Pretreatment device for DMF (dimethyl formamide)-containing wastewater

A pretreatment device and wastewater technology, applied in water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of high cost and economic value of DMF recovery, secondary pollution, and low DMF concentration. Achieve stable treatment effect, increase service life, and improve biochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

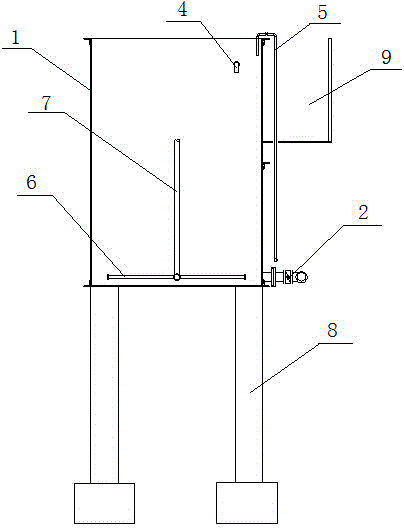

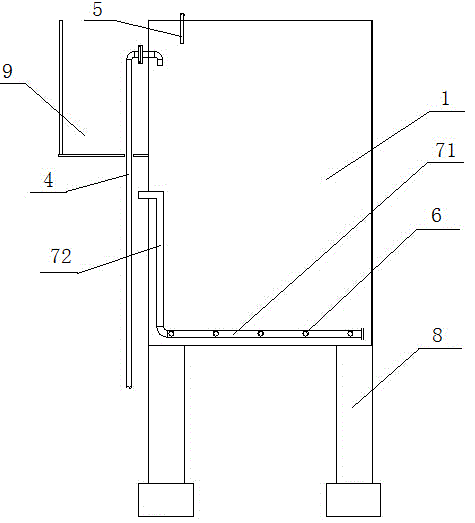

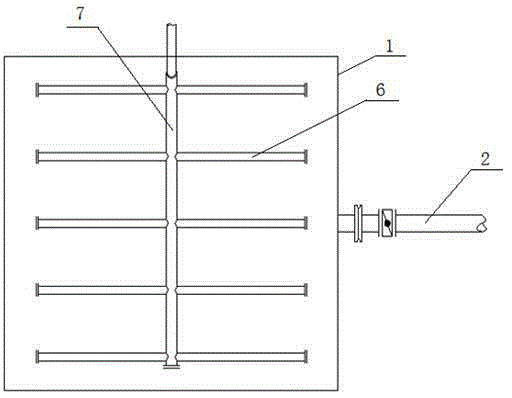

[0032] The high-concentration DMF waste water of a certain food additives Co., Ltd. is passed into the water inlet pipe 4 of the reactor body 1 of the present invention, and alkali is added through the alkali dosing pipe 5 at the same time, and steam is passed into the reactor body 1 through the steam pipe 7 to carry out the process. Heating, using the air distribution pipe 6 inside the reactor body 1 to diffuse the steam, heating under this alkaline condition, when the wastewater reaches 60°C, DMF reacts with NaOH, after 30 minutes of degassing, DMF has been completely decomposed, and the wastewater after removing DMF is discharged Empty pipe is discharged.

[0033] Through experiments, we have concluded that the removal rate of DMF in this wastewater pretreatment device can reach 95%. And after alkaline hydrolysis treatment, the biochemical performance of wastewater is greatly improved.

[0034] The design principle of the present invention is to integrate the DMF-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com