Method for treating washing wastewater of coal chemical industry

A treatment method and technology of coal chemical industry, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high organic concentration, poor biodegradability, high ammonia nitrogen concentration, and achieve sludge concentration Low, fast filtration, high concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

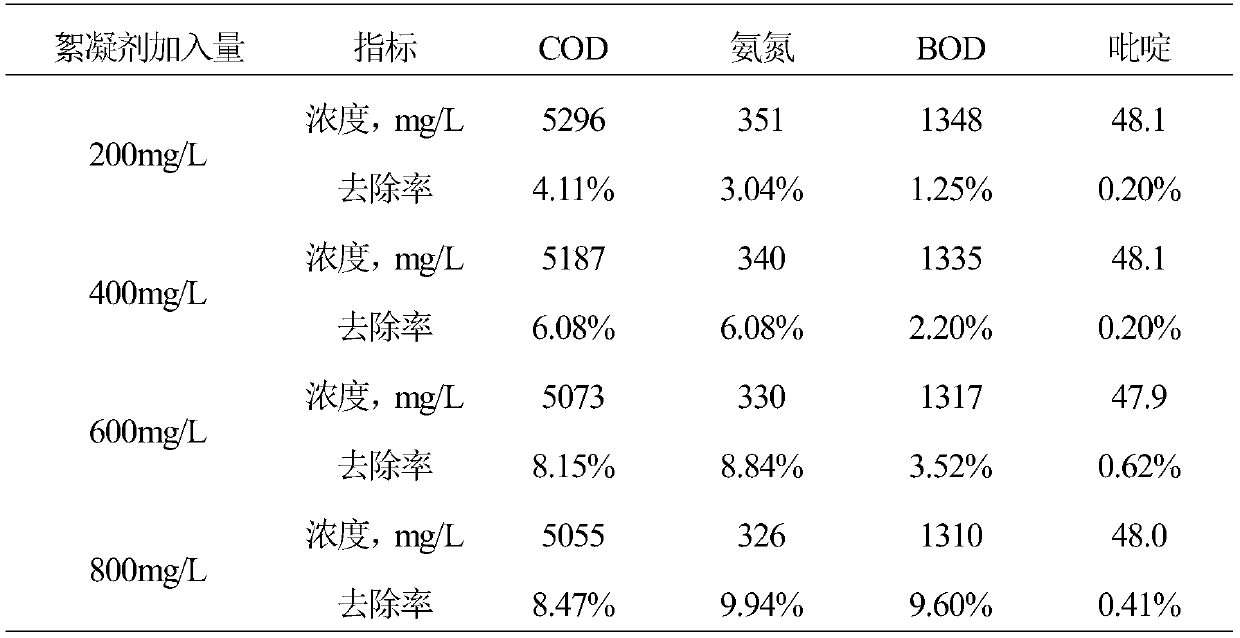

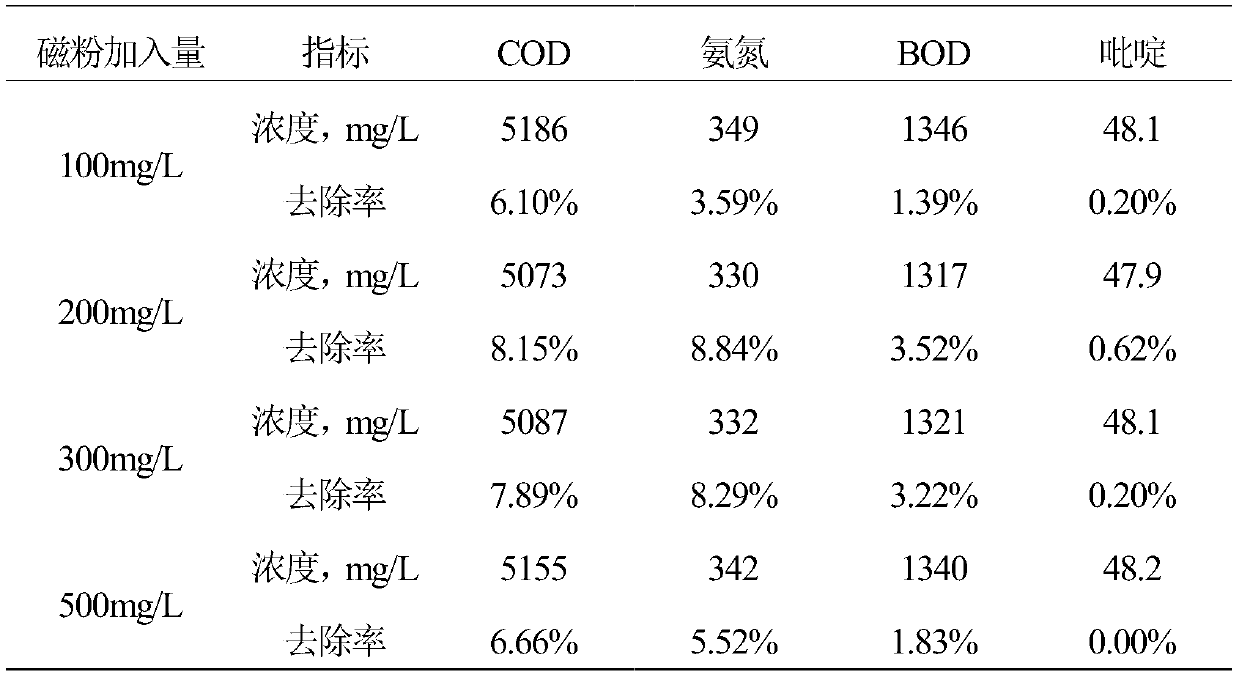

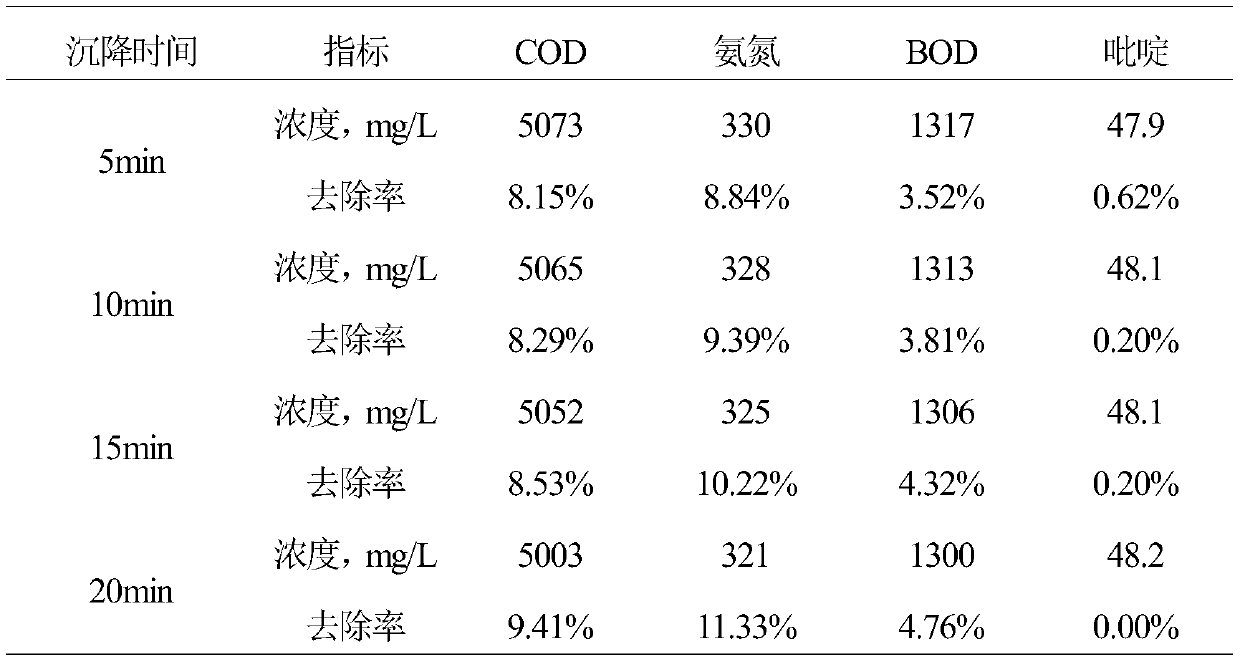

[0028] 1. Magnetic flocculation precipitation

[0029] Adjust 10L of waste water to pH 8 with sodium hydroxide, then add 6g of polyaluminum chloride to it, and add 2g of magnetic powder at the same time to make it integrate with pollutant flocculation and produce a large number of flocculent alum flowers. After settling for 5 minutes, filter and separate , The magnetic powder is recycled and reused, the sludge is treated as solid waste, and the filtrate is processed in the next step. After testing, the COD concentration in the filtrate was 5073mg / L, the BOD concentration was 1317mg / L, the ammonia nitrogen concentration was 330mg / L, and the pyridine concentration was 47.9mg / L. The corresponding removal rates of the first three were 8.15%, 3.52%, and 8.84%, respectively.

[0030] 2. UV-activated persulfate oxidation

[0031] In the filtrate that step 1 obtains, add sulfuric acid to adjust pH to 3, then in intensity 9mW / cm 2Sodium persulfate was added under ultraviolet light, s...

Embodiment 2

[0041] 1. Magnetic flocculation precipitation

[0042] Adjust 10L of waste water to pH 8 with sodium hydroxide, then add 2g of polyaluminum chloride to it, and add 1g of magnetic powder at the same time to make it flocculate and combine with pollutants to form a large amount of flocculent alum flowers. After settling for 15 minutes, filter and separate , The magnetic powder is recycled and reused, the sludge is treated as solid waste, and the filtrate is processed in the next step.

[0043] 2. UV-activated persulfate oxidation

[0044] In the filtrate that step 1 obtains, add sulfuric acid to adjust pH to 3, then in intensity 9mW / cm 2 Sodium persulfate was added under ultraviolet light to make the concentration of sodium persulfate in the filtrate 1.5mmol / L, and the reaction was stirred and reacted at 100r / min for 20min.

[0045] 3. Photoelectric-Fenton oxidation

[0046] The filtrate treated in step 2 was adjusted to pH 4 with sodium hydroxide, and then Na was added 2 SO ...

Embodiment 3

[0048] 1. Magnetic flocculation precipitation

[0049] Adjust 10L of waste water to pH 8 with sodium hydroxide, then add 8g of polyaluminum chloride to it, and add 5g of magnetic powder at the same time to make it flocculate and combine with pollutants to form a large amount of flocculent alum flowers. After settling for 10 minutes, filter and separate , The magnetic powder is recycled and reused, the sludge is treated as solid waste, and the filtrate is processed in the next step.

[0050] 2. UV-activated persulfate oxidation

[0051] In the filtrate that step 1 obtains, add sulfuric acid to adjust pH to 4, then in the intensity of 11mW / cm 2 Sodium persulfate was added under ultraviolet light, so that the concentration of sodium persulfate in the filtrate was 1.0 mmol / L, and the reaction was stirred and reacted at 100 r / min for 40 min.

[0052] 3. Photoelectric-Fenton oxidation

[0053] The filtrate treated in step 2 was adjusted to pH 3 with sodium hydroxide, and then Na ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com