Hydrothermal treatment device and method for waste plastics

A technology for waste plastics and hydrothermal treatment, which is applied in the field of waste plastics hydrothermal treatment equipment, and waste plastics are partially oxidized under high temperature and high pressure conditions and then hydrolyzed. It can solve the problems of increased separation and purification of degradation products, complex components of waste plastics, and high cost. problems, to achieve the effect of easy separation and purification, conducive to resource recovery and proper disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

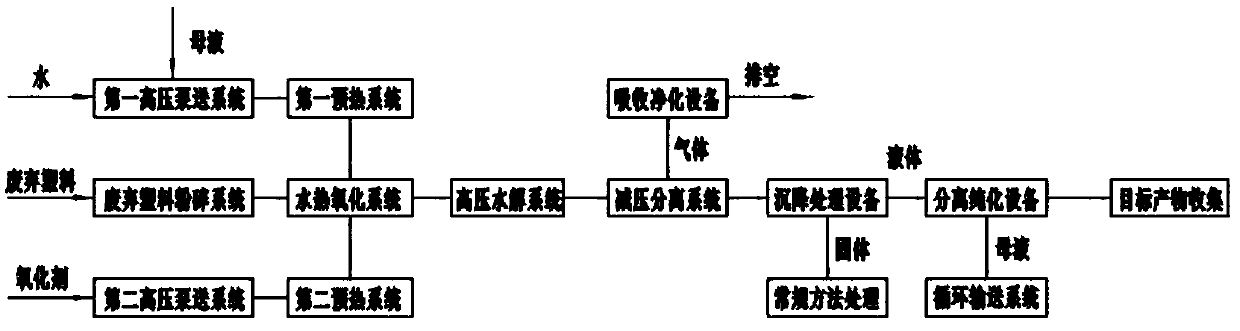

[0043] refer to figure 1 According to the present invention, a waste plastic hydrothermal treatment device includes: a hydrothermal oxidation system, a high-pressure hydrolysis system, a waste plastic crushing system, a batching pumping system and an oxidant pumping system. Among them, the hydrothermal oxidation system is used for partial oxidation reaction of waste plastics, even if the crushed waste plastic particles undergo partial oxidation reaction in high temperature and high pressure hydrothermal fluid; The mouth is connected to further hydrolyze the product after the oxidation reaction of the hydrothermal oxidation system to convert it into the target degradation product as much as possible; the waste plastic crushing system is connected to the feed port of the hydrothermal oxidation system to The plastic is pulverized and transported to the hydrotherma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com