Method for processing coal gasification wastewater

A technology for coal gasification wastewater and treatment method, which is applied in the fields of gaseous effluent wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Problems such as low COD removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

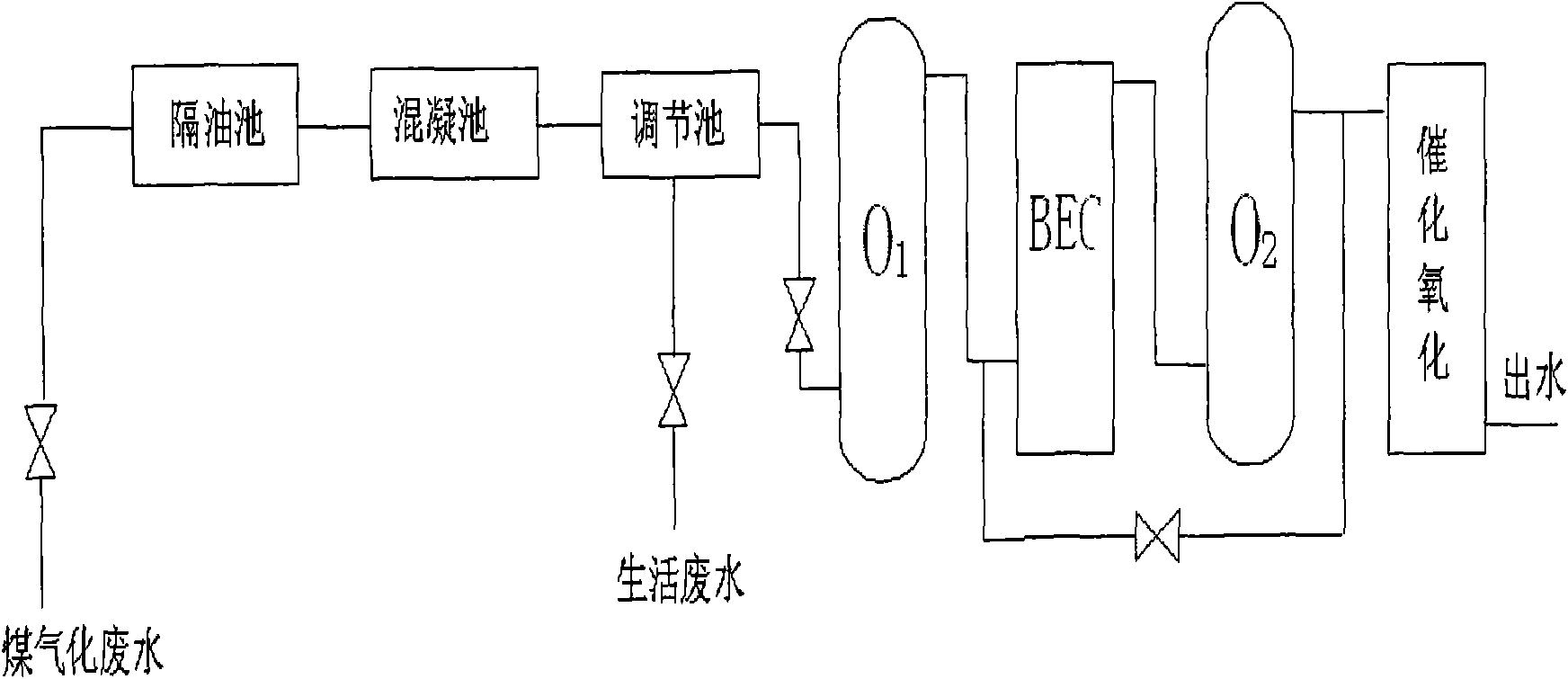

Embodiment 1

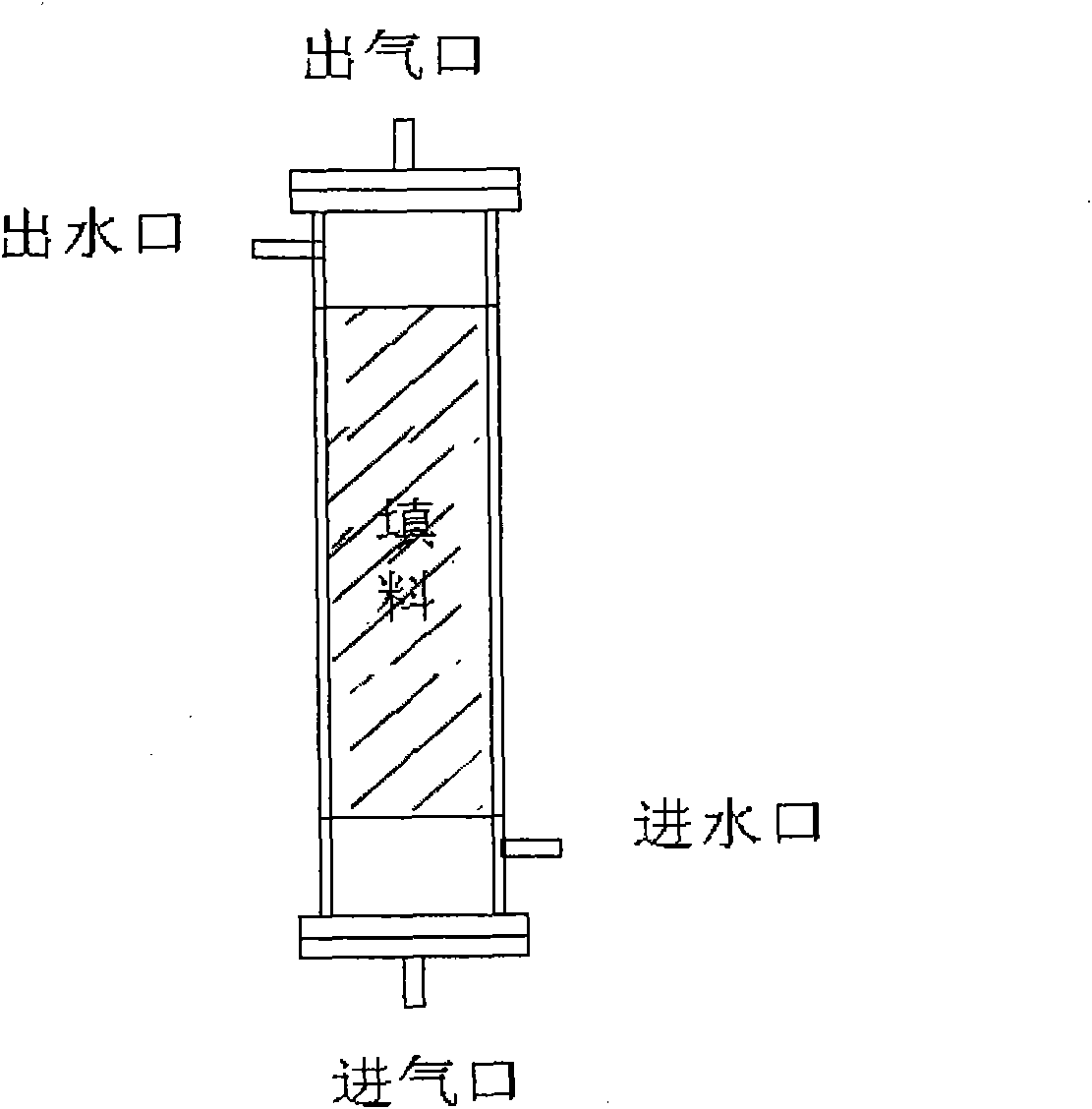

[0042] The method of the present invention is used to carry out small-scale experimental treatment of the coal gasification summary wastewater of a certain company whose COD and ammonia nitrogen are about 5000-8000 mg / L and 500-800 mg / L respectively. Each reactor is made of plexiglass, and the waste water enters the coagulation sedimentation tank after passing through the flat grease trap. The coagulants added are polyaluminum chloride (PAC) and polyacrylamide (PAM), and the dosage is 200-300mg respectively / L and 3-6mg / L, after stirring, coagulation and sedimentation, the wastewater enters the regulating tank. It is mixed with the company's domestic sewage in the adjustment tank. The mixing ratio of coal gasification wastewater and domestic sewage is 3:1, and then the pH value of the mixed wastewater is controlled at 6-9. After mixing, the waste water is pumped into O1, which uses granular carbon felt filler, the filling volume of the filler is 70%, the acclimatization time o...

Embodiment 2

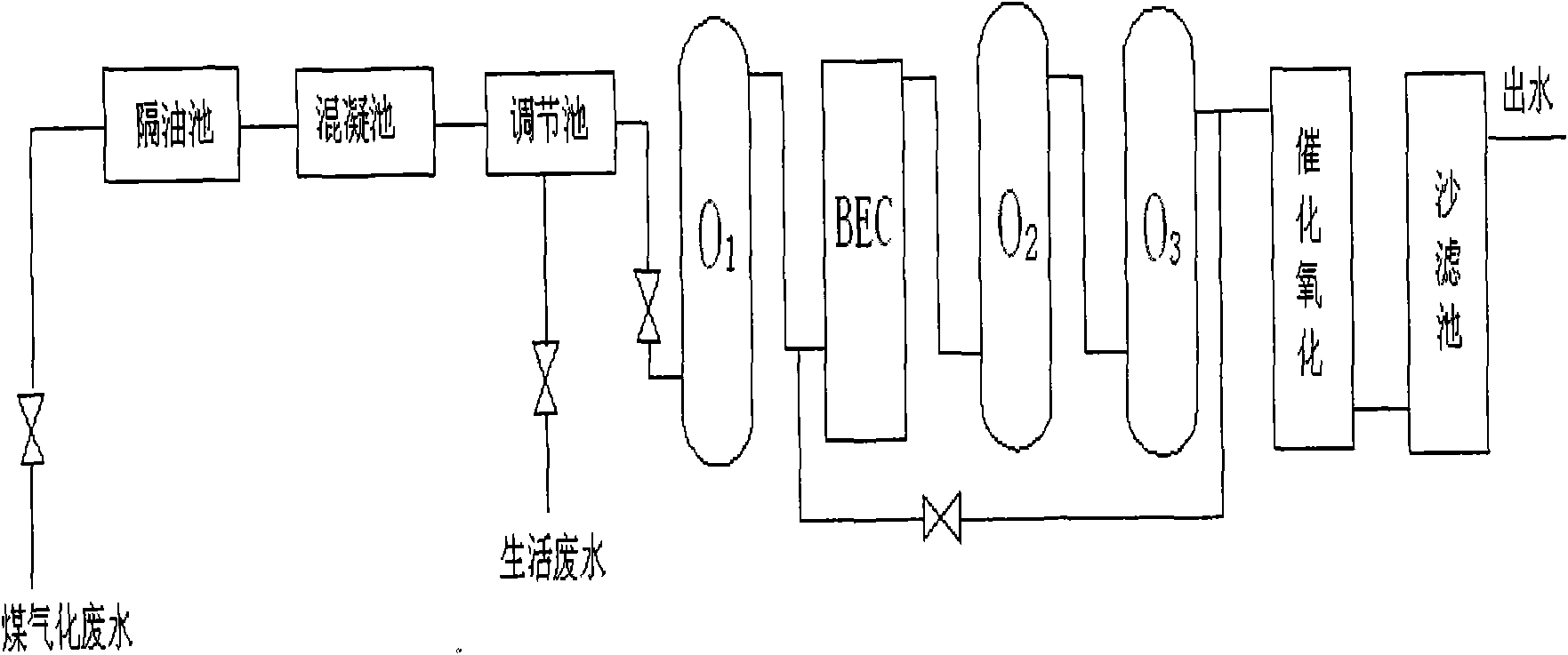

[0046] The comprehensive coal gasification wastewater COD and ammonia nitrogen produced in various sections of a coal chemical company are 3000-4000mg / L and 300-400mg / L respectively, and the process of the present invention is used for pilot treatment. Wastewater is treated by oil separation and coagulation (PAC and PAM dosages are 200-300mg / L and 3-6mg / L respectively) and then pumped directly into O1, which uses a mixture of granular carbon felt, granular plastic and mesh plastic Filler, the filling amount is 80%, the acclimatization time of film formation is 20 days, the hydraulic retention time is 15h, the dissolved oxygen is controlled at 3-6mg / L, and the pH is controlled at 6.5-8.5. The materials of the anode and cathode of BEC are all carbon felts, and the surface of the cathode is coated with a hydrogen evolution catalyst (60% Ni, 30% Al, 2% Co, 8% Sn), and the two poles are connected to the external power supply by wires. There is an anaerobic sludge layer, the acclima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com