High-salinity and high-ammonia-nitrogen-concentration wastewater treatment method based on MBR

A treatment method and technology of ammonia nitrogen concentration, applied in water treatment parameter control, biological water/sewage treatment, special chemical compound water treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0036] A kind of trace element concentrated solution is prepared by the following method: 0.5g H 3 BO 3 , 0.5g ZnCl, 0.5g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.5g NiCl 6H 2 O, 0.5g AlCl 3 ·6H 2 O, 0.5g CoCl 2 ·6H 2 O, 0.5g CuSO 4 ·5H 2 O, 2g Fe 2 (SO 4 ) 3 , 1gMnCl 2 4H 2 O, 5gMgSO 4 ·7H 2 O. 5mL of 37wt% HCl solution was all dissolved in 1000mL of water to obtain a trace element concentrate.

Embodiment

[0038] A treatment method for wastewater with high salinity and high ammonia nitrogen concentration based on MBR, using a submerged MBR membrane bioreactor with a total volume of 13.5L and an effective volume of 10L, and the membrane material is a hollow polyvinylidene fluoride fiber membrane (pore size 0.03 μm, membrane inner diameter 1.0mm, outer diameter 2.2mm, membrane area 0.235m 2 ), the outlet of the membrane module communicates with the suction pump through the pump tube to realize constant flow of water, and a pressure sensor is installed between the membrane module and the suction pump to record the change of the transmembrane pressure of the membrane module in real time during operation. The processing method specifically includes the following steps:

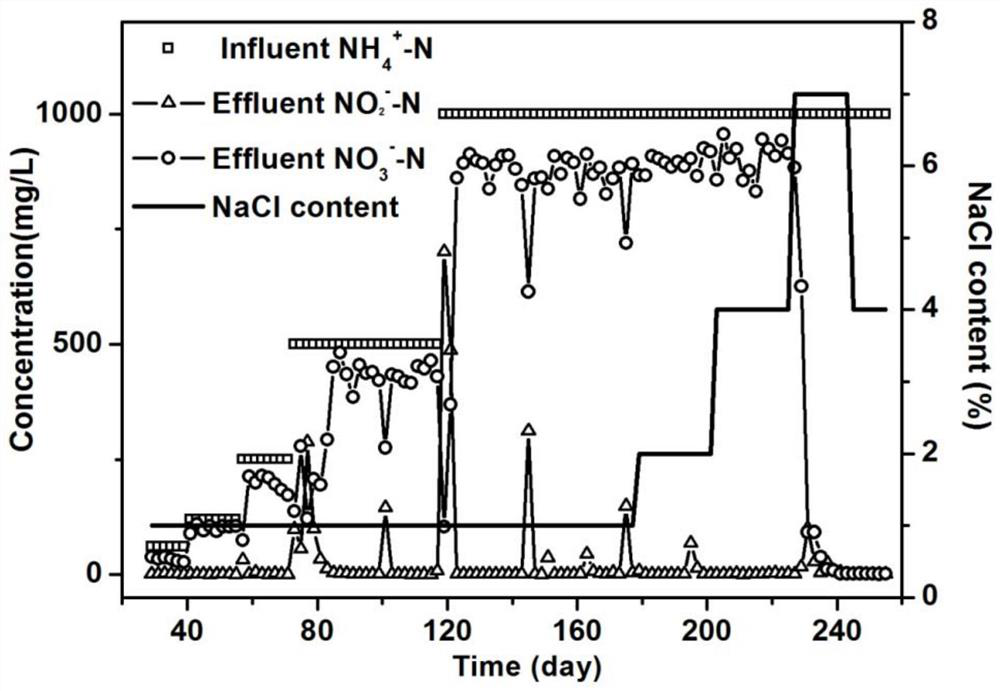

[0039] S1. Start-up stage: control the conditions required for equipment start-up and the alkalinity required for wastewater, start the MBR reactor, use artificially simulated wastewater, and control the influent con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Membrane inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com