Process for treating epoxy resin production wastewater

An epoxy resin and waste water production technology, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as inability to meet standards stably, water resource environmental pollution, etc., and achieve biochemical benefits The effect of processing, large processing capacity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

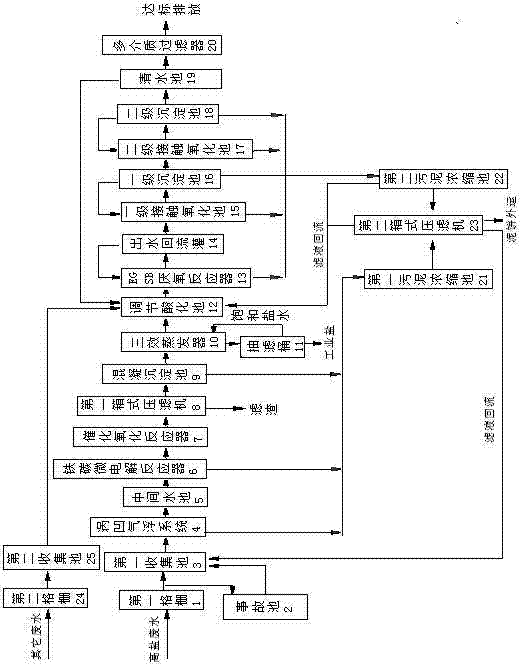

Image

Examples

Embodiment Construction

[0026] A treatment process for epoxy resin production waste water, comprising the following steps:

[0027] (1) The high-salt wastewater generated in the production of epoxy resin is intercepted by the first grid 1 to intercept the large debris in the wastewater, and the wastewater treated by the first grid 1 first enters the accident pool 2 (considering the accident situation For the treatment of production drainage and the situation when the influent concentration exceeds the design index, this wastewater treatment project has 2 accident pools, and the design effective volume is about 360m 3 , and then transported to the first collection pool 3 (the hydraulic adjustment time of the first collection pool 3 is 10 to 16 hours, and a submersible mixer is set in the first collection pool 3 to fully mix the wastewater in the first collection pool 3 and prevent solid particle deposition ), then lift the vortex-concave air flotation system 4, and add sodium hydroxide or calcium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com