Apparatus and process for combined treating waste water containing pesticide with ozone/hydrogen peroxide solution

A technology of pesticide wastewater and combined treatment, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of complex pollutant composition, difficult biodegradation, high wastewater concentration, and achieve high degree of equipment automation, simple device operation, and reduced effluent toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

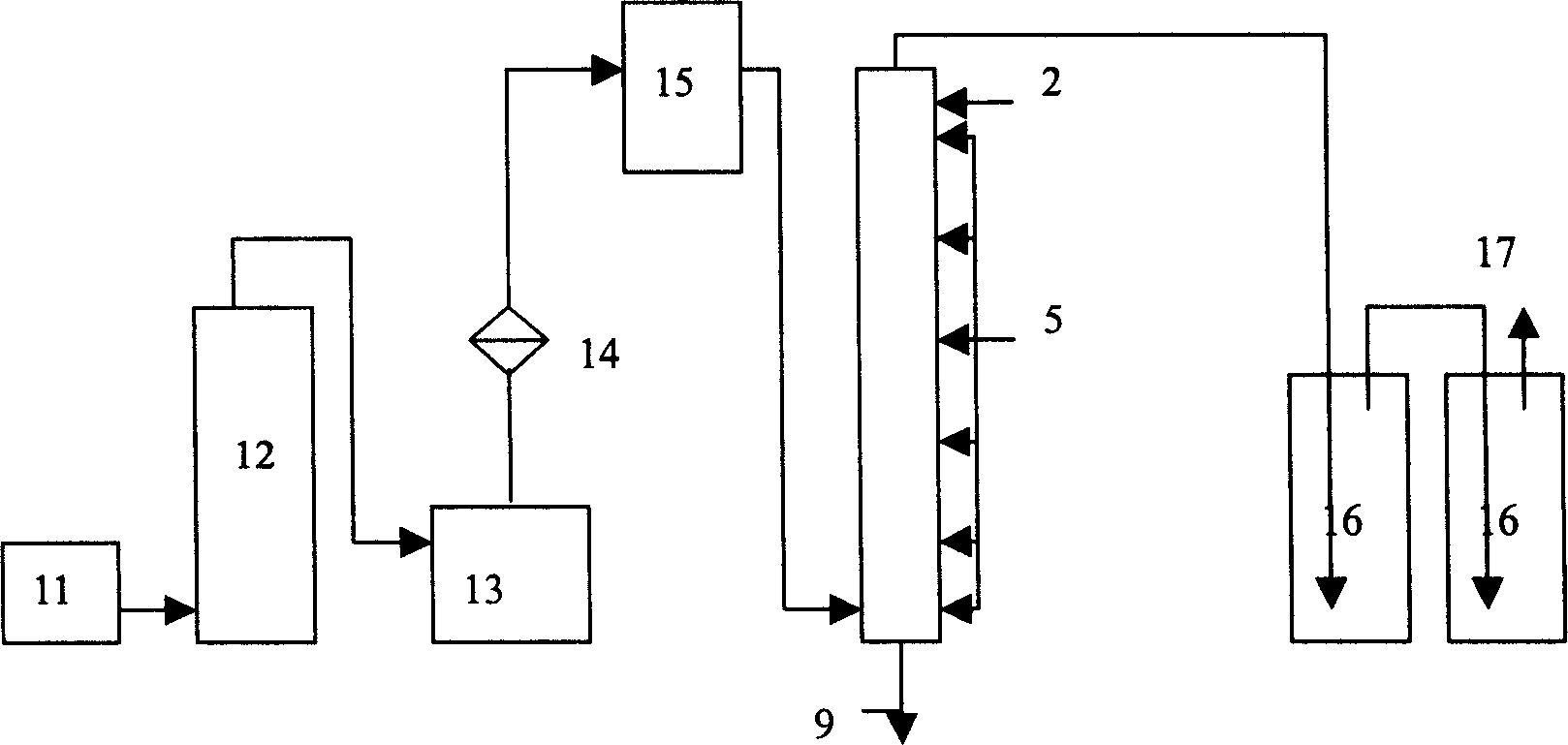

[0029] Use the 2,4-D pesticide raw material produced by a pesticide factory to prepare a 2,4-D pesticide solution with a concentration of 200mg / L as the water to be treated. The pesticide-containing wastewater treatment device that uses ozone / hydrogen peroxide to jointly generate free radicals is purified under the following conditions:

[0030] Treatment method: one-time influent treatment for 60 minutes, ozonated air, hydrogen peroxide, and pH regulator are all added intermittently, and added once every 15 minutes;

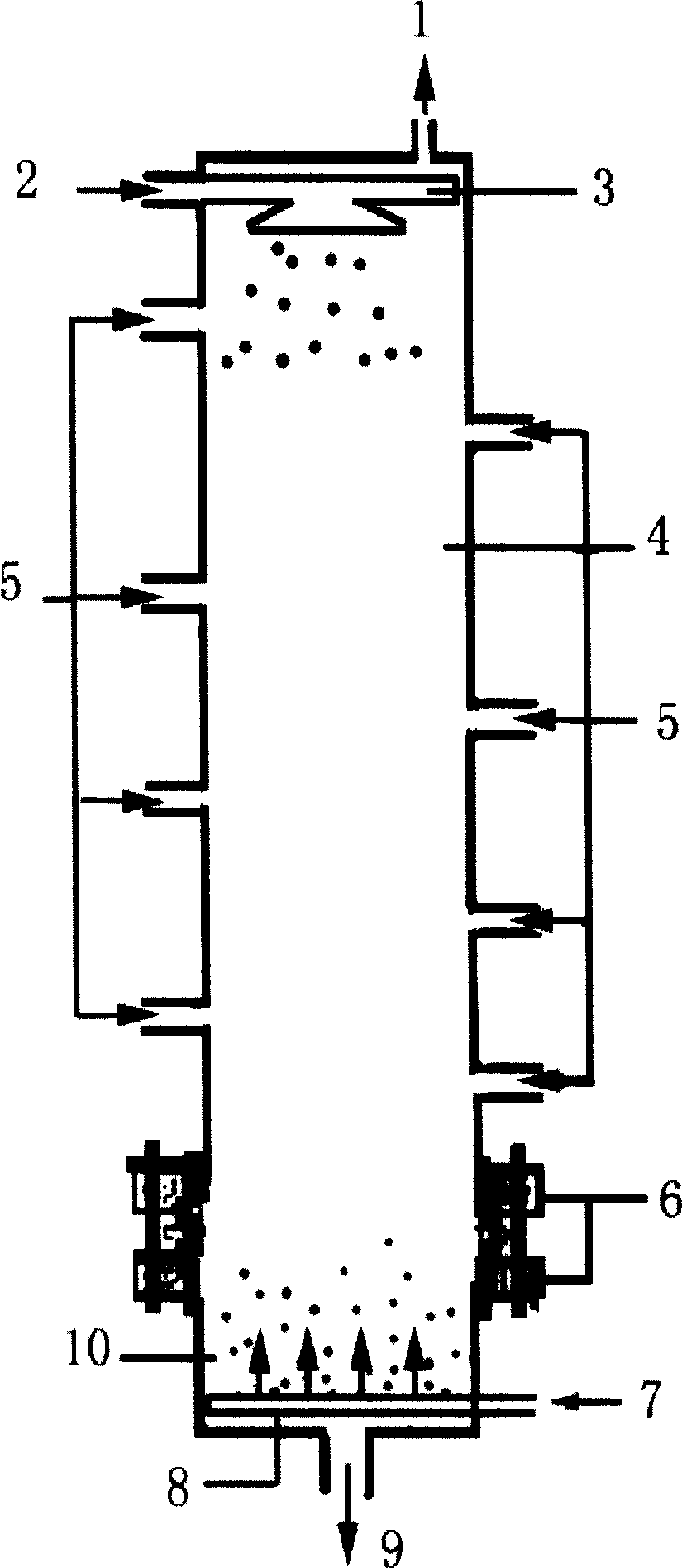

[0031] Design parameters of the ozone / hydrogen peroxide mixed contact reaction unit: the net height of the reactor is 650mm, the diameter of the reaction chamber is 50mm, and the effective volume is 1.2L;

[0032] The ozonated air is filled into the system for 5 minutes every 15 minutes, and the ozone concentration in the solution phase is maintained at 5 mg / L;

[0033] Hydrogen peroxide concentration: 50mg / L

[0034] pH adjuster: 1mol / L NaOH solution to maint...

Embodiment 2

[0037] The carbofuran pesticide technical product produced by a pesticide factory was used to prepare a carbofuran pesticide solution with a concentration of 200mg / L as the water to be treated. The pesticide-containing wastewater treatment device that uses ozone / hydrogen peroxide to jointly generate free radicals is purified under the following conditions:

[0038] Treatment method: one-time influent treatment for 60 minutes, ozonated air, hydrogen peroxide, and pH regulator are all added intermittently, and added once every 15 minutes;

[0039] Design parameters of the ozone / hydrogen peroxide mixed contact reaction unit: the net height of the reactor is 650mm, the diameter of the reaction chamber is 50mm, and the effective volume is 1.2L;

[0040] The ozonated air is filled into the system for 5 minutes every 15 minutes, and the ozone concentration in the solution phase is maintained at 5 mg / L;

[0041] Hydrogen peroxide concentration: 50mg / L

[0042] pH adjuster: 1mol / L Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com