weir notches are arranged in the first-stage and second-stage aerobic cavities; effluent of the second-stage aerobic cavity is introduced into a guide cylinder through a water collecting weir to enter a sedimentation tank, is converged into a water discharging groove after sedimentation, and enters an active carbon filter cavity, the filtered water enters a disinfection reaction cavity, and a disinfectant of a dosing container inflows automatically through high head for disinfection reaction; water subjected to reaction flows automatically into a water storage cavity from bottom to top; and the water is discharged through a water outlet or recycled. The treater can denitrify and dephosphorize wastewater; and the wastewater sequentially flows through anaerobic units and aeration units and is synchronously subjected to wastewater clarifying processes such as nitrification, denitrification, phosphorus release, phosphorus uptake, sludge discharge and the like so as to be purified.

Owner:刘情生 +4

SRR deodorant for treating garbage stench and deodorization method thereof

The invention discloses an SRR deodorant for treating garbage stench and a deodorization method thereof. The deodorant comprises the following raw materials: an active free radical source, an active excitation agent, a balanced stabilizer and a persistent effect accelerant, wherein the free radical source is a mixture of a halogen free radical source, an SR free radical source and a hydroxyl free radical source; the SRR deodorant can be used for deodorizing garbage; the odor of the garbage processed by the process can be removed or relieved for 2-3 days; the garbage ripening process is accelerated; maximal utilization of garbage resources is facilitated; toxic and harmful organic matters in landfill leachate are reduced; subsequent treatment is facilitated; the organic matter concentration, heavy metal ions, COD and BOD content in the landfill leachate are reduced; and subsequent biochemical treatment of the landfill leachate is facilitated.

Owner:成都安捷芮环保科技有限公司

Treatment process for tannery wastewater

InactiveCN110451733AImprove biodegradabilityFacilitate subsequent biochemical treatmentWater treatment compoundsWater contaminantsHigh concentrationChemical oxygen demand

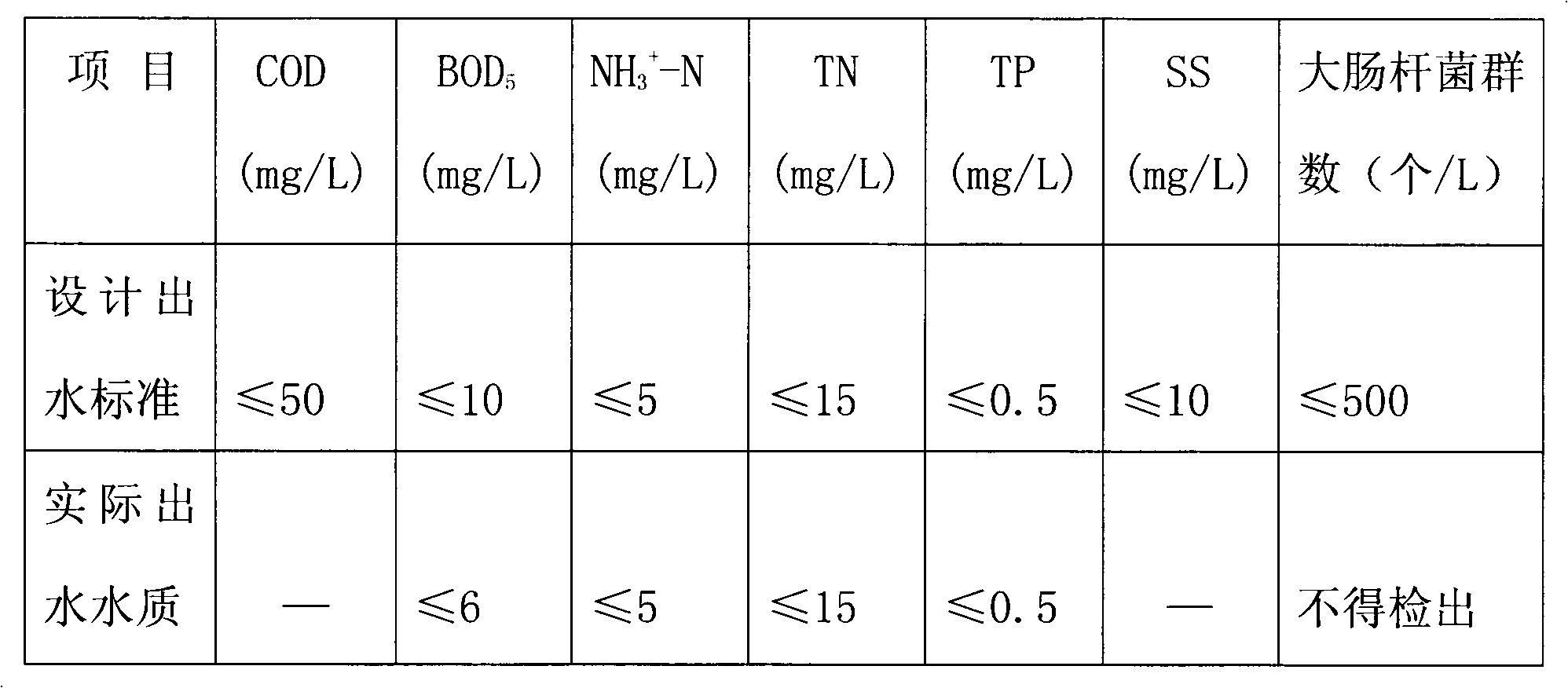

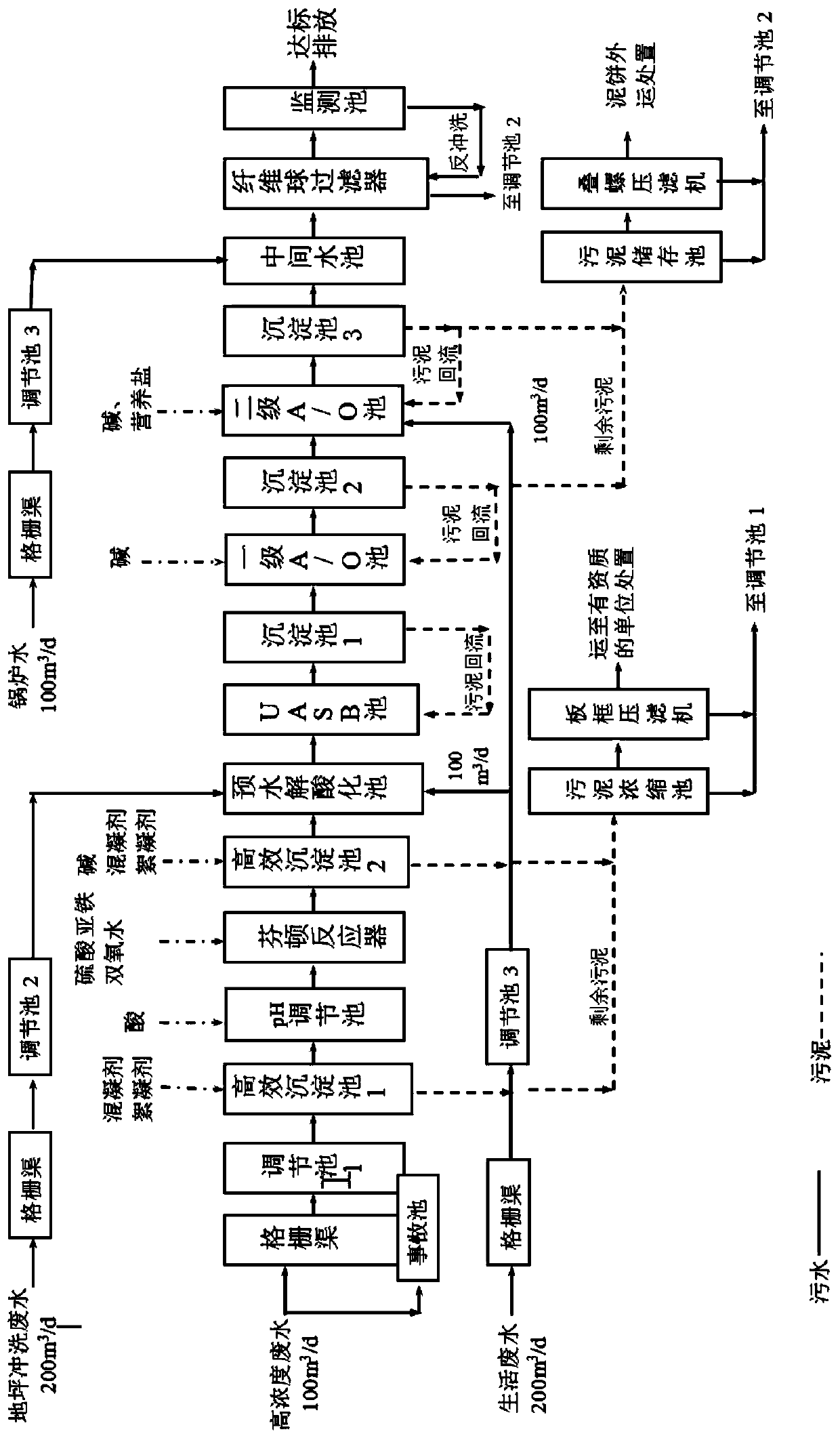

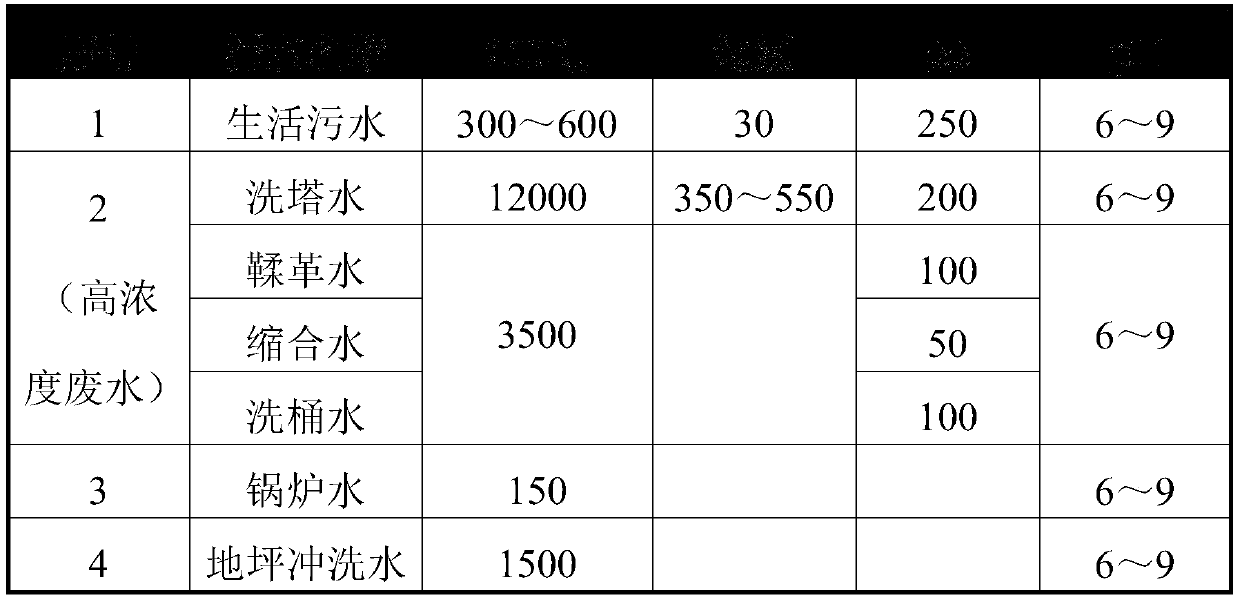

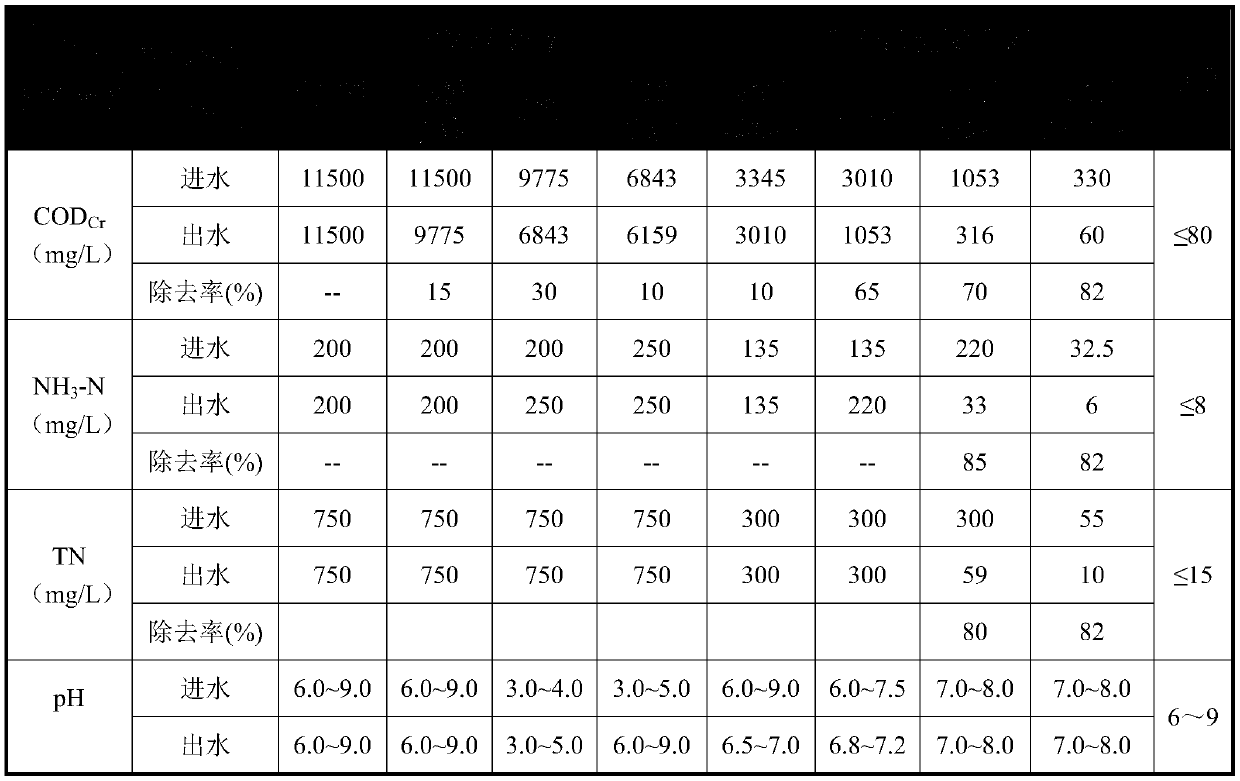

The invention discloses a treatment process for tannery wastewater and relates to the technical field of sewage treatment. The treatment process comprises the following steps: enabling high-concentration wastewater to flow into a grid canal and an adjusting tank 1, performing pretreatment through coagulating sedimentation, Fenton oxidation and coagulating sedimentation, and feeding the effluent into a pre-hydrolysis acidification tank; enabling floor washing water to flow into the grid canal and an adjusting tank 2, enabling the effluent to flow into the pre-hydrolysis acidification tank, mixing the effluent with the high-concentration wastewater, and performing hydrolysis and acidification; pumping the effluent into a UASB (upflow anaerobic sludge blanket) reactor, enabling the effluent to flow into a settling pond 1, enabling upper clear water of the settling pond 1 to flow into an air stripping tank, further feeding the effluent into a primary A / O (anoxic / oxic) tank, enabling the effluent to flow into a settling pond 2, enabling upper clear water to flow into a secondary A / O tank, feeding the effluent into a settling pond 3, and feeding upper clear water into a middle water tank; enabling boiler water to flow into the grid canal and an adjusting tank 3, performing coagulating sedimentation, and enabling upper clear water into the middle water tank; and filtering the effluentby using a fiber sphere filter, and feeding the effluent into a monitoring tank. By adopting the treatment process, a good treatment effect on pollutants such as SSs (suspended solids), CODs (chemical oxygen demands), ammonia nitrogen and organic matters in tannery wastewater can be achieved, and the effluent can meet the emission standard of GB 21902-2008.

Owner:安徽环境科技集团股份有限公司

System for extracting plant protein from cassava starch wastewater

InactiveCN103570800AFacilitate subsequent biochemical treatmentPeptide preparation methodsMultistage water/sewage treatmentEmission standardWastewater

The invention discloses a system for extracting plant protein from cassava starch wastewater, which comprises a sedimentation tank and is characterized by further comprising a reaction sedimentation tank, a sediment stirring tank, a slurry storage tank, a pressure pump, a filter press, a crusher and a dryer, wherein the bottom surface of the reaction sedimentation tank is conical; a discharge valve is arranged on the conical tip of the reaction sedimentation tank; the sediment stirring tank is provided with a stirrer and is introduced to the bottom of the reaction sedimentation tank to precipitate slurry and inject a flocculating agent, so that the viscosity of sedimentation slurry is reduced; the slurry storage tank is used for storing sediment discharged from the sediment stirring tank; the pressure pump is used for pumping out sediment in the slurry storage tank; the filter press is used for separating water from residues; the crusher is used for thinning filter residues; and the dryer is used for further removing water in filter residues. Yellow slurry wastewater is processed through the sedimentation tank, the reaction sedimentation tank, the sediment stirring tank, the slurry storage tank, the filter press and the like, therefore, plant protein is extracted from the wastewater; wastewater is purified, so that wastewater is beneficial to subsequent biochemical treatment; and favourable conditions are provided for enabling wastewater discharged from production of cassava starch to meet national emission standards.

Owner:潘增强

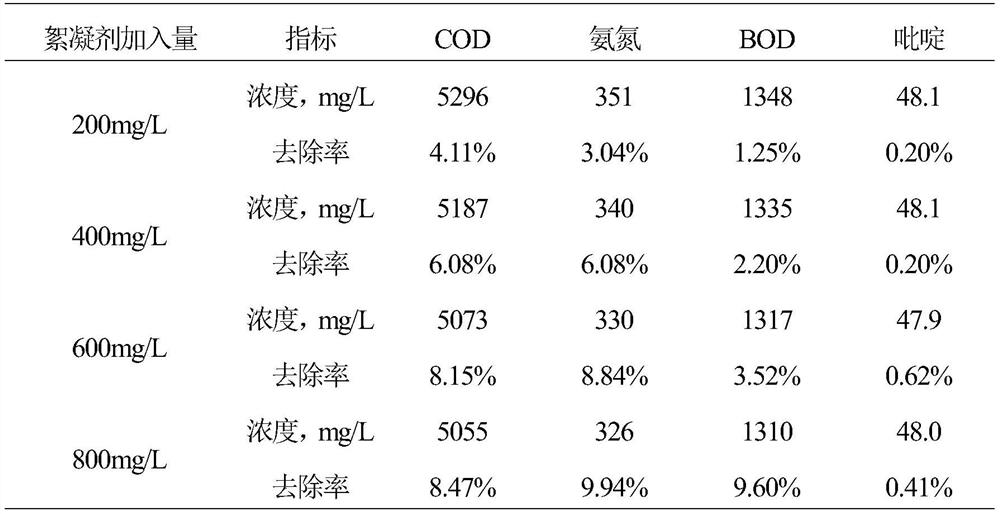

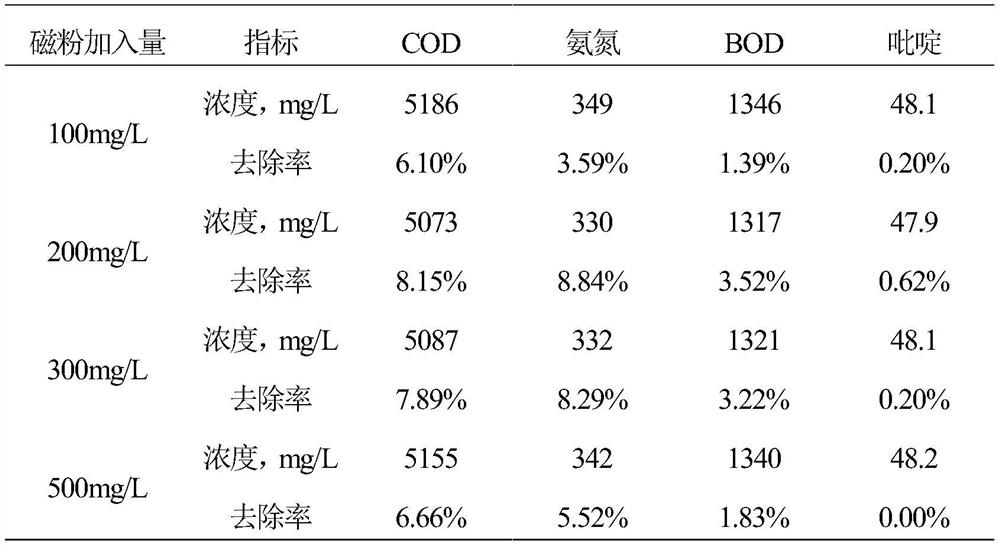

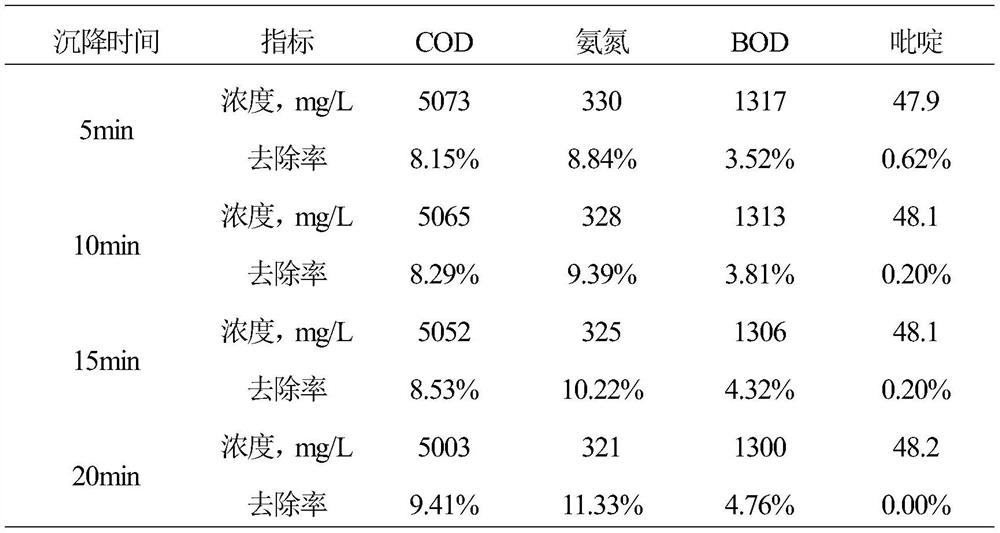

Method for treating washing wastewater of coal chemical industry

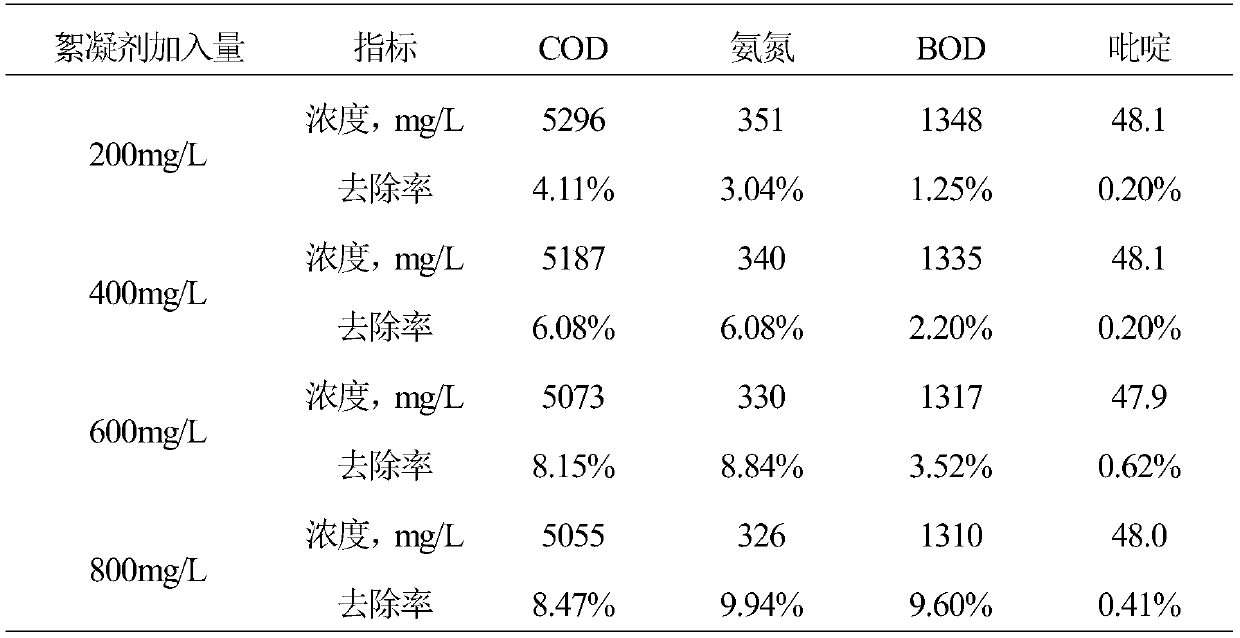

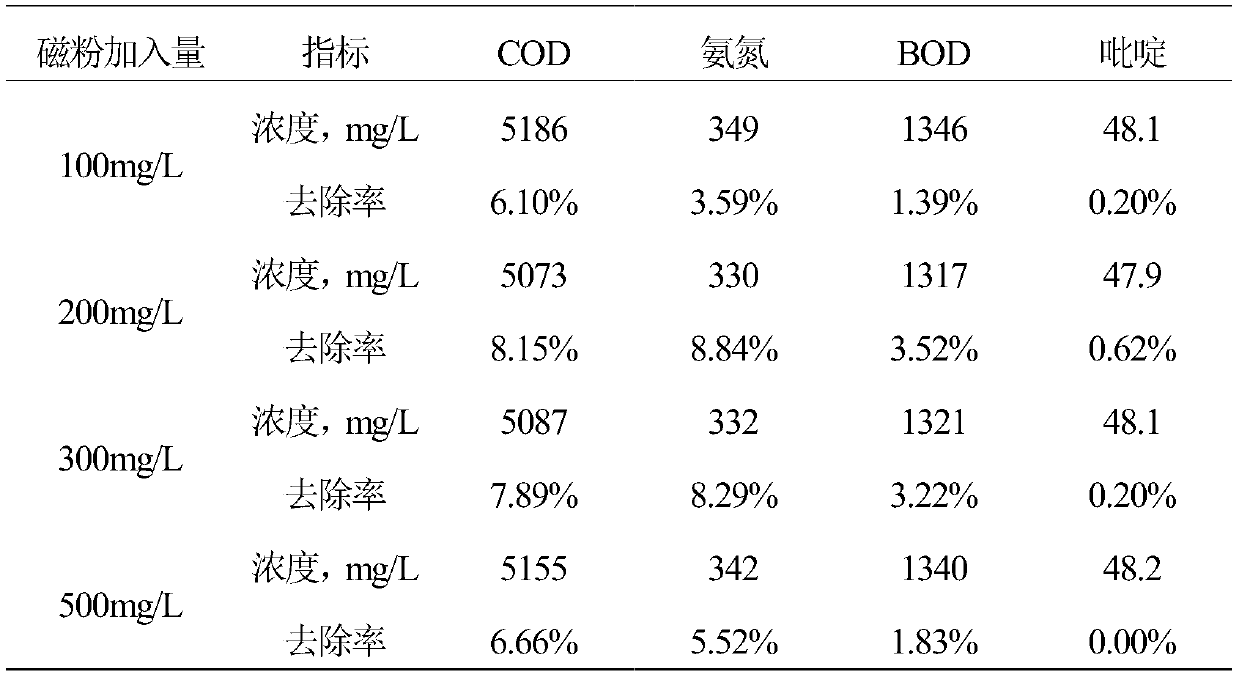

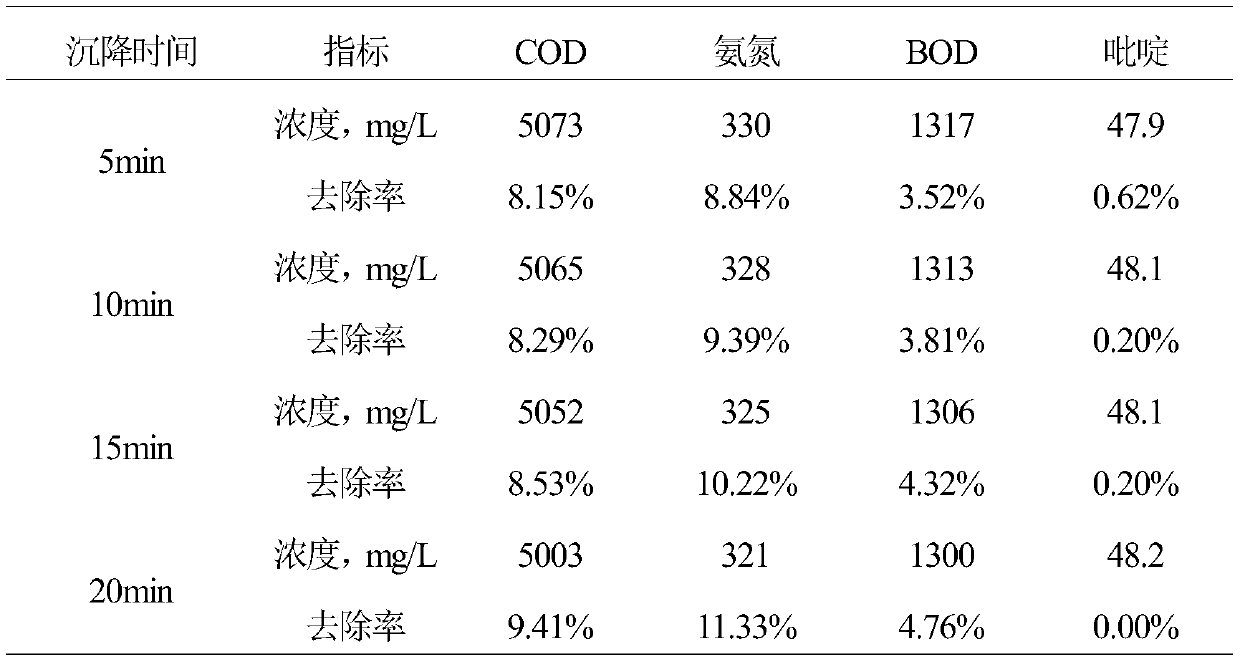

ActiveCN110759578AHigh densityIncrease settling velocityWater/sewage treatment by irradiationWater contaminantsOrganic matter mineralizationSulfate radicals

The invention discloses a method for treating washing wastewater of coal chemical industry. The method comprises the following steps: firstly, carrying out partial removal on tar, suspended impuritiesand other macromolecular substances in the wastewater through a magnetic flocculation precipitation strengthening flocculation effect, then carrying out ultraviolet activated persulfate oxidation toexcite generation of sulfate radicals, effectively carrying out ring opening on refractory organic matters such as pyridine and quinoline to be decomposed into easily degradable substances such as allyl alcohol and acetamide, and thus improving the removal rate of the refractory organic matters and improving the biodegradability of the wastewater; reusing an photoelectric-Fenton oxidation method,producing a Fenton reagent by using an electrochemical method to treat the wastewater, and meanwhile, introducing ultraviolet light, wherein the ultraviolet light and Fe<2+> have a synergistic effecton the catalytic decomposition of H2O2, so that the decomposition rate is greatly improved, the refractory organic matters can be effectively treated, the degree of mineralization is high, secondary pollution cannot be generated, the operation is simple, the control parameters are only voltage and current, and the automatic control can be conveniently realized.

Owner:神美科技有限公司

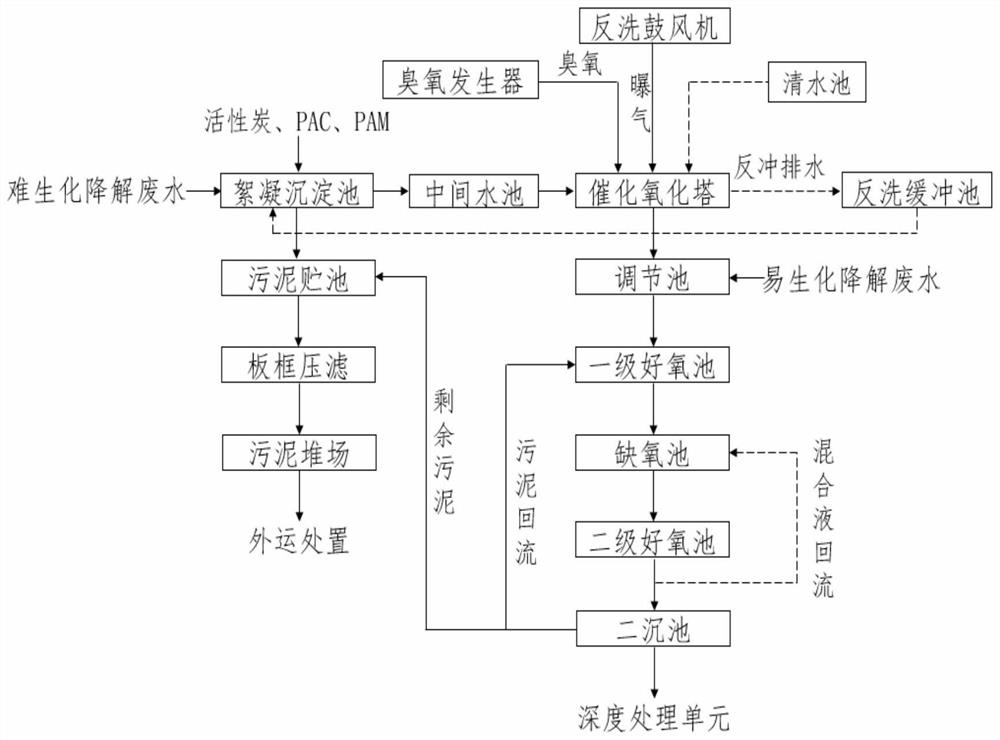

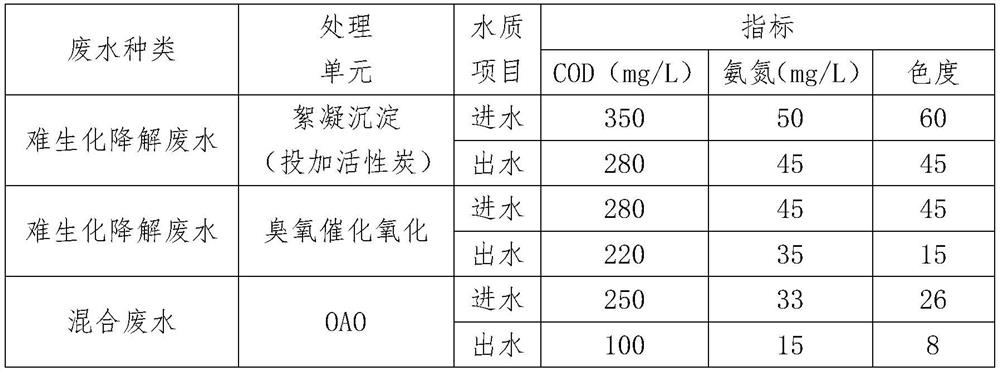

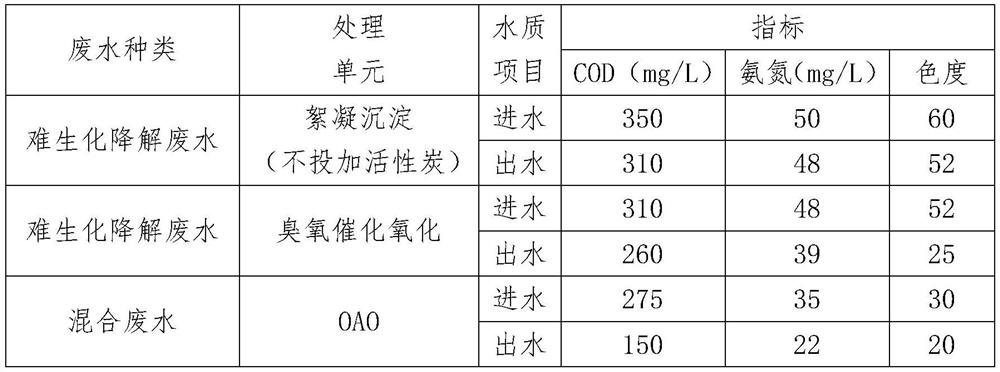

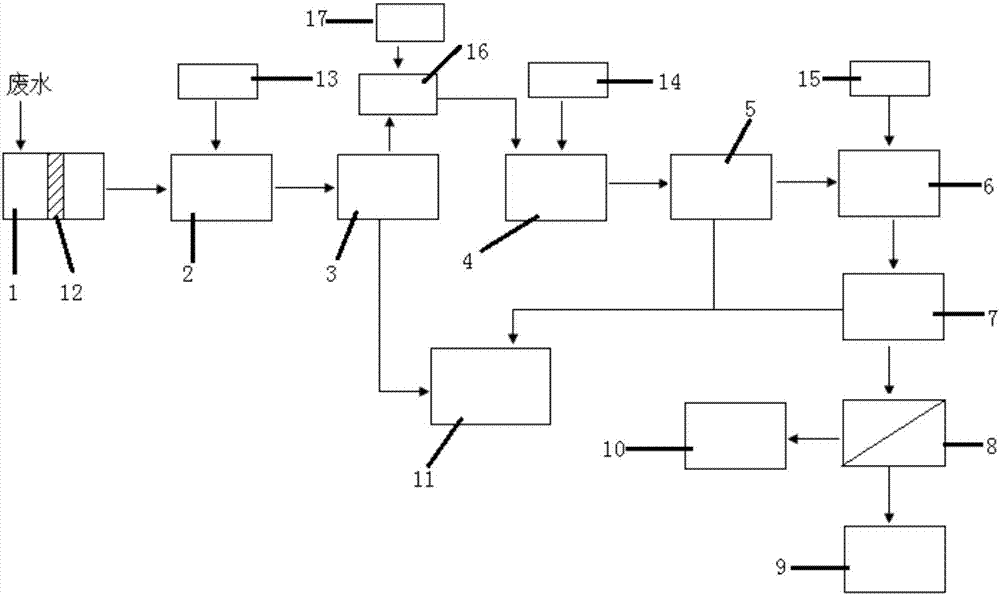

Comprehensive treatment process method for chemical industrial park wastewater

ActiveCN112374694AImprove biodegradabilityEasy to handleSludge treatment by de-watering/drying/thickeningWater treatment compoundsFlocculationSewage

The invention belongs to the field of environmental engineering sewage treatment, relates to pretreatment and biochemical treatment of wastewater, and particularly relates to a comprehensive treatmentprocess method for chemical industrial park wastewater. The method comprises the following steps: carrying out quality-divided treatment on wastewater in a chemical industrial park, firstly feeding the wastewater difficult to biochemically degrade into a flocculation sedimentation tank for flocculation treatment, feeding the treated wastewater into a catalytic ozonation tower, and carrying out mineralization decomposition on substances difficult to degrade in the wastewater by virtue of hydroxyl radicals generated by catalytic ozonation reaction; the wastewater subjected to catalytic ozonation and the wastewater easy to biochemically treat enter an adjusting tank together, the mixed wastewater is homogenized and then enters a biochemical treatment unit, the biochemical treatment unit adopts an OAO process, the treated wastewater enters a secondary sedimentation tank, and after solid-liquid separation, the treated wastewater is discharged into an advanced treatment unit. The process issafe and reliable, and an economic, feasible and stable combined technology is provided for comprehensive treatment of the wastewater in the chemical industrial park.

Owner:DESIGN ENG OF SYRICI +1

Straw pulping paper-making or sulfite method pulping paper-making middle piece waste water treatment technique

InactiveCN101234833AEliminate the effects ofReduce pollution loadWater/sewage treatmentMultistage water/sewage treatmentPapermakingSulfite process

The invention discloses a technology for processing wastewater in middle section of wheat straw cleaning pulping papermaking or sulfite process pulping papermaking. The technology carries out pretreatment to the wastewater of the middle section of the pulping papermaking, which comprises the processes: precipitant with calcium is selected and added in the wastewater of the middle section before the wastewater of the middle section is biochemistry processed; firstly, sulfite ion in the wastewater is removed so that the content of the sulfite ion in the wastewater is reduced; then the biochemistry processing is carried out. The technology for processing wastewater in middle section of wheat straw cleaning pulping papermaking or sulfite process pulping papermaking is economically feasible, uses waste to control waste, is suiting for national environmental policy and has a good application value for popularizing.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD +1

Treatment method and treatment system of wastewater of sweet potato vermicelli

InactiveCN107500475ATake advantage ofReduce wasteWater/sewage treatment by centrifugal separationTreatment involving filtrationOscillatory reactionReverse osmosis

The invention provides a treatment method and a treatment system of wastewater of sweet potato vermicelli. The treatment method comprises the following steps: filtering the wastewater through a filter screen, adding organic polymeric flocculants and inorganic flocculants into filtrate, uniformly mixing to form stable floccules, and centrifuging through a horizontal type scroll discharge sedimentary centrifuge to remove insoluble substances; adding a pH regulator into the wastewater and regulating pH, maintaining the temperature, adding pentosanase, and carrying out oscillatory reaction to obtain enzymolysis liquid, and carrying out centrifugal separation to obtain starch granules; adding a protein separation agent into the wastewater, uniformly stirring and mixing and then standing, then carrying out solid-liquid separation to obtain protein agglomeration substances; carrying out enzyme deactivation on the wastewater, and filtering through a reverse osmosis treatment device to obtain concentrated liquid containing macromolecular organic matters and recyclable water. The method and the system are capable of effectively separating starch and proteins in the wastewater; the separated starch and proteins can be reused; the separated wastewater is fully used; the waste of resources is reduced; the environmental pollution is reduced; the pollution load is alleviated; the subsequent biochemical treatment is facilitated.

Owner:湖南城头山丝念食品股份有限公司

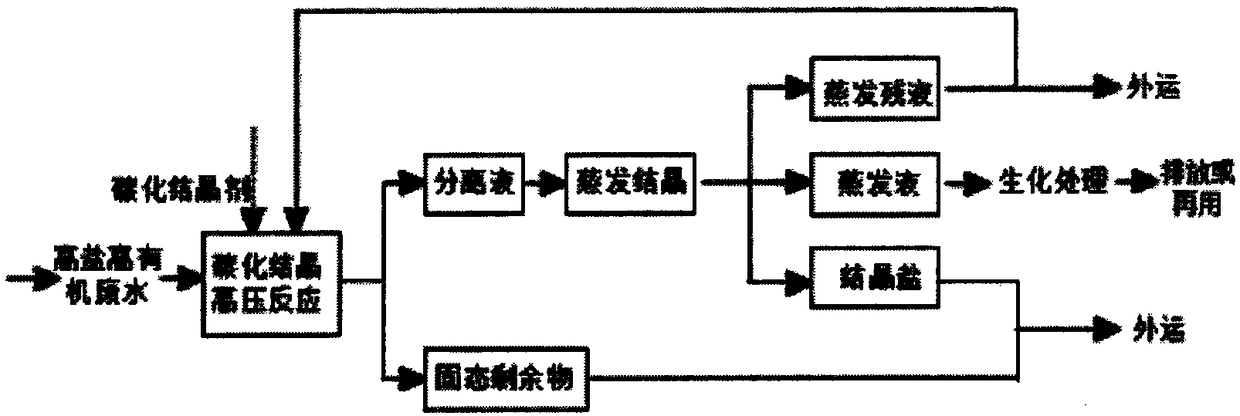

Carbonization and crystallization method for treating high-salt high-organic waste water

ActiveCN108558102AMild reaction conditionsShorten the timeWater treatment compoundsWater contaminantsHigh concentrationOrganic acid

The invention discloses a carbonization and crystallization method for treating high-salt high-organic waste water. The method is characterized in that a metal salt carbonization and crystallization agent containing organic acid and inorganic acid is prepared; the high-salt high-organic waste water is added into a reaction still, the metal carbonization and crystallization agent is added into thereaction still, the liquid is stirred and mixed, and after the liquid is uniformly mixed, the reaction still is closed; the reaction still is heated to a predetermined temperature, the constant temperature carbonation reaction is conducted, the liquid is stirred constantly, after the reaction is finished, the reaction still is cooled to the indoor temperature, and the mixture in the reaction stillis subjected to solid-liquid separation to obtain separating liquid; the separating liquid is subjected to evaporative crystallization treatment to obtain evaporated liquid, salt and high-concentration evaporated residual liquid. The method utilizes the hydrothermal carbonization technology with mild reaction conditions, short reaction time, strong adaptability and lower energy consumption to pretreat the waste water, organic concentration is reduced, therefore the evaporative crystallization effect of the high-salt high-organic waste water is improved, and subsequent biotreatment loading anddifficulty degree of up-to-standard discharge or cyclic utilization of condensed fluid are reduced.

Owner:DONGHUA UNIV

Process for treating epoxy resin production wastewater

ActiveCN103613244BEasy to handleHigh degree of automationMultistage water/sewage treatmentNature of treatment waterSuspended particlesEpoxy

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

Method for extracting plant protein from cassava starch waste water

The invention discloses a method for extracting plant protein from cassava starch waste water, wherein starch-containing yellow serofluid waste water discharged in a process for producing starch by utilizing cassava is fully utilized. The method is characterized by comprising the following steps of: 1, introducing the yellow serofluid waste water into a reaction sedimentation tank by virtue of a premixing groove, metering and throwing protein precipitant and lime water into the premixing groove, controlling alkalinity of water in a pond and controlling settling time to be 1-2 hours, so as to produce precipitate; 2, introducing the precipitate into a stirring pond, adding ferrous-iron-containing salt and uniformly stirring to obtain dissolved matter; 3, pumping by virtue of a pump to convey the dissolved matter into a pressure filter to be subjected to filter pressing, so as to obtain filter residue; and 4, baking the filter residue and smashing the filter residue into powder, and packaging to obtain finished products. The method disclosed by the invention has low cost and simple process, reaction of protein to certain medicine is utilized, the plant protein is condensed and separated under the condition of slight alkalinity, the added drug and the protein are condensed into a whole and precipitated, the products are recycled by virtue of a machine, water is discharged and no drug residue is left, pollutant is greatly reduced, and follow-up biochemical treatment can be beneficially carried out.

Owner:潘增强

High-salinity comprehensive wastewater treatment system for chemical industry parks

PendingCN108706839ALow toxicityReduce COD concentrationTreatment using aerobic processesGeneral water supply conservationChemical industryEvaporation

The invention relates to the technical field of wastewater treatment and particularly relates to a high-salinity comprehensive wastewater treatment system for chemical industry parks. The high-salinity comprehensive wastewater treatment system comprises a classified storage unit, a positive osmosis treatment unit, a pretreatment unit, a coagulating sedimentation unit, an adjusting tank unit, an intermediate temperate anaerobic unit, an aerobic reaction unit and a desalting unit. According to the treatment system provided by the invention, the treatment rate and biodegradability of a wastewaterphysical and chemical area are increased, two purposes of dilution and concentration are achieved by virtue of the energy of high-salinity wastewater, meanwhile, the problems that organic matters arehardened during the direct evaporation of front-section high-sanity and high-COD wastewater, the evaporation efficiency is reduced, and a front-end electroosmosis membrane is polluted are solved, andthe secondary utilization of waste membranes of a power plant is realized, so that the operation cost of a sewage plant is greatly lowered, and the benefit of the sewage plant is increased.

Owner:山东默锐环境产业股份有限公司

Environment-friendly wastewater denitrification treatment device and use method thereof

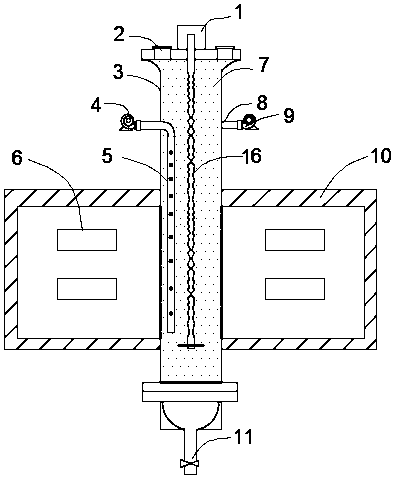

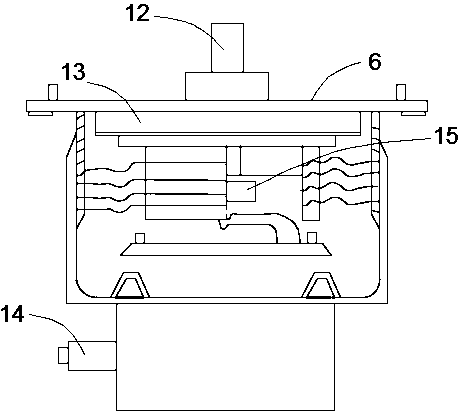

InactiveCN107746109AIncrease contact areaAvoid wastingWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesMicrowaveFilling materials

The invention discloses an environment-friendly wastewater denitrification treatment device, which comprises a denitrification reaction pipe, an aeration pipe and a microwave reaction box, wherein a stirring motor is arranged above the denitrification reaction pipe; a stirring paddle is coaxially arranged inside the stirring motor; the stirring paddle penetrates through the denitrification reaction pipe; reaction gas recovery openings are symmetrically formed in the two sides of the stirring motor; the denitrification reaction pipe is internally filled with reaction filling materials; an L-shaped aeration pipe penetrates through one side of the denitrification reaction pipe; a water inlet is formed in the other side of the denitrification reaction pipe; a water outlet is formed under the denitrification reaction pipe; the denitrification reaction pipe penetrates through the microwave reaction box; a plurality of microwave generators are arranged inside the microwave reaction box; a microwave energy output device is arranged above the microwave generators; a magnet is connected under the microwave energy output device. The environment-friendly wastewater denitrification treatment device has the advantages that the investment is low; the operation cost is low; the occupied area of the equipment is small; the treatment efficiency is high; the management is convenient, and the like. The equipment has good market application and industrial prospects.

Owner:张延艳

Flocculation pretreatment method for penicillin fermentation waste water

ActiveCN101811791BSimple methodLow costMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludge cakePretreatment method

The invention discloses a flocculation pretreatment method for penicillin fermentation waste water, which is suitable for the pre-treatment of high-concentration bacterium slurry residual liquid generated in a penicillin fermentation process and mainly comprises the following steps: a, adjusting the quality of the waste water with a counter-ion auxiliary agent; b, performing flocculation reaction with a high-molecular organic flocculating agent, namely polyacrylamide; and c, performing solid-liquid separation. The counter-ion auxiliary agent is one of CaO, Ca(OH)2, polymeric silicate, polyaluminium chloride or tannin. By the method, the content of SS and COD in the waste water, which affect biochemical treatment, can be greatly decreased; subsequent biochemical treatment difficulty is effectively reduced; the treated waste water can meet the requirements of the subsequent biochemical treatment; and the water content of sludge cakes after the solid-liquid separation is more lower at the same time. Compared with other pre-treatment methods for the waste water generated in a penicillin production process, the method of the invention has better effect and more simple operation.

Owner:河北协同环境科技有限公司

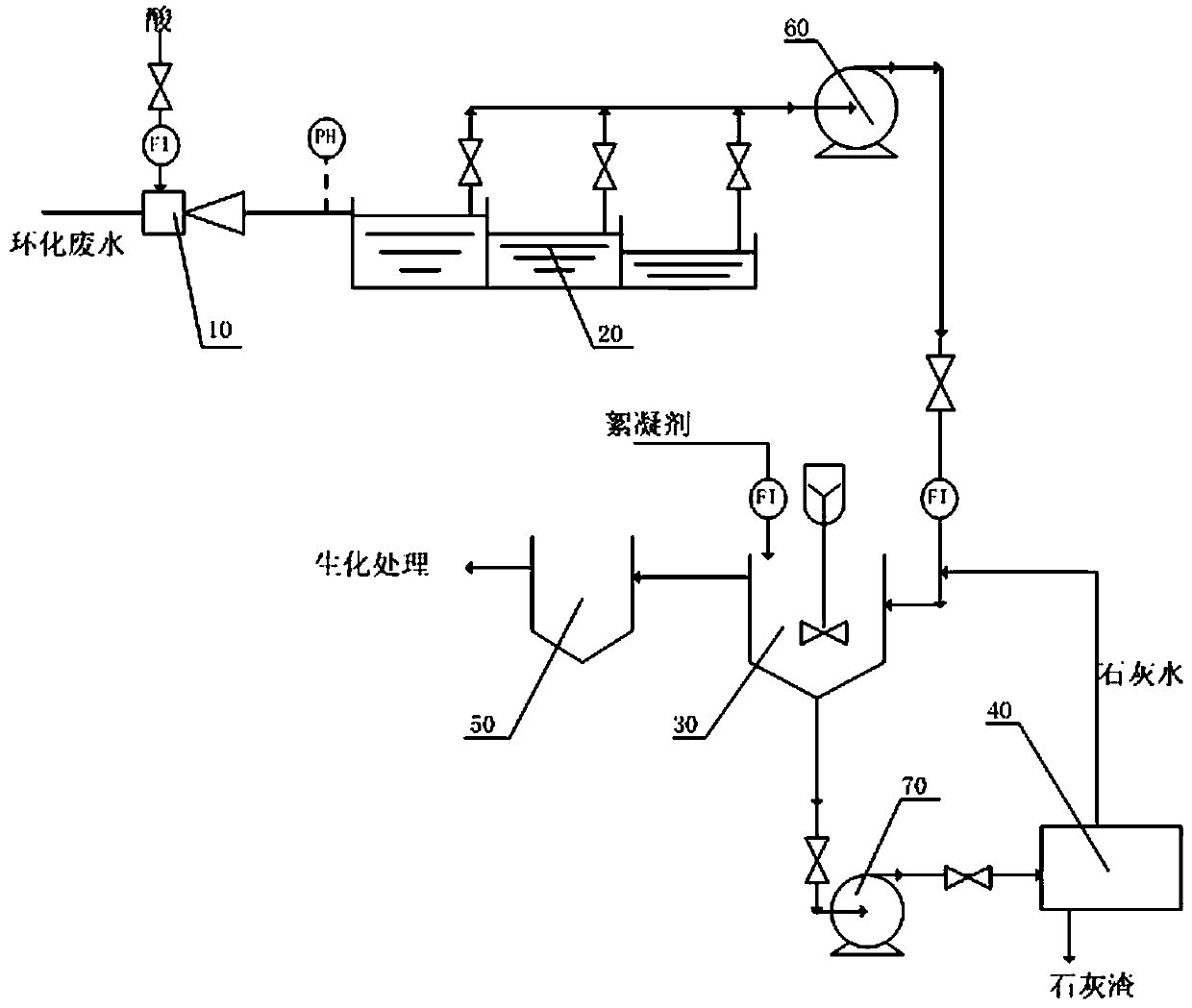

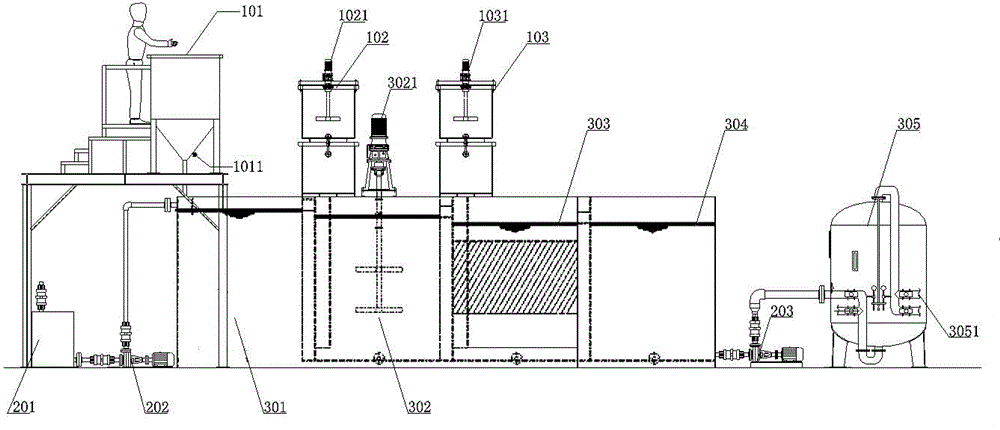

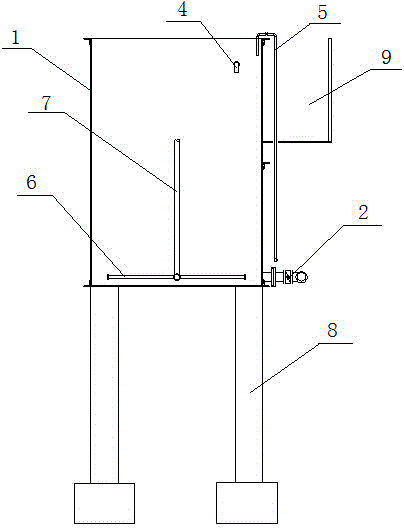

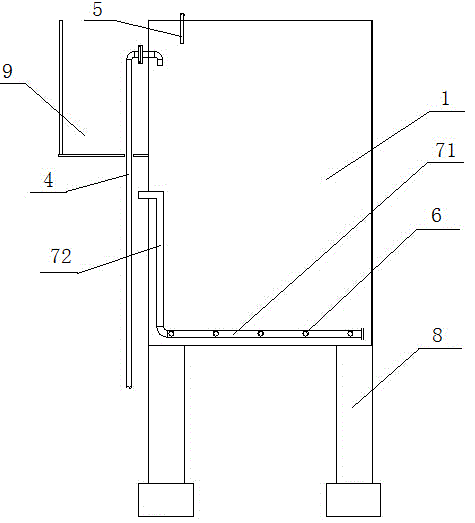

Pretreatment method and system for wastewater in technology for preparing epoxy chloropropane by propylene high-temperature chlorination process

InactiveCN107686209AImprove processing efficiencySimple processWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentPretreatment methodWastewater

The invention provides a pretreatment method and system for wastewater in a technology for preparing epoxy chloropropane by a propylene high-temperature chlorination process. The pretreatment method comprises the following steps: obtaining cyclization wastewater in the technology for preparing epoxy chloropropane by the propylene high-temperature chlorination process; mixing the cyclization wastewater with acid to obtain a mixed solution, wherein a pH value of the mixed solution is 8 to 9; mixing the mixed solution with a flocculant, stirring and settling to obtain a clear solution and sediment; centrifugally separating the sediment to obtain lime water and waste lime; returning the lime water to be flocculated and settled. According to the pretreatment method and system for wastewater inthe technology for preparing the epoxy chloropropane by the propylene high-temperature chlorination process, the acid is added to adjust the pH value of the cyclization wastewater, and the flocculantis added to flocculate suspended matter to pretreat the cyclization wastewater. The pretreatment method has the advantages of simple technological process and high treating efficiency; a content of suspension matter in the treated wastewater is as low as about 50ppm, and follow-up biochemical treatment is more facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Equipment for pretreating sewage from preparation of biopharmaceuticals

InactiveCN104529004AHX reductionReduce salinityMultistage water/sewage treatmentNature of treatment waterBiochemical engineeringSewage

The invention belongs to the technical field of preparation of biopharmaceuticals and particularly relates to equipment for pretreating sewage from preparation of biopharmaceuticals. The equipment comprises a pharmaceutical feeding device, a power device and a reaction processing device. The equipment integrates an HX technology with treatment modes of air flotation, coagulation and adsorption, and the pretreating equipment can be used for reducing SS (suspended solids), salts, most of the COD and bio-inhibitory substances in sewage and improving the degradability of sewage to facilitate the subsequent biochemical treatment of sewage.

Owner:JIANGSU HUAXING ELECTRICAL TECH

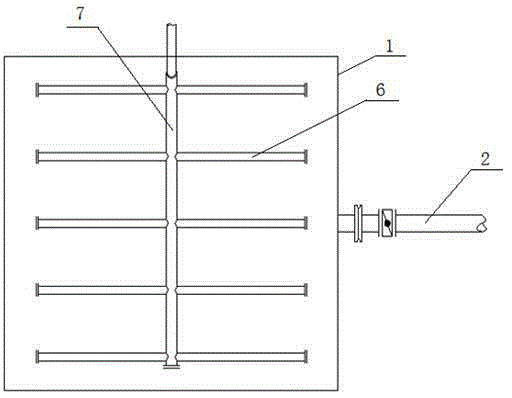

Pretreatment device for DMF (dimethyl formamide)-containing wastewater

InactiveCN104828880AImprove biodegradabilityEasy to handleWater contaminantsWater/sewage treatmentWastewaterTherapeutic effect

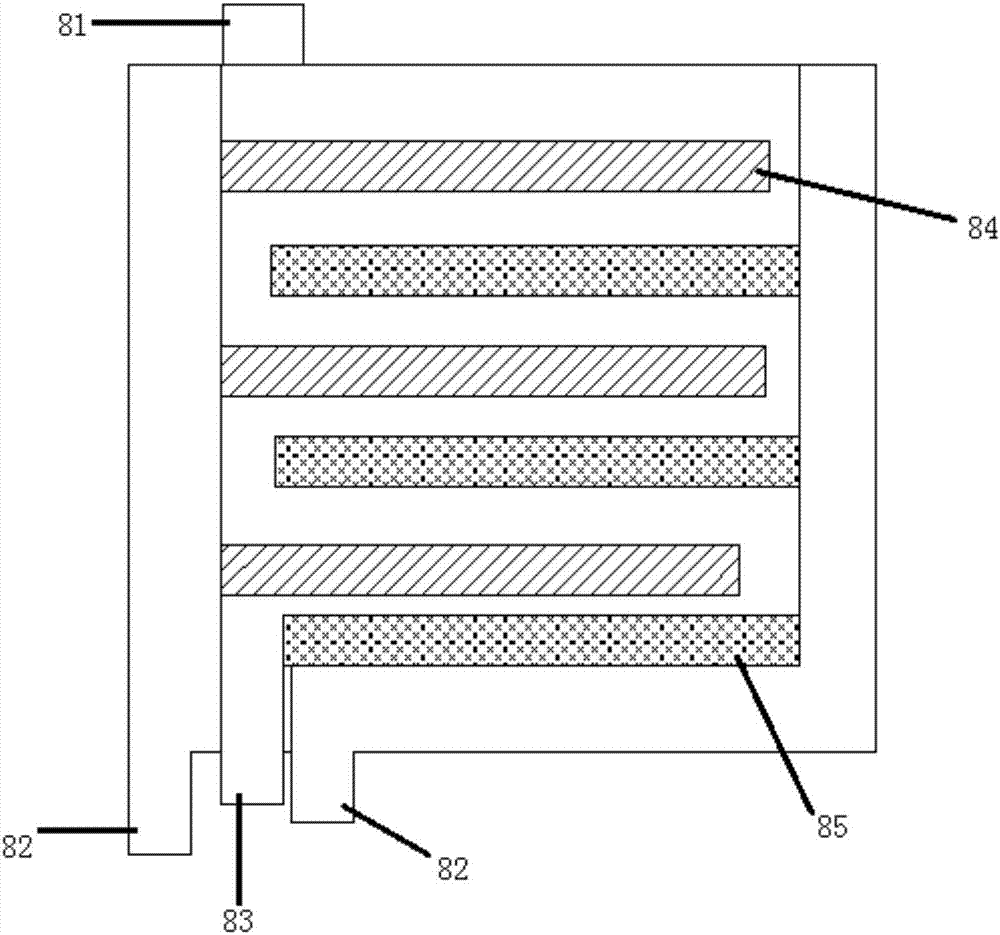

The present invention discloses a pretreatment device for DMF (dimethyl formamide)-containing wastewater. The device comprises a reaction body which is of a cuboid steel structure. An unloading opening which is fixedly communicated with an unloading pipe is formed in the side wall at the lower end of the body, and a steam inlet hole is formed in the side wall at the upper end of the body. A water inlet and an alkali feeding opening are formed in the top of the body, the water inlet is fixedly communicated with the water inlet pipe, and the alkali feeding opening is fixedly communicated with an alkali feeding pipe. A plurality of air distributing pipes which are arranged in parallel are mounted on the bottom face inside the body, a steam pipeline which is perpendicularly communicated among the plurality of air distributing pipes is an integrally formed L-shaped structure comprising a section communicated with the air distributing pipes and a section parallel to the side face of the body, and the steam pipeline is communicated with the end opening of the section parallel to the side face of the body and the steam inlet hole. According to the device disclosed by the present invention, the biodegradable performance of the treated wastewater can be greatly improved, and the treated wastewater does not cause a great influence on the surrounding environment and is directly discharged into air. The treatment effect is stable, and the subsequent bio-treatment is facilitated, and the device is simple in structure and convenient to mount and operate.

Owner:NANTONG DAHENG ENVIRONMENTAL ENG CO LTD

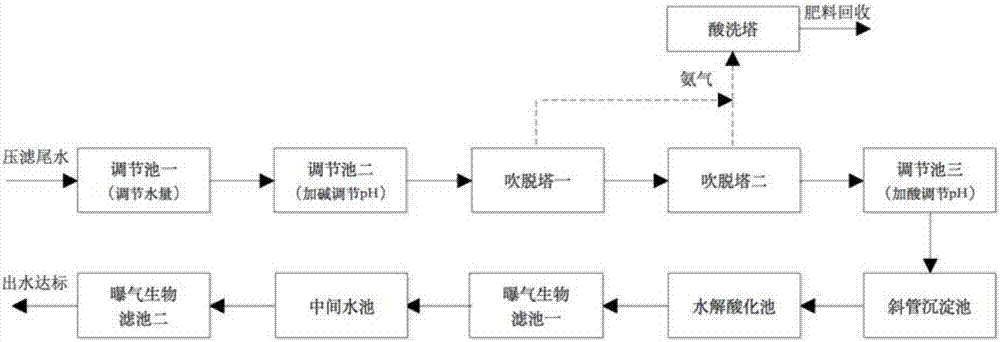

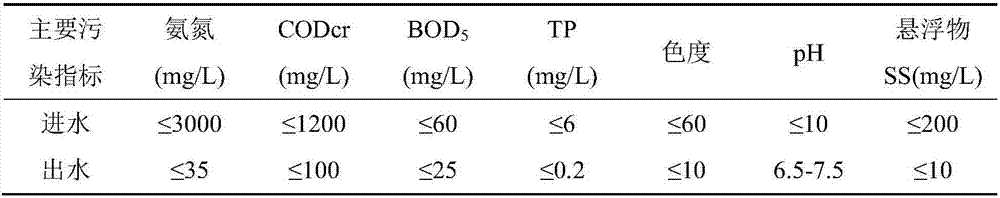

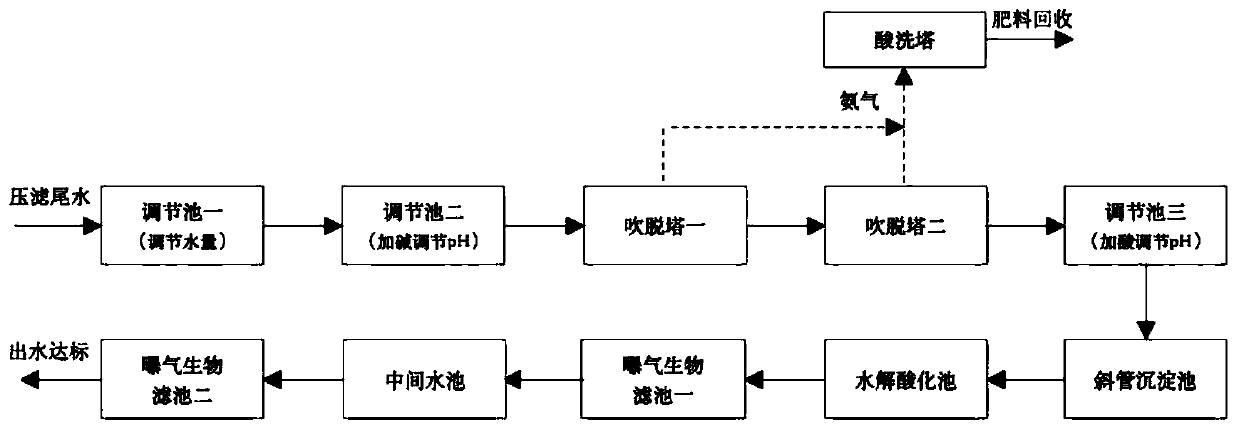

Treatment process of landfill municipal sludge press filtering tail water

ActiveCN106995260AHigh concentration of ammonia nitrogenLow C/N valueWater contaminantsMultistage water/sewage treatmentLand resourcesProper treatment

The invention discloses a treatment process of landfill municipal sludge press filtering tail water, and belongs to the field of sewage treatment. The land resources in China are limited; when no proper treatment technology and no excessive regions are used for sludge landfill, the further volume reduction of the landfill sludge becomes the present searching direction. After chemical conditioning agents are added into the landfill sludge, the tail water subjected to press filtering has complicated ingredients and high contaminant contents; the treatment difficulty is high. By aiming at the pollution characteristics of the tail water, the existing advanced treatment technology can be combined; a combined process of blowoff, inclined pipe precipitation, hydrolysis acidification pool and two-stage biological aerated filter is used for realizing the effective treatment on the tail water with high ammonia nitrogen concentration, low C / N value, low B / C value and high chloride ion concentration; in addition, the operation and the management are simple; the removal effect is stable; the anti-impact load is high; the quantity of the generated sludge is small; the cost is low.

Owner:NAT ENG RES CENT OF DREDGING TECH & EQUIP

A kind of deodorant and deodorizing method for controlling garbage stench

The invention discloses an SRR deodorant for treating garbage stench and a deodorization method thereof. The deodorant comprises the following raw materials: an active free radical source, an active excitation agent, a balanced stabilizer and a persistent effect accelerant, wherein the free radical source is a mixture of a halogen free radical source, an SR free radical source and a hydroxyl free radical source; the SRR deodorant can be used for deodorizing garbage; the odor of the garbage processed by the process can be removed or relieved for 2-3 days; the garbage ripening process is accelerated; maximal utilization of garbage resources is facilitated; toxic and harmful organic matters in landfill leachate are reduced; subsequent treatment is facilitated; the organic matter concentration, heavy metal ions, COD and BOD content in the landfill leachate are reduced; and subsequent biochemical treatment of the landfill leachate is facilitated.

Owner:成都安捷芮环保科技有限公司

Treatment process of landfill municipal sludge press filter tail water

ActiveCN106995260BHigh concentration of ammonia nitrogenLow C/N valueWater contaminantsMultistage water/sewage treatmentAmmoniacal nitrogenSludge

The invention discloses a treatment process of landfill municipal sludge press filtering tail water, and belongs to the field of sewage treatment. The land resources in China are limited; when no proper treatment technology and no excessive regions are used for sludge landfill, the further volume reduction of the landfill sludge becomes the present searching direction. After chemical conditioning agents are added into the landfill sludge, the tail water subjected to press filtering has complicated ingredients and high contaminant contents; the treatment difficulty is high. By aiming at the pollution characteristics of the tail water, the existing advanced treatment technology can be combined; a combined process of blowoff, inclined pipe precipitation, hydrolysis acidification pool and two-stage biological aerated filter is used for realizing the effective treatment on the tail water with high ammonia nitrogen concentration, low C / N value, low B / C value and high chloride ion concentration; in addition, the operation and the management are simple; the removal effect is stable; the anti-impact load is high; the quantity of the generated sludge is small; the cost is low.

Owner:NAT ENG RES CENT OF DREDGING TECH & EQUIP

A kind of treatment method of coal chemical industry washing wastewater

ActiveCN110759578BHigh densityIncrease settling velocityWater/sewage treatment by irradiationWater contaminantsOrganic matter mineralizationSulfate radicals

The invention discloses a treatment method for coal chemical washing wastewater, which firstly strengthens the flocculation effect through magnetic flocculation precipitation, partially removes tars, suspended impurities and other macromolecular substances in the wastewater, and then activates persulfate oxidation through ultraviolet light to activate Generate sulfate radicals, which can effectively decompose refractory organics such as pyridine and quinoline into easily degradable substances such as propenyl alcohol and acetamide, thereby improving the removal rate of refractory organics and improving the biodegradability of wastewater; Oxidation method, using electrochemical method to produce Fenton's reagent to treat wastewater, while introducing ultraviolet light, ultraviolet light and Fe 2+ to H 2 o 2 The catalytic decomposition has a synergistic effect, the decomposition rate is greatly improved, it can effectively treat refractory organic matter, the degree of mineralization is high, no secondary pollution is generated, and the operation is simple. The control parameters are only voltage and current, which is convenient for automatic control.

Owner:神美科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com