High performance tower for picking off ammonia nitrogen

A technology for removing ammonia nitrogen and tower body is applied in the field of industrial wastewater treatment equipment, which can solve the problems of inability to scale up industrial applications, difficult normal operation of wastewater treatment process, and inability to remove reaction products in time, so as to achieve convenient maintenance, space saving, The effect of reducing the total gas-liquid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

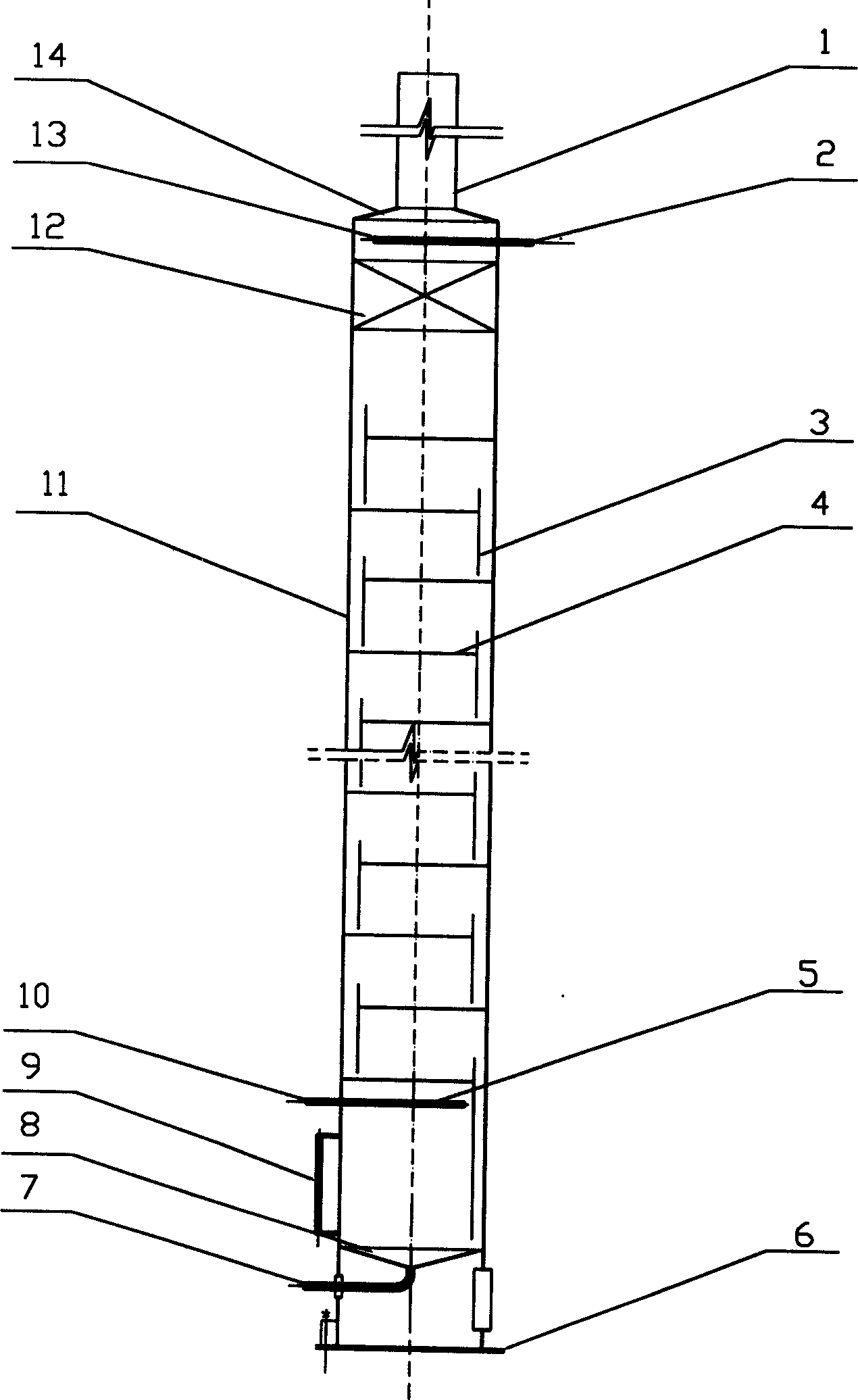

[0019] The structure of the nitrogen removal tower is as follows figure 1 As shown, the tower body 11 made of carbon steel is fixedly connected to the base plate 6, and the top and bottom are respectively closed with a top head 14 and a bottom head 8, and a treated water outlet pipe 7 is fixedly installed on the bottom head 8. And stretch out outside the tower, the top seal head 14 is provided with a release pipe 1 leading to the atmosphere.

[0020] In the middle of the tower body 11, there is a multi-layer sieve tray 4, and a downcomer 3 arranged on each tray 4, and an air distributor 5 is arranged at the bottom of the tray 4, and is connected and fixed on the tower body. The air inlet pipe 10 on 11 and the liquid distribution pipe 13 are also connected to the waste water inlet pipe 2 fixed on the tower body 11, and are arranged below the top head 14 in the tower body 11, and the demister 12 is arranged on the liquid distribution pipe 13 Between the tray 4 and the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com