Treatment process of landfill municipal sludge press filter tail water

A treatment process and municipal sludge technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, degassed water/sewage treatment, etc., can solve complex components, high pollutant content, and difficult treatment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

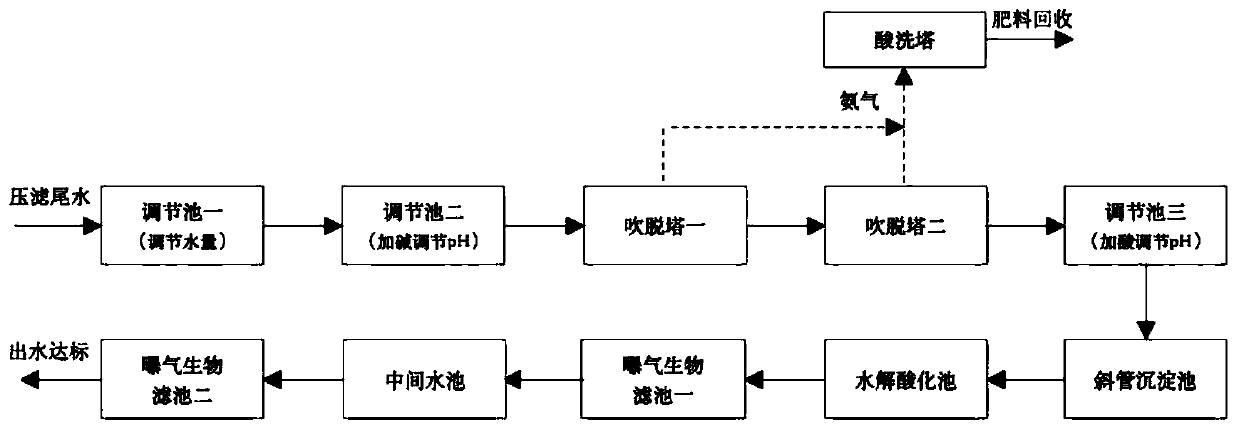

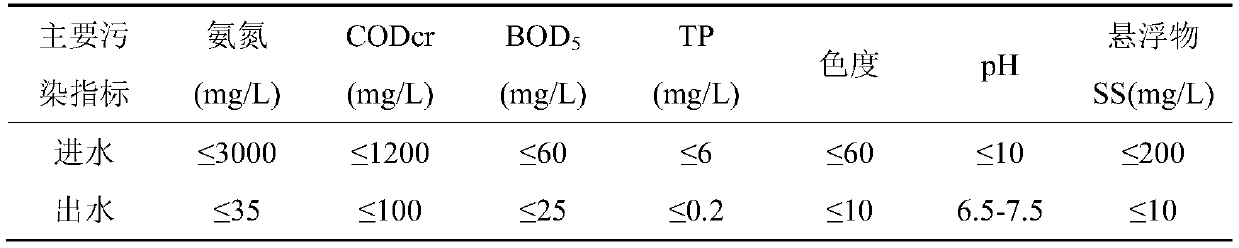

[0020] my country's land resources are limited. When there is no suitable disposal technology and no extra area for sludge landfill, further volume reduction of landfill sludge has become the direction of exploration. After the landfill sludge is added with chemical conditioners and then press-filtered, the tail water has complex components, high pollutant content, and difficult treatment. Aiming at the pollution characteristics of such tail water, the present invention discloses a treatment process for landfilling municipal sludge filter press tail water, which can be combined with the existing advanced treatment technology by adopting blow off, inclined tube sedimentation, hydrolysis acidification tank and secondary aeration The combination process of biofilter realizes the effective treatment of tail water with high ammonia nitrogen concentration, low C / N value, low B / C value and high chloride ion concentration, and the operation and management are simple, the removal effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com