System for extracting plant protein from cassava starch wastewater

A technology of plant protein and cassava starch, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, peptide preparation method, etc., can solve problems such as being in the blank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

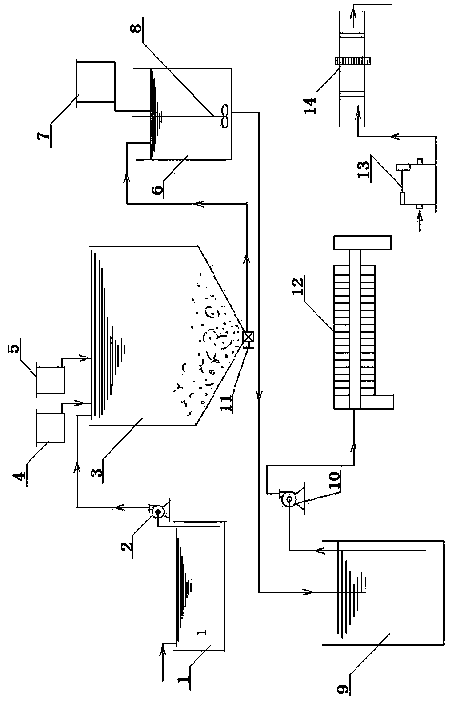

[0023] figure 1 Shown is the structural principle diagram of the present invention. It is known from the figure that the yellow pulp wastewater discharged from cassava starch production passes through sedimentation tank 1, lift pump 2, reaction sedimentation tank 3, discharge valve 11, sediment stirring tank 6, agitator 8, and slurry storage tank 9. Pressure pump 10——hydraulic plunger mud pump, filter press 12, crusher 13 and dryer 14. The powder after coming out of the dryer 14 is the finished product, which is packaged by the packaging machine as the product . Wherein, in the reaction sedimentation tank 3, the protein precipitant and lime water are respectively injected from the medicine tank 4 and the lime water tank 5, and the protein precipitant and the lime water are mixed with the waste water by the action of water flow, as in the delivery pipe of waste water Add protein precipitant and lime water at the same time, the three liquids are uniformly mixed in the delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com