Comprehensive treatment process method for chemical industrial park wastewater

A chemical industry park and process method technology, applied in the fields of special compound water treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of poor wastewater treatment effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

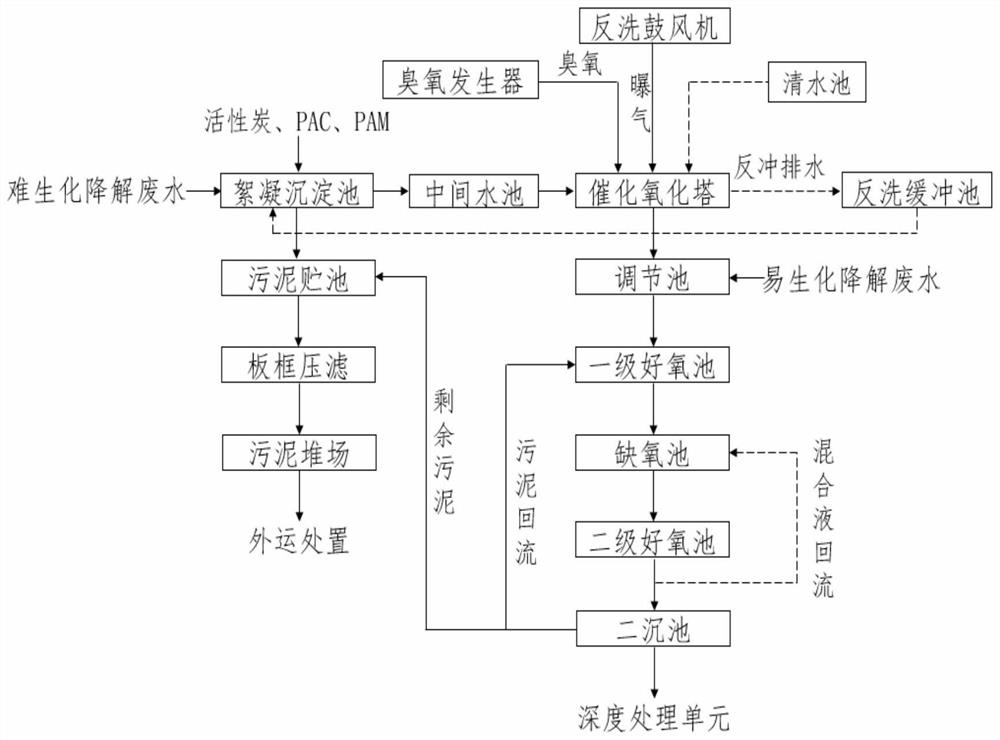

[0049] like figure 1 As shown, the wastewater treatment in the chemical industry park follows the principle of "separate treatment". The wastewater that is difficult to biochemically degrade enters the flocculation sedimentation tank, the intermediate pool, the catalytic oxidation tower, and the adjustment tank in turn; the wastewater that is easily biodegradable directly enters the adjustment tank. The degraded wastewater is evenly mixed, and after homogenization, it enters the biochemical treatment unit. After that, the wastewater enters the primary aerobic pool, the anoxic pool, and the secondary aerobic pool, and then is discharged into the advanced treatment unit after solid-liquid separation in the secondary sedimentation tank.

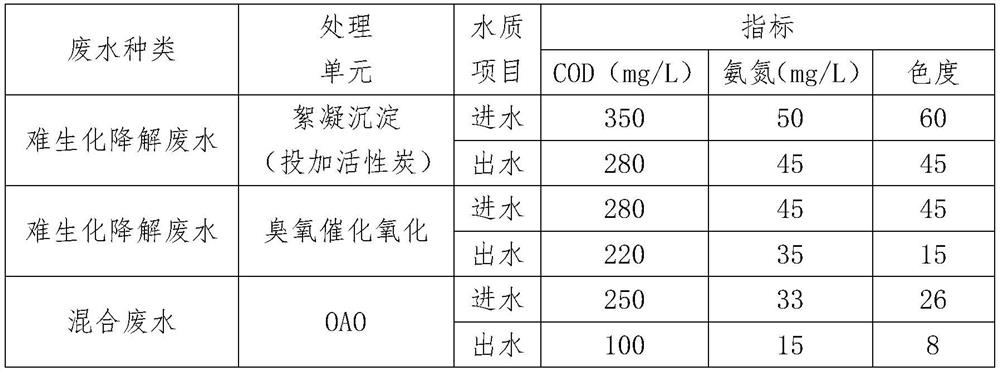

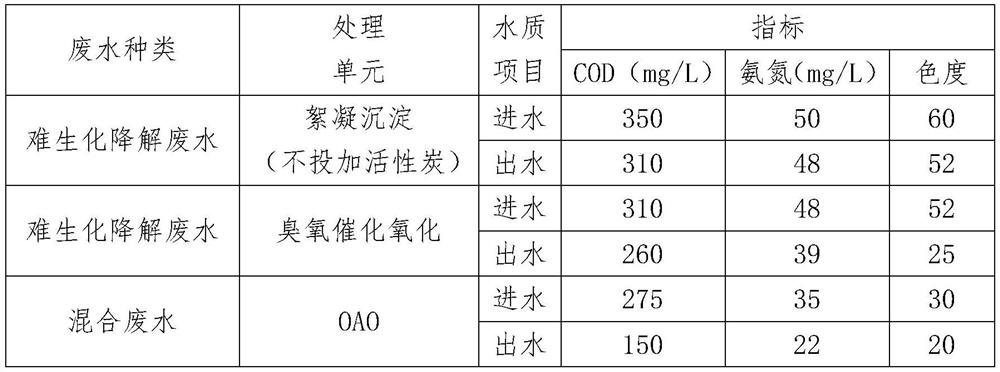

[0050] Collect all the wastewater in the park and mix the wastewater with BOD / COD less than 0.3, which is refractory wastewater; refractory biodegradable wastewater COD: 350mg / L; ammonia nitrogen: 50mg / L; chroma: 60; other wastewater collection i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com